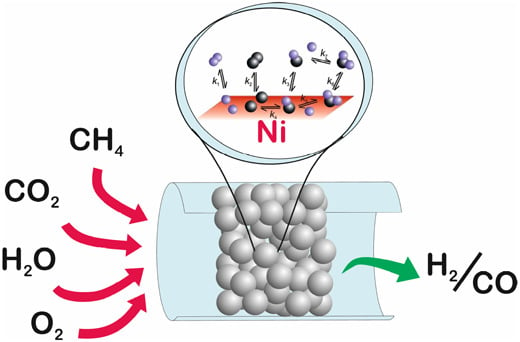

Surface Reaction Kinetics of Steam- and CO2-Reforming as Well as Oxidation of Methane over Nickel-Based Catalysts

Abstract

:1. Introduction

2. Experimental Setup

| Fuel composition | CH4 (vol.%) | O2 (vol.%) | CO2 (vol.%) | H2 (vol.%) | H2O (vol.%) | N2 (vol.%) |

|---|---|---|---|---|---|---|

| CH4/O2 | 1.33 | 0.81 | - | - | - | 97.86 |

| CH4/H2O | 1.60 | - | - | - | 2.00 | 96.40 |

| CH4/CO2 | 2.00 | - | 2.00 | - | - | 96.00 |

| CH4/CO2/H2 | 1.62 | - | 2.08 | 1.80 | - | 94.50 |

| CH4/CO2/H2O | 1.67 | - | 2.13 | - | 2.13 | 94.07 |

3. Mathematical Model and Numerical Simulation

3.1. Modeling the Flow Field in the Packed Bed Reactor

3.2. Modeling the Surface Reaction Kinetics

3.3. Sensitivity Analysis

3.4. Reaction Flow Analysis

3.5. Thermodynamic Consistency

4. Surface Reaction Mechanism

| ORx | Reaction | Reaction Enthalpy |

|---|---|---|

| Methane Steam Reforming | ||

| OR1 | CH4 + H2O↔CO + 3H2 | ΔH°298 = 205.9 kJ/mol |

| OR2 | CH4 + 2H2O↔CO2 + 4H2 | ΔH°298 = 164.7 kJ/mol |

| Methane dry reforming | ||

| OR3 | CH4 + CO2↔2CO + 2H2 | ΔH°298 = 247.3 kJ/mol |

| Methane partial oxidation | ||

| OR4 | CH4 + 1/2O2↔CO + 2H2 | ΔH°298 = −35.6 kJ/mol |

| Methane total oxidation | ||

| OR5 | CH4 + 2O2↔CO2 + 2H2O | ΔH°298 = −880 kJ/mol |

| Water-gas shift | ||

| OR6 | CO + H2O↔CO2 + H2 | ΔH°298 = −41.2 kJ/mol |

| Methanation | ||

| OR7 | CO + 3H2↔CH4 + H2O | ΔH°298 = −206 kJ/mol |

| OR8 | 2CO + 2H2↔CH4 + CO2 | ΔH°298 = −247 kJ/mol |

| Boudouard reaction | ||

| OR9 | 2CO↔* C + CO2 | ΔH°298 = −172.4 kJ/mol |

| Methane cracking | ||

| OR10 | CH4↔* C + 2H2 | ΔH°298 = 74.9 kJ/mol |

| Gasification of carbon | ||

| OR11 | * C + H2O↔CO + H2 | ΔH°298 = 131.3 kJ/mol |

| OR12 | * C + O2↔CO2 | ΔH°298 = −393.5 kJ/mol |

4.1. H2 on Ni Surface

| Rx | Reaction | A/(cm2/mol·s)/S0 | β | Ea/(kJ/mol) | ɛI (kJ/mol) |

|---|---|---|---|---|---|

| R1 | H2 +Ni (s) + Ni(s) → H(s) + H(s) | 3.00 × 10−2 | 0.000 | 5.0 | |

| R2 | H(s) + H(s) → Ni(s) + Ni(s) +H2 | 2.54 × 10+20 | 0.000 | 95.2 | |

| R3 | O2 + Ni(s) + Ni(s) → O(s) + O(s) | 4.36 × 10−2 | −0.206 | 1.5 | |

| R4 | O(s) + O(s) → Ni(s) + Ni(s) + O2 | 1.18 × 10+21 | 0.823 | 468.9 | |

| R5 | H2O + Ni(s) → H2O(s) | 1.00 × 10−1 | 0.000 | 0.0 | |

| R6 | H2O(s) → H2O + Ni(s) | 3.73 × 10+12 | 0.000 | 60.7 | |

| R7 | CO2 + Ni(s) → CO2(s) | 7.00 × 10−6 | 0.000 | 0.0 | |

| R8 | CO2(s) → CO2 + Ni(s) | 6.44 × 10+7 | 0.000 | 25.9 | |

| R9 | CO + Ni(s) → CO(s) | 5.00 × 10−1 | 0.000 | 0.0 | |

| R10 | CO(s) → CO + Ni(s) | 3.56 × 10+11 | 0.000 | 111.2 | −50.0 θCO(s) |

| R11 | CH4 + Ni(s) → CH4(s) | 8.00 × 10−3 | 0.000 | 0.0 | |

| R12 | CH4(s) → CH4 + Ni(s) | 8.70 × 10+15 | 0.000 | 37.5 | |

| R13 | CH4(s) + Ni(s) → CH3(s) + H(s) | 1.54 × 10+21 | 0.087 | 55.8 | |

| R14 | CH3(s) + H(s) → CH4(s) + Ni(s) | 1.44 × 10+22 | −0.087 | 63.4 | |

| R15 | CH3(s) + Ni(s) → CH2(s) + H(s) | 1.54 × 10+24 | 0.087 | 98.1 | |

| R16 | CH2(s) + H(s) → CH3(s) + Ni(s) | 3.09 ×10+23 | −0.087 | 57.2 | |

| R17 | CH2(s) +Ni(s) → CH(s) + H(s) | 3.70 × 10+24 | 0.087 | 95.2 | |

| R18 | CH(s) + H(s) → CH2(s) + Ni(s) | 9.77 × 10+24 | −0.087 | 81.0 | |

| R19 | CH(s) + Ni(s) → C(s) + H(s) | 9.88 × 10+20 | 0.500 | 21.9 | |

| R20 | C(s) + H(s) → CH(s) + Ni(s) | 1.70 × 10+24 | −0.500 | 157.9 | |

| R21 | CH4(s) + O(s) → CH3(s) + OH(s) | 5.62 × 10+24 | −0.101 | 92.7 | |

| R22 | CH3(s) + OH(s) → CH4(s) + O(s) | 2.98 × 10+22 | 0.101 | 25.8 | |

| R23 | CH3(s) + O(s) → CH2(s) + OH(s) | 1.22 × 10+25 | −0.101 | 134.6 | |

| R24 | CH2(s) + OH(s) → CH3(s) + O(s) | 1.39 × 10+21 | 0.101 | 19.0 | |

| R25 | CH2(s) + O(s) → CH(s) + OH(s) | 1.22 × 10+25 | −0.101 | 131.3 | |

| R26 | CH(s) + OH(s) → CH2(s) + O(s) | 4.40 × 10+22 | 0.101 | 42.4 | |

| R27 | CH(s) + O(s) → C(s) + OH(s) | 2.47 × 10+21 | 0.312 | 57.7 | |

| R28 | C(s) + OH(s) → CH(s) + O(s) | 2.43 × 10+21 | −0.312 | 118.9 | |

| R29 | H2O(s) + Ni(s) → H(s) + OH(s) | 3.67 ×10+21 | −0.086 | 92.9 | |

| R30 | H(s) + OH(s) → H2O(s) + Ni(s) | 1.85 ×10+20 | 0.086 | 41.5 | |

| R31 | H(s) + O(s) → OH(s) + Ni(s) | 3.95 × 10+23 | −0.188 | 104.3 | |

| R32 | OH(s) + Ni(s) → H(s) + O(s) | 2.25 × 10+20 | 0.188 | 29.6 | |

| R33 | OH(s) + OH(s) → H2O(s) + O(s) | 2.34 × 10+20 | 0.274 | 92.3 | |

| R34 | H2O(s) + O(s) → OH(s) + OH(s) | 8.14 × 10+24 | −0.274 | 218.4 | |

| R35 | C(s) + O(s) → CO(s) + Ni(s) | 3.40 × 10+23 | 0.000 | 148.1 | |

| R36 | CO(s) + Ni(s) → C(s) + O(s) | 1.75 × 10+13 | 0.000 | 116.2 | |

| R37 | CO(s) + H(s) → C(s) + OH(s) | 3.52 × 10+18 | −0.188 | 105.4 | |

| R38 | C(s) + OH(s) → H(s) + CO(s) | 3.88 × 10+25 | 0.188 | 62.5 | −50.0 θCO(s) |

| R39 | CO(s) + CO(s) → C(s) + CO2(s) | 1.62 × 10+14 | 0.500 | 241.7 | −50.0 θCO(s) |

| R40 | CO2(s) + C(s) → CO(s) + CO(s) | 7.29 × 10+28 | −0.500 | 239.2 | −100.0 θCO(s) |

| R41 | CO(s) + O(s) → CO2(s) + Ni(s) | 2.00 × 10+19 | 0.000 | 123.6 | |

| R42 | CO2(s) + Ni(s) → CO(s) + O(s) | 4.64 × 10+23 | −1.000 | 89.3 | −50.0 θCO(s) |

| R43 | CO(s) + OH(s) → COOH(s) + Ni(s) | 6.00 × 10+21 | 0.213 | 97.6 | |

| R44 | COOH(s) + Ni(s) → CO(s) + OH(s) | 1.46 × 10+24 | −0.213 | 54.3 | |

| R45 | CO2(s) + H(s) → COOH(s) + Ni(s) | 6.25 × 10+24 | −0.475 | 117.2 | |

| R46 | COOH(s) + Ni(s) → CO2(s) + H(s) | 3.73 × 10+20 | 0.475 | 33.6 | |

| R47 | CO(s) + H(s) → HCO(s) + Ni(s) | 4.00 × 10+2° | −1.000 | 132.2 | −50.0 θCO(s) |

| R48 | HCO(s) + Ni(s) → CO(s) + H(s) | 3.71 × 10+21 | 0.000 | 0.0 | |

| R49 | HCO(s) + Ni(s) → CH(s) + O(s) | 3.79 × 10+14 | 0.000 | 81.9 | +50.0θCO(s) |

| R50 | CH(s) + O(s) → HCO(s) + Ni(s) | 4.59 × 10+20 | 0.000 | 109.9 | |

| R51 | H(s) + COOH(s) → HCO(s) + OH(s) | 6.00 × 10+22 | −1.163 | 104.8 | |

| R52 | HCO(s) + OH(s) → COOH(s) + H(s) | 2.28 × 10+20 | 0.263 | 15.9 |

4.2. O2 on Ni Surface

4.3. H2O on Ni Surface

4.4. CO on Ni Surface

4.5. CH4 on Ni Surface

4.6. C on the Ni Surface

4.7. COOH on Ni Surface

4.8. HCO on Ni surface

5. Results and Discussion

5.1. Methane Catalytic Partial Oxidation (CPOX)

5.2. Methane Steam Reforming (SR)

5.3. Methane Dry Reforming (DR)

5.4. Influence of H2 and H2O on Methane Reforming with CO2

6. Summary

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rostrup-Nielsen, J.; Dybkjaer, I.; Aasberg-Petersen, K. Synthesis gas for large scale fischer-tropsch synthesis. Am. Chem. Soc. Div. Pet. Chem. Prepr. 2000, 45, 186–189. [Google Scholar]

- Rostrup-Nielsen, J.R.; Sehested, J.; Nørskov, J.K. Hydrogen and synthesis gas by steam- and CO2 reforming. In Advances in Catalysis; Elsevier: Amherst, MA, USA, 2002; Volume 47, pp. 65–139. [Google Scholar]

- Iglesia, E. Design, synthesis, and use of cobalt-based fischer-tropsch synthesis catalysts. Appl. Catal. A 1997, 161, 59–78. [Google Scholar] [CrossRef]

- Rostrup-Nielsen, J.R. New aspects of syngas production and use. Catal. Today 2000, 63, 159–164. [Google Scholar] [CrossRef]

- Hickman, D.A.; Schmidt, L.D. Production of syngas by direct catalytic oxidation of methane. Science 1993, 259, 343–346. [Google Scholar] [CrossRef] [PubMed]

- Peña, M.A.; Gómez, J.P.; Fierro, J.L.G. New catalytic routes for syngas and hydrogen production. Appl. Catal. A 1996, 144, 7–57. [Google Scholar] [CrossRef]

- Shao, Z.; Haile, S.M. A high-performance cathode for the next generation of solid-oxide fuel cells. Nature 2004, 431, 170–173. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Vohs, J.M.; Gorte, R.J. Direct oxidation of hydrocarbons in a solid-oxide fuel cell. Nature 2000, 404, 265–267. [Google Scholar] [PubMed]

- Singhal, S.C. Advances in solid oxide fuel cell technology. Solid State Ionics 2000, 135, 305–313. [Google Scholar] [CrossRef]

- Aparicio, L.M. Transient isotopic studies and microkinetic modeling of methane reforming over nickel catalysts. J. Catal. 1997, 165, 262–274. [Google Scholar] [CrossRef]

- Xu, J.; Froment, G.F. Methane steam reforming, methanation and water-gas shift: I. Intrinsic kinetics. AIChE J. 1989, 35, 88–96. [Google Scholar] [CrossRef]

- Rostrup-Nielsen, J. Catalytic Steam Reforming. In Catalysis; Anderson, J., Boudart, M., Eds.; Springer: Berlin/Heidelberg, Germany, 1984; Volume 5, pp. 1–117. [Google Scholar]

- Bradford, M.C.J.; Vannice, M.A. CO2 reforming of ch4. Catal. Rev. 1999, 41, 1–42. [Google Scholar] [CrossRef]

- Zhu, Y.-A.; Chen, D.; Zhou, X.-G.; Yuan, W.-K. DFT studies of dry reforming of methane on Ni catalyst. Catal. Today 2009, 148, 260–267. [Google Scholar] [CrossRef]

- Dissanayake, D.; Rosynek, M.P.; Kharas, K.C.C.; Lunsford, J.H. Partial oxidation of methane to carbon monoxide and hydrogen over a Ni/Al2O3 catalyst. J. Catal. 1991, 132, 117–127. [Google Scholar] [CrossRef]

- Zhu, T.; Flytzani-Stephanopoulos, M. Catalytic partial oxidation of methane to synthesis gas over Ni–CeO2. Appl. Catal. A 2001, 208, 403–417. [Google Scholar] [CrossRef]

- Tang, S.; Lin, J.; Tan, K.L. Partial oxidation of methane to syngas over Ni/MgO, Ni/CaO and Ni/CeO2. Catal. Lett. 1998, 51, 169–175. [Google Scholar] [CrossRef]

- Goula, M.A.; Lemonidou, A.A.; Grünert, W.; Baerns, M. Methane partial oxidation to synthesis gas using nickel on calcium aluminate catalysts. Catal. Today 1996, 32, 149–156. [Google Scholar] [CrossRef]

- Liu, Z.-W.; Jun, K.-W.; Roh, H.-S.; Park, S.-E.; Oh, Y.-S. Partial oxidation of methane over nickel catalysts supported on various aluminas. Korean J. Chem. Eng. 2002, 19, 735–741. [Google Scholar] [CrossRef]

- Vernon, P.F.; Green, M.H.; Cheetham, A.; Ashcroft, A. Partial oxidation of methane to synthesis gas. Catal. Lett. 1990, 6, 181–186. [Google Scholar] [CrossRef]

- Li, C.; Yu, C.; Shen, S. Role of the surface state of Ni/Al2O3 in partial oxidation of CH4. Catal. Lett. 2000, 67, 139–145. [Google Scholar] [CrossRef]

- Rostrup-Nielsen, J.R. Sulfur-passivated nickel-catalysts for carbon-free steam reforming of methane. J. Catal. 1984, 85, 31–43. [Google Scholar] [CrossRef]

- Trimm, D.L. Formation and removal of coke from nickel-catalyst. Catal. Rev. Sci. Eng. 1977, 16, 155–189. [Google Scholar] [CrossRef]

- Bartholomew, C.H. Carbon deposition in steam reforming and methanation. Catal. Rev. 1982, 24, 67–112. [Google Scholar] [CrossRef]

- Blekkan, E.A.; Myrstad, R.; Olsvik, O.; Rokstad, O.A. Characterization of tars and coke formed during the pyrolysis of methane in a tubular reactor. Carbon 1992, 30, 665–673. [Google Scholar] [CrossRef]

- Kahle, L.C.S.; Roussière, T.; Maier, L.; Herrera Delgado, K.; Wasserschaff, G.; Schunk, S.A.; Deutschmann, O. Methane dry reforming at high temperature and elevated pressure: Impact of gas-phase reactions. Ind. Eng. Chem. Res. 2013, 52, 11920–11930. [Google Scholar] [CrossRef]

- Wang, S.; Lu, G.Q.M. CO2 reforming of methane on Ni catalysts: Effects of the support phase and preparation technique. Appl. Catal. B 1998, 16, 269–277. [Google Scholar] [CrossRef]

- Ross, J.R.H.; vanKeulen, A.N.J.; Hegarty, M.E.S.; Seshan, K. The catalytic conversion of natural gas to useful products. Catal. Today 1996, 30, 193–199. [Google Scholar] [CrossRef]

- Ginsburg, J.M.; Pina, J.; El Solh, T.; de Lasa, H.I. Coke formation over a nickel catalyst under methane dry reforming conditions: Thermodynamic and kinetic models. Ind. Eng. Chem. Res. 2005, 44, 4846–4854. [Google Scholar] [CrossRef]

- Guo, J.; Lou, H.; Zheng, X.M. The deposition of coke from methane on a Ni/MgAl2O4 catalyst. Carbon 2007, 45, 1314–1321. [Google Scholar] [CrossRef]

- Chen, D.; Lodeng, R.; Anundskas, A.; Olsvik, O.; Holmen, A. Deactivation during carbon dioxide reforming of methane over ni catalyst: Microkinetic analysis. Chem. Eng. Sci. 2001, 56, 1371–1379. [Google Scholar] [CrossRef]

- Chen, D.; Lødeng, R.; Svendsen, H.; Holmen, A. Hierarchical multiscale modeling of methane steam reforming reactions. Ind. Eng. Chem. Res. 2010, 50, 2600–2612. [Google Scholar]

- Kunz, L.; Maier, L.; Tischer, S.; Deutschmann, O. Modeling the rate of heterogeneous reactions. In Modeling and Simulation of Heterogeneous Catalytic Reactions; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; pp. 113–148. [Google Scholar]

- Mhadeshwar, A.B.; Vlachos, D.G. Hierarchical multiscale mechanism development for methane partial oxidation and reforming and for thermal decomposition of oxygenates on Rh. J. Phys. Chem. B 2005, 109, 16819–16835. [Google Scholar] [CrossRef] [PubMed]

- Wei, J.; Iglesia, E. Isotopic and kinetic assessment of the mechanism of reactions of CH4 with CO2 or H2O to form synthesis gas and carbon on nickel catalysts. J. Catal. 2004, 224, 370–383. [Google Scholar] [CrossRef]

- Blaylock, D.W.; Zhu, Y.-A.; Green, W. Computational investigation of the thermochemistry and kinetics of steam methane reforming over a multi-faceted nickel catalyst. Top. Catal. 2011, 54, 828–844. [Google Scholar] [CrossRef]

- Blaylock, D.W.; Ogura, T.; Green, W.H.; Beran, G.J.O. Computational investigation of thermochemistry and kinetics of steam methane reforming on Ni(111) under realistic conditions. J. Phys. Chem. C 2009, 113, 4898–4908. [Google Scholar] [CrossRef]

- Wang, S.-G.; Liao, X.-Y.; Hu, J.; Cao, D.-B.; Li, Y.-W.; Wang, J.; Jiao, H. Kinetic aspect of CO2 reforming of CH4 on Ni(111): A density functional theory calculation. Surf. Sci. 2007, 601, 1271–1284. [Google Scholar] [CrossRef]

- Schwiedernoch, R.; Tischer, S.; Correa, C.; Deutschmann, O. Experimental and numerical study on the transient behavior of partial oxidation of methane in a catalytic, monolith. Chem. Eng. Sci. 2003, 58, 633–642. [Google Scholar] [CrossRef]

- Nogare, D.D.; Degenstein, N.J.; Horn, R.; Canu, P.; Schmidt, L.D. Modeling spatially resolved data of methane catalytic partial oxidation on Rh foam catalyst at different inlet compositions and flowrates. J. Catal. 2011, 277, 134–148. [Google Scholar] [CrossRef]

- Diehm, C.; Deutschmann, O. Hydrogen production by catalytic partial oxidation of methane over staged Pd/Rh coated monoliths: Spatially resolved concentration and temperature profiles. Int. J. Hydrog. Energy 2014, 39, 17998–18004. [Google Scholar] [CrossRef]

- Horn, R.; Williams, K.A.; Degenstein, N.J.; Bitsch-Larsen, A.; Dalle Nogare, D.; Tupy, S.A.; Schmidt, L.D. Methane catalytic partial oxidation on autothermal Rh and Pt foam catalysts: Oxidation and reforming zones, transport effects, and approach to thermodynamic equilibrium. J. Catal. 2007, 249, 380–393. [Google Scholar] [CrossRef]

- Donazzi, A.; Beretta, A.; Groppi, G.; Forzatti, P. Catalytic partial oxidation of methane over a 4% Rh/α-Al2O3 catalyst: Part i: Kinetic study in annular reactor. J. Catal. 2008, 255, 241–258. [Google Scholar] [CrossRef]

- Christian Enger, B.; Lødeng, R.; Holmen, A. A review of catalytic partial oxidation of methane to synthesis gas with emphasis on reaction mechanisms over transition metal catalysts. Appl. Catal. A 2008, 346, 1–27. [Google Scholar]

- De Groote, A.M.; Froment, G.F.; Kobylinski, T. Synthesis gas production from natural gas in a fixed bed reactor with reversed flow. Can. J. Chem. Eng. 1996, 74, 735–742. [Google Scholar] [CrossRef]

- Maier, L.; Schädel, B.; Herrera Delgado, K.; Tischer, S.; Deutschmann, O. Steam reforming of methane over nickel: Development of a multi-step surface reaction mechanism. Top. Catal. 2011, 54, 845–858. [Google Scholar] [CrossRef]

- Hartmann, M.; Maier, L.; Minh, H.D.; Deutschmann, O. Catalytic partial oxidation of iso-octane over rhodium catalysts: An experimental, modeling, and simulation study. Combust. Flame 2010, 157, 1771–1782, ™. [Google Scholar] [CrossRef]

- Deutschmann, O.; Tischer, S.; Kleditzsch, S.; Janardhanan, V.M.; Correa, C.; Chatterjee, D.; Mladenov, N.; Minh, H.D. DETCHEM™ software package. Available online: www.detchem.com (accessed on 26 May 2015).

- Pushnov, A.S. Calculation of average bed porosity. Chem. Petrol. Eng. 2006, 42, 14–17. [Google Scholar] [CrossRef]

- Deutschmann, O. Computational Fluid Dynamics Simulation of Catalytic Reactors. In Handbook of Heterogeneous Catalysis; Erlt, H.K.G., Schüth, F., Weitkamp, J., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2008; pp. 1811–1828. [Google Scholar]

- Kee, R.J.; Coltrin, M.E.; Glarborg, P. Heterogeneous chemistry. In Chemically Reacting Flow; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005; pp. 445–486. [Google Scholar]

- Mhadeshwar, A.B.; Vlachos, D.G. A thermodynamically consistent surface reaction mechanism for co oxidation on pt. Combust. Flame 2005, 142, 289–298. [Google Scholar] [CrossRef]

- Lee, M.B.; Yang, Q.Y.; Tang, S.L.; Ceyer, S.T. Activated dissociative chemisorption of CH4 on Ni(111): Observation of a methyl radical and implication for the pressure gap in catalysis. J. Chem. Phys. 1986, 85, 1693. [Google Scholar] [CrossRef]

- Shustorovich, E. The Bond-Order Conservation Approach to Chemisorption and Heterogeneous Catalysis: Applications and Implications; WILEY-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 1991; Volume 22, pp. 1522–2667. [Google Scholar]

- Sellers, H. The generalized ubi-qep method for modeling the energetics of reactions on transition metal surfaces. Surf. Sci. 2003, 524, 29–39. [Google Scholar] [CrossRef]

- Qin, D.; Lapszewicz, J.; Jiang, X. Comparison of partial oxidation and steam-CO2 mixed reformingof CH4 to syngas on MgO-supported metals. J. Catal. 1996, 159, 140–149. [Google Scholar] [CrossRef]

- Bartholomew, C. Hydrogen adsorption on supported cobalt, iron, and nickel. Catal. Lett. 1990, 7, 27–51. [Google Scholar] [CrossRef]

- Weatherbee, G.D.; Bartholomew, C.H. Effects of support on hydrogen adsorption/desorption kinetics of nickel. J. Catal. 1984, 87, 55–65. [Google Scholar] [CrossRef]

- Kratzer, P.; Hammer, B.; Norskov, J.K. A theoretical study of CH4 dissociation on pure and gold-alloyed Ni(111) surfaces. J. Chem. Phys. 1996, 105, 5595–5604. [Google Scholar] [CrossRef]

- Zhu, X.Y.; White, J.M. Hydrogen interaction with nickel (100): A static secondary ion mass spectroscopy study. J. Phys. Chem. 1988, 92, 3970–3974. [Google Scholar] [CrossRef]

- Bengaard, H.S.; Nørskov, J.K.; Sehested, J.; Clausen, B.S.; Nielsen, L.P.; Molenbroek, A.M.; Rostrup-Nielsen, J.R. Steam reforming and graphite formation on Ni catalysts. J. Catal. 2002, 209, 365–384. [Google Scholar] [CrossRef]

- Stuckless, J.T.; Wartnaby, C.E.; Al-Sarraf, N.; Dixon-Warren, S.J.B.; Kovar, M.; King, D.A. Oxygen chemisorption and oxide film growth on Ni{100}, {110}, and {111}: Sticking probabilities and microcalorimetric adsorption heats. J. Chem. Phys. 1997, 106, 2012–2030. [Google Scholar] [CrossRef]

- Siegbahn, P.E.M.; Wahlgren, U. A theoretical study of atomic oxygen chemisorption on the Ni(100) and Ni(111) surfaces. Int. J. Quantum Chem. 1992, 42, 1149–1169. [Google Scholar] [CrossRef]

- Stulen, R.H.; Thiel, P.A. Electron-stimulated desorption and thermal desorption spectrometry of H2O on nickel (111). Surf. Sci 1985, 157, 99–118. [Google Scholar] [CrossRef]

- Pache, T.; Steinrück, H.P.; Huber, W.; Menzel, D. The adsorption of H2O on clean and oxygen precovered Ni(111) studied by arups and tpd. Surf. Sci. 1989, 224, 195–214. [Google Scholar] [CrossRef]

- Zakharov, I.I.; Avdeev, V.I.; Zhidomirov, G.M. Non-empirical cluster model calculations of the adsorption of H2O on Ni(111). Surf. Sci. 1992, 277, 407–413. [Google Scholar] [CrossRef]

- Shustorovich, E.; Sellers, H. The UBI-QEP method: A practical theoretical approach to understanding chemistry on transition metal surfaces. Surf. Sci. Rep. 1998, 31, 1–119. [Google Scholar] [CrossRef]

- Shustorovich, E. Reaction Energetics on Transition Metal Surfaces: A Bond-Order Conservation Approach. In Quantum Chemistry Approaches to Chemisorption and Heterogeneous Catalysis; Ruette, F., Ed.; Springer: Dordrecht, The Netherlands, 1992; Volume 6, pp. 231–252. [Google Scholar]

- Bjorgum, E.; Chen, D.; Bakken, M.G.; Christensen, K.O.; Holmen, A.; Lytken, O.; Chorkendorff, I. Energetic mapping of ni catalysts by detailed kinetic modeling. J. Phys. Chem. B 2005, 109, 2360–2370. [Google Scholar] [CrossRef] [PubMed]

- Al-Sarraf, N.; Stuckless, J.T.; Wartnaby, C.E.; King, D.A. Adsorption microcalorimetry and sticking probabilities on metal single crystal surfaces. Surf. Sci. 1993, 283, 427–437. [Google Scholar] [CrossRef]

- Chan, D.; Tischer, S.; Heck, J.; Diehm, C.; Deutschmann, O. Correlation between catalytic activity and catalytic surface area of a Pt/Al2O3 doc: An experimental and microkinetic modeling study. Appl. Catal. B 2014, 156–157, 153–165. [Google Scholar] [CrossRef]

- Jacobs, G.; Graham, U.M.; Chenu, E.; Patterson, P.M.; Dozier, A.; Davis, B.H. Low-temperature water-gas shift: Impact of Pt promoter loading on the partial reduction of ceria and consequences for catalyst design. J. Catal. 2005, 229, 499–512. [Google Scholar] [CrossRef]

- Jacobs, G.; Patterson, P.M.; Williams, L.; Chenu, E.; Sparks, D.; Thomas, G.; Davis, B.H. Water-gas shift: In situ spectroscopic studies of noble metal promoted ceria catalysts for co removal in fuel cell reformers and mechanistic implications. Appl. Catal. A 2004, 262, 177–187. [Google Scholar] [CrossRef]

- Jacobs, G.; Patterson, P.M.; Graham, U.M.; Sparks, D.E.; Davis, B.H. Low temperature water-gas shift: Kinetic isotope effect observed for decomposition of surface formates for Pt/ceria catalysts. Appl. Catal. A 2004, 269, 63–73. [Google Scholar] [CrossRef]

- Jacobs, G.; Patterson, P.M.; Graham, U.M.; Crawford, A.C.; Davis, B.H. Low temperature water gas shift: The link between the catalysis of WGS and formic acid decomposition over Pt/ceria. Int. J. Hydrog. Energy 2005, 30, 1265–1276. [Google Scholar] [CrossRef]

- Jacobs, G.; Williams, L.; Graham, U.; Sparks, D.; Davis, B.H. Low-temperature water-gas shift: In-situ drifts-reaction study of a Pt/CeO2 catalyst for fuel cell reformer applications. J. Phys. Chem. B 2003, 107, 10398–10404. [Google Scholar] [CrossRef]

- Kalamaras, C.M.; Olympiou, G.G.; Efstathiou, A.M. The water-gas shift reaction on Pt/γ-Al2O3 catalyst: Operando ssitka-drifts-mass spectroscopy studies. Catal. Today 2008, 138, 228–234. [Google Scholar] [CrossRef]

- Tibiletti, D.; Goguet, A.; Reid, D.; Meunier, F.C.; Burch, R. On the need to use steady-state or operando techniques to investigate reaction mechanisms: An in situ drifts and ssitka-based study example. Catal. Today 2006, 113, 94–101. [Google Scholar] [CrossRef]

- Shido, T.; Iwasawa, Y. Reactant-promoted reaction mechanism for water-gas shift reaction on Rh-doped ceo2. J. Catal. 1993, 141, 71–81. [Google Scholar] [CrossRef]

- Gokhale, A.A.; Dumesic, J.A.; Mavrikakis, M. On the mechanism of low-temperature water gas shift reaction on copper. J. Am. Chem. Soc. 2008, 130, 1402–1414. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wang, H.; Burch, R.; Hardacre, C.; Hu, P. New insight into mechanisms in water-gas-shift reaction on Au/CeO2(111): A density functional theory and kinetic study. Faraday Discuss. 2011, 152, 121–133. [Google Scholar] [PubMed]

- Lin, C.-H.; Chen, C.-L.; Wang, J.-H. Mechanistic studies of water–gas-shift reaction on transition metals. J. Phys. Chem. C 2011, 115, 18582–18588. [Google Scholar] [CrossRef]

- Boisen, A.; Janssens, T.V.W.; Schumacher, N.; Chorkendorff, I.; Dahl, S. Support effects and catalytic trends for water gas shift activity of transition metals. J. Mol. Catal. A 2010, 315, 163–170. [Google Scholar] [CrossRef]

- Grabow, L.C.; Gokhale, A.A.; Evans, S.T.; Dumesic, J.A.; Mavrikakis, M. Mechanism of the water gas shift reaction on Pt: First principles, experiments, and microkinetic modeling. J. Phys. Chem. C 2008, 112, 4608–4617. [Google Scholar] [CrossRef]

- Karakaya, C.; Otterstätter, R.; Maier, L.; Deutschmann, O. Kinetics of the water-gas shift reaction over rh/Al2O3 catalysts. Appl. Catal. A 2014, 470, 31–44. [Google Scholar] [CrossRef]

- Inderwildi, O.R.; Jenkins, S.J.; King, D.A. An unexpected pathway for the catalytic oxidation of methylidyne on Rh(111) as a route to syngas. J. Am. Chem. Soc. 2007, 129, 1751–1759. [Google Scholar] [CrossRef] [PubMed]

- Inderwildi, O.R.; Jenkins, S.J.; King, D.A. Mechanistic studies of hydrocarbon combustion and synthesis on noble metals. Angew. Chem. Int. Ed. 2008, 47, 5253–5255. [Google Scholar]

- Pistonesi, C.; Juan, A.; Irigoyen, B.; Amadeo, N. Theoretical and experimental study of methane steam reforming reactions over nickel catalyst. Appl. Surf. Sci. 2007, 253, 4427–4437. [Google Scholar] [CrossRef]

- Weng, W.Z.; Chen, M.S.; Yan, Q.G.; Wu, T.H.; Chao, Z.S.; Liao, Y.Y.; Wan, H.L. Mechanistic study of partial oxidation of methane to synthesis gas over supported rhodium and ruthenium catalysts using in situ time-resolved FTIR spectroscopy. Catal. Today 2000, 63, 317–326. [Google Scholar] [CrossRef]

- Hei, M.J.; Chen, H.B.; Yi, J.; Lin, Y.J.; Lin, Y.Z.; Wei, G.; Liao, D.W. CO2-reforming of methane on transition metal surfaces. Surf. Sci. 1998, 417, 82–96. [Google Scholar] [CrossRef]

- Horn, R.; Williams, K.A.; Degenstein, N.J.; Schmidt, L.D. Syngas by catalytic partial oxidation of methane on rhodium: Mechanistic conclusions from spatially resolved measurements and numerical simulations. J. Catal. 2006, 242, 92–102. [Google Scholar] [CrossRef]

- Deutschmann, O.; Schmidt, L.D. Two-dimensional modeling of partial oxidation of methane on rhodium in a short contact time reactor. Symp. (Int.) Combust. 1998, 27, 2283–2291. [Google Scholar]

- Deutschmann, O.; Schmidt, L.D. Modeling the partial oxidation of methane in a short-contact-time reactor. AIChE J. 1998, 44, 2465–2477. [Google Scholar] [CrossRef]

- Li, C.; Yu, C.; Shen, S. Isotopic studies on the mechanism of partial oxidation of CH4 to syngas over a Ni/Al2O3 catalyst. Catal. Lett. 2001, 75, 183–189. [Google Scholar] [CrossRef]

- Tang, S.; Lin, J.; Tan, K.L. Pulse-ms studies on CH4/Cd4 isotope effect in the partial oxidation of methane to syngas over Pt/α-Al2O3. Catal. Lett. 1998, 55, 83–86. [Google Scholar] [CrossRef]

- Wang, H.Y.; Ruckenstein, E. Catalytic partial oxidation of methane to synthesis gas over γ- Al2O2-supported Rhodium catalysts. Catal. Lett. 1999, 59, 121–127. [Google Scholar] [CrossRef]

- Kim, S.-B.; Kim, Y.-K.; Lim, Y.-S.; Kim, M.-S.; Hahm, H.-S. Reaction mechanism of partial oxidation of methane to synthesis gas over supported Ni catalysts. Korean J. Chem. Eng. 2003, 20, 1023–1025. [Google Scholar] [CrossRef]

- Choudhary, V.R.; Rajput, A.M.; Prabhakar, B. Nonequilibrium oxidative conversion of methane to CO and H2 with high selectivity and productivity over Ni/Al2O3 at low temperatures. J. Catal. 1993, 139, 326–328. [Google Scholar] [CrossRef]

- Menon, V.; Janardhanan, V.M.; Tischer, S.; Deutschmann, O. A novel approach to model the transient behavior of solid-oxide fuel cell stacks. J. Power Sources 2012, 214, 227–238. [Google Scholar] [CrossRef]

- Menon, V.; Fu, Q.; Janardhanan, V.M.; Deutschmann, O. A model-based understanding of solid-oxide electrolysis cells (soecs) for syngas production by H2O/CO2 co-electrolysis. J. Power Sources 2015, 274, 768–781. [Google Scholar] [CrossRef]

- Janardhanan, V.M.; Deutschmann, O. CFD analysis of a solid oxide fuel cell with internal reforming: Coupled interactions of transport, heterogeneous catalysis and electrochemical processes. J. Power Sources 2006, 162, 1192–1202. [Google Scholar] [CrossRef]

- Bessler, W.G.; Gewies, S.; Vogler, M. A new framework for physically based modeling of solid oxide fuel cells. Electrochim. Acta 2007, 53, 1782–1800. [Google Scholar] [CrossRef]

- Hecht, E.S.; Gupta, G.K.; Zhu, H.; Dean, A.M.; Kee, R.J.; Maier, L.; Deutschmann, O. Methane reforming kinetics within a ni–ysz sofc anode support. Appl. Catal. A 2005, 295, 40–51. [Google Scholar] [CrossRef]

- Zhu, H.; Kee, R.J.; Janardhanan, V.M.; Deutschmann, O.; Goodwin, D.G. Modeling elementary heterogeneous chemistry and electrochemistry in solid-oxide fuel cells. J. Electrochem. Soc. 2005, 152, A2427–A2440. [Google Scholar] [CrossRef]

- Ryu, J.-H.; Lee, K.-Y.; La, H.; Kim, H.-J.; Yang, J.-I.; Jung, H. Ni catalyst wash-coated on metal monolith with enhanced heat-transfer capability for steam reforming. J. Power Sources 2007, 171, 499–505. [Google Scholar] [CrossRef]

- Mears, D.E. Diagnostic criteria for heat transport limitations in fixed bed reactors. J. Catal. 1971, 20, 127–131. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgado, K.H.; Maier, L.; Tischer, S.; Zellner, A.; Stotz, H.; Deutschmann, O. Surface Reaction Kinetics of Steam- and CO2-Reforming as Well as Oxidation of Methane over Nickel-Based Catalysts. Catalysts 2015, 5, 871-904. https://doi.org/10.3390/catal5020871

Delgado KH, Maier L, Tischer S, Zellner A, Stotz H, Deutschmann O. Surface Reaction Kinetics of Steam- and CO2-Reforming as Well as Oxidation of Methane over Nickel-Based Catalysts. Catalysts. 2015; 5(2):871-904. https://doi.org/10.3390/catal5020871

Chicago/Turabian StyleDelgado, Karla Herrera, Lubow Maier, Steffen Tischer, Alexander Zellner, Henning Stotz, and Olaf Deutschmann. 2015. "Surface Reaction Kinetics of Steam- and CO2-Reforming as Well as Oxidation of Methane over Nickel-Based Catalysts" Catalysts 5, no. 2: 871-904. https://doi.org/10.3390/catal5020871

APA StyleDelgado, K. H., Maier, L., Tischer, S., Zellner, A., Stotz, H., & Deutschmann, O. (2015). Surface Reaction Kinetics of Steam- and CO2-Reforming as Well as Oxidation of Methane over Nickel-Based Catalysts. Catalysts, 5(2), 871-904. https://doi.org/10.3390/catal5020871