Effect of Continuous Annealing Temperature on the Microstructure, Mechanical Properties and Texture of Annealed Drawn and Ironed Plate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Heat Treatment

2.2. Microstructure and Mechanical Properties Characterization

3. Results and Discussion

3.1. Microstructure Analysis

3.2. Mechanical Properties

3.3. Texture Analysis

4. Conclusions

- (1)

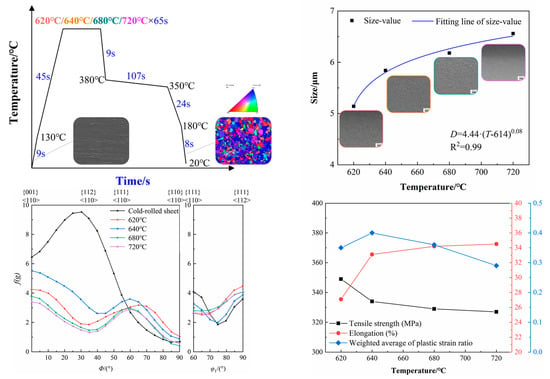

- With the increase of the annealing temperature, the degree of recrystallization increased, the proportion of equiaxed grains improved and the average grain size grew from 5.14 μm to 6.56 μm. The formula D = 4.44·(T − 614)0.08 is used to establish the link between the average recrystallization grain size and the annealing temperature. It shows that the increase in recrystallized grain size steadily diminishes with the increase of the annealing temperature during a shorter annealing time.

- (2)

- After annealing, the rolling textures greatly diminished, while the {111} textures significantly increased. The texture content of {111} <110> was the highest when annealed at a lower temperature of 620 °C. The texture content of {111} <112> was higher than that of {111} <110> when the annealing temperature increased to 640 °C, 680 °C and 720 °C.

- (3)

- When the annealing temperature rose from 620–720 °C, the yield strength and tensile strength decreased, the elongation increased, and the value first increased and then decreased. The DI plate annealed at 640 °C possesses a higher value and a lower |∆r| value, and its mechanical properties are the best, which will have guiding significance for the industrial production of the DI plate.

Author Contributions

Funding

Conflicts of Interest

References

- Dey, S.; Agrawal, D.M.K. Tinplate as a Sustainable Packaging Material: Recent Innovation and Developments to Remain Environment Friendly and Cost Effective. Int. J. Res. IT Manag. Eng. 2016, 8, 9–22. [Google Scholar]

- Hutchinson, W.B. Development and control of annealing textures in low-carbon steels. Int. Met. Rev. 1984, 29, 25–42. [Google Scholar] [CrossRef]

- Tian, P.; Liao, L.; Zhu, G.; Kang, Y. Effect of Secondary Cold Reduction Rates on Microstructure, Texture and Earing Behavior of Double Reduction Tinplate. Materials 2021, 14, 4040. [Google Scholar] [CrossRef]

- Liao, L.; Zheng, X.; Kang, Y.; Liu, W.; Yan, Y.; Mo, Z. Crystallographic texture and earing behavior analysis for different second cold reductions of double-reduction tinplate. Int. J. Miner. Metall. Mater. 2018, 25, 652–662. [Google Scholar] [CrossRef]

- Černík, M.; Gburík, R.; Hrabčáková, L.; Vranec, P. Texture analysis of tinplate steel and its application in production of double reduced high strength tinplate grades with controlled earing properties. IOP Conf. Ser. Mater. Sci. Eng. 2015, 82, 012108. [Google Scholar] [CrossRef] [Green Version]

- Saiji, M.; Kei, S.; Susumu, S.; Toshiyuki, K. Effect of hot-rolling strain rate in the ferrite region on the recrystallization texture of extra-low c sheet steels. ISIJ Int. 1994, 34, 77–84. [Google Scholar]

- Cai, G.; Li, C.; Wang, D.; Zhou, Y. Investigation of annealing temperature on microstructure and texture of Fe-19Cr-2Mo-Nb-Ti ferritic stainless steel. Mater. Charact. 2018, 141, 169–176. [Google Scholar] [CrossRef]

- Burke, J.E.; Turnbull, D. Recrystallization and Grain Growth. Prog. Met. Phys. 1952, 3, 220–292. [Google Scholar] [CrossRef]

- Shin, D.H.; Kim, B.C.; Park, K.-T.; Choo, W.Y. Microstructural changes in equal channel angular pressed low carbon steel by static annealing. Acta Mater. 2000, 48, 3245–3252. [Google Scholar] [CrossRef]

- Yazawa, Y. Development of ferritic stainless steel sheets with excellent deep drawability by {111} recrystallization texture control. JSAE Rev. 2003, 24, 483–488. [Google Scholar] [CrossRef]

- Wauthier-Monnin, A.; Chauveau, T.; Castelnau, O.; Réglé, H.; Bacroix, B. The evolution with strain of the stored energy in different texture components of cold-rolled IF steel revealed by high resolution X-ray diffraction. Mater. Charact. 2015, 104, 31–41. [Google Scholar] [CrossRef]

- Bernier, N.; Leunis, E.; Furtado, C.; Van De Putte, T.; Ban, G. EBSD study of angular deviations from the Goss component in grain-oriented electrical steels. Micron 2013, 54, 43–51. [Google Scholar] [CrossRef]

- Ray, R.K.; Jonas, J.J.; Hook, R.E. Cold rolling and annealing textures i~ low carbon and extra low carbon steels. Int. Mater. Rev. 1994, 39, 129–172. [Google Scholar] [CrossRef]

- Wierzbanowski, K.; Baczmanski, A.; Tarasiuk, J.; Lipiński, P.; Bacroix, B.; Lodini, A. Stored Energy and Recrystallisation in Cold Rolled Steel. Mater. Sci. Forum 2007, 558, 1207–1212. [Google Scholar] [CrossRef]

- Fang, C.; Garcia, C.I.; Choi, S.H.; DeArdo, A.J. Assessment of the Stored Energy Evolution during Batch Annealing Process of Cold Rolled HSLA Steels. Mater. Sci. Forum 2012, 715, 557–562. [Google Scholar] [CrossRef]

- Choi, S.-H.; Barlat, F.; Chung, J.H. Modeling of textures and yield surfaces during recrystallization in IF steel sheets. Scr. Mater. 2001, 45, 1155–1162. [Google Scholar] [CrossRef]

- Pan, H.; Wan, Y.; Wang, H.; Shen, X.; Fu, B.; Li, D.Y.; Dai, Y.; Yan, J. An Investigation of Friction Coefficient on Microstructure and Texture Evolution of Interstitial-Free Steel during Warm Rolling and Subsequent Annealing. Crystals 2019, 9, 565. [Google Scholar] [CrossRef] [Green Version]

- Nagataki, Y.; Hosoya, Y. Origin of the Recrystallization Texture Formation in an Interstitial Free Steel. ISIJ Int. 1996, 36, 451–460. [Google Scholar] [CrossRef]

- Yang, P.; Li, Z.C.; Mao, W.M.; Zhao, Z.S. Formation of the {111} <112> annealing texture in steels. Trans. Mater. Heat Treat. 2009, 30, 46. [Google Scholar]

- He, T.; Liu, Y.; Sun, W.; Zuo, L. Formation of Nuclei with {111} and {111} Orientations of IF Steel at Early Stage of Recrystallization Using EBSD Analysis. J. Iron Steel Res. Int. 2013, 20, 61–66. [Google Scholar] [CrossRef]

- Li, S.; Zhang, X.M. A new method for predicting earing tendency of textured sheets. Acta Metall. Sin. 1996, 32, 884–890. [Google Scholar]

- Ning, B.; Zhao, Z.; Mo, Z.; Wu, H.; Peng, C.; Gong, H. Influence of Continuous Annealing Temperature on Mechanical Properties and Texture of Battery Shell Steel. Metals 2019, 10, 52. [Google Scholar] [CrossRef] [Green Version]

| C≤ | Si≤ | Mn | P≤ | S≤ | Als | N≤ | [O]≤ |

|---|---|---|---|---|---|---|---|

| 0.003 | 0.015 | 0.35 | 0.010 | 0.006 | 0.03 | 0.0025 | 0.0020 |

| Annealing Temperature | Direction | ReL/MPa | Rm/MPa | A/% | r | △r | |

|---|---|---|---|---|---|---|---|

| 620 °C | 0° | 319 | 352 | 21.5 | 0.28 | 0.35 | 0.19 |

| 90° | 321 | 351 | 22.3 | 0.62 | |||

| 45° | 312 | 349 | 27.1 | 0.26 | |||

| 640 °C | 0° | 316 | 340 | 34.5 | 0.36 | 0.40 | −0.06 |

| 90° | 309 | 335 | 30.8 | 0.39 | |||

| 45° | 295 | 334 | 33.1 | 0.43 | |||

| 680 °C | 0° | 278 | 325 | 34.6 | 0.26 | 0.36 | −0.10 |

| 90° | 294 | 328 | 36.0 | 0.35 | |||

| 45° | 300 | 329 | 34.2 | 0.41 | |||

| 720 °C | 0° | 295 | 336 | 37.8 | 0.29 | 0.29 | 0.02 |

| 90° | 307 | 339 | 38.8 | 0.27 | |||

| 45° | 279 | 327 | 34.5 | 0.31 |

| Samples | {111} <112> | {111} <110> | {001} <001> | {001} <011> | {112} <110> | {110} <001> | {111}/{100} |

|---|---|---|---|---|---|---|---|

| CR | 14.7 | 26.4 | 0.70 | 18.2 | 46.8 | 0.05 | 2.1 |

| 620 °C | 28.4 | 36 | 2.63 | 7.23 | 2.74 | 2.2 | 6.5 |

| 640 °C | 36.6 | 22.9 | 3.92 | 4.55 | 17.8 | 1.95 | 7.0 |

| 680 °C | 33.6 | 23.3 | 2.33 | 7.52 | 22.5 | 1.81 | 5.8 |

| 720 °C | 24.8 | 19.8 | 7.05 | 7.03 | 19.3 | 3.82 | 3.2 |

| Texture | Δr | |

|---|---|---|

| {001} <110> | 0.4 | −0.8 |

| {114} <110> | 1.2 | −2.1 |

| {113} <110> | 1.0 | −1.7 |

| {112} <110> | 2.1 | −2.7 |

| {111} <110> | 2.6 | 0 |

| {111} <112> | 2.6 | 0 |

| {554} <225> | 2.6 | 1.1 |

| {110} <001> | 5.1 | 8.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mo, Z.; Chu, X.; Gao, P.; Yang, D.; Cui, H.; Fang, Y.; Li, H.; Yin, X.; Zhao, Z. Effect of Continuous Annealing Temperature on the Microstructure, Mechanical Properties and Texture of Annealed Drawn and Ironed Plate. Crystals 2021, 11, 1569. https://doi.org/10.3390/cryst11121569

Mo Z, Chu X, Gao P, Yang D, Cui H, Fang Y, Li H, Yin X, Zhao Z. Effect of Continuous Annealing Temperature on the Microstructure, Mechanical Properties and Texture of Annealed Drawn and Ironed Plate. Crystals. 2021; 11(12):1569. https://doi.org/10.3390/cryst11121569

Chicago/Turabian StyleMo, Zhiying, Xiaohong Chu, Pengfei Gao, Dengcui Yang, Heng Cui, Yuan Fang, Haixu Li, Xiandong Yin, and Zhengzhi Zhao. 2021. "Effect of Continuous Annealing Temperature on the Microstructure, Mechanical Properties and Texture of Annealed Drawn and Ironed Plate" Crystals 11, no. 12: 1569. https://doi.org/10.3390/cryst11121569

APA StyleMo, Z., Chu, X., Gao, P., Yang, D., Cui, H., Fang, Y., Li, H., Yin, X., & Zhao, Z. (2021). Effect of Continuous Annealing Temperature on the Microstructure, Mechanical Properties and Texture of Annealed Drawn and Ironed Plate. Crystals, 11(12), 1569. https://doi.org/10.3390/cryst11121569