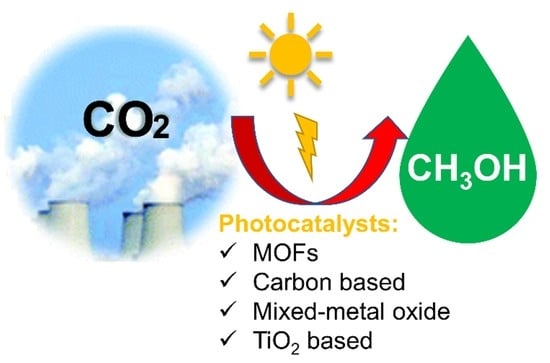

Recent Advances of Photocatalytic Hydrogenation of CO2 to Methanol

Abstract

:1. Introduction

2. Scope and Focus of This Review

3. Applications

3.1. Photocatalyst Based on MOFs

3.2. Mixed-Metal-Oxide-Based Photocatalyst

Transition and Non-Transition Metals

3.3. Photocatalysts Based on Carbon Materials

3.4. TiO2 Based Photocatalysts

3.5. Photocatalysts with Plasmonic Properties

4. Conclusions and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, C.; Wang, W.; Liu, B.; Qiao, J.; Lv, L.; Gao, X.; Zhang, X.; Xu, D.; Liu, W.; Liu, J.; et al. Recent Advances in MOF-based Nanocatalysts for Photo-Promoted CO2 Reduction Applications. Catalysts 2019, 9, 658. [Google Scholar] [CrossRef] [Green Version]

- Sen, R.; Goeppert, A.; Kar, S.; Prakash, G.K.S. Hydroxide Based Integrated CO2 Capture from Air and Conversion to Methanol. J. Am. Chem. Soc. 2020, 142, 4544–4549. [Google Scholar] [CrossRef]

- Singh, A.K.; Montoya, J.H.; Gregoire, J.M.; Persson, K.A. Robust and synthesizable photocatalysts for CO2 reduction: A data-driven materials discovery. Nat. Commun. 2019, 10, 443. [Google Scholar] [CrossRef] [Green Version]

- Rathi, A.K.; Kmentová, H.; Naldoni, A.; Goswami, A.; Gawande, M.B.; Varma, R.S.; Kment, Š.; Zbořil, R. Significant Enhancement of Photoactivity in Hybrid TiO2/g-C3N4 Nanorod Catalysts Modified with Cu–Ni-Based Nanostructures. ACS Appl. Nano Mater. 2018, 1, 2526–2535. [Google Scholar] [CrossRef]

- Bharath, G.; Rambabu, K.; Hai, A.; Othman, I.; Ponpandian, N.; Banat, F.; Loke Show, P. Hybrid Pd50-Ru50/MXene (Ti3C2Tx) nanocatalyst for effective hydrogenation of CO2 to methanol toward climate change control. Chem. Eng. J. 2021, 414, 128869. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Qi, M.-Y.; Li, Y.-H.; Tang, Z.-R.; Wang, T.; Gong, J.; Xu, Y.-J. Activating two-dimensional Ti3C2Tx-MXene with single-atom cobalt for efficient CO2 photoreduction. Cell Rep. Phys. Sci. 2021, 2, 100371. [Google Scholar] [CrossRef]

- Yang, H.; Wu, Y.; Li, G.; Lin, Q.; Hu, Q.; Zhang, Q.; Liu, J.; He, C. Scalable Production of Efficient Single-Atom Copper Decorated Carbon Membranes for CO2 Electroreduction to Methanol. J. Am. Chem. Soc. 2019, 141, 12717–12723. [Google Scholar] [CrossRef]

- Liang, L.; Lei, F.; Gao, S.; Sun, Y.; Jiao, X.; Wu, J.; Qamar, S.; Xie, Y. Single Unit Cell Bismuth Tungstate Layers Realizing Robust Solar CO2 Reduction to Methanol. Angew. Chem. Int. Ed. 2015, 54, 13971–13974. [Google Scholar] [CrossRef]

- Rezvani, A.; Abdel-Mageed, A.M.; Ishida, T.; Murayama, T.; Parlinska-Wojtan, M.; Behm, R.J. CO2 Reduction to Methanol on Au/CeO2 Catalysts: Mechanistic Insights from Activation/Deactivation and SSITKA Measurements. ACS Catal. 2020, 10, 3580–3594. [Google Scholar] [CrossRef]

- Zhu, J.; Ciolca, D.; Liu, L.; Parastaev, A.; Kosinov, N.; Hensen, E.J.M. Flame Synthesis of Cu/ZnO–CeO2 Catalysts: Synergistic Metal–Support Interactions Promote CH3OH Selectivity in CO2 Hydrogenation. ACS Catal. 2021, 11, 4880–4892. [Google Scholar] [CrossRef]

- Yang, D.; Zhu, Q.; Chen, C.; Liu, H.; Liu, Z.; Zhao, Z.; Zhang, X.; Liu, S.; Han, B. Selective electroreduction of carbon dioxide to methanol on copper selenide nanocatalysts. Nat. Commun. 2019, 10, 677. [Google Scholar] [CrossRef]

- Sharma, R.K.; Yadav, S.; Dutta, S.; Kale, H.B.; Warkad, I.R.; Zbořil, R.; Varma, R.S.; Gawande, M.B. Silver nanomaterials: Synthesis and (electro/photo) catalytic applications. Chem. Soc. Rev. 2021, 50, 11293–11380. [Google Scholar] [CrossRef] [PubMed]

- Al Jitan, S.; Palmisano, G.; Garlisi, C. Synthesis and Surface Modification of TiO2-Based Photocatalysts for the Conversion of CO2. Catalysts 2020, 10, 227. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Wang, D. Photocatalysis: From Fundamental Principles to Materials and Applications. ACS Appl. Energy Mater. 2018, 1, 6657–6693. [Google Scholar] [CrossRef]

- Kumar, S.; Gawande, M.B.; Kopp, J.; Kment, S.; Varma, R.S.; Zboril, R. P- and F-co-doped Carbon Nitride Nanocatalysts for Photocatalytic CO2 Reduction and Thermocatalytic Furanics Synthesis from Sugars. ChemSusChem 2020, 13, 5231–5238. [Google Scholar] [CrossRef]

- Sharma, P.; Kumar, S.; Tomanec, O.; Petr, M.; Zhu Chen, J.; Miller, J.T.; Varma, R.S.; Gawande, M.B.; Zbořil, R. Carbon Nitride-Based Ruthenium Single Atom Photocatalyst for CO2 Reduction to Methanol. Small 2021, 17, 2006478. [Google Scholar] [CrossRef]

- Goyal, S.; Shaharun, M.S.; Jayabal, G.S.; Kait, C.F.; Abdullah, B.; Wei, L.J. Photocatalytic Reduction of CO2 to Methanol Using a Copper-Zirconia Imidazolate Framework. Catalysts 2021, 11, 346. [Google Scholar] [CrossRef]

- Izadpanah Ostad, M.; Niknam Shahrak, M.; Galli, F. Photocatalytic carbon dioxide reduction to methanol catalyzed by ZnO, Pt, Au, and Cu nanoparticles decorated zeolitic imidazolate framework-8. J. CO2 Util. 2021, 43, 101373. [Google Scholar] [CrossRef]

- Wu, Y.A.; McNulty, I.; Liu, C.; Lau, K.C.; Liu, Q.; Paulikas, A.P.; Sun, C.-J.; Cai, Z.; Guest, J.R.; Ren, Y.; et al. Facet-dependent active sites of a single Cu2O particle photocatalyst for CO2 reduction to methanol. Nat. Energy 2019, 4, 957–968. [Google Scholar] [CrossRef]

- Zeng, Z.; Yan, Y.; Chen, J.; Zan, P.; Tian, Q.; Chen, P. Boosting the Photocatalytic Ability of Cu2O Nanowires for CO2 Conversion by MXene Quantum Dots. Adv. Funct. Mater. 2019, 29, 1806500. [Google Scholar] [CrossRef]

- Adekoya, D.O.; Tahir, M.; Amin, N.A.S. g-C3N4/(Cu/TiO2) nanocomposite for enhanced photoreduction of CO2 to CH3OH and HCOOH under UV/visible light. J. CO2 Util. 2017, 18, 261–274. [Google Scholar] [CrossRef]

- Gao, G.; Jiao, Y.; Waclawik, E.R.; Du, A. Single Atom (Pd/Pt) Supported on Graphitic Carbon Nitride as an Efficient Photocatalyst for Visible-Light Reduction of Carbon Dioxide. J. Am. Chem. Soc. 2016, 138, 6292–6297. [Google Scholar] [CrossRef] [Green Version]

- Fu, J.; Zhu, B.; Jiang, C.; Cheng, B.; You, W.; Yu, J. Hierarchical Porous O-Doped g-C3 N4 with Enhanced Photocatalytic CO2 Reduction Activity. Small 2017, 13, 1603938. [Google Scholar] [CrossRef]

- Albo, J.; Qadir, M.I.; Samperi, M.; Fernandes, J.A.; de Pedro, I.; Dupont, J. Use of an optofluidic microreactor and Cu nanoparticles synthesized in ionic liquid and embedded in TiO2 for an efficient photoreduction of CO2 to methanol. Chem. Eng. 2021, 404, 126643. [Google Scholar] [CrossRef]

- Billo, T.; Fu, F.Y.; Raghunath, P.; Shown, I.; Chen, W.F.; Lien, H.T.; Shen, T.H.; Lee, J.F.; Chan, T.S.; Huang, K.Y.; et al. Ni-Nanocluster Modified Black TiO2 with Dual Active Sites for Selective Photocatalytic CO2 Reduction. Small 2018, 14, 1702928. [Google Scholar] [CrossRef]

- Rechberger, F.; Niederberger, M. Translucent nanoparticle-based aerogel monoliths as 3-dimensional photocatalysts for the selective photoreduction of CO2 to methanol in a continuous flow reactor. Mater. Horiz. 2017, 4, 1115–1121. [Google Scholar] [CrossRef]

- Wu, J.; Feng, Y.; Logan, B.E.; Dai, C.; Han, X.; Li, D.; Liu, J. Preparation of Al–O-Linked Porous-g-C3N4/TiO2-Nanotube Z-Scheme Composites for Efficient Photocatalytic CO2 Conversion and 2,4-Dichlorophenol Decomposition and Mechanism. ACS Sustain. Chem. Eng. 2019, 7, 15289–15296. [Google Scholar] [CrossRef]

- Zeng, G.; Qiu, J.; Li, Z.; Pavaskar, P.; Cronin, S.B. CO2 Reduction to Methanol on TiO2-Passivated GaP Photocatalysts. ACS Catal. 2014, 4, 3512–3516. [Google Scholar] [CrossRef]

- Guo, H.; Wan, S.; Wang, Y.; Ma, W.; Zhong, Q.; Ding, J. Enhanced photocatalytic CO2 reduction over direct Z-scheme NiTiO3/g-C3N4 nanocomposite promoted by efficient interfacial charge transfer. Chem. Eng. J. 2021, 412, 128646. [Google Scholar] [CrossRef]

- Nor, N.U.M.; Amin, N.A.S. Glucose precursor carbon-doped TiO2 heterojunctions for enhanced efficiency in photocatalytic reduction of carbon dioxide to methanol. J. CO2 Util. 2019, 33, 372–383. [Google Scholar] [CrossRef]

- Liu, J.-Y.; Gong, X.-Q.; Alexandrova, A.N. Mechanism of CO2 Photocatalytic Reduction to Methane and Methanol on Defected Anatase TiO2 (101): A Density Functional Theory Study. J. Phys. Chem. C 2019, 123, 3505–3511. [Google Scholar] [CrossRef]

- Bahadori, E.; Tripodi, A.; Villa, A.; Pirola, C.; Prati, L.; Ramis, G.; Dimitratos, N.; Wang, D.; Rossetti, I. High pressure CO2 photoreduction using Au/TiO2: Unravelling the effect of co-catalysts and of titania polymorphs. Catal. Sci. Technol. 2019, 9, 2253–2265. [Google Scholar] [CrossRef]

- Olowoyo, J.O.; Saini, U.; Kumar, M.; Valdés, H.; Singh, H.; Omorogie, M.O.; Babalola, J.O.; Vorontsov, A.V.; Kumar, U.; Smirniotis, P.G. Reduced graphene oxide/NH2-MIL-125(Ti) composite: Selective CO2 photoreduction to methanol under visible light and computational insights into charge separation. J. CO2 Util. 2020, 42, 101300. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Sun, Q.; Wang, Z.; Huang, B.; Dai, Y.; Qin, X.; Zhang, X. Chemical adsorption enhanced CO2 capture and photoreduction over a copper porphyrin based metal organic framework. ACS Appl. Mater. Interfaces 2013, 5, 7654–7658. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Low, Z.-X.; Li, L.; Razmjou, A.; Wang, K.; Yao, J.; Wang, H. ZIF-8/Zn2GeO4 nanorods with an enhanced CO2 adsorption property in an aqueous medium for photocatalytic synthesis of liquid fuel. J. Mater. Chem. A 2013, 1, 11563–11569. [Google Scholar] [CrossRef]

- Alhaddad, M.; Shawky, A. Pt-decorated ZnMn2O4 nanorods for effective photocatalytic reduction of CO2 into methanol under visible light. Ceram. Int. 2021, 47, 9763–9770. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Pan, Q.; Ding, N.; Yang, C.; Zhang, Z.; Jia, C.; Li, Z.; Liu, J.; Zhao, Y. Construction of Thiazolo[5,4-d]thiazole-based Two-Dimensional Network for Efficient Photocatalytic CO2 Reduction. ACS Appl. Mater. Interfaces 2020, 12, 46483–46489. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liu, X.; Han, X.; Godin, R.; Chen, J.; Zhou, W.; Jiang, C.; Thompson, J.F.; Mustafa, K.B.; Shevlin, S.A.; et al. Unique hole-accepting carbon-dots promoting selective carbon dioxide reduction nearly 100% to methanol by pure water. Nat. Commun. 2020, 11, 2531. [Google Scholar] [CrossRef]

- Chen, K.; Zhao, X.; Zhang, X.-J.; Zhang, W.-S.; Wu, Z.-F.; Wang, H.-Y.; Han, D.-X.; Niu, L. Enhanced photocatalytic CO2 reduction by constructing an In2O3–CuO heterojunction with CuO as a cocatalyst. Catal. Sci. Technol. 2021, 11, 2713–2717. [Google Scholar] [CrossRef]

- McFarlan, A. Techno-economic assessment of pathways for electricity generation in northern remote communities in Canada using methanol and dimethyl ether to replace diesel. Renew. Sustain. Energy Rev. 2018, 90, 863–876. [Google Scholar] [CrossRef]

- Bunyakiat, K.; Makmee, S.; Sawangkeaw, R.; Ngamprasertsith, S. Continuous Production of Biodiesel via Transesterification from Vegetable Oils in Supercritical Methanol. Energy Fuels 2006, 20, 812–817. [Google Scholar] [CrossRef]

- Williams, R.H.; Larson, E.D.; Katofsky, R.E.; Chen, J. Methanol and hydrogen from biomass for transportation. Energy Sustain. Dev. 1995, 1, 18–34. [Google Scholar] [CrossRef]

- Bowker, M. Methanol Synthesis from CO2 Hydrogenation. ChemCatChem 2019, 11, 4238–4246. [Google Scholar] [CrossRef] [Green Version]

- Din, I.U.; Shaharun, M.S.; Alotaibi, M.A.; Alharthi, A.I.; Naeem, A. Recent developments on heterogeneous catalytic CO2 reduction to methanol. J. CO2 Util. 2019, 34, 20–33. [Google Scholar] [CrossRef]

- Yang, Z.; Qi, Y.; Wang, F.; Han, Z.; Jiang, Y.; Han, H.; Liu, J.; Zhang, X.; Ong, W.J. State-of-the-art advancements in photo-assisted CO2 hydrogenation: Recent progress in catalyst development and reaction mechanisms. J. Mater. Chem. A 2020, 8, 24868–24894. [Google Scholar] [CrossRef]

- Li, X.; Yu, J.; Jaroniec, M.; Chen, X. Cocatalysts for Selective Photoreduction of CO2 into Solar Fuels. Chem. Rev. 2019, 119, 3962–4179. [Google Scholar] [CrossRef]

- Adekoya, D.; Tahir, M.; Amin, N.A.S. Recent trends in photocatalytic materials for reduction of carbon dioxide to methanol. Renew. Sustain. Energy Rev. 2019, 116, 109389. [Google Scholar] [CrossRef]

- Fu, Z.; Yang, Q.; Liu, Z.; Chen, F.; Yao, F.; Xie, T.; Zhong, Y.; Wang, D.; Li, J.; Li, X.; et al. Photocatalytic conversion of carbon dioxide: From products to design the catalysts. J. CO2 Util. 2019, 34, 63–73. [Google Scholar] [CrossRef]

- Li, D.; Kassymova, M.; Cai, X.; Zang, S.-Q.; Jiang, H.-L. Photocatalytic CO2 reduction over metal-organic framework-based materials. Coord. Chem. Rev. 2020, 412, 213262. [Google Scholar] [CrossRef]

- Lei, Z.; Xue, Y.; Chen, W.; Qiu, W.; Zhang, Y.; Horike, S.; Tang, L. MOFs-Based Heterogeneous Catalysts: New Opportunities for Energy-Related CO2 Conversion. Adv. Energy Mater. 2018, 8, 1801587. [Google Scholar] [CrossRef]

- Chen, Y.; Jia, G.; Hu, Y.; Fan, G.; Tsang, Y.H.; Li, Z.; Zou, Z. Two-dimensional nanomaterials for photocatalytic CO2 reduction to solar fuels. Sustain. Energy Fuels 2017, 1, 1875–1898. [Google Scholar] [CrossRef]

- Wang, C.; Sun, Z.; Zheng, Y.; Hu, Y.H. Recent progress in visible light photocatalytic conversion of carbon dioxide. J. Mater. Chem. A 2019, 7, 865–887. [Google Scholar] [CrossRef]

- Zhong, J.; Yang, X.; Wu, Z.; Liang, B.; Huang, Y.; Zhang, T. State of the art and perspectives in heterogeneous catalysis of CO2 hydrogenation to methanol. Chem. Soc. Rev. 2020, 49, 1385–1413. [Google Scholar] [CrossRef] [PubMed]

- Maina, J.W.; Pozo-Gonzalo, C.; Kong, L.; Schütz, J.; Hill, M.; Dumée, L.F. Metal organic framework based catalysts for CO2 conversion. Mater. Horiz. 2017, 4, 345–361. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, Z.; Liu, H.; Wang, Y. Cd0.2Zn0.8S@UiO-66-NH2 nanocomposites as efficient and stable visible-light-driven photocatalyst for H2 evolution and CO2 reduction. Appl. Catal. B Environ. 2017, 200, 448–457. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Z.; Wu, J. Construction of a Z-scheme heterojunction for high-efficiency visible-light-driven photocatalytic CO2 reduction. Nanoscale 2021, 13, 4359–4389. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Zhang, L.; Yu, J.; Wageh, S.; Al-Ghamdi, A.A.; Jaroniec, M. Direct Z-scheme photocatalysts: Principles, synthesis, and applications. Mater. Today 2018, 21, 1042–1063. [Google Scholar] [CrossRef]

- Meng, J.; Chen, Q.; Lu, J.; Liu, H. Z-Scheme Photocatalytic CO2 Reduction on a Heterostructure of Oxygen-Defective ZnO/Reduced Graphene Oxide/UiO-66-NH2 under Visible Light. ACS Appl. Mater. Interfaces 2019, 11, 550–562. [Google Scholar] [CrossRef]

- Wang, G.; He, C.-T.; Huang, R.; Mao, J.; Wang, D.; Li, Y. Photoinduction of Cu Single Atoms Decorated on UiO-66-NH2 for Enhanced Photocatalytic Reduction of CO2 to Liquid Fuels. J. Am. Chem. Soc. 2020, 142, 19339–19345. [Google Scholar] [CrossRef]

- Liu, S.; Chen, F.; Li, S.; Peng, X.; Xiong, Y. Enhanced photocatalytic conversion of greenhouse gas CO2 into solar fuels over g-C3N4 nanotubes with decorated transparent ZIF-8 nanoclusters. Appl. Catal. B Environ. 2017, 211, 1–10. [Google Scholar] [CrossRef]

- Maina, J.W.; Schutz, J.A.; Grundy, L.; Des Ligneris, E.; Yi, Z.; Kong, L.; Pozo-Gonzalo, C.; Ionescu, M.; Dumee, L.F. Inorganic Nanoparticles/Metal Organic Framework Hybrid Membrane Reactors for Efficient Photocatalytic Conversion of CO2. ACS Appl. Mater. Interfaces 2017, 9, 35010–35017. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, J.C.; Stulp, S.; de Brito, J.F.; Flor, J.B.S.; Frem, R.C.G.; Zanoni, M.V.B. MOFs based on ZIF-8 deposited on TiO2 nanotubes increase the surface adsorption of CO2 and its photoelectrocatalytic reduction to alcohols in aqueous media. Appl. Catal. B Environ. 2018, 225, 563–573. [Google Scholar] [CrossRef] [Green Version]

- An, B.; Zhang, J.; Cheng, K.; Ji, P.; Wang, C.; Lin, W. Confinement of Ultrasmall Cu/ZnOx Nanoparticles in Metal–Organic Frameworks for Selective Methanol Synthesis from Catalytic Hydrogenation of CO2. J. Am. Chem. Soc. 2017, 139, 3834–3840. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Liu, X.; Zhou, J.; Chen, W.; Liu, M. Encapsulating CuO quantum dots in MIL-125(Ti) coupled with g-C3N4 for efficient photocatalytic CO2 reduction. Chem. Eng. J. 2020, 399, 125782. [Google Scholar] [CrossRef]

- Li, J.; Luo, D.; Yang, C.; He, S.; Chen, S.; Lin, J.; Zhu, L.; Li, X. Copper(II) imidazolate frameworks as highly efficient photocatalysts for reduction of CO2 into methanol under visible light irradiation. J. Solid State Chem. 2013, 203, 154–159. [Google Scholar] [CrossRef]

- Chen, S.; Yu, J.; Zhang, J. Enhanced photocatalytic CO2 reduction activity of MOF-derived ZnO/NiO porous hollow spheres. J. CO2 Util. 2018, 24, 548–554. [Google Scholar] [CrossRef]

- Goyal, S.; Shaharun, M.; Kait, C.; Abdullah, B.; Ameen, M. Photoreduction of Carbon Dioxide to Methanol over Copper Based Zeolitic Imidazolate Framework-8: A New Generation Photocatalyst. Catalysts 2018, 8, 581. [Google Scholar] [CrossRef] [Green Version]

- Nadeem, S.; Mumtaz, A.; Mumtaz, M.; Abdul Mutalib, M.I.; Shaharun, M.S.; Abdullah, B. Visible light driven CO2 reduction to methanol by Cu-porphyrin impregnated mesoporous Ti-MCM-48. J. Mol. Liq. 2018, 272, 656–667. [Google Scholar] [CrossRef]

- Becerra, J.; Nguyen, D.-T.; Gopalakrishnan, V.-N.; Do, T.-O. Plasmonic Au Nanoparticles Incorporated in the Zeolitic Imidazolate Framework (ZIF-67) for the Efficient Sunlight-Driven Photoreduction of CO2. ACS Appl. Energy Mater. 2020, 3, 7659–7665. [Google Scholar] [CrossRef]

- Burange, A.S.; Gawande, M.B. Role of Mixed Metal Oxides in Heterogeneous Catalysis. In Encyclopedia of Inorganic and Bioinorganic Chemistry; Wiley: Hoboken, NJ, USA, 2016; pp. 1–19. [Google Scholar]

- Gawande, M.B.; Pandey, R.K.; Jayaram, R.V. Role of mixed metal oxides in catalysis science—Versatile applications in organic synthesis. Catal. Sci. Technol. 2012, 2, 1113–1125. [Google Scholar] [CrossRef]

- Thompson, W.A.; Olivo, A.; Zanardo, D.; Cruciani, G.; Menegazzo, F.; Signoretto, M.; Maroto-Valer, M.M. Systematic study of TiO2/ZnO mixed metal oxides for CO2 photoreduction. RSC Adv. 2019, 9, 21660–21666. [Google Scholar] [CrossRef] [Green Version]

- Singhal, N.; Goyal, R.; Kumar, U. Visible-Light-Assisted Photocatalytic CO2 Reduction over InTaO4: Selective Methanol Formation. Energy Fuels 2017, 31, 12434–12438. [Google Scholar] [CrossRef]

- Wang, Z.; Jiao, X.; Chen, D.; Li, C.; Zhang, M. Porous Copper/Zinc Bimetallic Oxides Derived from MOFs for Efficient Photocatalytic Reduction of CO2 to Methanol. Catalysts 2020, 10, 1127. [Google Scholar] [CrossRef]

- Kumar, P.; Joshi, C.; Barras, A.; Sieber, B.; Addad, A.; Boussekey, L.; Szunerits, S.; Boukherroub, R.; Jain, S.L. Core–shell structured reduced graphene oxide wrapped magnetically separable rGO@CuZnO@Fe3O4 microspheres as superior photocatalyst for CO2 reduction under visible light. Appl. Catal. B Environ. 2017, 205, 654–665. [Google Scholar] [CrossRef]

- Gao, S.; Gu, B.; Jiao, X.; Sun, Y.; Zu, X.; Yang, F.; Zhu, W.; Wang, C.; Feng, Z.; Ye, B.; et al. Highly Efficient and Exceptionally Durable CO2 Photoreduction to Methanol over Freestanding Defective Single-Unit-Cell Bismuth Vanadate Layers. J. Am. Chem. Soc. 2017, 139, 3438–3445. [Google Scholar] [CrossRef]

- Cao, S.; Shen, B.; Tong, T.; Fu, J.; Yu, J. 2D/2D Heterojunction of Ultrathin MXene/Bi2WO6 Nanosheets for Improved Photocatalytic CO2 Reduction. Adv. Funct. Mater. 2018, 28, 1800136. [Google Scholar] [CrossRef]

- Jeyalakshmi, V.; Mahalakshmy, R.; Ramesh, K.; Rao, P.V.C.; Choudary, N.V.; Thirunavukkarasu, K.; Krishnamurthy, K.R.; Viswanathan, B. Metal oxides as photo catalysts: Modified sodium tantalate as catalyst for photo reduction of carbon dioxide. Mol. Catal. 2018, 451, 105–113. [Google Scholar] [CrossRef]

- Kumar, A.; Prajapati, P.K.; Pal, U.; Jain, S.L. Ternary rGO/InVO4/Fe2O3 Z-Scheme Heterostructured Photocatalyst for CO2 Reduction under Visible Light Irradiation. ACS Sustain. Chem. Eng. 2018, 6, 8201–8211. [Google Scholar] [CrossRef]

- Yan, T.; Wang, L.; Liang, Y.; Makaremi, M.; Wood, T.E.; Dai, Y.; Huang, B.; Jelle, A.A.; Dong, Y.; Ozin, G.A. Polymorph selection towards photocatalytic gaseous CO2 hydrogenation. Nat. Commun. 2019, 10, 2521. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Ghoussoub, M.; Wang, H.; Shao, Y.; Sun, W.; Tountas, A.A.; Wood, T.E.; Li, H.; Loh, J.Y.Y.; Dong, Y.; et al. Photocatalytic Hydrogenation of Carbon Dioxide with High Selectivity to Methanol at Atmospheric Pressure. Joule 2018, 2, 1369–1381. [Google Scholar] [CrossRef]

- Kandy, M.M. Carbon-based photocatalysts for enhanced photocatalytic reduction of CO2 to solar fuels. Sustain. Energy Fuels 2020, 4, 469–484. [Google Scholar] [CrossRef]

- Lin, J.; Tian, W.; Zhang, H.; Duan, X.; Sun, H.; Wang, S. Graphitic Carbon Nitride-Based Z-Scheme Structure for Photocatalytic CO2 Reduction. Energy Fuels 2021, 35, 7–24. [Google Scholar] [CrossRef]

- Gusain, R.; Kumar, P.; Sharma, O.P.; Jain, S.L.; Khatri, O.P. Reduced graphene oxide–CuO nanocomposites for photocatalytic conversion of CO2 into methanol under visible light irradiation. Appl. Catal. B Environ. 2016, 181, 352–362. [Google Scholar] [CrossRef]

- Liu, S.-H.; Lu, J.-S.; Pu, Y.-C.; Fan, H.-C. Enhanced photoreduction of CO2 into methanol by facet-dependent Cu2O/reduce graphene oxide. J. CO2 Util. 2019, 33, 171–178. [Google Scholar] [CrossRef]

- Xu, D.; Cheng, B.; Wang, W.; Jiang, C.; Yu, J. Ag2CrO4/g-C3N4/graphene oxide ternary nanocomposite Z-scheme photocatalyst with enhanced CO2 reduction activity. Appl. Catal. B Environ. 2018, 231, 368–380. [Google Scholar] [CrossRef]

- Kumar, A.; Prajapati, P.K.; Aathira, M.S.; Bansiwal, A.; Boukherroub, R.; Jain, S.L. Highly improved photoreduction of carbon dioxide to methanol using cobalt phthalocyanine grafted to graphitic carbon nitride as photocatalyst under visible light irradiation. J. Colloid Interface Sci. 2019, 543, 201–213. [Google Scholar] [CrossRef]

- Li, A.; Wang, T.; Li, C.; Huang, Z.; Luo, Z.; Gong, J. Adjusting the Reduction Potential of Electrons by Quantum Confinement for Selective Photoreduction of CO2 to Methanol. Angew. Chem. Int. Ed. 2019, 58, 3804–3808. [Google Scholar] [CrossRef]

- Bafaqeer, A.; Tahir, M.; Amin, N.A.S. Well-designed ZnV2O6/g-C3N4 2D/2D nanosheets heterojunction with faster charges separation via pCN as mediator towards enhanced photocatalytic reduction of CO2 to fuels. Appl. Catal. B Environ. 2019, 242, 312–326. [Google Scholar] [CrossRef]

- Olowoyo, J.O.; Kumar, M.; Jain, S.L.; Babalola, J.O.; Vorontsov, A.V.; Kumar, U. Insights into Reinforced Photocatalytic Activity of the CNT-TiO2 Nanocomposite for CO2 Reduction and Water Splitting. J. Phys. Chem. C 2019, 123, 367–378. [Google Scholar] [CrossRef]

- Xu, H.; Ouyang, S.; Liu, L.; Reunchan, P.; Umezawa, N.; Ye, J. Recent advances in TiO2-based photocatalysis. J. Mater. Chem. A 2014, 2, 12642–12661. [Google Scholar] [CrossRef]

- Kou, J.; Lu, C.; Wang, J.; Chen, Y.; Xu, Z.; Varma, R.S. Selectivity Enhancement in Heterogeneous Photocatalytic Transformations. Chem. Rev. 2017, 117, 1445–1514. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alves Melo Júnior, M.; Morais, A.; Nogueira, A.F. Boosting the solar-light-driven methanol production through CO2 photoreduction by loading Cu2O on TiO2-pillared K2Ti4O9. Microporous Mesoporous Mater. 2016, 234, 1–11. [Google Scholar] [CrossRef]

- Wang, W.; Xu, D.; Cheng, B.; Yu, J.; Jiang, C. Hybrid carbon@TiO2 hollow spheres with enhanced photocatalytic CO2 reduction activity. J. Mater. Chem. A 2017, 5, 5020–5029. [Google Scholar] [CrossRef]

- Yadav, R.; Sinha, A.K. Titania Cowrapped α-Sulfur Composite as a Visible Light Active Photocatalyst for Hydrogen Evolution Using in Situ Methanol from CO2 as a Sacrificial Agent. ACS Sustain. Chem. Eng. 2017, 5, 6736–6745. [Google Scholar] [CrossRef]

- Sharma, A.; Lee, B.-K. Photocatalytic reduction of carbon dioxide to methanol using nickel-loaded TiO2 supported on activated carbon fiber. Catal. Today 2017, 298, 158–167. [Google Scholar] [CrossRef]

- Meng, A.; Wu, S.; Cheng, B.; Yu, J.; Xu, J. Hierarchical TiO2/Ni(OH)2 composite fibers with enhanced photocatalytic CO2 reduction performance. J. Mater. Chem. A 2018, 6, 4729–4736. [Google Scholar] [CrossRef]

- Seeharaj, P.; Kongmun, P.; Paiplod, P.; Prakobmit, S.; Sriwong, C.; Kim-Lohsoontorn, P.; Vittayakorn, N. Ultrasonically-assisted surface modified TiO2/rGO/CeO2 heterojunction photocatalysts for conversion of CO2 to methanol and ethanol. Ultrason. Sonochem. 2019, 58, 104657. [Google Scholar] [CrossRef]

- Zhu, Q.; Xuan, Y.; Zhang, K.; Chang, K. Enhancing photocatalytic CO2 reduction performance of g-C3N4-based catalysts with non-noble plasmonic nanoparticles. Appl. Catal. B Environ. 2021, 297, 120440. [Google Scholar] [CrossRef]

- Collado, L.; Reynal, A.; Coronado, J.M.; Serrano, D.P.; Durrant, J.R.; de la Peña O’Shea, V.A. Effect of Au surface plasmon nanoparticles on the selective CO2 photoreduction to CH4. Appl. Catal. B Environ. 2015, 178, 177–185. [Google Scholar] [CrossRef]

- Tahir, M.; Tahir, B.; Amin, N.A.S. Synergistic effect in plasmonic Au/Ag alloy NPs co-coated TiO2 NWs toward visible-light enhanced CO2 photoreduction to fuels. Appl. Catal. B Environ. 2017, 204, 548–560. [Google Scholar] [CrossRef]

- Mahyoub, S.A.; Hezam, A.; Qaraah, F.A.; Namratha, K.; Nayan, M.B.; Drmosh, Q.A.; Ponnamma, D.; Byrappa, K. Surface Plasmonic Resonance and Z-Scheme Charge Transport Synergy in Three-Dimensional Flower-like Ag–CeO2–ZnO Heterostructures for Highly Improved Photocatalytic CO2 Reduction. ACS Appl. Energy Mater. 2021, 4, 3544–3554. [Google Scholar] [CrossRef]

- Zhang, X.; Ke, X.; Yao, J. Recent development of plasmon-mediated photocatalysts and their potential in selectivity regulation. J. Mater. Chem. A 2018, 6, 1941–1966. [Google Scholar] [CrossRef]

- Vu, N.N.; Kaliaguine, S.; Do, T.O. Plasmonic Photocatalysts for Sunlight-Driven Reduction of CO2: Details, Developments, and Perspectives. ChemSusChem 2020, 13, 3967–3991. [Google Scholar] [CrossRef]

- Jun, H.; Choi, S.; Yang, M.Y.; Nam, Y.S. A ruthenium-based plasmonic hybrid photocatalyst for aqueous carbon dioxide conversion with a high reaction rate and selectivity. J. Mater. Chem. A 2019, 7, 17254–17260. [Google Scholar] [CrossRef]

- Verma, R.; Belgamwar, R.; Polshettiwar, V. Plasmonic Photocatalysis for CO2 Conversion to Chemicals and Fuels. ACS Mater. Lett. 2021, 3, 574–598. [Google Scholar] [CrossRef]

- Becerra, J.; Gopalakrishnan, V.N.; Quach, T.-A.; Do, T.-O. Enhancing CO2 photoreduction over ZIF-based reticular materials by morphology control of Au plasmonic nanoparticles. Sustain. Energy Fuels 2022. [Google Scholar] [CrossRef]

- Yadav, R.; Amoli, V.; Singh, J.; Tripathi, M.K.; Bhanja, P.; Bhaumik, A.; Sinha, A.K. Plasmonic gold deposited on mesoporous TixSi1−xO2 with isolated silica in lattice: An excellent photocatalyst for photocatalytic conversion of CO2 into methanol under visible light irradiation. J. CO2 Util. 2018, 27, 11–21. [Google Scholar] [CrossRef]

- Wang, Z.-J.; Song, H.; Pang, H.; Ning, Y.; Dao, T.D.; Wang, Z.; Chen, H.; Weng, Y.; Fu, Q.; Nagao, T.; et al. Photo-assisted methanol synthesis via CO2 reduction under ambient pressure over plasmonic Cu/ZnO catalysts. Appl. Catal. B Environ. 2019, 250, 10–16. [Google Scholar] [CrossRef]

- Liu, E.; Qi, L.; Bian, J.; Chen, Y.; Hu, X.; Fan, J.; Liu, H.; Zhu, C.; Wang, Q. A facile strategy to fabricate plasmonic Cu modified TiO2 nano-flower films for photocatalytic reduction of CO2 to methanol. Mater. Res. Bull. 2015, 68, 203–209. [Google Scholar] [CrossRef]

- Wang, R.; Ding, J.; Zhong, Q.; Hu, J.; Guo, H.; Liu, Q. Plasmonic Ag Nanoparticles Decorated Acid-Aching Carbon Fibers for Enhanced Photocatalytic Reduction of CO2 into CH3OH Under Visible-Light Irradiation. Catal. Lett. 2021, 151, 3079–3088. [Google Scholar] [CrossRef]

| Photocatalyst | Light Source | Method | ProductsYield (µmol h−1 g−1) | Proton Donor/ Reaction Reagent | Year | Ref. |

|---|---|---|---|---|---|---|

| Cu-porphyrin MOFs | Visible | CH3OH (262.6) | TEOA | 2013 | [34] | |

| Cu (II) ZIF | Visible | Hydrothermal | CH3OH (1712.7) | H2O | 2013 | [65] |

| Zn2GeO4/ZIF-8 | UV | Hydrothermal | CH3OH (0.22) | H2O | 2013 | [35] |

| Cd0.2Zn0.8S@UiO-66-NH2 | Visible | Solvothermal method | CH3OH (6.8) | H2O | 2017 | [55] |

| g-C3N4/ZIF-8 | 300 W Xe lamp | In situ heterogeneous deposition method | CH3OH (0.75) | H2O | 2017 | [60] |

| Cu/ZnOx MOFs | - | Solvothermal | CH3OH (2.59) | H2 | 2017 | [63] |

| Cu-TiO2 ZIF-8 | UV | Rapid thermal deposition (RTD) | CH3OH, CO | TEOA | 2017 | [61] |

| TiO2 ZIF-8 | UV-Visible | Layer-by-layer process | CH3OH, CH3CH2OH | Na2SO4 | 2018 | [62] |

| Zn-Ni bimetallic MOF | Calcination/Thermal | CH3OH | 2018 | [66] | ||

| 2Cu-ZIF-8N2 | Visible | Hydrothermal | CH3OH (35.82) | Na2SO3 | 2018 | [67] |

| Cu-porphyrin-Ti-MCM-48 | Visible | Impregnation | CH3OH (297) | Na2SO3 | 2018 | [68] |

| O-ZnO/rGO/UiO-66-NH2 | Solvothermal | CH3OH (34.85), HCOOH (6.41) | TEOA | 2019 | [58] | |

| rGO-NH2-MIL-125(Ti) | Visible | CH3OH | TEOA | 2020 | [33] | |

| g-C3N4/CuO@MIL-125(Ti) | Visible light | Complexation-oxidation method | CH3OH, CO, CH3CH2OH, CH3CHO | 2020 | [64] | |

| Aux@ZIF-67 | Visible | CH3OH (2.5), CH3CH2OH (0.5) | 2020 | [69] | ||

| CuSA@UiO-66 NH2 | Visible | CH3OH (5.33), CH3CH2OH (4.22) | TEOA | 2020 | [59] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shinde, G.Y.; Mote, A.S.; Gawande, M.B. Recent Advances of Photocatalytic Hydrogenation of CO2 to Methanol. Catalysts 2022, 12, 94. https://doi.org/10.3390/catal12010094

Shinde GY, Mote AS, Gawande MB. Recent Advances of Photocatalytic Hydrogenation of CO2 to Methanol. Catalysts. 2022; 12(1):94. https://doi.org/10.3390/catal12010094

Chicago/Turabian StyleShinde, Gajanan Y., Abhishek S. Mote, and Manoj B. Gawande. 2022. "Recent Advances of Photocatalytic Hydrogenation of CO2 to Methanol" Catalysts 12, no. 1: 94. https://doi.org/10.3390/catal12010094

APA StyleShinde, G. Y., Mote, A. S., & Gawande, M. B. (2022). Recent Advances of Photocatalytic Hydrogenation of CO2 to Methanol. Catalysts, 12(1), 94. https://doi.org/10.3390/catal12010094