Thermal Performance of Micro Hotplates with Novel Shapes Based on Single-Layer SiO2 Suspended Film

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication Details

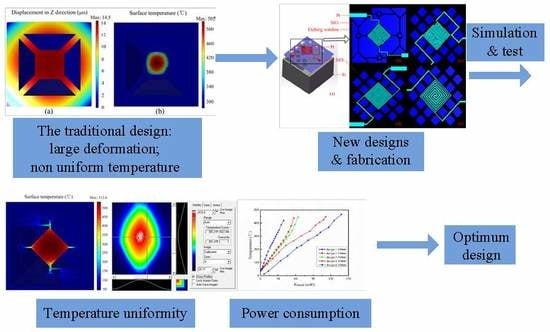

2.2. Design

2.3. Simulation

2.4. Experiment

3. Results and Discussion

3.1. Temperature Uniformity

3.2. Power Consumption

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chang, W.Y.; Hsihe, Y.S. Multilayer microheater based on glass substrate using MEMS technology. Microelectron. Eng. 2016, 149, 25–30. [Google Scholar]

- Courbat, J.; Canonica, M.; Teyssieux, D.; Briand, D.; De Rooij, N. Design and fabrication of micro-hotplates made on a polyimide foil: Electrothermal simulation and characterization to achieve power consumption in the low mW range. J. Micromech. Microeng. 2010, 21, 196–201. [Google Scholar] [CrossRef]

- Hwang, W.J.; Shin, K.S.; Roh, J.H.; Lee, D.S.; Choa, S.H. Development of micro-heaters with optimized temperature compensation design for gas sensors. Sensors 2011, 11, 2580–2591. [Google Scholar] [CrossRef] [PubMed]

- Yi, X.; Lai, J.; Liang, H.; Zhai, X. Fabrication of a MEMS micro-hotplate. JPCS 2011, 276, 12098–12106. [Google Scholar] [CrossRef]

- Bhattacharyya, P. Technological journey towards reliable microheater development for mems gas sensors: A review. IEEE. Trans. Device Mater. Reliab. 2014, 14, 589–599. [Google Scholar] [CrossRef]

- Prasad, M. Design, development and reliability testing of a low power bridge-type micromachined hotplate. Microelectron. Reliab. 2015, 55, 937–944. [Google Scholar] [CrossRef]

- Verma, S.; Rajnish; Singhal, A.; Jindal, P. Design and simulation of closed membrane type micro hotplate for gas sensing applications. Int. J. Eng. Sci. Metal. 2012, 2, 768–771. [Google Scholar]

- Rossi, C.; Templeboyer, P.; Esteve, D. Realization and performance of thin SiO2/SiNx membrane for microheater applications. Sensor. Actuat. A. Phys. 1998, 64, 241–245. [Google Scholar] [CrossRef]

- Ali, S.Z.; Udrea, F.; Milne, W.I.; Gardner, J.W. Tungsten-based SOI microhotplates for smart gas sensors. J. Microelectromech. S. 2008, 17, 1408–1416. [Google Scholar] [CrossRef]

- Saxena, G.; Paily, R. Analytical modeling of square microhotplate for gas sensing application. IEEE. Sens. J. 2013, 13, 4851–4858. [Google Scholar] [CrossRef]

- Simon, I.; BaÃrsan, N.; Bauer, M.; Weimar, U. Micromachined metal oxide gas sensors: opportunities to improve sensor performance. Sensor. Actuat. B. Chem. 2001, 73, 1–26. [Google Scholar] [CrossRef]

- Tommasi, A.; Cocuzza, M.; Perrone, D.; Pirri, C.; Mosca, R.; Mosca, R.; Villani, M.; Delmonte, N.; Zappttini, A.; Calestani, D.; et al. Modeling, fabrication and testing of a customizable micromachined hotplate for sensor applications. Sensors 2017, 17, 62. [Google Scholar] [CrossRef] [PubMed]

- Samaeifar, F.; Afifi, A.; Abdollahi, H. Simple fabrication and characterization of a platinum microhotplate based on suspended membrane structure. Exp. Techniques. 2014, 40, 755–763. [Google Scholar] [CrossRef]

- Kaur, M.; Prasad, M. Development of double spiral MEMS hotplate using front-side etching cavity for gas sensors. NCTP 2016, 1724, 2088–2106. [Google Scholar]

- Prasad, M.; Khanna, V.K. A low-power, micromachined, double spiral hotplate for MEMS gas sensors. Microsyst. Technol. 2015, 21, 2123–2131. [Google Scholar] [CrossRef]

- Belmonte, J.C.; Puigcorbe, J.; Arbiol, J.; Vila, A.; Morante, J.R.; Sabate, N.; Gracia, I.; Cane, C. High-temperature low-power performing micromachined suspended micro-hotplate for gas sensing applications. Sensor. Actuat. B. Chem. 2006, 114, 826–835. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, Y.P.; Yao, J.Y.; Ding, G.F. Impact resistance and static strength analysis of an extremely simplified micro hotplate with novel suspended film. Sensor. Actuat. B. Phys. 2018, 280, 495–504. [Google Scholar] [CrossRef]

- Chiou, J.C.; Tsai, S.W.; Lin, C.Y. Liquid phase deposition based SnO2 gas sensor integrated with TaN heater on a micro-hotplate. IEEE. Sens. J. 2013, 13, 2466–2473. [Google Scholar] [CrossRef]

- Marasso, S.L.; Tommasi, A.; Perrone, D.; Cocuzza, M.; Mosca, R.; Villani, M.; Zappettini, A.; Calestani, D. A new method to integrate ZnO nanotetrapods on MEMS micro-hotplates for large scale gas sensor production. Nanotechnology 2016, 27, 385–503. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.N.; Lee, D.S.; Jung, S.W.; Jang, Y.H.; Kim, Y.K.; Seong, W.K. A high-temperature MEMS heater using suspended silicon structures. J. Micromech. Microeng. 2009, 19, 115011. [Google Scholar] [CrossRef]

- Samaeifar, F.; Hajghassem, H.; Afifi, A.; Abdollahi, H. Implementation of high-performance MEMS platinum micro-hotplate. Sensor Rev. 2015, 35, 116–124. [Google Scholar] [CrossRef]

- Peirs, J.; Reynaerts, D.; Van Brussel, H. Scale effects and thermal considerations for micro-actuators. ICRA 1998, 2, 1516–1521. [Google Scholar]

- Hu, X.J.; Jain, A.; Goodson, K.E. Investigation of the natural convection boundary condition in microfabricated structures. Int. J. Therma. Sci. 2008, 47, 820–824. [Google Scholar] [CrossRef]

| Structure | Membrane size/Heater size (μm2) | Maximum Temperature/Temperature Difference (°C) | Power Consumption (mW) | Type | Ref. |

|---|---|---|---|---|---|

| SiN/Cr/CrN/Pt/CrN/Cr/ | 2500 × 2500 | 498 | 2350 | closed | [1] |

| SiO/SiN/Glass/SiN | 1000 × 910 | 22 | membrane | ||

| Pt/PI film/PI sheet | 200 × 200 | 300 | 15.5 | closed | [2] |

| 100 × 100 | 22 | membrane | |||

| SiO/Poly-Si/SiN/SiO/ | 1400 × 1600 | 460 | 250 | closed | [3] |

| Si/SiO/SiN | 1100 × 1100 | 90 | membrane | ||

| Poly-Si/SiN/SiO/Si/SiO | 500 × 500 | 645 | 62.8 | closed | [7] |

| 340 × 340 | -- | membrane | |||

| Insulation nitride/heater/ | 120 × 120 | 421 | 30 | Closed | [10] |

| SiN/SiO/Si | 100 × 100 | 22 | membrane | ||

| Pt/SiO/TaN/SiO/SiN/SiO/ | 300 × 300 | 450 | 100 | Closed | [18] |

| Si/ SiO/SiN/SiO | 100 × 100 | 30 | membrane | ||

| Pt/SiO/Si/SiO | 50 × 50 | 400 | 11.8 | suspended | [6] |

| -- | -- | membrane | |||

| Pt/SiO/Si/SiO | 1000 × 1000 | 500 | 50 | suspended | [13] |

| (with Si island) | 440 × 440 | 30(with Si island) >80(without Si island) | membrane | ||

| Pt/SiO/Si/SiO | 500 × 500 | 600 | -- | Suspended | [14] |

| -- | >100 | membrane | |||

| Pt/SiO/Si/SiO | 120 × 120 | 500 | 20 | suspended | [15] |

| -- | >100 °C | membrane |

| Material | Density (Kg/m3) | Young’s modulus (Pa) | Poisson’s Ratio | Thermal conductivity (W/m*K) | Thermal-expansion coefficient (1/K) |

|---|---|---|---|---|---|

| Si | 2330 | 1.9e11 | 0.2 | 148 | 2.5e-6 |

| SiO2 | 2200 | 70e9 | 0.17 | 1.4 | 0.5e-6 |

| Pt | 21,450 | 168e9 | 0.38 | 71.6 | 8.8e-6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Ding, G.; Wang, Y.; Yao, J. Thermal Performance of Micro Hotplates with Novel Shapes Based on Single-Layer SiO2 Suspended Film. Micromachines 2018, 9, 514. https://doi.org/10.3390/mi9100514

Liu Q, Ding G, Wang Y, Yao J. Thermal Performance of Micro Hotplates with Novel Shapes Based on Single-Layer SiO2 Suspended Film. Micromachines. 2018; 9(10):514. https://doi.org/10.3390/mi9100514

Chicago/Turabian StyleLiu, Qi, Guifu Ding, Yipin Wang, and Jinyuan Yao. 2018. "Thermal Performance of Micro Hotplates with Novel Shapes Based on Single-Layer SiO2 Suspended Film" Micromachines 9, no. 10: 514. https://doi.org/10.3390/mi9100514

APA StyleLiu, Q., Ding, G., Wang, Y., & Yao, J. (2018). Thermal Performance of Micro Hotplates with Novel Shapes Based on Single-Layer SiO2 Suspended Film. Micromachines, 9(10), 514. https://doi.org/10.3390/mi9100514