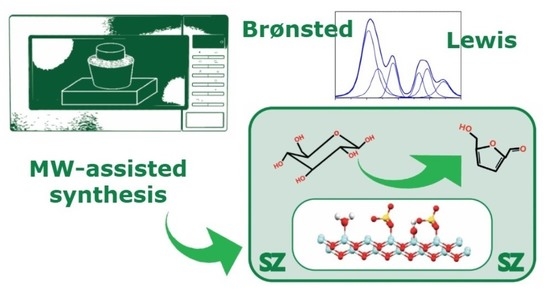

Innovative Synthetic Approaches for Sulphate-Promoted Catalysts for Biomass Valorisation

Abstract

:1. Introduction

2. Results and Discussion

2.1. MW-Assisted Synthesis of ZrO2

2.2. MW-Assisted Synthesis of SZ Powders

2.3. SZ as Catalyst for Biomass Valorization

2.3.1. FTIR Study of Surface Properties of SZ Catalysts

2.3.2. Catalytic Tests in Glucose Hydrolysis

3. Discussion

- (i)

- S1Z_5 (by IWI xerogel) partially amorphous, showing surface sulphates with a less pronounced covalent character and presenting weak L and B acid sites;

- (ii)

- S2Z_WI (by WI on t-ZrO2) having surface sulphates with a covalent character and presenting weak L and B sites;

- (iii)

- S2Z_8 (by WI on t-ZrO2) that has surface sulphate species with covalent character and present L and B acid sites of medium strength;

- (iv)

- a ‘model’ SZ (obtained from standard precipitation route) presenting strong L and B acid sites.

4. Materials and Methods

4.1. Synthesis

4.2. Characterizations

4.3. Catalytic Tests

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hino, M.; Arata, K. Synthesis of Solid Superacid Catalyst with Acid Strength of H0 ⩽ −16.04. J. Chem. Soc. Chem. Commun. 1980, 18, 851–852. [Google Scholar] [CrossRef]

- Song, X.; Sayari, A. Sulfated Zirconia-Based Strong Solid-Acid Catalysts: Recent Progress. Catal. Rev. 1996, 38, 329–412. [Google Scholar] [CrossRef]

- Yan, G.X.; Wang, A.; Wachs, I.E.; Baltrusaitis, J. Critical Review on the Active Site Structure of Sulfated Zirconia Catalysts and Prospects in Fuel Production. Appl. Catal. Gen. 2019, 572, 210–225. [Google Scholar] [CrossRef]

- Comelli, R.A.; Vera, C.R.; Parera, J.M. Influence of ZrO2 Crystalline Structure and Sulfate Ion Concentration on the Catalytic Activity of SO4−2–ZrO2. J. Catal. 1995, 151, 96–101. [Google Scholar] [CrossRef]

- Morterra, C.; Cerrato, G.; Signoretto, M. On the Role of the Calcination Step in the Preparation of Active (Superacid) Sulfated Zirconia Catalysts. Catal. Lett. 1996, 41, 101–109. [Google Scholar] [CrossRef]

- Stichert, W.; Schüth, F. Synthesis of Catalytically Active High Surface Area Monoclinic Sulfated Zirconia. J. Catal. 1998, 174, 242–245. [Google Scholar] [CrossRef]

- Morterra, C.; Cerrato, G.; Meligrana, G.; Signoretto, M.; Pinna, F.; Strukul, G. Catalytic Activity and Some Related Spectral Features of Yttria-Stabilised Cubic Sulfated Zirconia. Catal. Lett. 2001, 73, 113–119. [Google Scholar] [CrossRef]

- Kumari, N.; Sareen, S.; Verma, M.; Sharma, S.; Sharma, A.; Sohal, H.S.; Mehta, S.K.; Park, J.; Mutreja, V. Zirconia-Based Nanomaterials: Recent Developments in Synthesis and Applications. Nanoscale Adv. 2022, 4, 4210–4236. [Google Scholar] [CrossRef]

- Joo, J.B.; Vu, A.; Zhang, Q.; Dahl, M.; Gu, M.; Zaera, F.; Yin, Y. A Sulfated ZrO2 Hollow Nanostructure as an Acid Catalyst in the Dehydration of Fructose to 5-Hydroxymethylfurfural. ChemSusChem 2013, 6, 2001–2008. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Z.; Huang, J.; Jiang, Y. Zirconia-Based Solid Acid Catalysts for Biomass Conversion. Energy Fuels 2021, 35, 9209–9227. [Google Scholar] [CrossRef]

- Bozell, J.J.; Petersen, G.R. Technology Development for the Production of Biobased Products from Biorefinery Carbohydrates—The US Department of Energy’s “Top 10” Revisited. Green Chem. 2010, 12, 539. [Google Scholar] [CrossRef]

- Zhu, L.; Fu, X.; Hu, Y.; Hu, C. Controlling the Reaction Networks for Efficient Conversion of Glucose into 5-Hydroxymethylfurfural. ChemSusChem 2020, 13, 4812–4832. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Peng, K.; Liu, X.; Xia, Q.; Wang, Y. Comprehensive Understanding of the Role of Brønsted and Lewis Acid Sites in Glucose Conversion into 5-Hydromethylfurfural. ChemCatChem 2017, 9, 2739–2746. [Google Scholar] [CrossRef]

- Agarwal, B.; Kailasam, K.; Sangwan, R.S.; Elumalai, S. Traversing the History of Solid Catalysts for Heterogeneous Synthesis of 5-Hydroxymethylfurfural from Carbohydrate Sugars: A Review. Renew. Sustain. Energy Rev. 2018, 82, 2408–2425. [Google Scholar] [CrossRef]

- Kang, S.; Fu, J.; Zhang, G. From Lignocellulosic Biomass to Levulinic Acid: A Review on Acid-Catalyzed Hydrolysis. Renew. Sustain. Energy Rev. 2018, 94, 340–362. [Google Scholar] [CrossRef]

- Yang, G.; Pidko, E.A.; Hensen, E.J.M. Mechanism of Brønsted Acid-Catalyzed Conversion of Carbohydrates. J. Catal. 2012, 295, 122–132. [Google Scholar] [CrossRef]

- Osatiashtiani, A.; Lee, A.F.; Brown, D.R.; Melero, J.A.; Morales, G.; Wilson, K. Bifunctional SO4/ZrO2 Catalysts for 5-Hydroxymethylfufural (5-HMF) Production from Glucose. Catal. Sci. Technol. 2014, 4, 333–342. [Google Scholar] [CrossRef] [Green Version]

- Kitchen, H.J.; Vallance, S.R.; Kennedy, J.L.; Tapia-Ruiz, N.; Carassiti, L.; Harrison, A.; Whittaker, A.G.; Drysdale, T.D.; Kingman, S.W.; Gregory, D.H. Modern Microwave Methods in Solid-State Inorganic Materials Chemistry: From Fundamentals to Manufacturing. Chem. Rev. 2014, 114, 1170–1206. [Google Scholar] [CrossRef]

- Tompsett, G.A.; Conner, W.C.; Yngvesson, K.S. Microwave Synthesis of Nanoporous Materials. ChemPhysChem 2006, 7, 296–319. [Google Scholar] [CrossRef]

- Zhu, Y.-J.; Chen, F. Microwave-Assisted Preparation of Inorganic Nanostructures in Liquid Phase. Chem. Rev. 2014, 114, 6462–6555. [Google Scholar] [CrossRef]

- Mirzaei, A.; Neri, G. Microwave-Assisted Synthesis of Metal Oxide Nanostructures for Gas Sensing Application: A Review. Sens. Actuators B Chem. 2016, 237, 749–775. [Google Scholar] [CrossRef]

- Manjunatha, S.; Dharmaprakash, M.S. Microwave Assisted Synthesis of Cubic Zirconia Nanoparticles and Study of Optical and Photoluminescence Properties. J. Lumin. 2016, 180, 20–24. [Google Scholar] [CrossRef]

- Hembram, K.P.S.S.; Mohan Rao, G. Microwave Synthesis of Zirconia Nanoparticles. J. Nanosci. Nanotechnol. 2008, 8, 4159–4162. [Google Scholar] [CrossRef] [PubMed]

- Bondioli, F.; Ferrari, A.M.; Leonelli, C.; Siligardi, C.; Pellacani, G.C. Microwave-Hydrothermal Synthesis of Nanocrystalline Zirconia Powders. J. Am. Ceram. Soc. 2001, 84, 2728–2730. [Google Scholar] [CrossRef]

- Liang, J.; Deng, Z.; Jiang, X.; Li, F.; Li, Y. Photoluminescence of Tetragonal ZrO2 Nanoparticles Synthesized by Microwave Irradiation. Inorg. Chem. 2002, 41, 3602–3604. [Google Scholar] [CrossRef] [PubMed]

- Batool, T.; Bukhari, B.S.; Riaz, S.; Batoo, K.M.; Raslan, E.H.; Hadi, M.; Naseem, S. Microwave Assisted Sol-Gel Synthesis of Bioactive Zirconia Nanoparticles—Correlation of Strength and Structure. J. Mech. Behav. Biomed. Mater. 2020, 112, 104012. [Google Scholar] [CrossRef]

- Fetter, G.; Bosch, P.; Pez, T.L. ZrO2 and Cu/ZrO2 Sol-Gel Synthesis in Presence of Microwave Irradiation. J. Sol-Gel Sci. Technol. 2002, 23, 199–203. [Google Scholar] [CrossRef]

- Dwivedi, R.; Maurya, A.; Verma, A.; Prasad, R.; Bartwal, K.S. Microwave Assisted Sol–Gel Synthesis of Tetragonal Zirconia Nanoparticles. J. Alloys Compd. 2011, 509, 6848–6851. [Google Scholar] [CrossRef]

- Silva Junior, E.; Antonio, S.G.; Longo, E. Synthesis and Structural Evolution of Partially and Fully Stabilized ZrO2 from a Versatile Method Aided by Microwave Power. Ceram. Int. 2018, 44, 3517–3522. [Google Scholar] [CrossRef] [Green Version]

- Mishra, R.R.; Sharma, A.K. Microwave–Material Interaction Phenomena: Heating Mechanisms, Challenges and Opportunities in Material Processing. Compos. Part Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Basak, T. A Review on the Susceptor Assisted Microwave Processing of Materials. Energy 2016, 97, 306–338. [Google Scholar] [CrossRef]

- Plyler, E.K. Infrared Spectra of Methanol, Ethanol, and n-Propanol. J. Res. Natl. Bur. Stand. 1952, 48, 281. [Google Scholar] [CrossRef]

- Southon, P.D.; Bartlett, J.R.; Woolfrey, J.L.; Ben-Nissan, B. Formation and Characterization of an Aqueous Zirconium Hydroxide Colloid. Chem. Mater. 2002, 14, 4313–4319. [Google Scholar] [CrossRef]

- Phillippi, C.M.; Mazdiyasni, K.S. Infrared and Raman Spectra of Zirconia Polymorphs. J. Am. Ceram. Soc. 1971, 54, 254–258. [Google Scholar] [CrossRef]

- Ayral, A.; Assih, T.; Abenoza, M.; Phalippou, J.; Lecomte, A.; Dauger, A. Zirconia by the Gel Route. J. Mater. Sci. 1990, 25, 1268–1274. [Google Scholar] [CrossRef]

- Arata, K. Organic Syntheses Catalyzed by Superacidic Metal Oxides: Sulfated Zirconia and Related Compounds. Green Chem. 2009, 11, 1719. [Google Scholar] [CrossRef]

- Yadav, G.D.; Nair, J.J. Sulfated Zirconia and Its Modified Versions as Promising Catalysts for Industrial Processes. Microporous Mesoporous Mater. 1999, 33, 1–48. [Google Scholar] [CrossRef]

- Erdey, L.; Gál, S.; Liptay, G. Thermoanalytical Properties of Analytical-Grade Reagents. Talanta 1964, 11, 913–940. [Google Scholar] [CrossRef]

- Kiyoura, R.; Urano, K. Mechanism, Kinetics, and Equilibrium of Thermal Decomposition of Ammonium Sulfate. Ind. Eng. Chem. Process Des. Dev. 1970, 9, 489–494. [Google Scholar] [CrossRef]

- Fernández López, E.; Sánchez Escribano, V.; Panizza, M.; Carnasciali, M.M.; Busca, G. Vibrational and Electronic Spectroscopic Properties of Zirconia Powders. J. Mater. Chem. 2001, 11, 1891–1897. [Google Scholar] [CrossRef]

- Platero, E.E.; Mentruit, M.P. IR Characterization of Sulfated Zirconia Derived from Zirconium Sulfate. Catal. Lett. 1995, 30, 31–39. [Google Scholar] [CrossRef]

- Cerrato, G.; Bolis, V. Lewis and Bronsted Acidity at the Surface of Sulfate- Doped ZrO2 Catalysts. Catal. Today 1993, 17, 505–515. [Google Scholar] [CrossRef]

- Morterra, C.; Cerrato, G.; Ardizzone, S.; Bianchi, C.L.; Signoretto, M.; Pinna, F. Surface Features and Catalytic Activity of Sulfated Zirconia Catalysts from Hydrothermal Precursors. Phys. Chem. Chem. Phys. 2002, 4, 3136–3145. [Google Scholar] [CrossRef]

- Sarzanini, C.; Sacchero, G.; Pinna, F.; Signoretto, M.; Cerrato, G.; Morterra, C. Amount and Nature of Sulfates at the Surface of Sulfate-Doped Zirconia Catalysts. J. Mater. Chem. 1995, 5, 353. [Google Scholar] [CrossRef]

- Nakamoto, K. Infrared and Raman Spectra of Inorganic and Coordination Compounds, 6th ed.; Wiley: Hoboken, NJ, USA, 2009; ISBN 978-0-471-74339-2. [Google Scholar]

- Morterra, C.; Cerrato, G.; Pinna, F.; Signoretto, M.; Strukul, G. On the Acid-Catalyzed Isomerization of Light Paraffins over a ZrO2/SO4 System: The Effect of Hydration. J. Catal. 1994, 149, 181–188. [Google Scholar] [CrossRef]

- Tsyganenko, A.A.; Filimonov, V.N. Infrared Spectra of Surface Hydroxyl Groups and Crystalline Structure of Oxides. J. Mol. Struct. 1973, 19, 579–589. [Google Scholar] [CrossRef]

- Morterra, C.; Cerrato, G.; Ferroni, L. Surface Characterization of Yttria-Stabilized Tetragonal ZrO2. Part 3.—CO2 Adsorption and the CO2–CO Interaction. J. Chem. Soc. Faraday Trans. 1995, 91, 125–132. [Google Scholar] [CrossRef]

- Morterra, C.; Cerrato, G.; Ferroni, L.; Negro, A.; Montanaro, L. Surface Characterization of Tetragonal ZrO2. Appl. Surf. Sci. 1993, 65–66, 257–264. [Google Scholar] [CrossRef]

- Bolis, V.; Fubini, B.; Garrone, E.; Morterra, C. Thermodynamic and Vibrational Characterization of CO Adsorption on Variously Pretreated Anatase. J. Chem. Soc. Faraday Trans. 1 Phys. Chem. Condens. Phases 1989, 85, 1383. [Google Scholar] [CrossRef]

- Morterra, C.; Meligrana, G.; Cerrato, G.; Solinas, V.; Rombi, E.; Sini, M.F. 2,6-Dimethylpyridine Adsorption on Zirconia and Sulfated Zirconia Systems. An FTIR and Microcalorimetric Study. Langmuir 2003, 19, 5344–5356. [Google Scholar] [CrossRef]

- McCue, A.J.; Mutch, G.A.; McNab, A.I.; Campbell, S.; Anderson, J.A. Quantitative Determination of Surface Species and Adsorption Sites Using Infrared Spectroscopy. Catal. Today 2016, 259, 19–26. [Google Scholar] [CrossRef]

- Morterra, C.; Cerrato, G.; Meligrana, G. Revisiting the Use of 2,6-Dimethylpyridine Adsorption as a Probe for the Acidic Properties of Metal Oxides. Langmuir 2001, 17, 7053–7060. [Google Scholar] [CrossRef]

- Onfroy, T.; Clet, G.; Houalla, M. Quantitative IR Characterization of the Acidity of Various Oxide Catalysts. Microporous Mesoporous Mater. 2005, 82, 99–104. [Google Scholar] [CrossRef]

- Morterra, C.; Cerrato, G.; Bolis, V.; Di Ciero, S.; Signoretto, M. On the Strength of Lewis- and Bronsted-Acid Sites at the Surface of Sulfated Zirconia Catalysts. J. Chem. Soc. Faraday Trans. 1997, 93, 1179–1184. [Google Scholar] [CrossRef]

- Girisuta, B.; Janssen, L.P.B.M.; Heeres, H.J. Green Chemicals A Kinetic Study on the Conversion of Glucose to Levulinic Acid. Chem. Eng. Res. Des. 2006, 84, 339–349. [Google Scholar] [CrossRef]

- Yan, H.; Yang, Y.; Tong, D.; Xiang, X.; Hu, C. Catalytic Conversion of Glucose to 5-Hydroxymethylfurfural over SO42−/ZrO2 and SO42−/ZrO2–Al2O3 Solid Acid Catalysts. Catal. Commun. 2009, 10, 1558–1563. [Google Scholar] [CrossRef]

- Qu, Y.; Zhao, Y.; Xiong, S.; Wang, C.; Wang, S.; Zhu, L.; Ma, L. Conversion of Glucose into 5-Hydroxymethylfurfural and Levulinic Acid Catalyzed by SO42–/ZrO2 in a Biphasic Solvent System. Energy Fuels 2020, 34, 11041–11049. [Google Scholar] [CrossRef]

- Muñoz Tabares, J.A.; Anglada, M.J. Quantitative Analysis of Monoclinic Phase in 3Y-TZP by Raman Spectroscopy. J. Am. Ceram. Soc. 2010, 93, 1790–1795. [Google Scholar] [CrossRef]

- Toraya, H.; Yoshimura, M.; Somiya, S. Calibration Curve for Quantitative Analysis of the Monoclinic-Tetragonal ZrO2 System by X-ray Diffraction. J. Am. Ceram. Soc. 1984, 67, C-119–C-121. [Google Scholar] [CrossRef]

- Priecel, P.; Lopez-Sanchez, J.A. Advantages and Limitations of Microwave Reactors: From Chemical Synthesis to the Catalytic Valorization of Biobased Chemicals. ACS Sustain. Chem. Eng. 2019, 7, 3–21. [Google Scholar] [CrossRef] [Green Version]

| Catalyst | Preparation Method | Crystalline Phase | Effective (Nominal) Sulphate w/w% |

|---|---|---|---|

| S2Z_W1 | WI on t-ZrO2 | t- + m-ZrO2 (Vm = 0.04) | 0.67 |

| S1Z_5 | IWI on xerogel | t-ZrO2 + amorphous | 2.80 (5) |

| S2Z_8 | IWI on t-ZrO2 | t-ZrO2 1 | 6.46 (8) |

| SZ_p | precipitation route | t-ZrO2 1 | 5.25 (8) |

| Catalyst | Reaction Condition | Conversion % | C Balance % | Product Yield (Selectivity) % | ||

|---|---|---|---|---|---|---|

| 5-HMF | LA | HCOOH | ||||

| S2Z_W1 | 180 °C, 1 h | 60.0 | 47.3 | 26.1 (43.4) | 0.17 (0.28) | 1.02 (1.70) |

| S2Z_W1 | 180 °C, 3 h | 76.0 | 47.7 | 28.0 (36.9) | 0.17 (0.22) | 6.74 (8.87) |

| SZ_p | 180 °C, 3 h | 88.9 | 28.9 | 17.0 (19.1) | 3.43 (3.86) | 4.09 (4.60) |

| S2Z_8 | 180 °C, 3 h | 59.0 | 16.6 | 10.1 (17.1) | 0.12 (0.21) | 0.00 (0.00) |

| S2Z_WI | 180 °C, 5 h | 78.0 | 49.3 | 34.9 (44.8) | 0.18 (0.23) | 1.71 (2.19) |

| S2Z_8 | 180 °C, 5 h | 91.4 | 24.0 | 14.6 (15.9) | 3.29 (3.60) | 2.67 (2.92) |

| S1Z_5 | 180 °C, 5 h | 91.3 | 7.7 | 6.4 (7.1) | 0.12 (0.13) | 0.24 (0.26) |

| SO42−/ZrO2 [17] | 120 °C, 6 h | 23.3 | 99 | (3.7) | – | – |

| SO42−/ZrO2 [57] | 130 °C, 4 h 1 | 95.2 | – | (19.2) | – | – |

| SO42−/ZrO2 [58] | 160 °C, 2 h 2 | 52 | – | 42 | 19 | 21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giordana, A.; Pizzolitto, C.; Ghedini, E.; Signoretto, M.; Operti, L.; Cerrato, G. Innovative Synthetic Approaches for Sulphate-Promoted Catalysts for Biomass Valorisation. Catalysts 2023, 13, 1094. https://doi.org/10.3390/catal13071094

Giordana A, Pizzolitto C, Ghedini E, Signoretto M, Operti L, Cerrato G. Innovative Synthetic Approaches for Sulphate-Promoted Catalysts for Biomass Valorisation. Catalysts. 2023; 13(7):1094. https://doi.org/10.3390/catal13071094

Chicago/Turabian StyleGiordana, Alessia, Cristina Pizzolitto, Elena Ghedini, Michela Signoretto, Lorenza Operti, and Giuseppina Cerrato. 2023. "Innovative Synthetic Approaches for Sulphate-Promoted Catalysts for Biomass Valorisation" Catalysts 13, no. 7: 1094. https://doi.org/10.3390/catal13071094

APA StyleGiordana, A., Pizzolitto, C., Ghedini, E., Signoretto, M., Operti, L., & Cerrato, G. (2023). Innovative Synthetic Approaches for Sulphate-Promoted Catalysts for Biomass Valorisation. Catalysts, 13(7), 1094. https://doi.org/10.3390/catal13071094