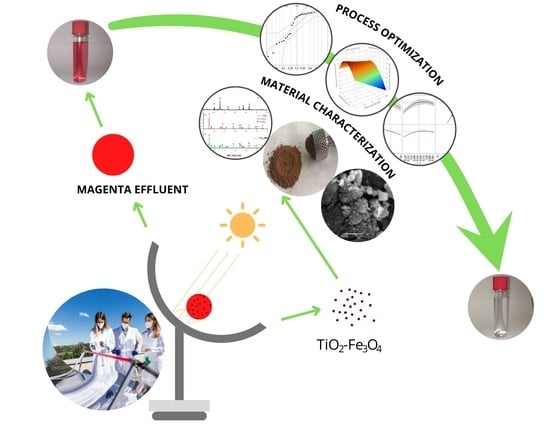

Photocatalytic Degradation of Magenta Effluent Using Magnetite Doped TiO2 in Solar Parabolic Trough Concentrator

Abstract

:1. Introduction

2. Results

2.1. Catalyst Characterisation

2.1.1. Scanning Electron Microscopy (SEM) and Energy Dispersive X-Ray (EDX)

2.1.2. Nitrogen Adsorption–Desorption Isotherms (BET)

2.1.3. X-Ray Diffraction (XRD)

2.1.4. Fourier-Transform Infrared Spectroscopy (FTIR)

2.2. Decolourisation Efficacy of Magenta Dye

2.3. DSD Regression Model

2.3.1. Response Area Diagrams

2.3.2. Process Optimisation

2.3.3. Mineralisation Efficiencies for Synthetic Dye Solution and Real Effluent

2.3.4. The Reusability of Photocatalytic Performance of TiO2–Fe3O4

3. Materials and Methods

3.1. Synthesis of Fe3O4 Nanoparticles

3.2. Synthesis of TiO2–Fe3O4 Catalyst

3.3. Characterisation of Nanoparticles

3.4. Parabolic Trough Concentrating Reactor

3.5. DSD Optimisation of the Photocatalytic Process

4. Conclusions

- TiO2–Fe3O4 have a spherical shape and have a tendency to agglomerate. Good incorporation of magnetite and lower porosity and a determined composition indicate on higher catalytic activity potential.

- The cubic spinel structure of magnetite attached to the surface of TiO2 was confirmed by XRD analysis, while both anatase and rutile titania phases were observed in both uncoated TiO2 and TiO2–Fe3O4.

- Within the obtained results, all process parameters (dye concentration, catalyst concentration, and pH value) are significant, and two two-factor interactions were established: dye concentration-pH; dye concentration-catalyst concentration.

- pH largely controls the process. Decreasing the pH value increases the decolourisation efficiency. In addition, the increase of catalyst concentration is favourable toward process efficiency, but only up to a certain value, while further increase leads to a decrease in efficiency.

- Maximum decolourisation efficiency reached during optimisation is 95.6%.

- Favouring milder process conditions and according to statistical modelling, decolourisation of magenta effluent of 85.07% is achieved following optimal conditions of dye concentration of 100 mg/L, TiO2–Fe3O4 concentration of 0.6 g/L, and pH of 6.5.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Natarajan, S.; Bajaj, H.C.; Tayade, R.J. Recent advances based on the synergetic effect of adsorption for removal of dyes from waste water using photocatalytic process. J. Environ. Sci. 2018, 65, 201–222. [Google Scholar] [CrossRef] [PubMed]

- Karimifard, S.; Moghaddam, M. Application of response surface methodology in physicochemical removal of dyes from wastewater: A critical review. Sci. Total Environ. 2018, 640–641, 772–797. [Google Scholar] [CrossRef] [PubMed]

- Katheresan, V.; Kansedo, J.; Lau, S. Efficiency of various recent wastewater dye removal methods: A review. J. Environ. Chem. Eng. 2018, 6, 46764697. [Google Scholar] [CrossRef]

- Kanakarajua, D.; Shahdad, N.R.M.; Lim, J.C.; Pace, A. Magnetic hybrid TiO2/Alg/FeNPs triads for the efficient removal of methylene blue from water. Sustain. Chem. Pharm. 2018, 8, 50–62. [Google Scholar] [CrossRef]

- Chen, D.; Cheng, Y.; Zhou, N.; Chen, P.; Wang, Y.; Li, K.; Ruan, R. Photocatalytic degradation of organic pollutants using TiO2-based photocatalysts: A review. J. Clean. Prod. 2020, 268, 121725. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, G.; Zhang, Z. TiO2-based catalysts for photocatalytic reduction of aqueous oxyanions: State-of-the-art and future prospects. Environ. Int. 2020, 136, 105453. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kang, D.; Jeong, S.; Do, H.T.; Kim, J.H. Photocatalytic Degradation of Rhodamine B Dye by TiO2 and Gold Nanoparticles Supported on a Floating Porous Polydimethylsiloxane Sponge under Ultraviolet and Visible Light Irradiation. ACS Omega 2020, 5, 4233–4241. [Google Scholar] [CrossRef]

- Reza, K.M.; Kurny, A.; Gulshan, F. Parameters affecting the photocatalytic degradation of dyes using TiO2: A review. Appl. Water Sci. 2017, 7, 1569–1578. [Google Scholar] [CrossRef]

- Hurum, D.C.; Agrios, A.G.; Gray, K.A. Explaining the Enhanced Photocatalytic Activity of Degussa P25 Mixed-Phase TiO2 Using EPR. J. Phys. Chem. B. 2003, 107, 4545–4549. [Google Scholar] [CrossRef]

- Wang, G.; Xu, L.; Zhang, J.; Yin, T.; Han, D. Enhanced Photocatalytic Activity of TiO2 Powders (P25) via Calcination Treatment. Int. J. Photoenergy 2012, 2012, 265760. [Google Scholar] [CrossRef] [Green Version]

- Qi, W.; Yang, Y.; Du, J.; Yang, J.; Guo, L.; Zhao, L. Highly photocatalytic electrospun Zr/Ag Co-doped titanium dioxide nanofibers for degradation of dye. J. Colloid. Interface Sci. 2021, 603, 594–603. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, C.H.; Fu, C.C.; Juang, R.Y. Degradation of methylene blue and methyl orange by palladium-doped TiO2 photocatalysis for water reuse: Efficiency and degradation pathways. J. Clean Prod. 2018, 202, 413–427. [Google Scholar] [CrossRef]

- Chakhtouna, H.; Benzeid, H.; Zari, N. Recent progress on Ag/TiO2 photocatalysts: Photocatalytic and bactericidal behaviors. Environ. Sci. Pollut. Res. 2021, 28, 44638–44666. [Google Scholar] [CrossRef]

- Arias, M.; Aguilar, C.; Piza, M.; Zarazua, E.; Anguebes, F.; Anguebes, F.; Anguebes, F.; Anguebes, F.; Cordova, V. Removal of the Methylene Blue Dye (MB) with Catalysts of Au-TiO2: Kinetic and Degradation Pathway. Modern Res. Catal. 2021, 10, 106960. [Google Scholar]

- Khasawneh, O.F.S.; Palaniandy, P. Removal of organic pollutants from water by Fe2O3/TiO2 based photocatalytic degradation: A review. Environ. Technol. Innov. 2021, 21, 101230. [Google Scholar] [CrossRef]

- Jacinto, M.J.; Ferreira, L.F.; Silva, V.C. Magnetic materials for photocatalytic applications—A review. J. Sol-Gel Sci. Technol. 2020, 96, 1–14. [Google Scholar] [CrossRef]

- Panda, S.K.; Aggarwal, I.; Kumar, H.; Prasad, L.; Kumar, A.; ·Sharma, A.; ·Vo, D.V.N.; Thuan, D.V.; Mishra, V. Magnetite nanoparticles as sorbents for dye removal: A review. Environ. Chem. Lett. 2021, 19, 2487–2525. [Google Scholar] [CrossRef]

- Thomas, N.; Dionysiou, D.D.; Pillai, S.C. Heterogeneous Fenton catalysts: A review of recent advances. J. Haz. Mat. 2021, 404, 124082. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, M.; Guo, M. Preparation and properties of a nano TiO2/Fe3O4 composite superparamagnetic photocatalyst. Rare Met. 2009, 28, 423–427. [Google Scholar] [CrossRef]

- Pang, Y.L.; Lim, S.; Ong, H.C.; Chong, W.T. Research progress on iron oxide-based magnetic materials: Synthesis techniques and photocatalytic applications. Ceram. Int. 2016, 42, 9–34. [Google Scholar] [CrossRef]

- Sunaryono, S.; Fitriana, D.R.; Novita, L.R.; Hidayat, M.F.; Hartatiek, H.; Mufti, N.; Taufiq, A. The effect of Fe3O4 concentration to photocatalytic activity of Fe3O4@TiO2-PVP core-shell nanocomposite. J. Phys. Conf. Ser. 2020, 1595, 012003. [Google Scholar] [CrossRef]

- Sun, L.; Zhou, Q.; Mao, J.; Ouyang, X.; Yuan, Z.; Song, X.; Gong, W.; Mei, S.; Xu, W. Study on Photocatalytic Degradation of Acid Red 73 by Fe3O4@TiO2 Exposed. Facets. Appl. Sci. 2022, 12, 3574. [Google Scholar] [CrossRef]

- Parast, F.; Montazeri-Pour, M.; Rajabi1, M.; Bavarsiha, F. Comparison of the Structural and Photo-catalytic Properties of Nanostructured Fe3O4/TiO2 Core-Shell Composites Synthesized by Ultrasonic and Stöber Methods. Sci. Sinter. 2020, 52, 415–432. [Google Scholar] [CrossRef]

- Gnanasekaran, L.; Hemamalini, R.; Rajendran, S.; Qin, J.; Lütfi Yola, M.; Atar, N.; Gracia, F. Nanosized Fe3O4 incorporated on a TiO2 surface for the enhanced photocatalytic degradation of organic pollutants. J. Mol. Liqid. 2019, 287, 110967. [Google Scholar] [CrossRef]

- Razip, N.I.M.; Lee, K.M.; LaI, C.W.; Ong, B.H. Recoverability of Fe3O4/TiO2 nanocatalyst in methyl orange degradation. Mater. Res. Express. 2019, 6, 075517. [Google Scholar] [CrossRef]

- Vinosel, V.M.; Janifer, M.A.; Anand, S.; Pauline, S. Structural and Functional Group Characterization of Nanocomposite Fe3O4/TiO2 and Its Magnetic Property Mechanics. Matter. Sci. Eng. J. 2017, 9, 1–7. [Google Scholar]

- Banisharif, A.; Hakim Elahi, S.; Anaraki Firooz, A.; Khodadadi, A.; Mortazavi, Y. TiO2/Fe3O4 Nanocomposite Photocatalysts for Enhanced Photo-Decolorization of Congo Red Dye. Int. J. Nanosci. Nanotechnol. 2013, 9, 193–202. [Google Scholar]

- Hasanpour, A.; Niyaifar, M.; Mohammadpour, H.; Amighian, J. A novel non-thermal process of TiO2-shell coating on Fe3O4-core nanoparticles. J. Phys. Chem. Solids 2012, 73, 1066–1070. [Google Scholar] [CrossRef]

- Jiang, W.; Zhang, X.; Gong, X.; Yan, F.; Zhang, Z. Sonochemical synthesis and characterization of magnetic separable Fe3O4–TiO2 nanocomposites and their catalytic properties. Int. J. Smart Nano Mater. 2010, 1, 278–287. [Google Scholar] [CrossRef]

- Dong, H.; Zeng, G.; Tang, L.; Fan, C.; Zhang, C.; He, X.; He, Y. An overview on limitations of TiO2-based particles for photocatalytic degradation of organic pollutants and the corresponding countermeasures. Water Res. 2015, 79, 128–146. [Google Scholar] [CrossRef]

- Nawsud, Z.A.; Altouni, A.; Akhijahani, H.S.; Kargarsharifabad, H. A comprehensive review on the use of nano-fluids and nano-PCM in parabolic trough solar collectors (PTC). Sustain. Energy Technol. Assess. 2022, 51, 101889. [Google Scholar] [CrossRef]

- Pucar Milidrag, G.; Becelic-Tomin, M.; Kulic Mandic, A.; Watson, M.; Kerkez, D. Scoping Review of Design and Applications of Parabolic Trough Collector (PTC). In Parabolic Troughs Design and Applications, 1st ed.; Sebastiaan, H., Ed.; Nova Science Publishers, Inc.: New York, NY, USA, 2020; pp. 1–30. [Google Scholar]

- Jones, B.; Nachtsheim, C.J. Definitive Screening Designs with Added Two-Level Categorical Factors. J. Qual. Technol. 2013, 45, 121–129. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Investigation on the Flexural Creep Stiffness Behavior of PC–ABS Material Processed by Fused Deposition Modeling Using Response Surface Definitive Screening Design. J. Met. Mater. Miner. 2017, 69, 498–505. [Google Scholar] [CrossRef]

- Fidaledo, M.; Lavecchia, R.; Petrucci, E.; Zuorro, A. Application of a novel definitive screening design to decolorization of an azo dye on boron-doped diamond electrodes. Int. J. Environ. Sci. Technol. 2016, 13, 835–842. [Google Scholar] [CrossRef]

- Zhao, J.; Li, W.; Qu, H.; Tian, G.; Wei, Y. Application of definitive screening design to quantify the effects of process parameters on key granule characteristics and optimize operating parameters in pulsed-spray fluid-bed granulation. Particuology 2019, 43, 56–65. [Google Scholar] [CrossRef]

- Marami, M.B.; Farahmandjou, M.; Khoshnevisan, B. Sol–Gel Synthesis of Fe-Doped TiO2 Nanocrystals. J. Electron. Mater. 2018, 47, 3741–3748. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- AL-Othman, Z.A. Review: Fundamental Aspects of Silicate Mesoporous Materials. Materials 2012, 5, 2874–2902. [Google Scholar] [CrossRef]

- Bessergenev, V.G.; Mateus, M.C.; Botelho do Rego, A.M.; Hantusch, M.; Burkel, E. An improvement of photocatalytic activity of TiO2 Degussa P25 powder. Appl. Catal. A General 2015, 500, 40–50. [Google Scholar] [CrossRef]

- McNaught, A.D.; Wilkinson, A. IUPAC. Compendium of Chemical Terminology, 2nd ed.; Blackwell Scientific Publications: Oxford, UK, 1997. [Google Scholar]

- Alonso-Tellez, A.; Masson, R.; Robert, D.; Keller, N.; Keller, V. Comparison of Hombikat UV100 and P25 TiO2 performance in gas-phase photocatalytic oxidation reactions. J. Photochem. Photobiol. A Chem. 2012, 250, 58–65. [Google Scholar] [CrossRef]

- Lezner, M.; Grabowska, E.; Zaleska, A. Preparation and photocatalytic activity of iron- modified titanium dioxide photocatalyst. Physicochem. Probl. Miner. Process. 2012, 48, 193–200. [Google Scholar]

- An, X.; Cheng, D.; Dai, L.; Wang, B.; Ocampo, H.J.; Nasrallah, J.; Jia, X.; Zou, J.; Long, Y.; Ni, Y. Synthesis of nano-fibrillated cellulose/magnetite/titanium dioxide (NFC@Fe3O4@TNP) nanocomposites and their application in the photocatalytic hydrogen generation. Appl. Catal. B 2017, 206, 53–64. [Google Scholar] [CrossRef]

- Nijpanich, S.; Nimpaiboon, A.; Rojruthai, P.; Sakdapipanich, J. Hydroxyl-Terminated Saponified Natural Rubber Based on the H2O2/P25-TiO2 Powder/UVC-Irradiation System. Polymers 2021, 13, 1319. [Google Scholar] [CrossRef] [PubMed]

- Abbas, M.; Rao, B.P.; Reddy, V.; Kim, C.G. Fe3O4/TiO2 core/shell nanocubes:Single-batch surfactantless synthesis, characterization and efficient catalysts for methyleneblue degradation. Ceram. Int. 2014, 40, 11177–11186. [Google Scholar] [CrossRef]

- Scherrer, P. Bestimmung der Grosse und der Inneren Struktur von Kolloidteilchen Mittels Rontgenstrahlen, Nachrichten von der Gesellschaft der Wissenschaften, Gottingen. Math.-Phys. Kl. 1918, 2, 98–100. [Google Scholar]

- Nikić, J.; Tubić, A.; Watson, M.; Maletić, S.; Šolić, M.; Majkić, T.; Agbaba, J. Arsenic Removal from Water by Green Synthesized Magnetic Nanoparticles. Water 2019, 11, 2520. [Google Scholar] [CrossRef]

- Klekotka, U.; Zambrzycka-Szelewa, E.; Satuła, D.; Kalska-Szostko, B. Stability Studies of Magnetite Nanoparticles in Environmental Solutions. Materials 2021, 14, 5069. [Google Scholar] [CrossRef]

- Uddin, M.J.; Cesano, F.; Chowdhury, A.R.; Trad, T.; Cravanzola, S.; Martra, G.; Mino, L.; Zecchina, A.; Scarano, D. Surface Structure and Phase Composition of TiO2 P25 Particles After Thermal Treatments and HF Etching. Front. Mater. 2020, 7, 192. [Google Scholar] [CrossRef]

- Jung, K.Y.; Park, S.B.; Ihm, S.K. Linear relationship between the crystallite size and the photoactivity of non-porous titania ranging from nanometer to micrometer size. Appl. Catal. 2002, 224, 229–237. [Google Scholar] [CrossRef]

- Salamat, S.; Younesi, H.; Bahramifar, N. Synthesis of magnetic core–shell Fe3O4@TiO2 nanoparticles from electric arc furnace dust for photocatalytic degradation of steel mill wastewater. RSC Adv. 2017, 7, 19391–19405. [Google Scholar] [CrossRef]

- Kecić, V.; Kerkez, Đ.; Prica, M.; Lužanina, O.; Bečelić-Tomin, M.; Tomašević Pilipović, D.; Dalamciaj, B. Optimization of azo printing dye removal with oak leaves-nZVI/H2O2 system using statistically designed experiment. J. Clean. Prod. 2018, 202, 65–80. [Google Scholar] [CrossRef]

- Pereira, A.C.; Reis, M.S.; Leca, J.M.; Rodrigues, P.M.; Marques, J.C. Definitive Screening Designs and latent variable modelling for the optimization of solid phase microextraction (SPME): Case study—Quantification of volatile fatty acids in wines. Chemom. Intell. Lab. Syst. 2018, 179, 73–81. [Google Scholar] [CrossRef]

- Gabbay, R.S.; Kenett, R.S.; Scaffaro, R.; Rubinstein, A. Synchronizing the release rates of salicylate and indomethacin from degradable chitosan hydrogel and its optimization by definitive screening design. Eur. J. Pharm. Sci. 2018, 125, 102–109. [Google Scholar] [CrossRef] [PubMed]

- Karimi-Shamsabadi, M.; Behpour, M.; Kazemi Babaheidari, A.; Saberi, Z. Efficiently Enhancing Photocatalytic Activity of NiO-ZnO doped onto nanozeolite X by synergistic effects of p-n heterojunction, supporting and zeolite nanoparticles in photo-degradation of Eriochrome Black T and Methyl Orange. J. Photochem. Photobio. A Chem. 2017, 346, 133. [Google Scholar] [CrossRef]

- Shamsabadi, M.K.; Behpour, M. Fabricated CuO–ZnO/nanozeolite X heterostructure with enhanced photocatalytic performance: Mechanism investigation and degradation pathway. Mater. Sci. Eng. B 2021, 269, 115170. [Google Scholar] [CrossRef]

- Kerkez, Đ.; Tomašević Pilipović, D.; Kozma, G.; Bečelić-Tomin, M.; Prica, M.; Rončević, S.; Kukovecz, A.; Dalmacija, B.; Konya, Z. Three different clay-supported nanoscale zero-valen iron materials for industrial azo dye degradation: A comparative study. J. Taiwan. Inst. Chem. Eng. 2014, 45, 2451–2461. [Google Scholar] [CrossRef]

- Mady, A.H.; Baynosa, M.L.; Tuma, D.; Shim, J.J. Heterogeneous activation of peroxymonosulfate by a novel magnetic 3D γ-MnO2@ZnFe2O4/rGO nanohybrid as a robust catalyst for phenol degradation. Appl. Catal. B-Environ. 2019, 244, 946–956. [Google Scholar] [CrossRef]

- Tu, Y.; Shao, G.; Zhang, W.; Chen, J.; Qu, J.; Zhang, F.; Tian, S.; Zhou, Z.; Ren, Z. The degradation of printing and dyeing wastewater by manganese-based catalysts. Sci. Total Environ. 2022, 828, 154390. [Google Scholar] [CrossRef]

- Alijani, H.; Abdouss, M.; Khataei, H. Efficient photocatalytic degradation of toxic dyes over BiFeO3/CdS/rGO nanocomposite under visible light irradiation. Diam. Relat. Mater. 2022, 122, 108817. [Google Scholar] [CrossRef]

- Aghaei, M.; Sajjadi, S.; Keihan, A.H. Sono-coprecipitation synthesis of ZnO/CuO nanophotocatalyst for removal of parathion from wastewater. Environ. Sci. Pollut. 2020, 27, 11541. [Google Scholar] [CrossRef]

- Kecić, V. Investigation of Fenton-process application in the treatment of dye wastewater in printing industry. Ph.D. Thesis, Faculty of Sciences, University of Novi Sad, Novi Sad, Serbia, 2019. [Google Scholar]

- Chen, Y.W.; Hsu, Y.H. Effects of Reaction Temperature on the Photocatalytic Activity of TiO2 with Pd and Cu Cocatalysts. Catalysts 2021, 11, 966. [Google Scholar] [CrossRef]

- Yamamoto, A.; Mizuno, Y.; Teramura, K.; Shishido, T.; Tanaka, T. Effects of reaction temperature on the photocatalytic activity of photo-SCR of NO with NH3 over a TiO2 photocatalyst. Catal. Sci. Technol. 2013, 3, 1771–1775. [Google Scholar] [CrossRef]

- Molins, F.; Küpper, K.; Schweers, E. Water quality—Determination of total organic carbon content. Chem. Photo. Chem. 2021, 5, 381–389. [Google Scholar]

- Water Quality—Guidelines for the Determination of Total Organic Carbon (TOC) and Dissolved Organic Carbon (DOC) (2007) SRPS ISO 8245:2007, Adopted by the Institute for Standardization of Serbia by Decision No. 3026/12-52-01/2007 of 19 April 2007, Identical to the International Standard ISO 8245:1999. Available online: https://iss.rs/en/project/show/iss:proj:17618 (accessed on 13 July 2022).

- Haddad, M.; Regti, A.; Laamri, M.R.; Mamouni, R.; Sffaj, N. Use of Fenton reagent as advanced oxidative process for removing textile dyes from aqueous solutions. J. Mater. Environ. Sci. 2014, 5, 667–674. [Google Scholar]

- Carvalho, N.S.; Carvalho, M. Dye degradation by green heterogeneous Fenton catalysts prepared in presence of Camellia sinensis. J. Environ. Manage. 2017, 187, 82–88. [Google Scholar] [CrossRef]

- Kecić, V.; Kerkez, Đ.; Prica, M.; Rapajić, S.; Leovac Maćerak, A.; Bečelić-Tomin, M.; Tomašević Pilipović, D. Optimization of Cyan flexo dye removal by nano zero-valent iron using response surface methodology. J. Graph. Eng. Des. 2017, 8, 35–45. [Google Scholar] [CrossRef]

- Bakole, P.; Adekunle, A.; Govindwar, S. Enhanced decolorization and biodegradation of acid red 88 dye by newly isolated fungus, Achaetomiumstrumarium. J. Environ. Chem. Eng. 2018, 6, 1589–1600. [Google Scholar] [CrossRef]

- Kerkez, Đ.; Bečelić-Tomin, M.; Tomašević Pilipović, D.; Prica, M.; Kulić, A.; Dalmacija, B.; Watson, M. Usage of green synthesized nZVI for degradation of three different dye molecules. In Proceedings of the 15th International Conference of Environmental Science and Technology, Global Network for Environmental Science and Technology (Global-Nest), University of Aegean, Rhodes, Greece, 31 August–2 September 2017. [Google Scholar]

| Parameters | Fe3O4 | TiO2 | TiO2–Fe3O4 |

|---|---|---|---|

| Specific surface area (m2/g) | 39.1 | 52.1 | 55.2 |

| Total pore volume (cm3/g) | 0.139 | 0.922 | 0.420 |

| Mesopore volume(cm3/g) | 0.138 | 0.921 | 0.423 |

| Micropore volume (cm3/g) | 0.0149 | 0.0212 | 0.0224 |

| Pore size (nm) | 7.34 | 35.1 | 17.1 |

| Wavenumber (cm−1) | Functional Group | Reference |

|---|---|---|

| 3424 | –OH stretching vibration | [4,43,44] |

| 1635 | –O–H bending vibration | |

| 1383 | Ti–O–Ti bridging stretching modes | [10] |

| 694 | –Fe–O stretching vibration | [45] |

| 639 | ||

| 560 | ||

| 650 | Ti–O stretching | [10] |

| No. | Dye (mg/L) | pH | Catalysts (g/L) | Efficiency (%) |

|---|---|---|---|---|

| 1 | 100 | 10 | 1 | 57.4 |

| 2 | 100 | 3 | 0.2 | 83.8 |

| 3 | 180 | 6.5 | 0.2 | 30.2 |

| 4 | 20 | 6.5 | 1 | 89.3 |

| 5 | 180 | 3 | 0.6 | 90.3 |

| 6 | 20 | 10 | 0.6 | 61.4 |

| 7 | 180 | 10 | 0.2 | 49.1 |

| 8 | 20 | 3 | 1 | 92.4 |

| 9 | 180 | 10 | 1 | 75.6 |

| 10 | 20 | 3 | 0.2 | 84.3 |

| 11 | 180 | 3 | 1 | 93.04 |

| 12 | 20 | 10 | 0.2 | 51.7 |

| 13 | 100 | 6.5 | 0.6 | 87.7 |

| 14 | 100 | 10 | 1 | 55.4 |

| 15 | 100 | 3 | 0.2 | 81.5 |

| 16 | 180 | 6.5 | 0.2 | 35.1 |

| 17 | 20 | 6.5 | 1 | 88.1 |

| 18 | 180 | 3 | 0.6 | 89.5 |

| 19 | 20 | 10 | 0.6 | 60.1 |

| 20 | 180 | 10 | 0.2 | 47.1 |

| 21 | 20 | 3 | 1 | 95.6 |

| 22 | 180 | 10 | 1 | 72.8 |

| 23 | 20 | 3 | 0.2 | 86.7 |

| 24 | 180 | 3 | 1 | 89.7 |

| 25 | 20 | 10 | 0.2 | 50.6 |

| 26 | 100 | 6.5 | 0.6 | 86.2 |

| 27 | 100 | 6.5 | 0.6 | 88.1 |

| 28 | 100 | 6.5 | 0.6 | 87.9 |

| Descriptive Factor | Value |

|---|---|

| R2 | 0.862 |

| R2 adj | 0.814 |

| AIC | 217.337 |

| BIC | 219.327 |

| RMSE | 8.417 |

| Source | DF a | SS b | MS c | F Parametar |

|---|---|---|---|---|

| Model | 8 | 21,955.430 | 2744.430 | 55.106 |

| Error | 19 | 946.260 | 49.800 | Prob > F |

| C. Total | 27 | 22,901.690 | - | <0.0001 |

| Lack of Fit | 5 | 1376.198 | 275.240 | 100,980 |

| Pure Error | 15 | 40.885 | 2.726 | Prob > F |

| Total Error | 20 | 1417.083 | - | 0.083 |

| Parameter | Estimated Value | Standard Error | t Value | Probability > |t| |

|---|---|---|---|---|

| pH | −15.282 | 1.88221 | −8.12 | <0.0001 |

| Catalyst (g/L) | 10.462 | 1.88221 | 5.56 | <0.0001 |

| Dye (mg/L) and pH | 7.3480 | 2.59358 | 2.83 | 0.0103 |

| Dye (mg/L) and Catalyst (g/L) | 7.1477 | 2.33902 | 3.06 | 0.0062 |

| Dye (mg/L) | −4.388 | 1.88221 | −2.33 | 0.0303 |

| pH and Catalyst (g/L) | −1.8577 | 2.33902 | −0.79 | 0.4364 |

| Variable | Unit | Encoded Value | Level | ||

|---|---|---|---|---|---|

| −1 | 0 | +1 | |||

| Dye concentration | mg/L | x1 | 20 | 100 | 180 |

| pH | x3 | 3 | 6.5 | 10 | |

| Catalyst concentration | g/L | x2 | 0.2 | 0.6 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pucar Milidrag, G.; Nikić, J.; Gvoić, V.; Kulić Mandić, A.; Agbaba, J.; Bečelić-Tomin, M.; Kerkez, D. Photocatalytic Degradation of Magenta Effluent Using Magnetite Doped TiO2 in Solar Parabolic Trough Concentrator. Catalysts 2022, 12, 986. https://doi.org/10.3390/catal12090986

Pucar Milidrag G, Nikić J, Gvoić V, Kulić Mandić A, Agbaba J, Bečelić-Tomin M, Kerkez D. Photocatalytic Degradation of Magenta Effluent Using Magnetite Doped TiO2 in Solar Parabolic Trough Concentrator. Catalysts. 2022; 12(9):986. https://doi.org/10.3390/catal12090986

Chicago/Turabian StylePucar Milidrag, Gordana, Jasmina Nikić, Vesna Gvoić, Aleksandra Kulić Mandić, Jasmina Agbaba, Milena Bečelić-Tomin, and Djurdja Kerkez. 2022. "Photocatalytic Degradation of Magenta Effluent Using Magnetite Doped TiO2 in Solar Parabolic Trough Concentrator" Catalysts 12, no. 9: 986. https://doi.org/10.3390/catal12090986

APA StylePucar Milidrag, G., Nikić, J., Gvoić, V., Kulić Mandić, A., Agbaba, J., Bečelić-Tomin, M., & Kerkez, D. (2022). Photocatalytic Degradation of Magenta Effluent Using Magnetite Doped TiO2 in Solar Parabolic Trough Concentrator. Catalysts, 12(9), 986. https://doi.org/10.3390/catal12090986