Microstructural and In Situ Lorentz TEM Domain Characterization of As-Quenched and γ’-Precipitated Co49Ni30Ga21 Monocrystal

Abstract

:1. Introduction

2. Materials and Methods

3. Results

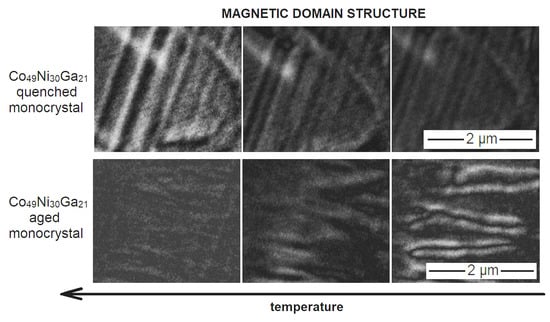

3.1. Co49Ni21Ga30 in the Quenched State

3.2. Co49Ni21Ga30 in the Quenched and Aged State

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Liu, G.D.; Liu, Z.H.; Dai, X.F.; Yu, S.Y.; Chen, J.L.; Wu, G.H. Investigation on ferromagnetic shape memory alloys. Sci. Technol. Adv. Mater. 2016, 6, 772–777. [Google Scholar] [CrossRef] [Green Version]

- Hellner, E.; Laves, F. Kristallchemie des In und Ga in Legierungen mit einigen bergangselementen (Ni Pd Pt Cu Ag und Au). Z. Nat. A 1946, 3, 177–184. [Google Scholar] [CrossRef]

- Cao, Z.-M.; Shi, X.; Xie, W.; Ohnuma, I.; Ishida, K.; Qiao, Z.-Y. Thermodynamic reassessment of Ni–Ga binary system. Rare Met. 2015, 34, 864–872. [Google Scholar] [CrossRef]

- Predel, B. Co-Ni (Cobalt-Nickel). Landolt-Börnstein-Group IV Physical Chemistry. In Numerical Data and Functional Relationships in Science and Technology; Springer: Berlin/Heidelberg, Germany, 1994; Volume 5, ISBN 978-3-540-56072-2. [Google Scholar]

- Liu, J.; Xie, H.; Huo, Y.; Zheng, H.; Li, J. Microstructure evolution in CoNiGa shape memory alloys. J. Alloy. Compd. 2006, 420, 145–157. [Google Scholar] [CrossRef]

- Brown, P.J.; Ishida, K.; Kainuma, R.; Kanomata, T.; Neumann, K.-U.; Oikawa, K.; Ouladdiaf, B.; Ziebeck, K.R.A. Crystal structures and phase transitions in ferromagnetic shape memory alloys based on Co–Ni–Al and Co–Ni–Ga. J. Phys. Condens. Matter 2005, 17, 1301–1310. [Google Scholar] [CrossRef]

- Chernenko, V.A.; Besseghini, S.; Villa, E.; Gambardella, A.; Pérez-Landazabal, J.I. Elastic and superelastic properties of Co49Ni22Ga29 single crystal. Appl. Phys. Lett. 2007, 90, 201914. [Google Scholar] [CrossRef]

- Oikawa, K.; Ota, T.; Imano, Y.; Omori, T.; Kainuma, R.; Ishida, K. Phase equilibria and phase transformation of Co−Ni−Ga ferromagnetic shape memory alloy system. J. Phase Equilibria Diffus. 2006, 27, 75–82. [Google Scholar] [CrossRef]

- Pond, R.C.; Muntifering, B.; Müllner, P. Deformation twinning in Ni2MnGa. Acta Mater. 2012, 60, 3976–3984. [Google Scholar] [CrossRef]

- Goryczka, T.; Gigla, M.; Morawiec, H. Effect of quenching on martensitic transformation course in non-stoichiometric NiMnGa alloy. Int. J. Appl. Electromagn. Mech. 2006, 23, 81–88. [Google Scholar] [CrossRef]

- Li, Y.; Xin, Y.; Chai, L.; Ma, Y.; Xu, H. Microstructures and shape memory characteristics of dual-phase Co–Ni–Ga high-temperature shape memory alloys. Acta Mater. 2010, 58, 3655–3663. [Google Scholar] [CrossRef]

- Prusik, K.; Kostrubiec, B.; Goryczka, T.; Dercz, G.; Ochin, P.; Morawiec, H. Effect of composition and heat treatment on the martensitic transformations in Co–Ni–Ga alloys. Mater. Sci. Eng. A 2008, 481–482, 330–333. [Google Scholar] [CrossRef]

- Dogan, E.; Karaman, I.; Chumlyakov, Y.I.; Luo, Z.P. Microstructure and martensitic transformation characteristics of CoNiGa high temperature shape memory alloys. Acta Mater. 2011, 59, 1168–1183. [Google Scholar] [CrossRef]

- Fu, H.; Yu, H.J.; Teng, B.H.; Zhang, X.Y.; Zu, X.T. Magnetic properties and magnetic entropy change of Co50Ni22Ga28 alloy. J. Alloy. Compd. 2009, 474, 595–597. [Google Scholar] [CrossRef]

- Kireeva, I.V.; Picornell, C.; Pons, J.; Kretinina, I.V.; Chumlyakov, Y.I.; Cesari, E. Effect of oriented γ′ precipitates on shape memory effect and superelasticity in Co–Ni–Ga single crystals. Acta Mater. 2014, 68, 127–139. [Google Scholar] [CrossRef]

- Kireeva, I.V.; Pons, J.; Picornell, C.; Chumlyakov, Y.I.; Cesari, E.; Kretinina, I.V. Influence of γ′ nanometric particles on martensitic transformation and twinning structure of L10 martensite in Co–Ni–Ga ferromagnetic shape memory single crystals. Intermetallics 2013, 35, 60–66. [Google Scholar] [CrossRef]

- Kuksgauzen, I.V. ТЕРМОУПРУГИЕ МАРТЕНСИТНЫЕ ПРЕВРАЩЕНИЯ И ФУНКЦИОНАЛЬНЫЕ СВОЙСТВА В МОНОКРИСТАЛЛАХ ФЕРРОМАГНИТНОГО СПЛАВА СO-NI-GA С НАНОРАЗМЕРНЫМИ ЧАСТИЦАМИ γ’-ФАЗЫ. Ph.D. Thesis, Tomsk Polytechnic University, Tomsk, Russia, 2015. [Google Scholar]

- Bartova, B.; Wiese, N.; Schryvers, D.; Chapman, J.N.; Ignacova, S. Microstructure of precipitates and magnetic domain structure in an annealed Co38Ni33Al29 shape memory alloy. Acta Mater. 2008, 56, 4470–4476. [Google Scholar] [CrossRef] [Green Version]

- Ma, J.; Hornbuckle, B.C.; Karaman, I.; Thompson, G.B.; Luo, Z.P.; Chumlyakov, Y.I. The effect of nanoprecipitates on the superelastic properties of FeNiCoAlTa shape memory alloy single crystals. Acta Mater. 2013, 61, 3445–3455. [Google Scholar] [CrossRef]

- Kishi, Y.; Graef, M.; Craciunescu, C.; Lograsso, T.A.; Neumann, D.A.; Wuttig, M. Microstructures and transformation behavior of CoNiGa ferromagnetic ahape memory alloys. J. Phys. IV 2003, 112, 1021–1024. [Google Scholar] [CrossRef]

- Planes, A.; Manosa, L.; Saxena, A. Magnetism and Structure in Functional Materials; Springer: Berlin/Heidelberg, Germany, 2005; ISBN 978-3-540-23672-6. [Google Scholar]

- de Graef, M.; Venkateswaran, S.; Kishi, Y.; Lograsso, T.A.; Viehland, D.; Wuttig, M. Magnetic Tweed Contrast In Ferromagnetic Shape Memory Alloys. Microsc. Microanal. 2003, 9, 584–585. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.R.; Ma, C.; Tian, H.F.; Wu, G.H.; Li, J.Q. Martensitic transformation of Ni2FeGa ferromagnetic shape-memory alloy studied via transmission electron microscopy and electron energy-loss spectroscopy. Phys. Rev. B 2008, 77, 301. [Google Scholar] [CrossRef] [Green Version]

- Nath, H.; Phanikumar, G. Premartensite transition in Ni2FeGa Heusler alloy. Mater. Charact. 2015, 102, 24–28. [Google Scholar] [CrossRef]

- Neudert, A.; Lai, Y.W.; Schäfer, R.; Kustov, M.; Schultz, L.; McCord, J. Magnetic Domains and Twin Boundary Movement of NiMnGa Magnetic Shape Memory Crystals. Adv. Eng. Mater. 2012, 14, 601–613. [Google Scholar] [CrossRef]

- Breczko, T.M.; Grechishkin, R.M.; Ilyashenko, S.E.; Nelaev, V.V.; Dovzhik, K.N.; Korpusov, O.M. Martensitic and magnetic domain structures of ferroics of the Ni-Mn-Ga and Co-Ni-Ga families. Phys. Solid State 2010, 52, 101–104. [Google Scholar] [CrossRef]

- Lai, Y.W.; Scheerbaum, N.; Hinz, D.; Gutfleisch, O.; Schäfer, R.; Schultz, L.; McCord, J. Absence of magnetic domain wall motion during magnetic field induced twin boundary motion in bulk magnetic shape memory alloys. Appl. Phys. Lett. 2007, 90, 192504. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.G. Magnetic force microscopy observations of Co–Ni–Ga and Co–Ni–Al alloys with two-phase structures. Scr. Mater. 2006, 55, 755–758. [Google Scholar] [CrossRef]

- Diestel, A.; Backen, A.; Neu, V.; Schultz, L.; Fähler, S. Magnetic domain structure of epitaxial Ni–Mn–Ga films. Scr. Mater. 2012, 67, 423–426. [Google Scholar] [CrossRef] [Green Version]

- Diestel, A.; Neu, V.; Backen, A.; Schultz, L.; Fähler, S. Magnetic domain pattern in hierarchically twinned epitaxial Ni-Mn-Ga films. J. Phys. Condens. Matter 2013, 25, 266002. [Google Scholar] [CrossRef]

- Pan, Q.; James, R.D. Micromagnetic study of Ni2MnGa under applied field (invited). J. Appl. Phys. 2000, 87, 4702–4706. [Google Scholar] [CrossRef]

- Morito, H.; Oikawa, K.; Fujita, A.; Fukamichi, K.; Kainuma, R.; Ishida, K. Stress-assisted large magnetic-field-induced strain in single-variant Co-Ni-Ga ferromagnetic shape memory alloy. J. Phys. Condens. Matter 2009, 21, 256002. [Google Scholar] [CrossRef]

- Venkateswaran, S.P.; Nuhfer, N.T.; de Graef, M. Magnetic domain memory in multiferroic Ni2MnGa. Acta Mater. 2007, 55, 5419–5427. [Google Scholar] [CrossRef]

- Gerstein, G.; L’vov, V.A.; Żak, A.; Dudziński, W.; Maier, H.J. Direct observation of nano-dimensional internal structure of ferromagnetic domains in the ferromagnetic shape memory alloy Co-Ni-Ga. J. Magn. Magn. Mater. 2018, 466, 125–129. [Google Scholar] [CrossRef]

- Żak, A.; Łaszcz, A.; Hasiak, M.; Gerstein, G.; Maier, H.J.; Dudziński, W. Ion polishing as a method of imaging the magnetic structures in CoNiGa monocrystal. Results Phys. 2018, 10, 277–280. [Google Scholar] [CrossRef]

- Kuksgauzen, I.V.; Kireeva, I.V.; Chumlyakov, Y.I.; Maier, H. Shape memory effect and superelasticity in [001]-single crystal of CoNiGa aged alloy. Tambov Univ. Rep. Ser. Nat. Tech. Sci. 2016, 21, 1085–1088. [Google Scholar] [CrossRef]

- Dadda, J. Thermomechanical and Microstructural Characterization of Co49Ni21Ga30 and Co38Ni33Al29 High-Temperature Shape Memory Alloy Single Crystals. Ph.D. Thesis, der Universit¨at Paderborn, Paderborn, Germany, 2009. [Google Scholar]

- Kireeva, I.V.; Pobedennaya, Z.V.; Chumlyakov, Y.I.; Pons, J.; Cesari, E.; Karaman, I. Effect of orientation on the high-temperature superelasticity in Co49Ni21Ga30 single crystals. Tech. Phys. Lett. 2009, 35, 186–189. [Google Scholar] [CrossRef]

- Fuller, H.W.; Hale, M.E. Determination of Magnetization Distribution in Thin Films Using Electron Microscopy. J. Appl. Phys. 1960, 31, 238–248. [Google Scholar] [CrossRef]

- Fuller, H.W.; Hale, M.E. Domains in Thin Magnetic Films Observed by Electron Microscopy. J. Appl. Phys. 1960, 31, 1699–1705. [Google Scholar] [CrossRef]

- Białobrzeska, B.; Dziurka, R.; Żak, A.; Bała, P. The influence of austenitization temperature on phase transformations of supercooled austenite in low-alloy steels with high resistance to abrasion wear. Arch. Civ. Mech. Eng. 2018, 18, 413–429. [Google Scholar] [CrossRef]

- Dmitruk, A.; Naplocha, K.; Żak, A.; Strojny-Nędza, A.; Dieringa, H.; Kainer, K.U. Development of Pore-Free Ti-Si-C MAX/Al-Si Composite Materials Manufactured by Squeeze Casting Infiltration. J. Mater. Eng Perform. 2019, 28, 6248–6257. [Google Scholar] [CrossRef] [Green Version]

- Naveed, M.; Obrosov, A.; Zak, A.; Dudzinski, W.; Volinsky, A.; Weiß, S. Sputtering Power Effects on Growth and Mechanical Properties of Cr2AlC MAX Phase Coatings. Metals 2016, 6, 265. [Google Scholar] [CrossRef]

- Hirsch, P.B. Electron Microscopy of Thin Crystals; Plenum Press: London, UK, 1967. [Google Scholar]

- Andrews, K.W.; Dyson, D.J.; Keown, S.R. Interpretation of Electron Diffraction Patterns; Springer Science+Business Media: Rotherkam, UK, 1967. [Google Scholar]

- Williams, D.; Carter, C. Transmission Electron Microscopy. A Textbook for Materials Science, 2nd ed.; Springer: New York, NY, USA, 2008; ISBN 9780387765006. [Google Scholar]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Dai, X.; Liu, G.; Li, Y.; Qu, J.; Li, J.; Chen, J.; Wu, G. Structure and magnetic properties of highly ordered Co2NiGa alloys. J. Appl. Phys. 2007, 101, 09N503. [Google Scholar] [CrossRef]

- Gentils, A.; Chapman, J.N.; Xiong, G.; Cowburn, R.P. Variation of domain-wall structures and magnetization ripple spectra in permalloy films with controlled uniaxial anisotropy. J. Appl. Phys. 2005, 98, 53905. [Google Scholar] [CrossRef]

- Hubert, A.; Schafer, R. Magnetic Domains. The Analysis of Magnetic Microstructures; Springer: Berlin/Heidelberg, Germany, 1998; ISBN 978-3-540-64108-7. [Google Scholar]

- Kuksgauzen, I.V.; Kireeva, I.V.; Chumlyakov, Y.I.; Maier, H. Orientation dependence of the shape memory effect and superelasticity in ferromagnetic Co 49 Ni 21 Ga 30 single crystals with γ’-phase particles. IOP Conf. Ser. Mater. Sci. Eng. 2015, 93, 12033. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zak, A.M.; Dudzinski, W. Microstructural and In Situ Lorentz TEM Domain Characterization of As-Quenched and γ’-Precipitated Co49Ni30Ga21 Monocrystal. Crystals 2020, 10, 153. https://doi.org/10.3390/cryst10030153

Zak AM, Dudzinski W. Microstructural and In Situ Lorentz TEM Domain Characterization of As-Quenched and γ’-Precipitated Co49Ni30Ga21 Monocrystal. Crystals. 2020; 10(3):153. https://doi.org/10.3390/cryst10030153

Chicago/Turabian StyleZak, Andrzej M., and Wlodzimierz Dudzinski. 2020. "Microstructural and In Situ Lorentz TEM Domain Characterization of As-Quenched and γ’-Precipitated Co49Ni30Ga21 Monocrystal" Crystals 10, no. 3: 153. https://doi.org/10.3390/cryst10030153

APA StyleZak, A. M., & Dudzinski, W. (2020). Microstructural and In Situ Lorentz TEM Domain Characterization of As-Quenched and γ’-Precipitated Co49Ni30Ga21 Monocrystal. Crystals, 10(3), 153. https://doi.org/10.3390/cryst10030153