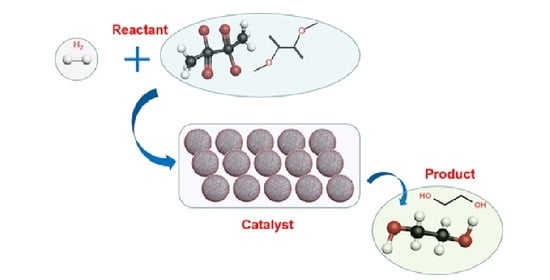

Anchoring Cu Species over SiO2 for Hydrogenation of Dimethyl Oxalate to Ethylene Glycol

Abstract

:1. Introduction

2. Results

2.1. Catalyst Structure Design and Characterization

2.2. Catalytic Performance

3. Discussion

4. Materials and Methods

4.1. Synthesis of HKUST-1

4.2. Synthesis of MOF-CmS Catalyst

4.2.1. Synthesis of Silica Microspheres

4.2.2. Synthesis of Modified Silica Microspheres

4.2.3. Synthesis of MOF-CmS Catalyst

4.3. Synthesis of MOF-CS Catalyst

4.4. Synthesis of CS Catalyst

4.5. Characterization

4.6. Catalytic Test

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, G.H.; Li, Y.C.; Li, Z.H.; Wang, H.J. Kinetics of the hydrogenation of diethyl oxalate to ethylene glycol. Ind. Eng. Chem. Res. 1995, 34, 2371–2378. [Google Scholar] [CrossRef]

- Yue, H.R.; Zhao, Y.J.; Ma, X.B.; Gong, J.L. Ethylene glycol: Properties, synthesis, and applications. Chem. Soc. Rev. 2012, 41, 4218–4244. [Google Scholar] [CrossRef] [PubMed]

- Ye, R.P.; Lin, L.; Wang, L.C.; Ding, D.; Zhou, Z.; Pan, P.; Yao, Y.G. Perspectives on the active sites and catalyst design for the hydrogenation of dimethyl oxalate. ACS Catal. 2020, 10, 4465–4490. [Google Scholar] [CrossRef]

- Yan, W.Q.; Zhang, J.B.; Zhou, R.J.; Cao, Y.Q.; Zhu, Y.A.; Zhou, J.H.; Zhou, X.G. Identification of synergistic actions between Cu0 and Cu+ sites in hydrogenation of dimethyl oxalate from microkinetic analysis. Ind. Eng. Chem. Res. 2020, 59, 22451–22459. [Google Scholar] [CrossRef]

- Zheng, X.; Lin, H.; Zheng, J.; Duan, X.; Yuan, Y. Lanthanum oxide-modified Cu/SiO2 as a high-performance catalyst for chemoselective hydrogenation of dimethyl oxalate to ethylene glycol. ACS Catal. 2013, 3, 2738–2749. [Google Scholar] [CrossRef]

- Boardman, B.; Hanton, M.J.; van Rensburg, H.; Tooze, R.P. A tripodal sulfur ligand for the selective ruthenium-catalysed hydrogenation of dimethyl oxalate. Chem. Commun. 2006, 2289–2291. [Google Scholar] [CrossRef] [PubMed]

- Teunissen, H.T.; Elsevier, C.J. Ruthenium catalysed hydrogenation of dimethyl oxalate to ethyleneglycol. Chem. Commun. 1997, 667–668. [Google Scholar] [CrossRef]

- Brands, D.S.; Poels, E.K.; Bliek, A. Ester hydrogenolysis over promoted Cu/SiO2 catalysts. Appl. Catal. A Gen. 1999, 184, 279–289. [Google Scholar] [CrossRef]

- Wall, R.G. Ester Hydrogenation Using Cobalt, Zinc and Copper Oxide Catalyst. U.S. Patent No. 4,149,021, 10 April 1979. [Google Scholar]

- Bartley, W.J. Process for the Preparation of Ethylene Glycol. U.S. Patent 4,628,129, 9 December 1986. [Google Scholar]

- Li, S.; Wang, Y.; Zhang, J.; Wang, S.; Xu, Y.; Zhao, Y.; Ma, X. Kinetics study of hydrogenation of dimethyl oxalate over Cu/SiO2 catalyst. Ind. Eng. Chem. Res. 2015, 54, 1243–1250. [Google Scholar] [CrossRef]

- Yin, A.; Wen, C.; Guo, X.; Dai, W.L.; Fan, K. Influence of Ni species on the structural evolution of Cu/SiO2 catalyst for the chemoselective hydrogenation of dimethyl oxalate. J. Catal. 2011, 280, 77–88. [Google Scholar] [CrossRef]

- Wen, C.; Yin, A.Y.; Cui, Y.Y.; Yang, X.L.; Dai, W.L.; Fan, K.N. Enhanced catalytic performance for SiO2-TiO2 binary oxide supported Cu-based catalyst in the hydrogenation of dimethyloxalate. Appl. Catal. A Gen. 2013, 458, 82–89. [Google Scholar] [CrossRef]

- Zhao, S.; Yue, H.; Zhao, Y.; Wang, B.; Geng, Y.; Lv, J.; Ma, X. Chemoselective synthesis of ethanol via hydrogenation of dimethyl oxalate on Cu/SiO2: Enhanced stability with boron dopant. J. Catal. 2013, 297, 142–150. [Google Scholar] [CrossRef]

- Liu, B.; Han, W.; Li, X.; Li, L.; Tang, H.; Lu, C.; Li, X. Quasi metal organic framework with highly concentrated Cr2O3 molecular clusters as the efficient catalyst for dehydrofluorination of 1,1,1,3,3-pentafluoropropane. Appl. Catal. B Environ. 2019, 257, 117939. [Google Scholar] [CrossRef]

- Tang, J.; Wang, J. MOF-derived three-dimensional flower-like FeCu@C composite as an efficient Fenton-like catalyst for sulfamethazine degradation. Chem. Eng. J. 2019, 375, 122007. [Google Scholar] [CrossRef]

- Li, Z.; Rayder, T.M.; Luo, L.; Byers, J.A.; Tsung, C.K. Aperture-opening encapsulation of a transition metal catalyst in a metal–organic framework for CO2 hydrogenation. J. Am. Chem. Soc. 2018, 140, 8082–8085. [Google Scholar] [CrossRef]

- Corma, A.; Garcia, H.I.; Llabrés i Xamena, F.X. Engineering metal organic frameworks for heterogeneous catalysis. Chem. Rev. 2010, 110, 4606–4655. [Google Scholar] [CrossRef]

- Rungtaweevoranit, B.; Baek, J.; Araujo, J.R.; Archanjo, B.S.; Choi, K.M.; Yaghi, O.M.; Somorjai, G.A. Copper nanocrystals encapsulated in Zr-based metal–organic frameworks for highly selective CO2 hydrogenation to methanol. Nano Lett. 2016, 16, 7645–7649. [Google Scholar] [CrossRef]

- Li, W.; Wang, K.; Huang, J.; Liu, X.; Fu, D.; Huang, J.; Zhan, G. MxOy–ZrO2 (M = Zn, Co, Cu) solid solutions derived from schiff base-bridged UiO-66 composites as high-performance catalysts for CO2 hydrogenation. ACS Appl. Mater. Interfaces 2019, 11, 33263–33272. [Google Scholar] [CrossRef]

- Yang, Q.; Yang, C.C.; Lin, C.H.; Jiang, H.L. Metal–organic-framework-derived hollow N-doped porous carbon with ultrahigh concentrations of single Zn atoms for efficient carbon dioxide conversion. Angew. Chem. 2019, 131, 3549–3553. [Google Scholar] [CrossRef]

- Ye, R.P.; Lin, L.; Chen, C.C.; Yang, J.X.; Li, F.; Zhang, X.; Yao, Y.G. Synthesis of robust MOF-Derived Cu/SiO2 catalyst with low copper loading via sol–gel method for the dimethyl oxalate hydrogenation reaction. ACS Catal. 2018, 8, 3382–3394. [Google Scholar] [CrossRef]

- Jonathan, C.S.; Vanessa, C.A.; Hiram, I.B.; Adriana, T.C.; Ilich, A.I.; Josueé, E.R.I.; Elí, S.G.; Sandra, L.S. Synthesis and characterization of an SWCNT@HKUST-1 composite: Enhancing the CO2 adsorption properties of HKUST-1. ACS Omega. 2019, 4, 5275–5282. [Google Scholar]

- Vrtovec, N.; Mazaj, M.; Buscarino, G.; Terracina, A.; Agnello, S.; Arčon, I.; Zabukovec Logar, N. Structural and CO2 Capture Properties of Ethylenediamine-Modified HKUST-1 Metal–Organic Framework. Cryst. Growth Des. 2020, 20, 5455–5465. [Google Scholar] [CrossRef]

- Guo, P.; Froese, C.; Fu, Q.; Chen, Y.T.; Peng, B.; Kleist, W.; Wang, Y. CuPd mixed-metal HKUST-1 as a catalyst for aerobic alcohol oxidation. J. Phys. Chem. C 2018, 122, 21433–21440. [Google Scholar] [CrossRef]

- Zhou, H.; Liu, X.; Zhang, J.; Yan, X.; Liu, Y.; Yuan, A. Enhanced room-temperature hydrogen storage capacity in Pt-loaded graphene oxide/HKUST-1 composites. Int. J. Hydrog. Energy 2014, 39, 2160–2167. [Google Scholar] [CrossRef]

- Decottignies, M.; Phalippou, J.; Zarzycki, J. Synthesis of glasses by hot-pressing of gels. J. Mater. Sci. 1978, 13, 2605–2618. [Google Scholar] [CrossRef]

- López, T.; Hernandez-Ventura, J.; Asomoza, M.; Campero, A.; Gómez, R. Support effect on Cu–Ru/SiO2 sol–gel catalysts. Mater. Lett. 1999, 41, 309–316. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Q.; Yu, J.; Wu, T.; Wang, G. Surface structure and catalytic behavior of silica-supported copper catalysts prepared by impregnation and sol–gel methods. Appl. Catal. A Gen. 2003, 239, 87–94. [Google Scholar] [CrossRef]

- Orel, B.; Svegel, F.; Bukovee, N.; Kosec, M. Structural and optical characterization of CuO particulate solid films and the corresponding gels and xerogels. J. Non-Cryst. Solids. 1993, 159, 49–64. [Google Scholar] [CrossRef]

- Yin, A.; Guo, X.; Dai, W.L.; Fan, K. The nature of active copper species in Cu-HMS catalyst for hydrogenation of dimethyl oxalate to ethylene glycol: New insights on the synergetic effect between Cu0 and Cu+. J. Phys. Chem. C 2009, 113, 11003–11013. [Google Scholar] [CrossRef]

- Yin, A.; Guo, X.; Dai, W.L.; Fan, K. Effect of initial precipitation temperature on the structural evolution and catalytic behavior of Cu/SiO2 catalyst in the hydrogenation of dimethyloxalate. Catal. Commun. 2011, 12, 412–416. [Google Scholar] [CrossRef]

- Lin, J.; Zhao, X.; Cui, Y.; Zhang, H.; Liao, D. Effect of feedstock solvent on the stability of Cu/SiO2 catalyst for vapor-phase hydrogenation of dimethyl oxalate to ethylene glycol. Chem. Commun. 2012, 48, 1177–1179. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Lin, H.; He, P.; Yuan, Y. Effect of boric oxide doping on the stability and activity of a Cu–SiO2 catalyst for vapor-phase hydrogenation of dimethyl oxalate to ethylene glycol. J. Catal. 2011, 277, 54–63. [Google Scholar] [CrossRef]

- Zheng, L.; Li, X.; Du, W.; Shi, D.; Ning, W.; Lu, X.; Hou, Z. Metal-organic framework derived Cu/ZnO catalysts for continuous hydrogenolysis of glycerol. Appl. Catal. B Environ. 2017, 203, 146–153. [Google Scholar] [CrossRef]

- Vasiliadou, E.S.; Yfanti, V.L.; Lemonidou, A.A. One-pot tandem processing of glycerol stream to 1,2-propanediol with methanol reforming as hydrogen donor reaction. Appl. Catal. B Environ. 2015, 163, 258–266. [Google Scholar] [CrossRef]

- Lin, H.; Zheng, X.; He, Z.; Zheng, J.; Duan, X.; Yuan, Y.Z. Cu/SiO2 hybrid catalysts containing HZSM-5 with enhanced activity and stability for selective hydrogenation of dimethyl oxalate to ethylene glycol. Appl. Catal. A Gen. 2012, 445, 287–296. [Google Scholar] [CrossRef]

- Yue, H.; Ma, X.; Gong, J. An alternative synthetic approach for efficient catalytic conversion of syngas to ethanol. Acc. Chem. Res. 2014, 47, 1483–1492. [Google Scholar] [CrossRef]

- Hao, L.; Zhao, Y.; Wang, S.; Yue, H.; Wang, B.; Lv, J.; Ma, X. Hydrogenation of dimethyl oxalate using extruded Cu/SiO2 catalysts: Mechanical strength and catalytic performance. Ind. Eng. Chem. Res. 2012, 51, 13935–13943. [Google Scholar]

- Li, X.L.; Xie, F.Y.; Gong, L.; Zhang, W.H.; Yu, X.L.; Chen, J. Effect of argon ion bombardment on copper oxide studied by X-ray photoelectron spectroscopy. J. Instrum. Anal. 2013, 32, 535–540. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

San, X.; Gong, X.; Lu, Y.; Xu, J.; He, L.; Meng, D.; Wang, G.; Qi, J.; Jin, Q. Anchoring Cu Species over SiO2 for Hydrogenation of Dimethyl Oxalate to Ethylene Glycol. Catalysts 2022, 12, 1326. https://doi.org/10.3390/catal12111326

San X, Gong X, Lu Y, Xu J, He L, Meng D, Wang G, Qi J, Jin Q. Anchoring Cu Species over SiO2 for Hydrogenation of Dimethyl Oxalate to Ethylene Glycol. Catalysts. 2022; 12(11):1326. https://doi.org/10.3390/catal12111326

Chicago/Turabian StyleSan, Xiaoguang, Xiaohui Gong, Yiming Lu, Juhua Xu, Liming He, Dan Meng, Guosheng Wang, Jian Qi, and Quan Jin. 2022. "Anchoring Cu Species over SiO2 for Hydrogenation of Dimethyl Oxalate to Ethylene Glycol" Catalysts 12, no. 11: 1326. https://doi.org/10.3390/catal12111326

APA StyleSan, X., Gong, X., Lu, Y., Xu, J., He, L., Meng, D., Wang, G., Qi, J., & Jin, Q. (2022). Anchoring Cu Species over SiO2 for Hydrogenation of Dimethyl Oxalate to Ethylene Glycol. Catalysts, 12(11), 1326. https://doi.org/10.3390/catal12111326