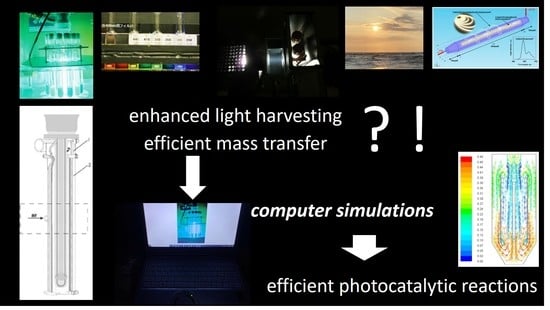

Computer Simulations of Photocatalytic Reactors

Abstract

:1. Introduction

2. Numerical Approaches Supporting Scaling-Up of Photocatalytic Reactors

2.1. Scaling-Up Methodology of Photocatalytic Reactors

2.2. Hydrodynamics Modeling

2.3. Lamp Emission and Radiation Modeling

2.4. Kinetic Modeling

3. Complex Photocatalytic Reactor Modeling Systems—The Available Software Tools

4. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bahnemann, D.W. Photocatalytic water treatment: Solar energy applications. Sol. Energy 2004, 77, 445–459. [Google Scholar] [CrossRef]

- Chen, X.; Shen, S.H.; Guo, L.J.; Mao, S.S. Semiconductor-based photocatalytic hydrogen generation. Chem. Rev. 2010, 110, 6503–6570. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Peng, B.S.; Peng, T.Y. Recent advances in heterogeneous photocatalytic CO2 conversion to solar fuels. ACS Catal. 2016, 6, 7485–7527. [Google Scholar] [CrossRef]

- Pelaez, M.; Nolan, N.T.; Pillai, S.C.; Seery, M.K.; Falaras, P.; Kontos, A.G.; Dunlop, P.S.M.; Hamilton, J.W.J.; Byrne, J.A.; O’Shea, K. A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl. Catal. B Environ. 2012, 125, 331–349. [Google Scholar] [CrossRef] [Green Version]

- Ohtani, B. Titania photocatalysis beyond recombination: A critical review. Catalysts 2013, 3, 942–953. [Google Scholar] [CrossRef] [Green Version]

- Janczarek, M.; Kowalska, E.; Ohtani, B. Decahedral-shaped anatase titania photocatalyst particles: Synthesis in a newly developed coaxial-flow gas-phase reactor. Chem. Eng. J. 2016, 289, 502–512. [Google Scholar] [CrossRef] [Green Version]

- Sundar, K.P.; Kanmani, S. Progression of photocatalytic reactors and it’s comparison: A review. Chem. Eng. Res. Des. 2020, 154, 135–150. [Google Scholar] [CrossRef]

- Kowalska, E.; Janczarek, M.; Hupka, J.; Grynkiewicz, M. H2O2/UV enhanced degradation of pesticides in wastewater. Water Sci. Technol. 2004, 49, 261–266. [Google Scholar] [CrossRef]

- Hoffmann, M.R.; Martin, S.T.; Choi, W.Y.; Bahnemann, D.W. Environmental applications of semiconductor photocatalysis. Chem. Rev. 1995, 95, 69–96. [Google Scholar] [CrossRef]

- Minero, C.; Pelizzetti, E.; Malato, S.; Blanco, J. Large solar plant photocatalytic water decontamination: Degradation of pentachlorophenol. Chemosphere 1993, 26, 2103–2119. [Google Scholar] [CrossRef]

- Malato, S.; Blanco, J.; Richter, C.; Curco, D.; Gimenez, J. Low-concentrating CPC collectors for photocatalytic water detoxification: Comparison with a medium concentrating solar collector. Water Sci. Technol. 1997, 35, 157–164. [Google Scholar] [CrossRef]

- Guillard, C.; Disdier, J.; Herrmann, J.M.; Lehaut, C.; Chopin, T.; Malato, S.; Blanco, J. Comparison of various titania samples of industrial origin in the solar photocatalytic detoxification of water containing 4-chlorophenol. Catal. Today 1999, 54, 217–228. [Google Scholar] [CrossRef]

- Blanco, J.; Malato, S.; Fernandez, P.; Vidal, A.; Morales, A.; Trincado, P.; Oliveira, J.C.; Minero, C.; Musci, M.; Casalle, C.; et al. Compound parabolic concentrator technology development to commercial solar detoxification applications. Sol. Energy 1999, 67, 317–330. [Google Scholar] [CrossRef]

- Kowalska, E.; Rau, S. Photoreactors for wastewater treatment: A review. Recent Pat. Eng. 2010, 4, 242–266. [Google Scholar] [CrossRef]

- Hupka, J.; Zaleska, A.; Janczarek, M.; Kowalska, E.; Gorska, P.; Aranowski, R. UV/VIS light-enhanced photocatalysis for water treatment and protection. In Soil and Water Pollution Monitoring, Protection and Remediation. NATO Science Series; Twardowska, I., Allen, H.E., Häggblom, M.M., Stefaniak, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 351–367. [Google Scholar]

- Artuna, E.; Hupka, J. H2O2/UV/air oxidation of organic contaminants in the gas-sparged cyclone reactor. Cent. Eur. J. Public Health 2000, 8, 88–89. [Google Scholar] [PubMed]

- Lelinski, D.; Bokotko, R.; Hupka, J.; Miller, J.D. Bubble generation in swirl flow during air-sparged hydrocyclone flotation. Miner. Metall. Process. 1996, 13, 87–92. [Google Scholar] [CrossRef]

- Aranowski, R.; Wojewodka, P.; Zielinska-Jurek, A.; Bokotko, R.; Jungnickel, C. Spinning Fluids Reactor: A new design of a gas—Liquid contactor. Chem. Eng. Process. 2017, 116, 40–47. [Google Scholar] [CrossRef]

- Cassano, A.E.; Martin, C.A.; Brandi, R.J.; Alfano, O.M. Photoreactor analysis and design: Fundamentals and applications. Ind. Eng. Chem. Res. 1995, 34, 2155–2201. [Google Scholar] [CrossRef]

- Cassano, A.E.; Alfano, O.M. Reaction engineering of suspended solid heterogeneous photocatalytic reactors. Catal. Today 2000, 58, 167–197. [Google Scholar] [CrossRef]

- Duran, J.E.; Mohseni, M.; Taghipour, F. Computational modeling of UV photocatalytic reactors: Model development, evaluation, and application. Water Qual. Res. J. 2015, 50, 21–33. [Google Scholar] [CrossRef]

- Pareek, V.K.; Adesina, A.A. Light intensity distribution in a photocatalytic reactor using finite volume. AIChE J. 2004, 50, 1273–1288. [Google Scholar] [CrossRef]

- Sacco, O.; Vaiano, V.; Sannino, D. Main parameters influencing the design of photocatalytic reactors for wastewater treatment: A mini review. J. Chem. Technol. Biotechnol. 2020, 95, 2608–2618. [Google Scholar] [CrossRef]

- Alexiadis, A. 2-D radiation field in photocatalytic channels of square, rectangular, equilateral triangular and isosceles triangular sections. Chem. Eng. Sci. 2006, 61, 516–525. [Google Scholar] [CrossRef]

- Moreira, J.; Serrano, B.; Ortiz, A.; de Lasa, H. Evaluation of photon absorption in an aqueous TiO2 slurry reactor using Monte Carlo simulations and macroscopic balance. Ind. Eng. Chem. Res. 2010, 49, 10524–10543. [Google Scholar] [CrossRef]

- Akach, J.; Ochieng, A. Monte Carlo simulation of the light distribution inan annular slurry bubble column photocatalytic reactor. Chem. Eng. Res. Des. 2018, 129, 248–258. [Google Scholar] [CrossRef]

- Akach, J.; Kabuba, J.; Ochieng, A. Simulation of the light distribution in a solar photocatalytic bubble column reactor using the Monte Carlo method. Ind. Eng. Chem. Res. 2020, 59, 17708–17719. [Google Scholar] [CrossRef]

- Cuevas, S.A.; Arancibia-Bulnes, C.A.; Serrano, B. Radiation field in an annular photocatalytic reactor by the P1 approximation. Int. J. Chem. React. Eng. 2007, 5, A58. [Google Scholar] [CrossRef]

- Arancibia-Bulnes, C.A.; Jimenez, A.E.; Estrada, C.A. Development and modeling of solar photocatalytic reactors. Adv. Chem. Eng. 2009, 36, 185–227. [Google Scholar]

- Orozco, S.L.; Villafan-Vidales, H.I.; Arancibia-Bulnes, C.A. Photon absorption in a hybrid slurry photocatalytic reactor: Assessment of differential approximations. AIChE J. 2012, 58, 3256–3265. [Google Scholar] [CrossRef]

- Romero, R.L.; Alfano, O.M.; Cassano, A.E. Radiation field in an annular, slurry photocatalytic reactor. 2. Model and experiments. Ind. Eng. Chem. Res. 2003, 42, 2479–2488. [Google Scholar] [CrossRef]

- Denny, F.; Scott, J.; Pareek, V.; Peng, G.D.; Amal, R. CFD modelling for a TiO2-coated glass-bead photoreactor irradiated by optical fibres: Photocatalytic degradation of oxalic acid. Chem. Eng. Sci. 2009, 64, 1695–1706. [Google Scholar] [CrossRef]

- Duran, J.E.; Mohseni, M.; Taghipour, F. Computational fluid dynamics modeling of immobilized photocatalytic reactors for water treatment. AIChE J. 2011, 57, 1860–1872. [Google Scholar] [CrossRef]

- Pareek, V. Light intensity distribution in a dual-lamp photoreactor. Int. J. Chem. React. Eng. 2005, 3, A56. [Google Scholar] [CrossRef]

- Pareek, V.; Brungs, M.P.; Adesina, A.A. A new simplified model for light scattering in photocatalytic reactors. Ind. Eng. Chem. Res. 2003, 42, 26–36. [Google Scholar] [CrossRef]

- Qi, N.; Zhang, H.; Jin, B.; Zhang, K. CFD modelling of hydrodynamics and degradation kinetics in an annular slurry photocatalytic reactor for wastewater treatment. Chem. Eng. J. 2011, 172, 84–95. [Google Scholar] [CrossRef]

- Trujillo, F.J.; Safinski, T.; Adesina, A.A. CFD analysis of the radiation distribution in a new immobilized catalyst bubble column externally illuminated photoreactor. J. Sol. Energy Eng. 2007, 129, 27–36. [Google Scholar] [CrossRef]

- Trujillo, F.J.; Safinski, T.; Adesina, A.A. Oxidative photomineralization of dichloroacetic acid in an externally-irradiated rectangular bubble tank reactor: Computational fluid dynamics modeling and experimental verification studies. Ind. Eng. Chem. Res. 2010, 49, 6722–6734. [Google Scholar] [CrossRef]

- Klenov, O.P.; Noskov, A.S. Computational fluid dynamics in the development of catalytic reactors. Catal. Ind. 2011, 3, 331–349. [Google Scholar] [CrossRef]

- Hettel, M.; Worner, M.; Deutschmann, O. Computational fluid dynamics of catalytic reactors. In Handbook of Materials Modeling; Andreoni, W., Yip, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–34. [Google Scholar]

- Boyjoo, Y.; Ang, M.; Pareek, V. CFD simulation of a pilot scale slurry photocatalytic reactor and design of multiple-lamp reactors. Chem. Eng. Sci. 2014, 111, 266–277. [Google Scholar] [CrossRef]

- Pareek, V.K.; Cox, S.J.; Brungs, M.P.; Young, B.; Adesina, A.A. Computational fuid dynamic (CFD) simulation of a pilot-scale annular bubble column photocatalytic reactor. Chem. Eng. Sci. 2003, 58, 859–865. [Google Scholar] [CrossRef]

- Taghipour, F.; Mohseni, M. CFD simulation of UV photocatalytic reactors for air treatment. AIChE J. 2005, 51, 3039–3047. [Google Scholar] [CrossRef]

- Castrillon, S.R.V.; De Lasa, H. Performance evaluation of photocatalytic reactors for air purification using computational fluid dynamics (CFD). Ind. Eng. Chem. Res. 2007, 46, 5867–5880. [Google Scholar] [CrossRef]

- Duran, J.E.; Taghipour, F.; Mohseni, M. CFD modeling of mass transfer in annular reactors. Int. J. Heat Mass Transf. 2009, 52, 5390–5401. [Google Scholar] [CrossRef]

- Jarandehei, A.; De Visscher, A. Three-dimensional CFD model for a flat plate photocatalytic reactor: Degradation of TCE in a serpentine flow field. AIChE J. 2009, 55, 312–320. [Google Scholar] [CrossRef]

- Duran, J.E.; Mohseni, M.; Taghipour, F. Modeling of annular reactors with surface reaction using computational fluid dynamics (CFD). Chem. Eng. Sci. 2010, 65, 1201–1211. [Google Scholar] [CrossRef]

- Duran, J.E.; Mohseni, M.; Taghipour, F. Design improvement of immobilized photocatalytic reactors using a CFD-Taguchi combined method. Ind. Eng. Chem. Res. 2011, 50, 824–831. [Google Scholar] [CrossRef]

- Vincent, G.; Schaer, E.; Marquaire, P.M.; Zahraa, O. CFD modelling of an annular reactor, application to the photocatalytic degradation of acetone. Process Saf. Environ. Prot. 2011, 89, 35–40. [Google Scholar] [CrossRef]

- Kumar, J.; Bansal, A. CFD modeling of hydrodynamics and mass transfer of Rhodamine B in annular reactor. Heat Mass Transf. 2012, 48, 2069–2077. [Google Scholar] [CrossRef]

- Misstear, T.; Gill, L. CFD modeling of fixed photocatalytic inserts for a continuous flow reactor for water disinfection. J. Adv. Oxid. Technol. 2012, 15, 153–162. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, J.; Dai, Y.; Dong, W.; Zhang, S.; Chen, J. CFD modeling of a UV-LED photocatalytic odor abatement process in a continuous reactor. J. Hazard. Mater. 2012, 215–216, 25–31. [Google Scholar] [CrossRef]

- Verbruggen, S.W.; Lenaerts, S.; Denys, S. Analytic versus CFD approach for kinetic modeling of gas phase photocatalysis. Chem. Eng. J. 2015, 262, 1–8. [Google Scholar] [CrossRef]

- Castedo, A.; Uriz, I.; Soler, L.; Gandia, L.M.; Llorca, J. Kinetic analysis and CFD simulations of the photocatalytic production of hydrogen in silicone microreactors from water-ethanol mixtures. Appl. Catal. B 2017, 203, 210–217. [Google Scholar] [CrossRef] [Green Version]

- Roegiers, J.; Van Walsem, J.; Denys, S. CFD- and radiation field modeling of a gas phase photocatalytic multi-tube reactor. Chem. Eng. J. 2018, 338, 287–299. [Google Scholar] [CrossRef]

- Tong, K.; Yang, L.; Du, X. Modelling of TiO2-based packing bed photocatalytic reactor with Raschig rings for phenol degradation by coupled CFD and DEM. Chem. Eng. J. 2020, 400, 125988. [Google Scholar] [CrossRef]

- Yusuf, A.; Palmisano, G. Three-dimensional CFD modelling of a photocatalytic parallel-channel microreactor. Chem. Eng. Sci. 2021, 229, 116051. [Google Scholar] [CrossRef]

- Satuf, M.L.; Brandi, R.J.; Cassano, A.E.; Alfano, O.M. Scaling-up of slurry reactors for the photocatalytic degradation of 4-chlorophenol. Catal. Today 2007, 129, 110–117. [Google Scholar] [CrossRef]

- Li Puma, G. Dimensionless analysis of photocatalytic reactors using suspended solid photocatalysts. Chem. Eng. Res. Des. 2005, 83, 820–826. [Google Scholar] [CrossRef]

- Ghafoori, S.; Mehrvar, M.; Chan, P.K. Photoreactor scale-up for degradation of aqueous poly(vinyl alcohol) using UV/H2O2 process. Chem. Eng. J. 2014, 245, 133–142. [Google Scholar] [CrossRef]

- Imobedorf, G.E.; Irazoqui, H.A.; Alfano, O.M.; Cassano, A.E. Scaling-up from first principles of a photocatalytic reactor for air pollution remediation. Chem. Eng. Sci. 2007, 62, 793–804. [Google Scholar] [CrossRef]

- Niewiadomski, M.; Hupka, J.; Bokotko, R.; Miller, J.D. Recovery of coke fines from fly ash by air sparged hydrocyclone flotation. Fuel 1999, 78, 161–168. [Google Scholar] [CrossRef]

- Bokotko, R.P.; Hupka, J.; Miller, J.D. Flue gas treatment for SO2 removal with air-sparged hydrocyclone technology. Environ. Sci. Technol. 2005, 39, 1184–1189. [Google Scholar] [CrossRef] [PubMed]

- Mohseni, M.; Taghipour, F. Experimental and CFD analysis of photocatalytic gas phase vinyl chloride (VC) oxidation. Chem. Eng. Sci. 2004, 59, 1601–1609. [Google Scholar] [CrossRef]

- Wang, X.; Tan, X.; TYu, T. Kinetic study of ozone photocatalytic decomposition using a thin film of TiO2 coated on a glass plate and the CFD modeling approach. Ind. Eng. Chem. Res. 2014, 53, 7902–7909. [Google Scholar] [CrossRef]

- Turolla, A.; Santoro, D.; de Bruyn, J.R.; Crapulli, F.; Antonelli, M. Nanoparticle scattering characterization and mechanistic modelling of UV-TiO2 photocatalytic reactors using computational fluid dynamics. Water Res. 2016, 88, 117–126. [Google Scholar] [CrossRef]

- Verbruggen, S.W.; Keulemans, M.; Van Walsem, J.; Tytgat, T.; Lenaerts, S.; Denys, S. CFD modeling of transient adsorption/desorption behavior in a gas phase photocatalytic fiber reactor. Chem. Eng. J. 2016, 292, 42–50. [Google Scholar] [CrossRef]

- van Walsem, J.; Verbruggen, S.W.; Modde, B.; Lenaerts, S.; Denys, S. CFD investigation of a multi-tube photocatalytic reactor in non-steadystate conditions. Chem. Eng. J. 2016, 304, 808–816. [Google Scholar] [CrossRef]

- Sozzi, D.A.; Taghipour, F. Computational and experimental study of annular photo-reactor hydrodynamics. Int. J. Heat Mass Transf. 2006, 27, 1043–1053. [Google Scholar] [CrossRef]

- Trujillo, F.J.; Lee, I.A.L.; Hsu, C.H.; Safinski, T.; Adesina, A.A. Hydrodynamically-enhanced light intensity distribution in an externally-irradiated novel aerated photoreactor: CFD simulation and experimental studies. Int. J. Chem. React. Eng. 2008, 6, A58. [Google Scholar] [CrossRef]

- Abe, K.; Kondoh, T.; Nagano, Y. A new turbulence model for predicting fluid flow and heat transfer in separating and reattaching flows-I. Flow field calculations. Int. J. Heat Mass Transf. 1994, 37, 139–151. [Google Scholar] [CrossRef]

- Boyjoo, Y.; Ang, M.; Pareek, V. Some aspects of photocatalytic reactor modeling using computational fluid dynamics. Chem. Eng. Sci. 2013, 101, 764–784. [Google Scholar] [CrossRef]

- Sengupta, T.K.; Kabir, M.F.; Ray, A.K. A Taylor vortex photocatalytic reactor for water purification. Ind. Eng. Chem. Res. 2001, 40, 5268–5281. [Google Scholar] [CrossRef]

- Dutta, P.K.; Ray, A.K. Experimental investigation of Taylor vortex photocatalytic reactor for water purification. Chem. Eng. Sci. 2004, 59, 5249–5259. [Google Scholar] [CrossRef]

- Pareek, V.; Chong, S.; Tade, M.; Adesina, A.A. Light intensity distribution in heterogenous photocatalytic reactors. Asia-Pac. J. Chem. Eng. 2008, 3, 171–201. [Google Scholar] [CrossRef]

- Ollis, D.F. Kinetics of liquid phase photocatalyzed reactions: An illuminating approach. J. Phys. Chem. B 2005, 109, 2439–2444. [Google Scholar] [CrossRef] [PubMed]

- Sannino, D.; Vaiano, V.; Sacco, O.; Ciambelli, P. Mathematical modelling of photocatalytic degradation of methylene blue under visible light irradiation. J. Environ. Chem. Eng. 2013, 1, 56–60. [Google Scholar] [CrossRef]

- Kowalska, E.; Rau, S.; Ohtani, B. Plasmonic Titania Photocatalysts Active under UV and Visible-Light Irradiation: Influence of Gold Amount, Size, and Shape. J. Nanotechnol. 2012, 2012, 361853. [Google Scholar] [CrossRef] [Green Version]

- Markowska-Szczupak, A.; Wei, Z.S.; Kowalska, E. The Influence of the light-activated titania P25 on human breast cancer cells. Catalysts 2020, 10, 238. [Google Scholar] [CrossRef] [Green Version]

- Khedr, T.M.; El-Sheikh, S.M.; Ismail, A.A.; Kowalska, E.; Bahnemann, D.W. Photodegradation of Microcystin-LR Using Visible Light-Activated C/N-co-Modified Mesoporous TiO2 Photocatalyst. Materials 2019, 12, 1027. [Google Scholar] [CrossRef] [Green Version]

- Dabrowski, B.; Zaleska, A.; Janczarek, M.; Hupka, J.; Miller, J.D. Photo-oxidation of dissolved cyanide using TiO2 catalyst. J. Photochem. Photobiol. A 2002, 151, 201–205. [Google Scholar] [CrossRef]

- Burgeth, G.; Kisch, H. Photocatalytic and photoelectrochemical properties of titania-chloroplatinate(IV). Coord. Chem. Rev. 2002, 230, 41–47. [Google Scholar] [CrossRef]

- Casado, C.; Marugan, J.; Timmers, R.; Munoz, M.; van Grieken, R. Comprehensive multiphysics modeling of photocatalytic processes by computational fluid dynamics based on intrinsic kinetic parameters determined in a differential photoreactor. Chem. Eng. J. 2017, 310, 368–380. [Google Scholar] [CrossRef] [Green Version]

- Moreno-SanSegundo, J.; Casado, C.; Marugan, J. Enhanced numerical simulation of photocatalytic reactors with an improved solver for the radiative transfer equation. Chem. Eng. J. 2020, 388, 124183. [Google Scholar] [CrossRef]

- Acosta-Herazo, R.; Canaveral-Velasquez, B.; Perez-Giraldo, K.; Mueses, M.A.; Pinzon-Cardenas, M.H.; Machuca-Martinez, F. A MATLAB-based application for modeling and simulation of solar slurry photocatalytic reactors for environmental applications. Water 2020, 12, 2196. [Google Scholar] [CrossRef]

- Prieto-Mahaney, O.O.; Murakami, N.; Abe, R.; Ohtani, B. Correlation between photocatalytic activities and structural and physical properties of titanium(IV) oxide powders. Chem. Lett. 2009, 38, 238–239. [Google Scholar] [CrossRef]

- Ohtani, B.; Prieto-Mahaney, O.O.; Li, D.; Abe, R. What is Degussa (Evonik) P25? Crystalline composition analysis, reconstruction from isolated pure particles and photocatalytic activity test. J. Photochem. Photobiol. A 2010, 216, 179–182. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.L.; Janczarek, M.; Wei, Z.S.; Raja-Mogan, T.; Endo-Kimura, M.; Khedr, T.M.; Ohtani, B.; Kowalska, E. Morphology- and crystalline composition-governed activity of titania-based photocatalysts: Overview and perspective. Catalysts 2019, 9, 1054. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.L.; Wei, Z.S.; Ohtani, B.; Kowalska, E. Interparticle electron transfer in methanol dehydrogenation on platinum-loaded titania particles prepared from P25. Catal. Today 2018, 303, 327–333. [Google Scholar] [CrossRef]

- Acosta-Herazo, R.; Monterroza-Romero, J.; Mueses, M.A.; Machuca-Martinez, F.; Li Puma, G. Coupling the Six Flux Absorption–Scattering Model to the Henyey–Greenstein scattering phase function: Evaluation and optimization of radiation absorption in solar heterogeneous photoreactors. Chem. Eng. J. 2016, 302, 86–96. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janczarek, M.; Kowalska, E. Computer Simulations of Photocatalytic Reactors. Catalysts 2021, 11, 198. https://doi.org/10.3390/catal11020198

Janczarek M, Kowalska E. Computer Simulations of Photocatalytic Reactors. Catalysts. 2021; 11(2):198. https://doi.org/10.3390/catal11020198

Chicago/Turabian StyleJanczarek, Marcin, and Ewa Kowalska. 2021. "Computer Simulations of Photocatalytic Reactors" Catalysts 11, no. 2: 198. https://doi.org/10.3390/catal11020198

APA StyleJanczarek, M., & Kowalska, E. (2021). Computer Simulations of Photocatalytic Reactors. Catalysts, 11(2), 198. https://doi.org/10.3390/catal11020198