Recent Progress in Chitosan-Containing Composite Materials for Sustainable Approaches to Adsorption and Catalysis

Abstract

:1. Introduction

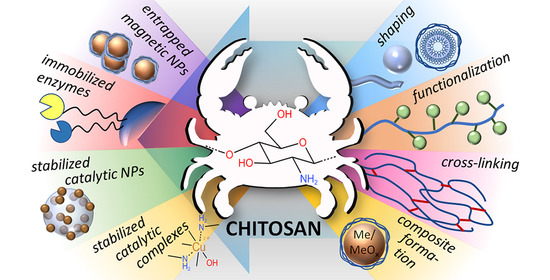

2. Chitosan Modifications

2.1. Grafting of Functional Groups

2.2. Gelation

- (i)

- Interactions between polysaccharide chains must be strong enough to form a molecular network;

- (ii)

- The network must be permeable to water molecules.

- −

- Reactions of polymer–analogous transformations [63];

- −

- −

- Preparation of mixtures with natural/synthetic polymers.

2.3. Formation of Nanoparticles

- (i)

- Physicochemical, in which NPs are formed by emulsification following solvent evaporation, solvent displacement, diffusion or saltingout [70];

- (ii)

- The in situ chemical synthesis of macromolecules, resulting in polymerization or interphase polycondensation;

- (iii)

- Mechanical processes using high-energy devices, such as high-pressure homogenizers, ultrasonic devices or high-energy wet grinding.

- (i)

- Ionotropic gelation:

- (ii)

- Complexation with PEs:

- (iii)

- Drying:

- (iv)

- Emulsification:

- (v)

- Self-assembly:

3. Chitosan-Containing Materials and Composites as Adsorbents

3.1. Structured Chitosan Materials

3.2. Chitosan-Based Organic/Inorganic Composite Adsorbents

3.3. Magnetically Separable Chitosan Composites

- (i)

- Based on calculation of the adsorption recovery index using the values of Q and recovery time (t) needed for achieving 98% material recovery, a higher adsorption recovery indexvalue shows bettermagnetic material performance;

- (ii)

- Based on effort vector data visualization, in which the position of a magnetic material is shown on a coordinate depicted using normalized Q and saturation magnetization value, the distance from the data point to the target indicates the performance of the material.

- (i)

- ZnFe2O4 (ZF) NPs were synthesized usingthe chemical coprecipitation method;

- (ii)

- rGO nanosheets were synthesized by using a modified Hummer’s method with natural graphite;

- (iii)

- Magnetic rGO–ZF@CB was synthesized by using a crosslinking reaction with GA (2.5%). Before magnetic bead preparation, rGO nanosheets and ZF NPs were added into the ethanol solution. A suspension of rGO and ZF NPs was mixed with CS solution in acetic acid. Then, this reaction mixture (rGO-ZF@CS) was dripped into 1 M NaOH solution using a syringe needle. The resulting wet magnetic beads, washed with water until reaching neutral pH, were treated with GA, which allowed magnetic rGO–ZF@CB to be obtained.

4. Chitosan as Catalytic Support

4.1. Catalytic Metal–Chitosan Composites

- (i)

- The ability of CS to effectively adsorb both organic and inorganic compounds can be used for the development of catalytic systems, in which the inorganic part, entrapped by CS, is in catalytically active phase while organic adsorbate is the subject of catalytic transformation;

- (ii)

- In spite of vast experience in the field of absorbent development, researchers working in catalysis seem to rarely use all the accessible achievements. For example, crosslinking agents are typically not used, as well as certain shaping at macro-level of the resulting catalytic material that could be useful in continuously operating reactors. Adsorption of metal cations was found to proceed more effectively while using CS grafted with different functional groups (see Section 3); hence, it is surprising that in many reported studies devoted to the use of metal ions as catalysts, native CS without any modifications was applied. Thus, there is room for further improvement;

- (iii)

- Magnetically separable catalysts obviously have the advantage of easy separation from the reaction mixture, but these catalysts have a limitation—sensitivity to low pH, since CS itself cannot prevent the dissolution of magnetic NPs. Thus, CS crosslinking and coating of magnetic NPs with a protective shell (carbonaceous or oxide), resistant to low pH, is a promising approach.

4.2. Chitosan-Containing Composite Biocatalysts

- (i)

- The PMA-co-PAA membrane was obtained using the electrospinning method;

- (ii)

- Carboxyl groups of PMA-co-PAA were activated with EDAC/NHS;

- (iii)

- The activated membrane was immersed in CS solution in 0.2 M acetic acid.

- (i)

- There are four main approaches to thepreparation of CS-based supports for the immobilization of enzymes: CS beads optionally crosslinked with different agents; CS capsules typically formed by ionotropic gelation with SA; core–shell NPs consisting of an inorganic core (usually magnetic) covered with CS; membranes;

- (ii)

- Enzymes can be immobilized usingthe following general approaches: encapsulation into CS-containing gel; covalent binding to the surface of a CS-based support; physical adsorption on the support surface. Among the mentioned approaches, covalent binding seems to be more promising for the development of sustainable biocatalysts, allowing high reusability and storage stability. Though, at the same, it should be noted that catalytic behavior strongly depends on the used substrate and the choice of solvent that makes data comparison difficult;

- (iii)

- In contrast to adsorbents, crosslinking of CS is rarely applied (typically in the case of CS beads), though it can benefit the properties of the resulting biocatalytic system. Among crosslinking agents, TPP and GP are prospective since they have low toxicity compared to GA. However, GA is still the most widespread activating agent for the covalent binding of enzymes;

- (iv)

- Metal ions, while presented in catalyst composition, can increase the pHstability of the biocatalyst and, in some cases, result in enzyme hyperactivation. Magnetic NPs incorporated in a polymeric environment do not always have an obvious positive impact on catalyst stability; however, they allow for an important advantage—the simplicity of biocatalyst separation from the reaction mixture.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

References

- Aranaz, I.; Alcántara, A.R.; Civera, M.C.; Arias, C.; Elorza, B.; Heras Caballero, A.; Acosta, N. Chitosan: An Overview of Its Properties and Applications. Polymers 2021, 13, 3256. [Google Scholar] [CrossRef] [PubMed]

- Boominathan, T.; Sivaramakrishna, A. Recent Advances in the Synthesis, Properties, and Applications of Modified Chitosan Derivatives: Challenges and Opportunities. Top. Curr. Chem. 2021, 379, 19. [Google Scholar] [CrossRef] [PubMed]

- Crini, G. Historical Review on Chitin and Chitosan Biopolymers. Environ. Chem. Lett. 2019, 17, 1623–1643. [Google Scholar] [CrossRef]

- Sivashankari, P.R.; Prabaharan, M. 5-Deacetylation Modification Techniques of Chitin and Chitosan. In Chitosan Based Biomaterials; Jennings, J.A., Bumgardner, J.D., Eds.; Woodhead Publishing: Sawston, UK, 2017; Volume 1, pp. 117–133. [Google Scholar] [CrossRef]

- Di Nardo, T.; Hadad, C.; Nguyen Van Nhien, A.; Moores, A. Synthesis of High Molecular Weight Chitosan from Chitin by Mechanochemistry and Aging. Green Chem. 2019, 21, 3276–3285. [Google Scholar] [CrossRef]

- Pillai, C.K.S.; Paul, W.; Sharma, C.P. Chitin and Chitosan Polymers: Chemistry, Solubility and Fiber Formation. Prog. Polym. Sci. 2009, 34, 641–678. [Google Scholar] [CrossRef]

- Pérez-Álvarez, L.; Ruiz-Rubio, L.; Vilas-Vilela, J.L. Determining the Deacetylation Degree of Chitosan: Opportunities to Learn Instrumental Techniques. J. Chem. Educ. 2018, 95, 1022–1028. [Google Scholar] [CrossRef]

- Yeul, P.; Shrivastava, S. Chitosan: An Overview. Int. J. Curr. Res. 2012, 4, 176–182. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, F.; Li, C.; An, H.; Wan, T.; Zhang, P. Application of Chitosan and Its Derivative Polymers in Clinical Medicine and Agriculture. Polymers 2022, 14, 958. [Google Scholar] [CrossRef]

- Chitosan Market Size, Share & Trends Analysis Report by Application (Pharmaceutical & Biomedical, Water Treatment, Cosmetics, Food & Beverage), by Region (APAC, North America, Europe, MEA), and Segment Forecasts, 2020–2027; Report ID: 978-1-68038-798-8; Grand View Research: San Francisco, CA, USA, 2020; Available online: https://www.grandviewresearch.com/industry-analysis/global-chitosan-market (accessed on 1 February 2023).

- Kumar, N.; Joshi, N.C. Adsorption Applications of Synthetically Prepared PANI-CuO Based Nanocomposite Material. J. Ind. Chem. Soc. 2022, 99, 100551. [Google Scholar] [CrossRef]

- Toumi, I.; Djelad, H.; Chouli, F.; Benyoucef, A. Synthesis of PANI@ZnO Hybrid Material and Evaluations in Adsorption of Congo Red and Methylene Blue Dyes: Structural Characterization and Adsorption Performance. J. Inorg. Organomet. Polym. 2022, 32, 112–121. [Google Scholar] [CrossRef]

- El-Shazly, A.H.; Elkady, M.; Abdelraheem, A. Investigating the Adsorption Behavior of Polyaniline and Its Clay Nanocomposite towards Ammonia Gas. Polymers 2022, 14, 4533. [Google Scholar] [CrossRef]

- Hajjaoui, H.; Soufi, A.; Boumya, W.; Abdennouri, M.; Barka, N. Polyaniline/Nanomaterial Composites for the Removal of Heavy Metals by Adsorption: A Review. J. Compos. Sci. 2021, 5, 233. [Google Scholar] [CrossRef]

- Peñas-Sanjuán, A.; López-Garzón, R.; López-Garzón, J.; Pérez-Mendoza, M.; Melguizo, M. Preparation of a Poly-alkylamine Surface-functionalized Carbon with Excellent Performance as a Pd(II) Scavenger. Carbon 2012, 50, 2350–2352. [Google Scholar] [CrossRef]

- Choi, W.; Min, K.; Kim, C.; Ko, Y.S.; Jeon, J.W.; Seo, H.; Park, Y.-K.; Choi, M. Epoxide-functionalization of Polyethyleneimine for Synthesis of Stable Carbon Dioxide Adsorbent in Temperature Swing Adsorption. Nat. Commun. 2016, 7, 12640. [Google Scholar] [CrossRef]

- Huang, X.; Wang, L.; Zhang, J.; Du, X.; Wu, S.; Wang, H.; Wei, X. A Novel ε-Polylysine-modified Microcrystalline Cellulose Based Antibacterial Hydrogel for Removal of Heavy Metal. Int. J. Biol. Macromol. 2020, 163, 1915–1925. [Google Scholar] [CrossRef] [PubMed]

- Rivas, B.L.; Maureira, A.; Guzmán, C. Poly(L-lysine) as a Polychelatogen to Remove Toxic Metals Using Ultrafiltration and Bactericide Properties of Poly(L-lysine)–Cu2+ Complexes. Polym. Bull. 2011, 67, 763–774. [Google Scholar] [CrossRef]

- Xue, W.; Liu, B.; Zhang, H.; Ryu, S.; Kuss, M.; Shukla, D.; Hu, G.; Shi, W.; Jiang, X.; Lei, Y.; et al. Controllable Fabrication of Alginate/poly-L-ornithine Polyelectrolyte Complex Hydrogel Networks as Therapeutic Drug and Cell Carriers. Acta Biomater. 2022, 138, 182–192. [Google Scholar] [CrossRef] [PubMed]

- Kaczmarek, M.B.; Struszczyk-Swita, K.; Li, X.; Szczęsna-Antczak, M.; Daroch, M. Enzymatic Modifications of Chitin, Chitosan, and Chito oligosaccharides. Front. Bioeng. Biotechnol. 2019, 7, 243. [Google Scholar] [CrossRef] [PubMed]

- Huang, K.-S.; Sheu, Y.-R.; Chao, I.-C. Preparation and Properties of Nanochitosan. Polym. Plast. Technol. Eng. 2009, 48, 1239–1243. [Google Scholar] [CrossRef]

- Ma, F.; Wang, Z.; Zhao, H.; Tian, S. Plasma Depolymerization of Chitosan in the Presence of Hydrogen Peroxide. Int. J. Mol. Sci. 2012, 13, 7788–7797. [Google Scholar] [CrossRef]

- Prasertsung, I.; Damrongsakkul, S.; Saito, N. Degradation of β-Chitosan by Solution Plasma Process (SPP). Polym. Degrad. Stab. 2013, 98, 2089–2093. [Google Scholar] [CrossRef]

- Li, J.; Cai, J.; Fan, L. Effect of Sonolysis on Kinetics and Physicochemical Properties of Treated Chitosan. J. Appl. Polym. Sci. 2008, 109, 2417–2425. [Google Scholar] [CrossRef]

- Tsao, C.T.; Chang, C.H.; Lin, Y.Y.; Wu, M.F.; Han, J.L.; Hsieh, K.H. Kinetic Study of Acid Depolymerization of Chitosan and Effects of Low Molecular Weight Chitosan on Erythrocyte Rouleaux Formation. Carbohydr. Res. 2011, 346, 94–102. [Google Scholar] [CrossRef] [PubMed]

- Pierre, G.; Salah, R.; Gardarin, C.; Traikia, M.; Petit, E.; Delort, A.-M.; Mameri, N.; Moulti-Mati, F.; Michaud, P. Enzymatic Degradation and Bioactivity Evaluation of C-6 Oxidized Chitosan. Int. J. Biol. Macromol. 2013, 60, 383–392. [Google Scholar] [CrossRef] [PubMed]

- Thadathil, N.; Velappan, S.P. Recent Developments in Chitosanase Research and Its Biotechnological Applications: A Review. Food Chem. 2014, 150, 392–399. [Google Scholar] [CrossRef] [PubMed]

- Kumar, M.N.V.R.; Muzzarelli, R.A.A.; Muzzarelli, C.; Sashiwa, H.; Domb, A.J. Chitosan Chemistry and Pharmaceutical Perspectives. Chem. Rev. 2004, 104, 6017–6084. [Google Scholar] [CrossRef]

- Berth, G.; Dautzenberg, H. The Degree of Acetylation of Chitosans and Its Effect on the Chain Conformation in Aqueous Solution. Carbohydr. Polym. 2002, 47, 39–51. [Google Scholar] [CrossRef]

- Balan, V.; Verestiuc, L. Strategies to Improve Chitosan Hemocompatibility: A Review. Eur. Polym. J. 2014, 53, 171–188. [Google Scholar] [CrossRef]

- Kahya, N. Water Soluble Chitosan Derivatives and Their Biological Activities: A Review. Polym. Sci. 2019, 5, 1–11. [Google Scholar] [CrossRef]

- Ayati, A.; Heravi, M.M.; Daraie, M.; Tanhaei, B.; Bamoharram, F.F.; Sillanpaa, M. H3PMo12O40 Immobilized Chitosan/Fe3O4 as a Novel Efficient, Green and Recyclable Nanocatalyst in the Synthesis of Pyrano-pyrazole Derivatives. J. Iran Chem. Soc. 2016, 13, 2301–2308. [Google Scholar] [CrossRef]

- Kong, A.; Wang, P.; Zhang, H.; Yang, F.; Huang, S.P.; Shan, Y. One-pot fabrication of magnetically recoverable acid nanocatalyst, heteropolyacids/chitosan/Fe3O4, and its catalytic performance. Appl. Catal. A Gen. 2012, 417–418, 183–189. [Google Scholar] [CrossRef]

- Nurunnabi, M.; Revuri, V.; Huh, K.M.; Lee, Y.-K. Chapter 14—Polysaccharide Based Nano/microformulation: An Effective and Versatile Oral Drug Delivery System. In Nanostructures for Oral Medicine. Micro and Nano Technologies; Andronescu, E., Grumezescu, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 409–433. [Google Scholar] [CrossRef]

- Coquery, C.; Negrell, C.; Caussé, N.; Pébère, N.; David, G. Synthesis of New High Molecular Weight Phosphorylated Chitosans for Improving Corrosion Protection. Pure Appl. Chem. 2019, 91, 509–521. [Google Scholar] [CrossRef]

- Olshannikova, S.S.; Malykhina, N.V.; Lavlinskaya, M.S.; Sorokin, A.V.; Yudin, N.E.; Vyshkvorkina, Y.M.; Lukin, A.N.; Holyavka, M.G.; Artyukhov, V.G. Novel Immobilized Biocatalysts Based on Cysteine Proteases Bound to 2-(4-Acetamido-2-sulfanilamide) Chitosan and Research on Their Structural Features. Polymers 2022, 14, 3223. [Google Scholar] [CrossRef]

- Suresh, R.; Deepa, M.; Sudha, P.N.; Gomathi, T.; Pavithra, S.; Moganavally, P. Synthesis, Characterization, Biological and Catalytic Activity of Carboxymethyl Chitosan Schiff Base Metal Complexes. IJMS 2022, 51, 423–431. [Google Scholar] [CrossRef]

- Rostami, N.; Dekamin, M.G.; Valiey, E.; Fanimoghadam, H. Chitosan-EDTA-Cellulose Network as a Green, Recyclable and Multifunctional Biopolymeric Organocatalyst for the One-pot Synthesis of 2-Amino-4H-pyran Derivatives. Sci. Rep. 2022, 12, 8642. [Google Scholar] [CrossRef] [PubMed]

- Federer, C.; Kurpiers, M.; Bernkop-Schnürch, A. Thiolated Chitosans: A Multi-talented Class of Polymers for Various Applications. Biomacromolecules 2021, 22, 24–56. [Google Scholar] [CrossRef]

- Raghavendra Naveen, N.; Gopinath, C.; Subba Rao, D. A Spotlight on Thiolated natural Polymers and Their Relevance in Mucoadhesive Drug Delivery System. Future J. Pharm. Sci. 2018, 4, 47–52. [Google Scholar] [CrossRef]

- Grosso, R.; de-Paz, M.-V. Thiolated-Polymer-Based Nanoparticles as an Avant-Garde Approach for Anticancer Therapies—Reviewing Thiomers from Chitosan and Hyaluronic Acid. Pharmaceutics 2021, 13, 854. [Google Scholar] [CrossRef]

- Bernkop-Schnürch, A.; Krauland, A.H.; Leitner, V.M.; Palmberger, T. Thiomers: Potential Excipients for Non-Invasive Peptide Delivery Systems. Eur. J. Pharm. Biopharm. 2004, 58, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Schmitz, T.; Grabovac, V.; Palmberger, T.F.; Hoffer, M.H.; Bernkop-Schnürch, A. Synthesis and Characterization of a Chitosan-N-acetyl Cysteine Conjugate. Int. J. Pharm. 2008, 347, 79–85. [Google Scholar] [CrossRef]

- ALSamman, M.T.; Sánchez, J. Recent Advances on Hydrogels Based on Chitosan and Alginate for the Adsorption of Dyes and Metal Ions from Water. Arab. J. Chem. 2021, 14, 103455. [Google Scholar] [CrossRef]

- Dragan, E.S.; Dinu, M.V. Advances in Porous Chitosan Based Composite Hydrogels: Synthesis and Applications. React. Funct. Polym. 2020, 146, 104372. [Google Scholar] [CrossRef]

- Ahmad, Z.; Salman, S.; Khan, S.A.; Amin, A.; Rahman, Z.U.; Al-Ghamdi, Y.O.; Akhtar, K.; Bakhsh, E.M.; Khan, S.B. Versatility of Hydrogels: From Synthetic Strategies, Classification, and Properties to Biomedical Applications. Gels 2022, 8, 167. [Google Scholar] [CrossRef] [PubMed]

- Berger, J.; Reist, M.; Mayer, J.M.; Felt, O.; Gurny, R. Structure and Interactions in Chitosan Hydrogels Formed by Complexation or Aggregation for Biomedical Applications. Eur. J. Pharm. Biopharm. 2004, 57, 35–52. [Google Scholar] [CrossRef]

- Boucard, N.; Viton, C.; Domard, A. New Aspects of the Formation of Physical Hydrogels of Chitosan in a Hydroalcoholic Medium. Biomacromolecules 2005, 6, 3227–3237. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Cid, P.; Jiménez-Rosado, M.; Romero, A.; Pérez-Puyana, V. Novel Trends in Hydrogel Development for Biomedical Applications: A Review. Polymers 2022, 14, 3023. [Google Scholar] [CrossRef]

- Shoueir, K.R.; El-Desouky, N.; Rashad, M.M.; Ahmed, M.K.; Janowska, I.; El-Kemary, M. Chitosan Based-Nanoparticles and Nanocapsules: Overview, Physicochemical Features, Applications of a Nanofibrous Scaffold, and Bioprinting. Int. J. Biol. Macromol. 2021, 167, 1176–1197. [Google Scholar] [CrossRef]

- Nasef, S.M.; Khozemy, E.E.; Kamoun, E.A.; El-Gendi, H. Gamma Radiation-Induced Crosslinked Composite Membranes Based on Polyvinyl Alcohol/chitosan/AgNO3/vitamin E for Biomedical Applications. Int. J. Biol. Macromol. 2019, 137, 878–885. [Google Scholar] [CrossRef] [PubMed]

- Mndlovu, H.; du Toit, L.C.; Kumar, P.; Choonara, Y.E.; Marimuthu, T.; Kondiah, P.P.D.; Pillay, V. Bioplatform Fabrication Approaches Affecting Chitosan-Based Interpolymer Complex Properties and Performance as Wound Dressings. Molecules 2020, 25, 222. [Google Scholar] [CrossRef]

- Chamkouri, H.; Chamkouri, M. A Review of Hydrogels, Their Properties and Applications in Medicine. Am. J. Biomed. Sci. Res. 2021, 11, 485–493. [Google Scholar] [CrossRef]

- Rasool, A.; Rizwan, M.; Islam, A.; Abdullah, H.; Shafqat, S.S.; Azeem, M.K.; Rasheed, T.; Bilal, M. Chitosan-Based Smart Polymeric Hydrogels and Their Prospective Applications in Biomedicine. Starch 2021, 2100150. [Google Scholar] [CrossRef]

- Bashir, S.; Teo, Y.Y.; Ramesh, S.; Ramesh, K.; Rizwan, M. Synthesis and Characterization of pH-Sensitive N-Succinyl Chitosan Hydrogel and Its Properties for Biomedical Applications. J. Chil. Chem. Soc. 2019, 64, 4571–4574. [Google Scholar] [CrossRef]

- Ghauri, Z.H.; Islam, A.; Qadir, M.A.; Gull, N.; Haider, B.; Khan, R.U.; Riaz, T. Development and Evaluation of pH-Sensitive Biodegradable Ternary Blended Hydrogel Films (chitosan/guar gum/PVP) for Drug Delivery Application. Sci. Rep. 2021, 11, 21255. [Google Scholar] [CrossRef] [PubMed]

- Lei, M.; Huang, W.; Sun, J.; Shao, Z.; Zhao, L.; Zheng, K.; Fang, Y. Synthesis and Characterization of Thermo-Responsive Polymer Based on Carboxymethyl Chitosan and Its Potential Application in Water-based Drilling Fluid. Colloids Surf. A Physicochem. Eng. Asp. 2021, 629, 127478. [Google Scholar] [CrossRef]

- Sarwan, T.; Kumar, P.; Choonara, Y.E.; Pillay, V. Hybrid Thermo-Responsive Polymer Systems and Their Biomedical Applications. Front. Mater. 2020, 7, 73. [Google Scholar] [CrossRef]

- Ahsan, A.; Farooq, M.A.; Parveen, A. Thermosensitive Chitosan-Based Injectable Hydrogel as an Efficient Anticancer Drug Carrier. ACS Omega 2020, 5, 20450–20460. [Google Scholar] [CrossRef] [PubMed]

- Shin, B.; Kim, J.; Vales, T.P.; Yang, S.K.; Kim, J.-K.; Sohn, H.; Kim, H.-J. Thermoresponsive Drug Controlled Release from Chitosan-Based Hydrogel Embedded with Poly(N-isopropylacrylamide) Nanogels. J. Polym. Sci. Part A Polym. Chem. 2018, 56, 1907–1914. [Google Scholar] [CrossRef]

- Dash, M.; Chiellini, F.; Ottenbrite, R.M.; Chiellini, E. Chitosan—A versatile semi-synthetic polymer in biomedical applications. Prog. Polym. Sci. 2011, 36, 981–1014. [Google Scholar] [CrossRef]

- Ranjha, N.M.; Khan, S. Chitosan/Poly (vinyl alcohol) Based Hydrogels for Biomedical Applications: A Review. J. Pharm. Altern. Med. 2013, 2, 30–41. Available online: https://iiste.org/Journals/index.php/JPAM/article/view/4379 (accessed on 1 February 2023).

- Babicheva, T.S.; Konduktorova, A.A.; Shmakov, S.L.; Shipovskaya, A.B. Formation of Liesegang Structures under the Conditions of the Spatiotemporal Reaction of Polymer-Analogous Transformation (Salt→Base) of Chitosan. J. Phys. Chem. B 2020, 124, 9255–9266. [Google Scholar] [CrossRef]

- Zohuriaan-Mehr, M.J. Advances in Chitin and Chitosan Modification through Graft Copolymerization: A Comprehensive Review. Iran. Polym. J. 2005, 14, 235–265. [Google Scholar]

- Jenkins, D.W.; Hudson, S.M. Review of Vinyl Graft Copolymerization Featuring Recent Advances toward Controlled Radical Based Reactions and Illustrated with Chitin/Chitosan Trunk Polymers. Chem. Rev. 2001, 101, 3245–3274. [Google Scholar] [CrossRef] [PubMed]

- Zakharova, N.V.; Simonova, M.A.; Zelinskii, S.N.; Annenkov, V.V.; Filippov, A.P. Synthesis, Molecular Characteristics, and Stimulus-Sensitivity of Graft Copolymer of Chitosan and Poly (N, N-diethylacrylamide). J. Mol. Liq. 2019, 292, 111355. [Google Scholar] [CrossRef]

- Erdodi, G.; Kennedy, J.P. Amphiphilic Conetworks: Definition, Synthesis, Applications. Prog. Polym. Sci. 2006, 31, 1–18. [Google Scholar] [CrossRef]

- Naskar, S.; Sharma, S.; Kuotsu, K. Chitosan-Based Nanoparticles: An Overview of Biomedical Applications and Its Preparation. J. Drug Deliv. Sci. Technol. 2019, 49, 66–81. [Google Scholar] [CrossRef]

- Ohya, Y.; Shiratani, M.; Kobayashi, H.; Ouchi, T. Release Behavior of 5-Fluorouracil from Chitosan-Gel Nanospheres Immobilizing 5-Fluorouracil Coated with Polysaccharides and Their Cell Specific Cytotoxicity. J. Macromol. Sci. Pure Appl. Chem. 1994, 31, 629–642. [Google Scholar] [CrossRef]

- Grabnar, P.A.; Kristl, J. The Manufacturing Techniques of Drug-Loaded Polymeric Nanoparticles from Preformed Polymers. J. Microencapsul. 2011, 28, 323–335. [Google Scholar] [CrossRef]

- Patiño-Ruiz, D.; Marrugo, L.; Reyes, N.; Acevedo-Morantes, M.; Herrera, A. Ionotropic Gelation Synthesis of Chitosan-Alginate Nanodisks for Delivery System and In Vitro Assessment of Prostate Cancer Cytotoxicity. Int. J. Polym. Sci. 2020, 2020, 5329747. [Google Scholar] [CrossRef]

- de Carvalho, F.G.; Magalhães, T.C.; Teixeira, N.M.; Gondim, B.L.C.; Carlo, H.L.; Dos Santos, R.L.; de Oliveira, A.R.; Denadai, Â.M.L. Synthesis and Characterization of TPP/Chitosan Nanoparticles: Colloidal Mechanism of Reaction and Antifungal Effect on C. albicans Biofilm Formation. Mater. Sci. Eng. C 2019, 104, 109885. [Google Scholar] [CrossRef]

- Nemati, Y.; Zahedi, P.; Baghdadi, M.; Ramezani, S. Microfluidics Combined with Ionic Gelation Method for Production of Nanoparticles Based on Thiol-Functionalized Chitosan to Adsorb Hg (II) from Aqueous Solutions. J. Environ. Manage. 2019, 238, 166–177. [Google Scholar] [CrossRef]

- Pati, F.; Adhikari, B.; Dhara, S. Development of Chitosan-Tripolyphosphate Fibers through pH Dependent Ionotropic Gelation. Carbohydr. Res. 2011, 346, 2582–2588. [Google Scholar] [CrossRef] [PubMed]

- Divya, K.; Jisha, M.S. Chitosan Nanoparticles Preparation and Applications. Environ. Chem. Lett. 2018, 16, 101–112. [Google Scholar] [CrossRef]

- Pessoa, A.C.S.N.; Sipoli, C.C.; de la Torre, L.G. Effects of Diffusion and Mixing Pattern on Microfluidic-Assisted Synthesis of Chitosan/ATP Nanoparticles. Lab. Chip. 2017, 17, 2281–2293. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Shi, J.; Li, Z.; Zhang, S.; Wu, H.; Jiang, Z.; Yang, C.; Tian, C. Facile One-Pot Preparation of Chitosan/Calcium Pyrophosphate Hybrid Microflowers. ACS Appl. Mater. Interfaces 2014, 6, 14522–14532. [Google Scholar] [CrossRef] [PubMed]

- Komoto, D.; Furuike, T.; Tamura, H. Preparation of Polyelectrolyte Complex Gel of Sodium Alginate with Chitosan Using Basic Solution of Chitosan. Int. J. Biol. Macromol. 2019, 126, 54–59. [Google Scholar] [CrossRef] [PubMed]

- Boudoukhani, M.; Yahoum, M.M.; Lefnaoui, S.; Moulai-Mostefa, N.; Banhobre, M. Synthesis, Characterization and Evaluation of Deacetylated Xanthan Derivatives as New Excipients in the Formulation of Chitosan-Based Polyelectrolytes for the Sustained Release of Tramadol. Saudi Pharm. J. 2019, 27, 1127–1137. [Google Scholar] [CrossRef]

- Livanovich, K.; Shutava, T. Influence of Chitosan/Dextran Sulfate Layer-by-Layer Shell on Colloidal Properties of Silver Nanoparticles. Int. J. Nanosci. 2019, 18, 1940077. [Google Scholar] [CrossRef]

- Karim, H.M.; Melike, D.G.; Seda, T.S.; Neslihan, G.R.; Emirhan, N.; Kezban, U.; Levent, Ö.; Hakan, E. Atorvastatin-Loaded Nanosprayed Chitosan Nanoparticles for Peripheral Nerve Injury. Bioinspired Biomim. Nanobiomater. 2020, 9, 74–84. [Google Scholar] [CrossRef]

- Ahmed, T.A.; Aljaeid, B.M. Preparation, Characterization, and Potential Application of Chitosan, Chitosan Derivatives, and Chitosan Metal Nanoparticles in Pharmaceutical Drug Delivery. Drug Des. Devel. Ther. 2016, 28, 483–507. [Google Scholar] [CrossRef]

- Lucas, J.; Ralaivao, M.; Estevinho, B.N.; Rocha, F. A New Approach for the Microencapsulation of Curcumin by a Spray Drying Method, in Order to Value Food Products. Powder Technol. 2020, 362, 428–435. [Google Scholar] [CrossRef]

- Crua, C.; Li, C.; Vogiatzaki, K. Effect of the Scale Resolution on the Two Phase Coupling Characteristics of High Speed Evaporating Sprays Using LES/Eulerian-Lagrangian Methodologies. Int. J. Multiph. Flow 2019, 120, 103060. [Google Scholar] [CrossRef]

- Luesakul, U.; Puthong, S.; Sansanaphongpricha, K.; Muangsin, N. Quaternized Chitosan-Coated Nanoemulsions: A Novel Platform for Improving the Stability, Anti-Inflammatory, Anti-Cancer and Transdermal Properties of Plai Extract. Carbohydr. Polym. 2020, 230, 115625. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, S.; Kumar, S.; Kumar, V.; Sharma, R. Chitosan Nanoemulsions as Advanced Edible Coatings for Fruits and Vegetables: Composition, Fabrication and Developments in Last Decade. Int. J. Biol. Macromol. 2020, 152, 154–170. [Google Scholar] [CrossRef] [PubMed]

- Yu, A.; Shi, H.; Liu, H.; Bao, Z.; Dai, M.; Lin, D.; Lin, D.; Xu, X.; Li, X.; Wang, Y. Mucoadhesive Dexamethasone-Glycol Chitosan Nanoparticles for Ophthalmic Drug Delivery. Int. J. Pharm. 2020, 575, 118943. [Google Scholar] [CrossRef]

- Liu, L.; Yang, H.; Lou, Y.; Wu, J.-Y.; Miao, J.; Lu, X.-Y.; Gao, J.-Q. Enhancement of Oral Bioavailability of Salmon Calcitonin through Chitosan-Modified, Dual Drug-Loaded Nanoparticles. Int. J. Pharm. 2019, 557, 170–177. [Google Scholar] [CrossRef]

- Zhang, H.; Li, X.; Kang, H. Chitosan Coatings Incorporated with Free or Nano-Encapsulated Paulownia Tomentosa Essential Oil to Improve shelf-Life of Ready-to-Cook Pork Chops. LWT 2019, 116, 108580. [Google Scholar] [CrossRef]

- Xu, T.; Ma, Y.; Huang, J.; Lai, H.; Yuan, D.; Tang, X.; Yang, L. Self-Organized Thermo-Responsive Poly (lactic-co-glycolic acid)-graft-pullulan Nanoparticles for Synergistic Thermo-Chemotherapy of Tumor. Carbohydr. Polym. 2020, 237, 116104. [Google Scholar] [CrossRef]

- Quiñones, J.P.; Peniche, H.; Peniche, C. Chitosan Based Self-Assembled Nanoparticles in Drug Delivery. Polymers 2018, 10, 235. [Google Scholar] [CrossRef]

- Khan, M.M.; Madni, A.; Torchilin, V.; Filipczak, N.; Pan, J.; Tahir, N.; Shah, H. Lipid-Chitosan Hybrid Nanoparticles for Controlled Delivery of Cisplatin. Drug Deliv. 2019, 26, 765–772. [Google Scholar] [CrossRef]

- Roy, H.; Nayak, B.S.; Nandi, S. Chitosan Anchored Nanoparticles in Current Drug Development Utilizing Computer-Aided Pharmacokinetic Modeling: Case Studies for Target Specific Cancer Treatment and Future Prospective. Curr. Pharm. Des. 2020, 26, 1666–1675. [Google Scholar] [CrossRef]

- Pathak, K.; Misra, S.K.; Sehgal, A.; Singh, S.; Bungau, S.; Najda, A.; Gruszecki, R.; Behl, T. Biomedical Applications of Quaternized Chitosan. Polymers 2021, 13, 2514. [Google Scholar] [CrossRef] [PubMed]

- Frigaard, J.; Jensen, J.L.; Galtung, H.K.; Hiorth, M. The Potential of Chitosan in Nanomedicine: An Overview of the Cytotoxicity of Chitosan Based Nanoparticles. Front. Pharmacol. 2022, 13, 880377. [Google Scholar] [CrossRef] [PubMed]

- Sriwidodo; Umar, A.K.; Wathoni, N.; Zothantluanga, J.H.; Das, S.; Luckanagul, J.A. Liposome-Polymer Complex for Drug Delivery System and Vaccine Stabilization. Heliyon 2022, 8, e08934. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhang, Y.; Ju, H.; Yang, F.; Luo, X.; Zhang, L. Uptake of Methylene Blue on Divinylbenzene Cross-Linked Chitosan/Maleic Anhydride Polymer by Adsorption Process. Colloids Surf. A Physicochem. Eng. Asp. 2021, 629, 127424. [Google Scholar] [CrossRef]

- Gonçalves, F.J.; Gurgel, L.V.A.; Soares, L.C.; Teodoro, F.S.; Ferreira, G.M.D.; Coelho, Y.L.; da Silva, L.H.M.; Prim, D.; Gil, L.F. Application of pyridine-modified chitosan Derivative for Simultaneous Adsorption of Cu(II) and Oxyanions of Cr(VI) from Aqueous Solution. J. Environ. Manag. 2021, 282, 111939. [Google Scholar] [CrossRef]

- Vakili, M.; Mojiri, A.; Zwain, H.M.; Yuan, J.; Giwa, A.S.; Wang, W.; Gholami, F.; Guo, X.; Cagnetta, G.; Yu, G. Effect of Beading Parameters on Cross-Linked Chitosan Adsorptive Properties. React. Funct. Polym. 2019, 144, 104354. [Google Scholar] [CrossRef]

- Vakili, M.; Deng, S.; Liu, D.; Li, T.; Yu, G. Preparation of Aminated Cross-Linked Chitosan Beads for Efficient Adsorption of Hexavalent Chromium. Int. J. Biol. Macromol. 2019, 139, 352–360. [Google Scholar] [CrossRef]

- Chanajaree, R.; Sriuttha, M.; Lee, V.S.; Wittayanarakul, K. Thermodynamics and Kinetics of Cationic/Anionic Dyes Adsorption on Cross-Linked Chitosan. J. Mol. Liq. 2021, 322, 114507. [Google Scholar] [CrossRef]

- Farias, P.V.S.; Aragão, D.C.; Farias, M.V.; Correia, L.M.; Carvalho, T.V.; Aguiar, J.E.; Vieira, R.S. Natural and Cross-Linked Chitosan Spheres as Adsorbents for Diesel Oil Removal. Adsorp. Sci. Technol. 2015, 33, 783–792. [Google Scholar] [CrossRef]

- Jawad, A.H.; Mamat, N.F.H.; Hameed, B.H.; Ismail, K. Biofilm of Cross-Linked Chitosan-Ethylene Glycol Diglycidyl Ether for removal of Reactive Red 120 and Methyl Orange: Adsorption and Mechanism Studies. J. Environ. Chem. Eng. 2019, 7, 102965. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Z.; Ouyang, X.-K.; Ji, C.; Liu, Y.; Huang, F.; Yang, L.-Y. Fabrication of Cross-Linked Chitosan Beads Grafted by Polyethylenimine for Efficient Adsorption of Diclofenac Sodium from Water. Int. J. Biol. Macromol. 2020, 145, 1180–1188. [Google Scholar] [CrossRef]

- Dos Santos, J.M.N.; Pereira, C.R.; Foletto, E.L.; Dotto, G.L. Alternative Synthesis for ZnFe2O4/Chitosan Magnetic Particles to Remove Diclofenac from Water by Adsorption. Int. J. Biol. Macromol. 2019, 131, 301–308. [Google Scholar] [CrossRef] [PubMed]

- Zhu, W.; Dang, Q.; Liu, C.; Yu, D.; Chang, G.; Pu, X.; Wang, Q.; Sun, H.; Zhang, B.; Cha, D. Cr(VI) and Pb(II) Capture on pH-Responsive Polyethyleneimine and Chloroacetic Acid Functionalized Chitosan Microspheres. Carbohydr. Polym. 2019, 219, 353–367. [Google Scholar] [CrossRef]

- Sabarudin, A.; Madjid, A.D.R. Preparation and Kinetic Studies of Cross-Linked Chitosan Beads Using Dual Crosslinkers of Tripolyphosphate and Epichlorohydrin for Adsorption of Methyl Orange. Sci. World J. 2021, 11, 6648457. [Google Scholar] [CrossRef]

- Urtasun, N.; Mignon, A.; Martínez-Alvarez, L.M.; Baieli, M.F.; Hirsch, D.B.; Cascone, O.; Dubruel, P.; Wolman, F.J. Synthesis and Characterization of Chitosan Mini-Spheres with Immobilized Dye as Affinity Ligand for the Purification of Lactoperoxidase and Lactoferrin from Dairy Whey. Sep. Purif. Technol. 2021, 255, 117700. [Google Scholar] [CrossRef]

- Hirsch, D.B.; Martínez Álvarez, L.M.; Urtasun, N.; Baieli, M.F.; Lázaro-Martínez, J.M.; Glisoni, R.J.; Miranda, M.V.; Cascone, O.; Wolman, F.J. Lactoferrin Purification and Whey Protein Isolate Recovery from Cheese Whey Using Chitosan Mini-Spheres. Int. Dairy J. 2020, 109, 104764. [Google Scholar] [CrossRef]

- Li, Q.; Mao, Q.; Li, M.; Zhang, S.; He, G.; Zhang, W. Cross-Linked Chitosan Microspheres Entrapping Silver Chloride via the Improved Emulsion Technology for Iodide Ion Adsorption. Carbohydr. Polym. 2020, 234, 115926. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhao, M.; Cheng, Q.; Wang, C.; Li, H.; Han, X.; Fan, Z.; Su, G.; Pan, D.; Li, Z. Research Progress of Adsorption and Removal of Heavy Metals by Chitosan and Its Derivatives: A Review. Chemosphere 2021, 279, 130927. [Google Scholar] [CrossRef]

- Khan, N.; Khan, I.; Zada, N.; Sadiq, M.; Saeed, K. Utilization of Cross-Linked Chitosan for Cobalt Adsorption and Its Reutilization as a Photocatalyst for the Photodegradation of Methyl Violet Dye in Aqueous Medium. Appl. Water Sci. 2022, 12, 107. [Google Scholar] [CrossRef]

- Begum, S.; Yuhana, N.Y.; Saleh, N.M.; Kamarudin, N.H.N.; Sulong, A.B. Review of Chitosan Composite as a Heavy Metal Adsorbent: Material Preparation and Properties. Carbohydr. Polym. 2021, 259, 117613. [Google Scholar] [CrossRef]

- Upadhyay, U.; Sreedhar, I.; Singh, S.A.; Patel, C.M.; Anitha, K.L. Recent Advances in Heavy Metal Removal by Chitosan Based Adsorbents. Carbohydr. Polym. 2021, 251, 117000. [Google Scholar] [CrossRef] [PubMed]

- Omer, A.M.; Dey, R.; Eltaweil, A.S.; El-Monaem, E.M.A.; Ziora, Z.M. Insights into Recent Advances of Chitosan-Based Adsorbents for Sustainable Removal of Heavy Metals and Anions. Arab. J. Chem. 2022, 15, 103543. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Z.; Guo, W.; Zhu, C.; Zou, Y. Simple Fabrication of Chitosan/Graphene Nanoplates Composite Spheres for Efficient Adsorption of Acid Dyes from Aqueous Solution. Int. J. Biol. Macromol. 2018, 112, 1048–1054. [Google Scholar] [CrossRef] [PubMed]

- Jawad, A.H.; Mubarak, N.S.A.; Abdulhameed, A.S. Tunable Schiff’s Base-Cross-Linked Chitosan Composite for the Removal of Reactive Red 120 Dye: Adsorption and Mechanism Study. Int. J. Biol. Macromol. 2020, 142, 732–741. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Zhu, Q.; Xing, Z. A Functionalized Chitosan Wrinkled Hollow Sphere Containing Calcium Ions: Efficient Adsorption of Sodium Dodecylbenzenesulfonate (SDBS) from Aqueous Solutions. J. Colloid Interface Sci. 2019, 555, 203–213. [Google Scholar] [CrossRef]

- Altun, T. Preparation and Application of Glutaraldehyde Cross-Linked Chitosan Coated Bentonite Clay Capsules: Chromium(VI) Removal from Aqueous Solution. J. Chil. Chem. Soc. 2020, 65, 4790–4797. [Google Scholar] [CrossRef]

- Patiño-Ruiz, D.A.; De Ávila, G.; Alarcón-Suesca, C.; González-Delgado, Á.D.; Herrera, A. Ionic Cross-Linking Fabrication of Chitosan-Based Beads Modified with FeO and TiO2 Nanoparticles: Adsorption Mechanism toward Naphthalene Removal in Seawater from Cartagena Bay Area. ACS Omega 2020, 5, 26463–26475. [Google Scholar] [CrossRef]

- Ohemeng-Boahen, G.; Sewu, D.D.; Tran, H.N.; Woo, S.H. Enhanced Adsorption of Congo Red from Aqueous Solution Using Chitosan/Hematite Nanocomposite Hydrogel Capsule Fabricated via Anionic Surfactant Gelation. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625, 126911. [Google Scholar] [CrossRef]

- Jeyaseelan, A.; Viswanathan, N. Facile Fabrication of Zirconium-Organic Framework-Embedded Chitosan Hybrid Spheres for Efficient Fluoride Adsorption. ACS ES&T Water 2022, 2, 52–62. [Google Scholar] [CrossRef]

- Wang, T.; Wusigale; Kuttappan, D.; Amalaradjou, M.A.; Luo, Y.; Luo, Y. Polydopamine-Coated Chitosan Hydrogel Beads for Synthesis and Immobilization of Silver Nanoparticles to Simultaneously Enhance Antimicrobial Activity and Adsorption Kinetics. Adv. Compos. Hybrid. Mater. 2021, 4, 696–706. [Google Scholar] [CrossRef]

- Warkara, S.G.; Meena, J. Synthesis and Applications of Biopolymer/FeO Nanocomposites: A Review. JNMES 2022, 25, 7–16. [Google Scholar] [CrossRef]

- Fan, C.; Li, K.; He, Y.; Wang, Y.; Qian, X.; Jia, J. Evaluation of Magnetic Chitosan Beads for Adsorption of Heavy Metal Ions. Sci. Total Environ. 2018, 627, 1396–1403. [Google Scholar] [CrossRef] [PubMed]

- Kloster, G.A.; Valiente, M.; Marcovich, N.E.; Mosiewicki, M.A. Adsorption of Arsenic onto Films Based on Chitosan and Chitosan/Nano-Iron Oxide. Int. J. Biol. Macromol. 2020, 165, 1286–1295. [Google Scholar] [CrossRef] [PubMed]

- Eivazzadeh-Keihan, R.; Radinekiyan, F.; Asgharnasl, S.; Maleki, A.; Bahreinizad, H. A Natural and Eco-Friendly Magnetic Nanobiocomposite Based on Activated Chitosan for Heavy Metals Adsorption and the In-vitro Hyperthermia of Cancer Therapy. J. Mater. Res. Technol. 2020, 9, 12244–12259. [Google Scholar] [CrossRef]

- Shahraki, S.; Delarami, H.S.; Khosravi, F.; Nejat, R. Improving the Adsorption Potential of Chitosan for Heavy Metal Ions Using Aromatic Ring-Rich Derivatives. J. Colloid Interface Sci. 2020, 576, 79–89. [Google Scholar] [CrossRef]

- Fu, C.-C.; Tran, H.N.; Chen, X.-H.; Juang, R.-S. Preparation of Polyaminated Fe3O4@Chitosan Core-Shell Magnetic Nanoparticles for Efficient Adsorption of Phosphate in Aqueous Solutions. J. Ind. Eng. Chem. 2020, 83, 235–246. [Google Scholar] [CrossRef]

- Elanchezhiyan, S.S.D.; Preethi, J.; Rathinam, K.; Njaramba, L.K.; Park, C.M. Synthesis of Magnetic Chitosan Biopolymeric Spheres and Their Adsorption Performances for PFOA and PFOS from Aqueous Environment. Carbohydr. Polym. 2021, 267, 118165. [Google Scholar] [CrossRef]

- Tanhaei, B.; Ayati, A.; Iakovleva, E.; Sillanpää, M. Efficient Carbon Interlayed Magnetic Chitosan Adsorbent for Anionic Dye Removal: Synthesis, Characterization and Adsorption Study. Int. J. Biol. Macromol. 2020, 164, 3621–3631. [Google Scholar] [CrossRef]

- Kang, H.; Buchman, J.T.; Rodriguez, R.S.; Ring, H.L.; He, J.; Bantz, K.C.; Haynes, C.L. Stabilization of Silver and Gold Nanoparticles: Preservation and Improvement of Plasmonic Functionalities. Chem. Rev. 2019, 119, 664–699. [Google Scholar] [CrossRef]

- Bashal, A.H.; Riyadh, S.M.; Alharbi, W.; Alharbi, K.H.; Farghaly, T.A.; Khalil, K.D. Bio-Based (Chitosan-ZnO) Nanocomposite: Synthesis, Characterization, and Its Use as Recyclable, Ecofriendly Biocatalyst for Synthesis of Thiazoles Tethered Azo Groups. Polymer 2022, 14, 386. [Google Scholar] [CrossRef]

- Verma, D.K.; Malik, R.; Meena, J.; Rameshwari, R. Synthesis, Characterization and Applications of Chitosan Based Metallic Nanoparticles: A Review. J. Appl. Nat. Sci. 2021, 13, 544–551. [Google Scholar] [CrossRef]

- Sun, L.; Li, J.; Cai, J.; Zhong, L.; Ren, G.; Ma, Q. One Pot Synthesis of Gold Nanoparticles Using Chitosan with Varying Degree of Deacetylation and Molecular Weight. Carbohyd. Polym. 2017, 178, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Tong, J.; Li, Y.; Bo, L.; Wang, W.; Li, T.; Zhang, Q. Core-Shell Fe3O4@NCS-Mn Derived from Chitosan-Schiff Based Mn Complex with Enhanced Catalytic Activity for Oxygen Reduction Reaction. Catalysts 2019, 9, 692. [Google Scholar] [CrossRef]

- Singh, H.; Rajput, J.K. Co(II) Anchored Glutaraldehyde Crosslinked Magnetic Chitosan Nanoparticles (MCS) for Synthesis of 2,4,5-Trisubstituted and 1,2,4,5-Tetrasubstituted Imidazoles. Appl. Organometal. Chem. 2018, 32, e3989. [Google Scholar] [CrossRef]

- Jennah, O.; Beniazza, R.; Lozach, C.; Jardel, D.; Molton, F.; Duboc, C.; Buffeteau, T.; El Kadib, A.; Lastécouères, D.; Lahcini, M.; et al. Photoredox Catalysis at Copper(II) on Chitosan: Application to PhotolatentCuAAC. Adv. Synth. Catal. 2018, 360, 4615. [Google Scholar] [CrossRef]

- Jiao, L.-Y.; Zhang, Z.; Hong, Q.; Ning, Z.-H.; Liu, S.; Sun, M.; Hao, Q.; Xu, L.; Li, Z.; Ma, X.-X. Recyclable Copper Catalyst on Chitosan for Facile Preparation of Alkyl/Aryl Mixed Phosphates via Deaminated Esterification between DiphenylphosphorylAzides and Aliphatic Alcohols. Mol. Catal. 2020, 494, 111120. [Google Scholar] [CrossRef]

- Reyes-Mercado, E.; Rivas-Loaiza, J.A.; García-Merinos, J.P.; López, Y.; González-Campos, J.B. Chitosan-supported copper salt and copper metal nanoparticles/copper (I) oxide Microcrystals: Efficient and Recyclable Heterogeneous Catalysts for the Synthesis of Bis(indolyl)methanes. Chem. Eng. Process. 2021, 159, 108201. [Google Scholar] [CrossRef]

- Ali, F.; Khan, S.B.; Kamal, T.; Alamry, K.A.; Bakhsh, E.M.; Asiri, A.M.; Sobahi, T.R.A. Synthesis and Characterization of Metal Nanoparticles Templated Chitosan-SiO2 Catalyst for the Reduction of Nitrophenols and Dyes. Carbohydr. Polym. 2018, 192, 217–230. [Google Scholar] [CrossRef]

- Raza, Z.A.; Mobeen, A.; Rehman, M.S.U.; Majeed, M.I. Synthesis of Copper Oxide Nanoparticles Embedded in Porous Chitosan Membrane for Photodegradation of Organic Dyes. Polym. Bull. 2022. [Google Scholar] [CrossRef]

- Sakthivel, S.; Periakaruppan, R.; Vallinayagam, S.; Gandhi, S.; Tappa, M.M.; Sharma, V.K.; Sivaramakrishnan, R.; Suresh, S.; Gurusamy, A. Synthesis and Characterization of Paddy Straw Chitosan Nanocomposite as an Efficient Photocatalytic Bio-adsorbent for the Removal of Rhodamine B and Malachite Green Dye from Aqueous Solution. Appl. Nanosci. 2022. [Google Scholar] [CrossRef]

- Khan, M.S.J.; Kamal, T.; Ali, F.; Asiri, A.M.; Khan, S.B. Chitosan-Coated Polyurethane Sponge Supported Metal Nanoparticles for Catalytic Reduction of Organic Pollutants. Int. J. Biol. Macromol. 2019, 132, 772–783. [Google Scholar] [CrossRef] [PubMed]

- Naghipour, A.; Fakhri, A. Efficient Oxidation of Sulfides into Sulfoxides Catalyzed by a Chitosan-Schiff Base Complex of Cu(II) Supported on Supramagnetic Fe3O4 Nanoparticles. Environ. Chem. Lett. 2016, 14, 207–213. [Google Scholar] [CrossRef]

- Fakhri, A.; Naghipour, A. Fe3O4@Chitosan-Bound Picolinaldehyde Cu Complex as the Magnetically Reusable Nanocatalyst for Adjustable Oxidation of Sulfides. Environ. Prog. Sustain. Energy 2018, 37, 1626–1631. [Google Scholar] [CrossRef]

- Laghrib, F.; Ajermoun, N.; Bakasse, M.; Lahrich, S.; El Mhammedi, M.A. Synthesis of Silver Nanoparticles Assisted by Chitosan and Its Application to Catalyze the Reduction of 4-Nitroaniline. Int. J. Biol. Macromol. 2019, 135, 752–759. [Google Scholar] [CrossRef] [PubMed]

- Wang, A.; Zhu, Q.; Xing, Z. Multifunctional QuaternizedChitosan@surface Plasmon Resonance Ag/N-TiO2 Core-Shell Microsphere for Synergistic Adsorption-Photothermal Catalysis Degradation of Low-Temperature Wastewater and Bacteriostasis under visible light. Chem. Eng. J. 2020, 393, 124781. [Google Scholar] [CrossRef]

- Khan, M.S.J.; Khan, S.B.; Kamal, T.; Asiri, A.M. Catalytic Application of Silver Nanoparticles in Chitosan Hydrogel Prepared by a Facile Method. J. Polym. Environ. 2020, 28, 962–972. [Google Scholar] [CrossRef]

- Sun, P.; Zhang, L.; Tao, S. Preparation of Hybrid Chitosan Membranes by Selective Laser Sintering for Adsorption and Catalysis. Mater. Des. 2019, 173, 107780. [Google Scholar] [CrossRef]

- Vedula, S.S.; Yadav, G.D. Chitosan-Based Membranes Preparation and Applications: Challenges and Opportunities. J. Indian Chem. Soc. 2021, 98, 100017. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, X.; Qin, Z.; Zhang, L.; Ye, Y.; Cao, M.; Gao, L.; Jiao, T. Preparation of PdNPs Doped Chitosan-Based Composite Hydrogels as Highly Efficient Catalysts for Reduction of 4-Nitrophenol. Colloids Surf. A Physicochem. Eng. Asp. 2021, 611, 125889. [Google Scholar] [CrossRef]

- Le Goff, R.; Mahé, O.; Le Coz-Botrel, R.; Malo, S.; Goupil, J.-M.; Brière, J.-F.; Dez, I. Insight in Chitosan Aerogels Derivatives—Application in Catalysis. React. Funct. Polym. 2020, 146, 104393. [Google Scholar] [CrossRef]

- Shen, Y.; Zheng, Q.; Liu, J.; Tu, T. Metallo-aerogels Derived from Chitosan with Encapsulated Metal Nanoparticles as Robust, Efficient and Selective Nanocatalysts Towards Reduction of Nitroarenes. Nano Res. 2021, 14, 59–65. [Google Scholar] [CrossRef]

- de Souza, J.F.; Lemos, T.S.A.; Biajoli, A.F.P.; Fajardo, A.R. Phosphine-Functionalized Chitosan Microparticles as Support Materials for Palladium Nanoparticles in Heck Reactions. Catal. Lett. 2022, 152, 2933–2946. [Google Scholar] [CrossRef]

- Khammarnia, S.; Akbari, A.; Ekrami-Kakhki, M.-S.; Saffari, J. Enhanced Catalytic Activity of Pt-NdFeO3 Nanoparticles Supported on Polyaniline-Chitosan Composite Towards Methanol Electro-Oxidation Reaction. J. Nanostruct. 2020, 10, 239–257. [Google Scholar] [CrossRef]

- Khodkari, V.; Nazeri, M.T.; Javanbakht, S.; Shaabani, A. In Situ Copper Nanoparticle Immobilization on the Indigo Carmine-Functionalized Chitosan: A Versatile Biocatalyst towards CO2 Fixation and Click Reactions in Water. React. Chem. Eng. 2023, 8, 152–163. [Google Scholar] [CrossRef]

- Riyadh, S.M.; Khalil, K.D.; Aljuhani, A. Chitosan-MgO Nanocomposite: One Pot Preparation and Its Utility as an Ecofriendly Biocatalyst in the Synthesis of Thiazoles and [1,3,4]thiadiazoles. Nanomaterials 2018, 8, 928. [Google Scholar] [CrossRef]

- Alayli, A.; Nadaroglu, H.; Turgut, E. Nanobiocatalyst Beds with Fenton Process for Removal of Methylene Blue. Appl. Water Sci. 2021, 11, 32. [Google Scholar] [CrossRef]

- Saba, R.; Aziz, M.K.; Mustafa, G.; Srivastava, A.; Srivastava, S. Schiff’s Base of Fe3O4@chitosan with 4,4’-Diselenobisbenzaldehyde: Preparation, Characterization and its Catalytic Activity for Oxidation of Sulphides. J. Polym. Mater. 2021, 38, 153–166. [Google Scholar] [CrossRef]

- Parandhaman, T.; Pentela, N.; Ramalingam, B.; Samanta, D.; Das, S.K. Metal Nanoparticle Loaded Magnetic-Chitosan Microsphere: Water Dispersible and Easily Separable Hybrid Metal Nano-biomaterial for Catalytic Applications. ACS Sustain. Chem. Eng. 2017, 5, 489–501. [Google Scholar] [CrossRef]

- Rinki, K.; Dutta, P.K.; Hunt, A.J.; Macquarrie, D.J.; Clark, J.H. Chitosan Aerogels Exhibiting High Surface Area for Biomedical Application: Preparation, Characterization, and Antibacterial Study. Int. J. Polym. Mater. 2011, 60, 988–999. [Google Scholar] [CrossRef]

- Wei, S.; Ching, Y.C.; Chuah, C.H. Synthesis of Chitosan Aerogels as Promising Carriers for Drug Delivery: A Review. Carbohydr. Polym. 2020, 231, 115744. [Google Scholar] [CrossRef]

- Takeshita, S.; Zhao, S.; Malfait, W.J.; Koebel, M.M. Chemistry of Chitosan Aerogels: Three-Dimensional Pore Control for Tailored Applications. Angew. Chem. Int. Ed. 2021, 60, 9828–9851. [Google Scholar] [CrossRef] [PubMed]

- Anju, R.P.P.; Sunil, J.T.; Dinoop, l.S. Chitosan Stabilized Fe/Ni Bimetallic Nanoparticles for the Removal of Cationic and Anionic Triphenylmethane Dyes from Water. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100295. [Google Scholar] [CrossRef]

- Bumagin, N.A. Chitosan-Based Magnetic Polymetallic Pd-Catalysts for Heck Reaction in Aqueous Media. Russ. J. Gen. Chem. 2022, 92, 63–68. [Google Scholar] [CrossRef]

- Krajewska, B. Application of Chitin- and Chitosan-based Materials for Enzyme Immobilizations: A Review. Enzyme Microb. Technol. 2004, 35, 126–139. [Google Scholar] [CrossRef]

- Biró, E.; Németh, Á.S.; Sisak, C.; Feczkó, T.; Gyenis, J. Preparation of Chitosan Particles Suitable for Enzyme Immobilization. J. Biochem. Biophys. Methods 2008, 70, 1240–1246. [Google Scholar] [CrossRef] [PubMed]

- Malmiri, H.J.; Jahanian, M.A.G.; Berenjian, A. Potential Applications of Chitosan Nanoparticles as Novel Support in Enzyme Immobilization. Am. J. Biochem. Biotechnol. 2012, 8, 203–219. [Google Scholar] [CrossRef]

- Wang, D.; Jiang, W. Preparation of Chitosan-based Nanoparticles for Enzyme Immobilization. Int. J. Biol. Macromol. 2019, 126, 1125–1132. [Google Scholar] [CrossRef]

- Verma, M.L.; Kumar, S.; Das, A.; Randhawa, J.S.; Chamundeeswari, M. Chitin and Chitosan-based Support Materials for Enzyme Immobilization and Biotechnological Applications. Environ. Chem. Lett. 2020, 18, 315–323. [Google Scholar] [CrossRef]

- Nunes, Y.L.; de Menezes, F.L.; de Sousa, I.G.; Cavalcante, A.L.G.; Cavalcante, F.T.T.; da Silva Moreira, K.; de Oliveira, A.L.B.; Mota, G.F.; da Silva Souza, J.E.; de Aguiar Falcão, I.R.; et al. Chemical and Physical Chitosan Modification for Designing Enzymatic Industrial Biocatalysts: How to Choose the Best Strategy? Int. J. Biol. Macromol. 2021, 181, 1124–1170. [Google Scholar] [CrossRef]

- Bilal, M.; Iqbal, H.M.N. Naturally-derived Biopolymers: Potential Platforms for Enzyme Immobilization. Int. J. Biol. Macromol. 2019, 130, 462–482. [Google Scholar] [CrossRef]

- Chatterjee, S.; Lee, M.W.; Woo, S.H. Enhanced Mechanical Strength of Chitosan Hydrogel Beads by Impregnation with Carbon Nanotubes. Carbon 2009, 47, 2933–2936. [Google Scholar] [CrossRef]

- Wahba, M.I. Porous Chitosan Beads of Superior Mechanical Properties for the Covalent Immobilization of Enzymes. Int. J. Biol. Macromol. 2017, 105, 894–904. [Google Scholar] [CrossRef] [PubMed]

- Ji, Q.; Wang, B.; Li, C.; Hao, J.; Feng, W. Co-Immobilised 7a- and 7b-HSDH as Recyclable Biocatalyst: High-Performance Production of TUDCA from Waste Chicken Bile. RSC Adv. 2018, 8, 34192–34201. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.S.; Singh, R.P.; Kennedy, J.F. Immobilization of yeast inulinase on chitosan beads for the hydrolysis of inulin in a batch system. Int. J. Biol. Macromol. 2017, 95, 87–93. [Google Scholar] [CrossRef]

- Manan, F.M.A.; Attan, N.; Zakaria, Z.; Mahat, N.A.; Wahab, R.A. Insight into the Rhizomucor miehei Lipase Supported on Chitosan-Chitin Nanowhiskers Assisted Esterification of Eugenol to Eugenyl Benzoate. J. Biotechnol. 2018, 280, 19–30. [Google Scholar] [CrossRef]

- de Freitas, M.F.M.; Hortencio, L.C.; de Albuquerque, T.L.; Rocha, M.V.P.; Goncalves, L.R.B. Simultaneous Hydrolysis of Cheese Whey and Lactulose Production Catalyzed by β-Galactosidase from Kluyveromyces lactis NRRL Y1564. Bioprocess Biosyst. Eng. 2020, 43, 711–722. [Google Scholar] [CrossRef]

- Okura, N.S.; Sabi, G.J.; Crivellenti, M.C.; Gomes, R.A.B.; Fernandez-Lafuente, R.; Mendes, A.A. Improved Immobilization of Lipase from Thermomyces lanuginosus on a New Chitosan-Based Heterofunctional Support: Mixed Ion Exchange Plus Hydrophobic Interactions. Int. J. Biol. Macromol. 2020, 163, 550–561. [Google Scholar] [CrossRef]

- Aggarwal, S.; Ikram, S. Zinc Oxide Nanoparticles-Impregnated Chitosan Surfaces for Covalent Immobilization of Trypsin: Stability & Kinetic Studies. Int. J. Biol. Macromol. 2022, 207, 205–221. [Google Scholar] [CrossRef]

- Aman, A.; Shahid, F.; Pervez, S. Exploration of a Three-Dimensional Matrix as Micro-Reactor in the Form of Reactive Polyaminosaccharide Hydrogel Beads Using Multipoint Covalent Interaction Approach. Biotechnol. Lett. 2022, 44, 299–319. [Google Scholar] [CrossRef]

- BôaMorte, E.F.; Marum, D.S.; Saitovitch, E.B.; Alzamora, M.; Monteiro, S.N.; Sanchez Rodriguez, R.J. Modified Magnetite Nanoparticle as Biocatalytic Support for Magnetically Stabilized Fluidized Bed Reactors. J. Mater. Res. Technol. 2021, 14, 1112–1125. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X. Synthesis of Chitosan-Functionalized Fibrous Membrane for Immobilization of Horseradish Peroxidase: Interfacial Propertyand Application for Catalytic Oxidationof P-Nitrophenol. J. Eng. Fibers Fabr. 2018, 13, 66–73. [Google Scholar] [CrossRef]

- Costa-Silva, T.A.; Carvalho, A.K.F.; Souza, C.R.F.; De Castro, H.F.; Bachmann, L.; Said, S.; Oliveira, W.P. Enhancement Lipase Activity via Immobilization onto Chitosan Beads Used as Seed Particles During Fluidized Bed Drying: Application in butyl Butyrate production. Appl. Catal. A Gen. 2021, 622, 118217. [Google Scholar] [CrossRef]

- Costa-Silva, T.A.; Carvalho, A.K.F.; Souza, C.R.F.; Freitas, L.; De Castro, H.F.; Oliveira, W.P. Highly Effective Candida rugosa Lipase Immobilization on Renewable Carriers: Integrated Drying and Immobilization Process to Improve Enzyme Performance. Chem. Eng. Res. Des. 2022, 183, 41–55. [Google Scholar] [CrossRef]

- Apriceno, A.; Girelli, A.M.; Scuto, F.R. Design of a Heterogeneous Enzymatic Catalyst on Chitosan: Investigation on the Role of Conjugation Chemistry in the Catalytic Activity of a Laccase from Trametes versicolor. J. Chem. Technol. Biotechnol. 2018, 93, 1413–1420. [Google Scholar] [CrossRef]

- Apriceno, A.; Silvestro, I.; Girelli, A.; Francolini, I.; Pietrelli, L.; Piozzi, A. Preparation and Characterization of Chitosan-Coated Manganese-Ferrite Nanoparticles Conjugated with Laccase for Environmental Bioremediation. Polymers 2021, 13, 1453. [Google Scholar] [CrossRef]

- Ariffin, M.F.K.; Idris, A.; Ngadiman, N.H.A. Optimization of Lipase Immobilization on Maghemite and Its Physico-Chemical Properties. Braz. J. Chem. Eng. 2019, 36, 171–179. [Google Scholar] [CrossRef]

- Carli, S.; Carneiro, L.A.B.C.; Ward, R.J.; Meleiro, L.P. Immobilization of a β-glucosidase and an endoglucanase in ferromagneticnanoparticles: A study of synergistic effects. Protein Expr. Purif. 2019, 160, 28–35. [Google Scholar] [CrossRef]

- Carneiro, L.A.B.C.; Ward, R.J. Functionalization of Paramagnetic Nanoparticles for Protein Immobilization and Purification. Anal. Biochem. 2018, 540–541, 45–51. [Google Scholar] [CrossRef]

- Charoenwongpaiboon, T.; Wangpaiboon, K.; Pichyangkura, R.; Prousoontorn, M.H. Highly Porous Core-Shell Chitosan Beads with Superb Immobilization Efficiency for Lactobacillus reuteri 121 Inulosucrase and Production of Inulin-Type Fructooligosaccharides. RSC Adv. 2018, 8, 17008–17016. [Google Scholar] [CrossRef]

- Tavernini, L.; Ottone, C.; Illanes, A.; Wilson, L. Entrapment of Enzyme Aggregates in Chitosan Beads for Aroma Release in White Wines. Int. J. Biol. Macromol. 2020, 154, 1082–1090. [Google Scholar] [CrossRef]

- Cui, L.; Xiong, Z.; Guo, Y.; Liu, Y.; Zhao, J.; Zhang, C.; Zhu, P. Fabrication of Interpenetrating Polymer Network Chitosan/Gelatin Porous Materials and Study on Dye Adsorption Properties. Carbohydr. Polym. 2015, 132, 330–337. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.; Wang, X.; Lou, X.; Yuan, H.; Tu, H.; Li, B.; Zhang, Y. Genipin-Crosslinked Electrospun Chitosan Nanofibers: Determination of Crosslinking Conditions and Evaluation of Cytocompatibility. Carbohydr. Polym. 2015, 130, 166–174. [Google Scholar] [CrossRef] [PubMed]

- Mekhail, M.; Jahan, K.; Tabrizian, M. Genipin-Crosslinked Chitosan/Poly-L-lysine Gels Promote Fibroblast Adhesion and Proliferation. Carbohydr. Polym. 2014, 108, 91–98. [Google Scholar] [CrossRef]

- Tacias-Pascacio, V.G.; García-Parra, E.; Vela-Gutiérrez, G.; Virgen-Ortiz, J.J.; Berenguer-Murcia, Á.; Alcántara, A.R.; Fernandez-Lafuente, R. Genipin as An Emergent Tool in the Design of Biocatalysts: Mechanism of Reaction and Applications. Catalysts 2019, 9, 1035. [Google Scholar] [CrossRef]

- Hyun, K.; Kang, S.; Kim, J.; Kwon, Y. New Biocatalyst Including a 4-Nitrobenzoic Acid MediatorEmbedded by the Cross-Linking of Chitosan and Genipin and Its Use in an Energy Device. ACS Appl. Mater. Interfaces 2020, 12, 23635–23643. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.-F.; Meng, G.; Cui, B.-K.; Si, J.; Dai, Y.-C. Chitosan Crosslinked with Genipin as Supporting Matrix for Biodegradation 24 of Synthetic Dyes: Laccase Immobilization and Characterization. Chem. Eng. Res. Des. 2018, 132, 664–676. [Google Scholar] [CrossRef]

- Klein, M.P.; Hackenhaar, C.R.; Lorenzoni, A.S.; Rodrigues, R.C.; Costa, T.M.; Ninow, J.L.; Hertz, P.F. Chitosan Crosslinked with Genipin as Support Matrix for Application in Food Process: Support Characterization and β-D-Galactosidase Immobilization. Carbohydr. Polym. 2016, 137, 184–190. [Google Scholar] [CrossRef] [PubMed]

- Rahman, I.N.A.; Wahab, R.A.; Mahat, N.A.; Jamalis, J.; Huri, M.A.M.; Kurniawan, C. Ternary Blended Chitosan/Chitin/Fe3O4 Nanosupport for Lipase Activation and Stabilization. Arab. J. Sci. Eng. 2019, 44, 6327–6337. [Google Scholar] [CrossRef]

- Saikia, K.; Rathankumar, A.K.; Varghese, B.A.; Kalita, S.; Subramanian, S.; Somasundaram, S.; Kumar, V.V. Magnetically Assisted Commercially Attractive Chemo-Enzymatic Route for the Production of 5-Hydroxymethylfurfural from Inulin. Biomass Convers. Biorefinery 2021, 11, 2557–2567. [Google Scholar] [CrossRef]

- Akil, E.; Pereira, A.D.S.; El-Bacha, T.; Amaral, P.F.F.; Torres, A.G. Efficient Production of Bioactive Structured Lipids by Fast Acidolysis Catalyzed by Yarrowiali polytica Lipase, Free and Immobilized in Chitosan-Alginate Beads, in Solvent-Free Medium. Int. J. Biol. Macromol. 2020, 163, 910–918. [Google Scholar] [CrossRef]

- Qiu, X.; Wang, S.; Miao, S.; Suo, H.; Xu, H.; Hu, Y. Co-Immobilization of Laccase and ABTS onto Amino-Functionalized Ionic Liquid-Modified Magnetic Chitosan Nanoparticles for Pollutants Removal. J. Hazard. Mater. 2021, 401, 123353. [Google Scholar] [CrossRef] [PubMed]

- Ospina, V.; Bernal, C.; Mesa, M. Thermal Hyperactivation and Stabilization of β-Galactosidase from Bacillus circulans through a Silica Sol–Gel Process Mediated by Chitosan–Metal Chelates. ACS Appl. Bio Mater. 2019, 2, 3380–3392. [Google Scholar] [CrossRef] [PubMed]

- Cai, Z.; Wei, Y.; Wu, M.; Guo, Y.; Xie, Y.; Tao, R.; Li, R.; Wang, P.; Ma, A.; Zhang, H. Lipase Immobilized on Layer-by-layer Polysaccharide-coated Fe3O4@SiO2 Microspheres as a Reusable Biocatalyst for the Production of Structured Lipids. ACS Sustain. Chem. Eng. 2019, 7, 6685–6695. [Google Scholar] [CrossRef]

- Ol’shannikova, S.S.; Red’ko, Y.A.; Lavlinskaya, M.S.; Sorokin, A.V.; Holyavka, M.G.; Artyukhov, V.G. Preparation of Papain Complexes with Chitosan Microparticles and Evaluation of Their Stability Using the Enzyme Activity Level. Pharm. Chem. J. 2022, 55, 1240–1244. [Google Scholar] [CrossRef]

- Red’ko, Y.A.; Ol’shannikova, S.S.; Holyavka, M.G.; Lavlinskaya, M.S.; Sorokin, A.V.; Artyukhov, V.G. Development of a Method for Obtaining Bromelain Associates with Chitosan Micro- and Nanoparticles. Pharm. Chem. J. 2022, 56, 984–988. [Google Scholar] [CrossRef]

- Xu, H.; Liang, H. Chitosan-Regulated Biomimetic Hybrid Nanoflower for Efficiently Immobilizing Enzymes to Enhance Stability and By-Product Tolerance. Int. J. Biol. Macromol. 2022, 220, 124–134. [Google Scholar] [CrossRef]

- Gu, Y.; Yuan, L.; Li, M.; Wang, X.; Rao, D.; Bai, X.; Shi, K.; Xu, H.; Hou, S.; Yao, H. Co-Immobilized Bienzyme of Horseradish Peroxidase and Glucose Oxidase on Dopamine modified Cellulose-Chitosan Composite Beads as a High-Efficiency Biocatalyst for Degradation of Acridine. RSC Adv. 2022, 12, 4290. [Google Scholar] [CrossRef]

- Bilal, M.; Rasheed, T.; Zhao, Y.; Iqbal, H.M.N. Agarose-Chitosan Hydrogel-Immobilized Horseradish Peroxidase with Sustainable Bio-Catalytic and Dye Degradation Properties. Int. J. Biol. Macromol. 2019, 124, 742–749. [Google Scholar] [CrossRef]

- Pereira, A.D.S.; Fraga, J.L.; Diniz, M.M.; Fontes-Sant’Ana, G.C.; Amaral, P.F.F. High Catalytic Activity of Lipase from Yarrowiali polytica Immobilized by Microencapsulation. Int. J. Mol. Sci. 2018, 19, 3393. [Google Scholar] [CrossRef]

- Benucci, I.; Caso, M.C.; Bavaro, T.; Masci, S.; Keršienė, M.; Esti, M. Prolyl Endopeptidase from Aspergillus niger Immobilized on a Food-Grade Carrier for the Production of Gluten-Reduced Beer. Food Control 2020, 110, 106987. [Google Scholar] [CrossRef]

- Chen, X.; Hu, Z.; Xie, H.; Ngo, H.H.; Guo, W.; Zhang, J. Enhanced Biocatalysis of Phenanthrene in Aqueous Phase by Novel CA-Ca-SBE-Laccase Biocatalyst: Performance and Mechanism. Colloids Surf. A Physicochem. Eng. Asp. 2021, 611, 125884. [Google Scholar] [CrossRef]

- El-Shishtawy, R.M.; Ahmed, N.S.E.; Almulaiky, Y.Q. Immobilization of Catalase on Chitosan/ZnO and Chitosan/ZnO/Fe2O3 Nanocomposites: A Comparative Study. Catalysts 2021, 11, 820. [Google Scholar] [CrossRef]

- Girelli, A.M.; Quattrocchi, L.; Scuto, F.R. Design of Bioreactor Based on Immobilized Laccase on Silica-Chitosan Support for Phenol Removal in Continuous Mode. J. Biotech. 2021, 337, 8–17. [Google Scholar] [CrossRef]

- Khan, M.; Husain, Q.; Ahmad, N. Elucidating the Binding Efficacy of β-Galactosidase on Polyaniline Chitosan Nanocomposite and Polyaniline Chitosan Silver Nanocomposite: Activity and Molecular Model. J. Chem. Technol. Biotechnol. 2019, 94, 837–849. [Google Scholar] [CrossRef]

- Vassiliadi, E.; Xenakis, A.; Zoumpanioti, M. Chitosan Hydrogels: A New and Simple Matrix for Lipase Catalyzed Biosyntheses. Mol. Catal. 2018, 445, 206–212. [Google Scholar] [CrossRef]

| CS-Containing Adsorbent | Crosslinking Agent | Shaping | Contaminant | Absorption Conditions | Absorption Capacity | Ref. |

|---|---|---|---|---|---|---|

| CS/MAH–DVB-3 | DVB | No | MB | 298 K, pH 10 | 503 mg/g | [97] |

| Pyridine-modified CS | No | No | Cu(II) | 25 °C, pH 5.5 | 1.84 mmol/g | [98] |

| Cr(VI) | 25 °C, pH 3.6 | 3.86 mmol/g | [98] | |||

| CS–DEO | DEO | Beads | RR2 | Room temperature, pH 2 | 788.6 mg/g | [99] |

| CS–DEO–SP | DEO | Beads | Cr(VI) | 25 °C, pH 2 | 352 mg/g | [100] |

| CS | GA | Beads | MG | 30–40 °C, pH 6 | 714.29 mg/g | [101] |

| IC | 30–40 °C, pH 6 | 11.02 mg/g | [101] | |||

| CS | GA | Beads | Diesel oil solution in hexane | Ambient | 1.820 mg/g | [102] |

| ECH | Ambient | 1.642 mg/g | [102] | |||

| No | Ambient | 1.065 mg/g | [102] | |||

| CS–EGDE | EGDE | Film | RR120 | 303 K, pH 5 | 165.3 mg/g | [103] |

| MO | 303 K, pH 4 | 131.2 mg/g | [103] | |||

| EPCS@PEI | ECH | Beads | DS | 308 K, pH 4.2 | 253.32 mg/g | [104] |

| PEI–ECH–FA–CS | ECH | Micro spheres | Cr(VI) | 298 K, pH 3 | 331.32 mg/g | [106] |

| Pb(II) | 298 K, pH 5 | 302.56 mg/g | [106] | |||

| CS | TPP and ECH | Beads | MO | Room temperature, pH 3 | 79.55 mg/g | [107] |

| AgCl@CS | GA | Microspheres | Iodide anion | 25 °C, pH 2–10 | 1.5267 mmol/g | [110] |

| CS–GNPs | GA | Spheres | MO | 298 K, pH 3 | 230.91 mg/g | [116] |

| AR 1 | 298 K, pH 4 | 132.94 mg/g | [116] | |||

| CS–GA/TNC-25 | GA | No | RR 120 | 303 K, pH 3 | 103.1 mg/g | [117] |

| ECS@Ca@CTA | GA | Hollow spheres | SDBS | Room temperature, pH 3 | 2430 mg/g | [118] |

| CS–bentonite clay | GA | Capsules | Cr(VI) | 25 °C, pH 2 | 106.444 mg/g | [119] |

| CS–FeO/TiO2 | No | Beads | Naphthalene | 25 °C, pH Not indicated | 149.3 mg/g | [120] |

| HC–H60 | SDS | Capsules | CR | 30 °C, pH 4 | 4705.6 mg/g | [121] |

| Zr@BDC–CS | No | Spheres | Fluoride ion | Room temperature, pH 6 | 4982 mg/kg | [122] |

| Ag@beads | Oxidized dextran | Beads | CR | 30 °C, pH 5 | 7 mg/g | [123] |

| Cu (II) | 30 °C, pH 5 | 9 mg/g | [123] | |||

| Magnetic composites | ||||||

| CS–Fe3O4 | No | Film | As(III) | 25 °C, pH 3 | 10.4 mg/g | [126] |

| MGC (guanidinylated CS) | No | Core(Fe3O4)–shell particles | Pb(II) | 60 °C, pH 7 | 22.64 mg/g | [127] |

| CS–PPIMB | No | Beads | Pb(II) | 303 K, pH 5.5 | 230.48 mg/g | [128] |

| Fe3O4/CS/PEI | TPP | Core–shell particles | Phosphate ion | 25 °C, pH 3 | 48.2 mg/g | [129] |

| rGO–ZF@CB | GA | Beads | PFOA | 25 °C, pH 3 | 16.07 mg/g | [130] |

| PFOS | 25 °C, pH 3 | 21.64 mg/g | [130] | |||

| CS-covered C/Fe3O4 | GA | Core–shell particles | MO | 45 °C, pH 3–11 | 425 mg/g | [131] |

| Enzyme | Support | Shape | Crosslinking Agent | Additional Activating Agent | Recycling Stability | Storage Stability | Ref. |

|---|---|---|---|---|---|---|---|

| LIP | CS/CNWs | Beads | Tannic acid | EDAC/NHS | Not indicated | Not indicated | [178] |

| CS–GA–Gly | Beads | No | GA | 34% of activity after ninereuses | Not indicated | [180] | |

| nM–OA–CS–GA | NPs | No | GA | Not indicated | Not indicated | [183] | |

| CS | Beads | No | GA | 75.2% of activity after 10 reuses | 85.5% of activity after 6 months at 5 °C | [185] | |

| Fe3O4–CS–GA | Microparticles | No | GA | 60% of activity after 10 reuses | 80% of activity after 6 months at 5 °C | [186] | |

| Maghemite/CS/TPP | NPs | TPP | GA | Not indicated | Not indicated | [189] | |

| Chitin/CS/Fe3O4 | NPs | GA | EDAC/NHS | Not indicated | 90% of activity after 40 days at 30 °C | [201] | |

| CS–alginate | Microcapsules | No | No | No loss of activity after five reuses | Not indicated | [203] | |

| Fe3O4@SiO2@ {CS/HA}3 | NPs | No | EDAC/NHS | 85% of activity after 9 reuses | 78% of activity after 30 days at 4 °C | [206] | |

| CS–SA | Microcapsules | No | No | 20% of activity after five reuses | Not indicated | [212] | |

| CS | - | No | No | 90% of activity after 12 reuses | 42% of activity after 4 days and more at −20 °C | [218] | |

| LAC | CS | Beads | No | No | 40% of activity after five reuses | 100% of activity after 30 days at 4 °C | [187] |

| CS–GA | Beads | GA | No | 20% of activity after five reuses | 50% of activity after 30 days at 4 °C | [187] | |

| MnFe2O4–CS | NPs | No | GA | no loss of activity after five reuses | No loss of activity after 30 days at 4 °C | [188] | |

| CS | Beads | No | GP | >55% of activity after 11 reuses | 57% of activity after 30 days at 4 °C | [199] | |

| MACS–NIL–Cu | NPs | - | - | 93.2% of activity after fivereuses | 95% of activity after 30 days at 4 °C | [204] | |

| CA–Ca–SBE | Beads | No | No | 83.1% of activity after 10 reuses | 92% of activity after 50 days at 4 °C | [214] | |

| SiO2–Ca–CS | - | No | No | 90–50% of activity after four reuses depending on CS | 70% of activity after 70 days at 4 °C | [216] | |

| β-galactosidase | CS | Microspheres | No | GA | Not indicated | 100% of activity after 105 days at 4 °C | [179] |

| CS–GP | Beads | GP | GP | No loss of activity after 25 reuses | Not indicated | [200] | |

| SiO2–Me–CS | - | No | No | Not indicated | Not indicated | [205] | |

| PANI–CS–Ag | - | No | No | 94% of activity after 10 reuses | 94% of activity after 60 days at 4 °C | [217] | |

| β-glucosidase | Fe3O4–CS/GA/ AB-NTA-Ni2+ | NPs | GA | 6-His tags of enzymes interacted with Ni2+ | 40% of activity after fivereuses | Not indicated | [190] |

| Endoglucanase | NPs | GA | 10% of activity after fivereuses | Not indicated | [190] | ||

| Catalase | CS/ZnO/Fe2O3 | - | No | No | 45% of activity after 10 reuses | 47% of activity after 60 days at 4 °C | [215] |

| HRP | PMA-co-PAA@CS fibers | Membrane | EDAC/NHS | GA | 70% of activity after 10 reuses | 80% of activity after 35 days at 30 °C | [184] |

| ACS | Membrane | no | NHS | >60% of activity after 10 reuses | Not indicated | [211] | |

| HRP&GOx | Cellulose–CS@DA | Beads | no | DA | 61.2% of activity after sixreuses | 88.8% of activity after 60 days at 4 °C | [210] |

| SPase | CS–CaP | Nano- flower | TPP | no | 80% of activity after 10 reuses | 75% of activity after 15 days at 4 °C | [209] |

| 7α-HSDH and 7β-HSDH | CM | Microspheres | TPP | GA | >85% of activity after sixreuses | Not indicated | [176] |

| Inulinase | CS | Beads | TPP | GA | 78.2% of activity after ninereuses | Not indicated | [177] |

| CS/Fe3O4 | NPs | no | EDAC/NHS | 50% of activity after 10 reuses | Not indicated | [202] | |

| INU | CSB | Beads | no | GA | 45% of activity after 12 reuses | Not indicated | [192] |

| Tripsin | GA–ZnO/CS | NPs | no | GA | 50% of activity after ninereuses | 50% of activity after 90 days at 4 °C | [181] |

| Dextran- sucrase | CS | Beads | GA | GA | 22% of activity after 10 reuses | 60% of activity after 28 days at 4 °C | [182] |

| βG and ARA (combi-CLEA) | CS | Beads | TPP | No | Not indicated | 100% activity after 91 days at 16 °C | [193] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikoshvili, L.Z.; Tikhonov, B.B.; Ivanov, P.E.; Stadolnikova, P.Y.; Sulman, M.G.; Matveeva, V.G. Recent Progress in Chitosan-Containing Composite Materials for Sustainable Approaches to Adsorption and Catalysis. Catalysts 2023, 13, 367. https://doi.org/10.3390/catal13020367

Nikoshvili LZ, Tikhonov BB, Ivanov PE, Stadolnikova PY, Sulman MG, Matveeva VG. Recent Progress in Chitosan-Containing Composite Materials for Sustainable Approaches to Adsorption and Catalysis. Catalysts. 2023; 13(2):367. https://doi.org/10.3390/catal13020367

Chicago/Turabian StyleNikoshvili, Linda Z., Boris B. Tikhonov, Pavel E. Ivanov, Polina Y. Stadolnikova, Mikhail G. Sulman, and Valentina G. Matveeva. 2023. "Recent Progress in Chitosan-Containing Composite Materials for Sustainable Approaches to Adsorption and Catalysis" Catalysts 13, no. 2: 367. https://doi.org/10.3390/catal13020367

APA StyleNikoshvili, L. Z., Tikhonov, B. B., Ivanov, P. E., Stadolnikova, P. Y., Sulman, M. G., & Matveeva, V. G. (2023). Recent Progress in Chitosan-Containing Composite Materials for Sustainable Approaches to Adsorption and Catalysis. Catalysts, 13(2), 367. https://doi.org/10.3390/catal13020367