Effect of Biomass Fly Ash on Fresh and Hardened Properties of High Volume Fly Ash Mortars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mortar Formulations and Characterization

- Edn is the dynamic modulus of elasticity of mortars (GPa),

- ρ is the hardened mortar density (kg/m3),

- c is the UPV (km/s), and

- υ is the Poisson’s ratio was assumed as 0.2 for all mortar mixtures.

- Ai—open porosity (%),

- m1—weight of water saturated specimen (g),

- m2—weight of saturated specimen immersed in water (g), and

- m3—weight of specimen (g).

3. Results and Discussion

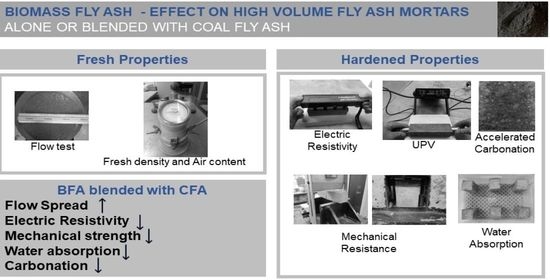

3.1. Fresh Properties

3.2. Hardened Properties

3.2.1. Electric Resistivity and Ultrasonic Velocity Pulse

3.2.2. Flexural and Compressive Strength Results

3.2.3. Water Absorption by Immersion and by Capillarity

3.2.4. Carbonation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gasparatos, A.; Doll, C.N.; Esteban, M.; Ahmed, A.; Olang, T.A. Renewable energy and biodiversity: Implications for transitioning to a Green Economy. Renew. Sustain. Energy Rev. 2017, 70, 161–184. [Google Scholar] [CrossRef] [Green Version]

- UNEP. Towards a Green Economy: Pathways to Sustainable Development and Poverty Eradication; UNEP: Nairobi, Kenya, 2011. [Google Scholar] [CrossRef]

- Barbosa, R.; Lapa, N.; Dias, D.; Mendes, B. Concretes containing biomass ashes: Mechanical, chemical, and ecotoxic performances. Constr. Build. Mater. 2013, 48, 457–463. [Google Scholar] [CrossRef]

- Morais, J.B.; Barbosa, R.; Lapa, N.; Mendes, B.; Gulyurtlu, I. Environmental and socio-economic assessment of co-combustion of coal, biomass and non-hazardous wastes in a Power Plant. Resour. Conserv. Recycl. 2011, 55, 1109–1118. [Google Scholar] [CrossRef]

- Wang, S.; Baxter, L. Comprehensive study of biomass fly ash in concrete: Strength, microscopy, kinetics and durability. Fuel Process. Technol. 2007, 88, 1165–1170. [Google Scholar] [CrossRef]

- Sami, M.; Annamalai, K.; Wooldridge, M. Co-firing of coal and biomass fuel blends. Prog. Energy Combust. Sci. 2001, 27, 171–214. [Google Scholar] [CrossRef]

- Haykırı-Açma, H. Combustion characteristics of different biomass materials. Energy Convers. Manag. 2003, 44, 155–162. [Google Scholar] [CrossRef]

- Al-Kassir, A.; Gañán-Gómez, J.; Mohamad, A.; Cuerda-Correa, E.M. A study of energy production from cork residues: Sawdust, sandpaper dust and triturated wood. Energy 2010, 35, 382–386. [Google Scholar] [CrossRef]

- González, J.F.G.; Ledesma, B.; Alkassir, A.; González, J. Study of the influence of the composition of several biomass pellets on the drying process. Biomass Bioenergy 2011, 35, 4399–4406. [Google Scholar] [CrossRef]

- Tarelho, L.; Teixeira, E.; Silva, D.; Modolo, R.; Labrincha, J.; Rocha, F. Characteristics of distinct ash flows in a biomass thermal power plant with bubbling fluidised bed combustor. Energy 2015, 90, 387–402. [Google Scholar] [CrossRef]

- European Commission. Commission Decision on the European List of Waste (COM 2000/532/EC). Off. J. Eur. Communities 2000, D0532, 1–31. [Google Scholar]

- Berra, M.; Mangialardi, T.; Paolini, A.E. Reuse of woody biomass fly ash in cement-based materials. Constr. Build. Mater. 2015, 76, 286–296. [Google Scholar] [CrossRef]

- Lima, A.T.; Ottosen, L.M.; Pedersen, A.; Ribeiro, A. Characterization of fly ash from bio and municipal waste. Biomass Bioenergy 2008, 32, 277–282. [Google Scholar] [CrossRef]

- Sarabèr, A.; Haasnoot, K. Recycling of Biomass Ashes in The Netherlands; Ash Utilisation; Springer: Berlin/Heidelberg, Germany, 2012; pp. 25–27. [Google Scholar]

- Kröppl, M.; Lanzerstorfer, C. Acidic extraction and precipitation of heavy metals from biomass incinerator cyclone fly ash. E3S Web Conf. 2013, 1, 16007. [Google Scholar] [CrossRef]

- Biricik, H.; Akoz, F.; Berktay, I.; Tulgar, A.N. Study of pozzolanic properties of wheat straw ash. Cem. Concr. Res. 1999, 29, 637–643. [Google Scholar] [CrossRef]

- Yu, Q.; Sawayama, K.; Sugita, S.; Shoya, M.; Isojima, Y. The reaction between rice husk ash and Ca(OH)2 solution and the nature of its product. Cem. Concr. Res. 1999, 29, 37–43. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Valencia-Morales, E.; González-Rodríguez, R.; Hernández-Ruíz, J. Kinetics of the pozzolanic reaction between lime and sugar cane straw ash by electrical conductivity measurement: A kinetic–diffusive model. Cem. Concr. Res. 2003, 33, 517–524. [Google Scholar] [CrossRef]

- Wang, S.; Miller, A.; Llamazos, E.; Fonseca, F.; Baxter, L. Biomass fly ash in concrete: Mixture proportioning and mechanical properties. Fuel 2008, 87, 365–371. [Google Scholar] [CrossRef]

- Lokare, S.S.; Dunaway, J.D.; Moulton, D.; Rogers, D.; Tree, D.R.; Baxter, L.L. Investigation of Ash Deposition Rates for a Suite of Biomass Fuels and Fuel Blends. Energy Fuels 2006, 20, 1008–1014. [Google Scholar] [CrossRef]

- Bridgeman, T.G.; Darvell, L.I.; Jones, J.M.; Williams, P.T.; Fahmi, R.; Bridgwater, A.V.; Barraclough, T.; Shield, I.; Yates, N.; Thain, S.C.; et al. Influence of particle size on the analytical and chemical properties of two energy crops. Fuel 2007, 86, 60–72. [Google Scholar] [CrossRef]

- Wiselogel, A.; Agblevor, F.; Johnson, D.; Deutch, S.; Fennell, J.; Sanderson, M. Compositional changes during storage of large round switchgrass bales. Bioresour. Technol. 1996, 56, 103–109. [Google Scholar] [CrossRef]

- Lewandowski, I.; Clifton-Brown, J.C.; Scurlock, J.M.O.; Huisman, W. Miscanthus: European experience with a novel energy crop. Biomass Bioenergy 2000, 19, 209–227. [Google Scholar] [CrossRef]

- Rafael, S.; Tarelho, L.; Monteiro, A.; Sá, E.; Miranda, A.I.; Borrego, C.; Lopes, M. Impact of forest biomass residues to the energy supply chain on regional air quality. Sci. Total. Environ. 2015, 505, 640–648. [Google Scholar] [CrossRef]

- Wang, S.; Llamazos, E.; Baxter, L.; Fonseca, F. Durability of biomass fly ash concrete: Freezing and thawing and rapid chloride permeability tests. Fuel 2008, 87, 359–364. [Google Scholar] [CrossRef]

- Thy, P.; Jenkins, B.; Grundvig, S.; Shiraki, R.; Lesher, C. High temperature elemental losses and mineralogical changes in common biomass ashes. Fuel 2006, 85, 783–795. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Wu, Y.; Wang, Y.; Wang, Y. Evaluation of the improved properties of SBR/weathered coal modified bitumen containing carbon black. Constr. Build. Mater. 2009, 23, 2678–2687. [Google Scholar] [CrossRef]

- Zheng, Y.; Jensen, P.A.; Jensen, A.D.; Sander, B.; Junker, H. Ash transformation during co-firing coal and straw. Fuel 2007, 86, 1008–1020. [Google Scholar] [CrossRef]

- Rajamma, R.; Ball, R.J.; Tarelho, L.A.; Allen, G.C.; Labrincha, J.A.; Ferreira, V.M. Characterisation and use of biomass fly ash in cement-based materials. J. Hazard. Mater. 2009, 172, 1049–1060. [Google Scholar] [CrossRef]

- Wieck-Hansen, K.; Overgaard, P.; Larsen, O.H. Cofiring coal and straw in a 150 MWe power boiler experiences. Biomass Bioenergy 2000, 19, 395–409. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: An overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Esteves, T.; Rajamma, R.; Soares, D.; Silva, A.S.; Ferreira, V.; Labrincha, J. Use of biomass fly ash for mitigation of alkali-silica reaction of cement mortars. Constr. Build. Mater. 2012, 26, 687–693. [Google Scholar] [CrossRef]

- Tarelho, L.A.C.; Teixeira, E.R.; Silva, D.F.R.; Modolo, R.C.E.; Silva, J.J.F. Characteristics, management and applications of ashes from thermochemical conversion of biomass to energy. In Proceedings of the World bioenergy 2012, Conference & Exhibition on Biomass for Energy, Jonkopin, Sweden, 29–31 May 2012. [Google Scholar]

- Cordeiro, G.C.; Filho, R.D.T.; Tavares, L.M.; Fairbairn, E.D.M.R. Ultrafine grinding of sugar cane bagasse ash for application as pozzolanic admixture in concrete. Cem. Concr. Res. 2009, 39, 110–115. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Mahmood, Y.A. Ash from timber waste as cement replacement material. Cem. Concr. Compos. 2002, 24, 219–222. [Google Scholar] [CrossRef]

- Shearer, C.R.; Yeboah, N.; Kurtis, K.E.; Burns, S.E. The Early Age Behavior of Biomass Fired and Co-fired Fly Ash in Concrete; World Coal Ash: Denver, CO, USA, 2011; Available online: http://www.flyash.info/2011/017-Shearer-2011.pdf (accessed on 22 November 2020).

- Barathan, S.; Gobinath, B. Evaluation of Wood Ash As a Partial Replacement To Cement. Int. J. Sci. Eng. Technol. Res. 2013, 2, 2009–2013. [Google Scholar]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

- Coelho, A.M.S.L. Gestão de Cinzas produzidas em centrais de cogeração operadas com biomassa (Management of ashes produced in biomass co-generation industries). Master’s Thesis, Department of Environment and Planning, University of Aveiro, Aveiro, Portugal, 2010. [Google Scholar]

- Tkaczewska, E.; Małolepszy, J. Hydration of coal–biomass fly ash cement. Constr. Build. Mater. 2009, 23, 2694–2700. [Google Scholar] [CrossRef]

- Udoeyo, F.F.; Inyang, H.; Young, D.T.; Oparadu, E.E. Potential of Wood Waste Ash as an Additive in Concrete. J. Mater. Civ. Eng. 2006, 18, 605–611. [Google Scholar] [CrossRef]

- ASTM C188-95. Standard Test Method for Density of Hydraulic Cement; ASTM: West Conshohocken, PA, USA, 2003. [Google Scholar] [CrossRef]

- Dahl, O.; Nurmesniemi, H.; Pöykiö, R.; Watkins, G. Comparison of the characteristics of bottom ash and fly ash from a medium-size (32 MW) municipal district heating plant incinerating forest residues and peat in a fluidized-bed boiler. Fuel Process. Technol. 2009, 90, 871–878. [Google Scholar] [CrossRef]

- Maschio, S.; Tonello, G.; Piani, L.; Furlani, E. Fly and bottom ashes from biomass combustion as cement replacing components in mortars production: Rheological behaviour of the pastes and materials compression strength. Chemosphere 2011, 85, 666–671. [Google Scholar] [CrossRef]

- Girón, R.; Ruiz, B.; Fuente, E.; Gil, R.; Suarezruiz, I. Properties of fly ash from forest biomass combustion. Fuel 2013, 114, 71–77. [Google Scholar] [CrossRef]

- Liao, C.; Wu, C.; Yan, Y. The characteristics of inorganic elements in ashes from a 1 MW CFB biomass gasification power generation plant. Fuel Process. Technol. 2007, 88, 149–156. [Google Scholar] [CrossRef]

- Latva-Somppi, J.; Moisio, M.; I Kauppinen, E.; Valmari, T.; Ahonen, P.; Tapper, U.; Keskinen, J. Ash formation during fluidized-bed incineration of paper mill waste sludge. J. Aerosol Sci. 1998, 29, 461–480. [Google Scholar] [CrossRef]

- Latva-Somppi, J.; I Kauppinen, E.; Valmari, T.; Ahonen, P.; Gurav, A.S.; Kodas, T.T.; Johanson, B. The ash formation during co-combustion of wood and sludge in industrial fluidized bed boilers. Fuel Process. Technol. 1998, 54, 79–94. [Google Scholar] [CrossRef]

- Miller, B.; Dugwell, D.; Kandiyoti, R. The Fate of Trace Elements during the Co-Combustion of Wood-Bark with Waste. Energy Fuels 2006, 20, 520–531. [Google Scholar] [CrossRef]

- Steenari, B.-M.; Fedje, K.K. Addition of kaolin as potassium sorbent in the combustion of wood fuel—Effects on fly ash properties. Fuel 2010, 89, 2026–2032. [Google Scholar] [CrossRef]

- Daczko, J.J. Mortar Testing for Estimating Strength. Concr. Int. 1999, 21, 63–67. [Google Scholar]

- Camões, A.; Aguiar, J.; Jalali, S. Estimating Compressive Strength of Concrete by Mortar Testing. In Proceedings of the INCOS’05, International Conference on Concrete for Structures, Coimbra, Portugual, 7–8 July 2005; Available online: https://www.academia.edu/21562504/Estimating_compressive_strength_of_concrete_by_mortar_testing (accessed on 26 February 2021).

- Strain-Rate Sensitive Behavior of Cement Paste and Mortar in Compression. ACI Mater. J. 1990, 87, 508–516. [CrossRef]

- Maroof, N.; Karim, H.; Hasan, A. Relationship between properties of cement mortar with that of concrete mix. Proj. Prod. Light. Therm. Insul. Clay Bricks Using Pap. 2016, 6, 391–404. [Google Scholar]

- Camões, A. Betões de Elevado Desempenho Com Elevado Volume de Cinzas Volantes. Restor. Ecol. 2005, 23, 55–64. [Google Scholar] [CrossRef]

- Vimmrová, A.; Keppert, M.; Michalko, O.; Černý, R. Calcined gypsum–lime–metakaolin binders: Design of optimal composition. Cem. Concr. Compos. 2014, 52, 91–96. [Google Scholar] [CrossRef]

- Reis, R.; Camões, A.; Ribeiro, M.; Malheiro, R. Matrizes Cimentíceas Com Elevado Volume de Cinzas Volantes e Hidróxido de Cálcio: Estudo da Carbonatação; 5as Jornadas Port. Eng. Estruturas; LNEC: Lisbon, Portugal, 2014; pp. 1–12. [Google Scholar]

- EN1015-2:1998. Methods of Test for Mortar for Masonry—Part 2: Bulk Sampling of Mortars and Preparation of Test Mortars; CEN: Brussels, Belgium, 1998; Available online: https://shop.bsigroup.com/ProductDetail?pid=000000000030151072 (accessed on 26 February 2021).

- EN 1015-3, European Standard. Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); CEN: Brussels, Belgium, 1998. [Google Scholar]

- EN 1015-7, European Standard. Methods of Test for Mortar for Masonry—Part 7: Determination of Air Content of Fresh Mortar; CEN: Brussels, Belgium, 1998. [Google Scholar]

- Perez, J.A.V.; Guzmán, E.M.A.; Molina, W.M.; García, H.L.C.; Moreno, I.T.; Sánchez, M.A. Evaluation of the Electrical Resistivity, Ultrasonic Pulse Velocity and Mechanical Properties in Portland Cement Pastes Type II. Key Eng. Mater. 2020, 841, 198–202. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of high volumes of unprocessed lignite-coal fly ash and rice husk ash in self-consolidating concrete. J. Clean. Prod. 2014, 78, 184–194. [Google Scholar] [CrossRef]

- NP EN 12504-4. Portuguese Standard—Testing Concrete in Structures—Part 4: Determination of ultrasonic pulse velocity; NP: Lisbon, Portugal, 2007. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Andiç-Çakir, Ö.; Ramyar, K. Freeze–thaw resistance and transport properties of high-volume fly ash roller compacted concrete designed by maximum density method. Cem. Concr. Compos. 2013, 37, 259–266. [Google Scholar] [CrossRef]

- Cusens, A. Concrete technology. Build. Environ. 1976, 11, 215. [Google Scholar] [CrossRef]

- EN 1015-11, European Standard. Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; CEN: Brussels, Belgium, 1999. [Google Scholar]

- Teixeira, E.R.; Camões, A.; Branco, F.G.; Tarelho, L. Biomass and coal fly ash as cement replacement on mortar properties. In Proceedings of the ICCS16—II International Conference on Concrete Sustainability, Madrid, Spain, 13–15 June 2016; pp. 1–12. [Google Scholar]

- EN 1015-10, European Standard. Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar; CEN: Brussels, Belgium, 1999. [Google Scholar]

- LNEC E 394_1993. Determination of the Absorption of Water Immersion; LNEC: Lisbon, Portugal, 1993. [Google Scholar]

- EN 1015-18, European Standard. Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient due to Capillary Action of Hardened Mortar; CEN: Brussels, Belgium, 2002. [Google Scholar]

- Rajamma, R.; Senff, L.; Ribeiro, M.; Labrincha, J.; Ball, R.J.; Allen, G.; Ferreira, V. Biomass fly ash effect on fresh and hardened state properties of cement based materials. Compos. Part B Eng. 2015, 77, 1–9. [Google Scholar] [CrossRef]

- Modolo, R.; Ferreira, V.; Tarelho, L.; Labrincha, J.; Senff, L.; Silva, L. Mortar formulations with bottom ash from biomass combustion. Constr. Build. Mater. 2013, 45, 275–281. [Google Scholar] [CrossRef]

- Kayali, O.; Ahmed, M.S. Assessment of high volume replacement fly ash concrete – Concept of performance index. Constr. Build. Mater. 2013, 39, 71–76. [Google Scholar] [CrossRef]

- Bouzoubaâ, N.; Zhang, M.; Malhotra, V. Mechanical properties and durability of concrete made with high-volume fly ash blended cements using a coarse fly ash. Cem. Concr. Res. 2001, 31, 1393–1402. [Google Scholar] [CrossRef]

- Sahmaran, M.; Yaman, I.O. Hybrid fiber reinforced self-compacting concrete with a high-volume coarse fly ash. Constr. Build. Mater. 2007, 21, 150–156. [Google Scholar] [CrossRef]

- Zhang, M.; Malhotra, V. Characteristics of a thermally activated alumino-silicate pozzolanic material and its use in concrete. Cem. Concr. Res. 1995, 25, 1713–1725. [Google Scholar] [CrossRef]

- Arezoumandi, M.; Volz, J.S. Effect of fly ash replacement level on the shear strength of high-volume fly ash concrete beams. J. Clean. Prod. 2013, 59, 120–130. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Kocabağ, M.E.; Bayram, V.; Mermerdaş, K. Fresh and hardened characteristics of self compacting concretes made with combined use of marble powder, limestone filler, and fly ash. Constr. Build. Mater. 2012, 37, 160–170. [Google Scholar] [CrossRef]

- Torgal, F.P.; Jalali, S. Eco-efficient Construction and Building Materials. 2011. Available online: https://www.sciencedirect.com/book/9780857097675/eco-efficient-construction-and-building-materials (accessed on 26 February 2021).

- Ferreira, R.M.; Jalali, S. Quality control based on electrical resistivity measurements. In Proceedings of the ESCS-2006: European Symposium on Service Life and Serviceability of Concrete Structures, Helnsink, Finland, 12 June 2006; pp. 325–332. [Google Scholar]

- Electrical Resistivity Measurements for Quality Control During Concrete Construction. ACI Mater. J. 2008, 105, 541–547. [CrossRef]

- Rajamma, R. Incorporação de cinzas volantes de biomassa em materiais cimentíceos (Biomass fly ash incorporation in cement based materials). Ph.D. Thesis, Department of Materials and Ceramic Engineering, University of Aveiro, Aveiro, Portugal, 2011. [Google Scholar]

- Sua-Iam, G.; Makul, N. Utilization of limestone powder to improve the properties of self-compacting concrete incorporating high volumes of untreated rice husk ash as fine aggregate. Constr. Build. Mater. 2013, 38, 455–464. [Google Scholar] [CrossRef]

- Zerbino, R.; Giaccio, G.; Isaia, G. Concrete incorporating rice-husk ash without processing. Constr. Build. Mater. 2011, 25, 371–378. [Google Scholar] [CrossRef]

- Turgut, P. Cement composites with limestone dust and different grades of wood sawdust. Build. Environ. 2007, 42, 3801–3807. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of wood ash in concrete manufacturing. Resour. Conserv. Recycl. 2012, 67, 27–33. [Google Scholar] [CrossRef]

- Elinwa, A. Experimental characterization of Portland cement-calcined soldier-ant mound clay cement mortar and concrete. Constr. Build. Mater. 2006, 20, 754–760. [Google Scholar] [CrossRef]

- Ramos, T.; Matos, A.M.; Sousa-Coutinho, J. Mortar with wood waste ash: Mechanical strength carbonation resistance and ASR expansion. Constr. Build. Mater. 2013, 49, 343–351. [Google Scholar] [CrossRef]

- Tangchirapat, W.; Jaturapitakkul, C.; Chindaprasirt, P. Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Constr. Build. Mater. 2009, 23, 2641–2646. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Homwuttiwong, S.; Jaturapitakkul, C. Strength and water permeability of concrete containing palm oil fuel ash and rice husk–bark ash. Constr. Build. Mater. 2007, 21, 1492–1499. [Google Scholar] [CrossRef]

- Sukumar, B.; Nagamani, K.; Raghavan, R.S. Evaluation of strength at early ages of self-compacting concrete with high volume fly ash. Constr. Build. Mater. 2008, 22, 1394–1401. [Google Scholar] [CrossRef]

- Horsakulthai, V.; Phiuvanna, S.; Kaenbud, W. Investigation on the corrosion resistance of bagasse-rice husk-wood ash blended cement concrete by impressed voltage. Constr. Build. Mater. 2011, 25, 54–60. [Google Scholar] [CrossRef]

- Elinwa, A.; Ejeh, S. Effects of the Incorporation of Sawdust Waste Incineration Fly Ash in Cement Pastes and Mortars. J. Asian Arch. Build. Eng. 2004, 3, 1–7. [Google Scholar] [CrossRef]

- Barbhuiya, S.A.; Gbagbo, J.K.; Russell, M.I.; Basheer, P.A.M. Properties of fly ash concrete modified with hydrated lime and silica fume. Constr. Build. Mater. 2009, 23, 3233–3239. [Google Scholar] [CrossRef]

- Da Silva, P.R.; De Brito, J. Experimental study of the porosity and microstructure of self-compacting concrete (SCC) with binary and ternary mixes of fly ash and limestone filler. Constr. Build. Mater. 2015, 86, 101–112. [Google Scholar] [CrossRef]

| Parameters | CFA | BFA | CEM 42.5I | Hydrated Lime | Sand |

|---|---|---|---|---|---|

| Chemical elements (by FRX) (%wt) | |||||

| SiO2 | 54.08 | 36.06 | 15.94 | - | 95.30 |

| Cao | 3.27 | 28.00 | 52.94 | 93.0 (CaOH)2 * | 0.13 |

| Na2O | 0.50 | 0.87 | 0.81 | - | 0.09 |

| Al2O3 | 26.38 | 8.42 | 3.27 | - | 2.22 |

| MgO | 1.55 | 3.53 | 4.43 | ≤3.0 | 0.11 |

| K2O | 1.64 | 5.42 | 7.43 | - | 1.03 |

| Loss on ignition | 2.73 | 6.27 | 2.34 | - | 0.11 |

| Physical Characteristics | |||||

| Diameter for 10% of retained material (µm) | 1.53 | 5.91 | 1.33 | - | 550 |

| Diameter for 50% of retained material (µm) | 8.55 | 46.70 | 9.30 | - | 1400 |

| Diameter for 90% of retained material (µm) | 20.19 | 230.74 | 24.16 | - | 4000 |

| Specific weight (kg/m3) | 2420 | 2619 | 3100 | 2230 | 2600 |

| Nomenclature | Binder |

|---|---|

| 100C | 100% Cement |

| 50C-50FA | 50% Cement + 50% Fly ash |

| 50C-50BFA | 50% Cement + 50% Biomass fly ash |

| 50C-49.5FA-0.5HL | 50% Cement + 49.5% Fly ash 0.5% Hydrated lime |

| 50C-48.75FA-1.25HL | 50% Cement + 48.75% Fly ash + 1.25% Hydrated lime |

| 50C-45FA-5HL | 50% Cement + 45% Fly ash + 5% Hydrated lime |

| 50C-49.5BFA-0.5HL | 50% Cement + 49.5% Biomass fly ash + 0.5% Hydrated Lime |

| 50C-48.75BFA-1.25HL | 50% Cement + 48.75% Biomass fly ash + 1.25% Hydrated Lime |

| 50C-45BFA-5HL | 50% Cement + 45% Biomass fly ash + 5% Hydrated Lime |

| 50C-49.5FA-0.5BFA | 50% Cement + 49.5% Fly ash + 0.5% Biomass fly ash |

| 50C-48.75FA-1.25BFA | 50% Cement + 48.75% Fly ash + 1.25% Biomass fly ash |

| 50C-45FA-5BFA | 50% Cement + 45% Fly ash + 5% Biomass fly ash |

| 50C-49.5FA-0.25BFA-0.25HL | 50% Cement + 49.5% Fly ash + 0.25% Biomass fly ash + 0.25% Hydrated lime |

| 50C-48.75FA-0.625BFA-0.625HL | 50% Cement + 48.75% Fly ash + 0.625% Biomass fly ash + 0.625% Hydrated lime |

| 50C-45FA-2.5BFA-2.5HL | 50% Cement + 45% Fly ash + 2.5% Biomass fly ash + 2.5% Hydrated lime |

| 50C-25BFA-25CFA | 50% Cement + 25% Biomass Fly Ash + 25% Coal Fly Ash |

| Test | State | Period of Curing (Days) | Unit | Standard |

|---|---|---|---|---|

| Flow test | Fresh | After mixing | mm | EN 1015-3:1998 |

| Density | After mixing | kg/mm3 | EN 1015-2:1998 | |

| Air volume content | After mixing | % | EN 1015-7:1998 | |

| Electric resistivity | Hardened | 2,7,28,56,90,180 | kΩ/cm | - |

| Ultrasound | 2,7,28,56,90,180 | µS | EN 12504-4:2007 | |

| Mechanical strength | 2,7,28,56,90,180 | N/mm2 | EN 1015-11:1999 | |

| Water absorption by Immersion | 2,7,28,56,90,180 | % | EN 1015-10:1999/LNEC E 394:1993 | |

| Water absorption by Capillarity | 2,7,28,56,90,180 | kg/(m2·min0.5) | EN 1015-18:2002 | |

| Accelerated Carbonation | 2,7,28,56,90,180 | mm | EN 1015-3:1998 |

| Mortar Formulation | Flow Spread (mm) | Density (kg/m3) | Air Content (%) |

|---|---|---|---|

| 100C | 203.20 | 2231.80 | 2.80 |

| 50C-50FA | 242.10 | 2190.30 | 0.70 |

| 50C-50BFA | 209.23 | 2215.57 | 1.75 |

| 50C-49.5FA-0.5HL | 236.68 | 2208.17 | 0.70 |

| 50C-48.75FA-1.25HL | 234.64 | 2190.77 | 0.75 |

| 50C-45FA-5HL | 230.36 | 2213.40 | 0.80 |

| 50C-49.5BFA-0.5HL | 212.73 | 2213.40 | 2.10 |

| 50C-48.75BFA-1.25HL | 200.45 | 2182.43 | 2.30 |

| 50C-45BFA-5HL | 198.10 | 2172.57 | 2.10 |

| 50C-49.5FA-0.5BFA | 242.82 | 2216.73 | 0.80 |

| 50C-48.75FA-1.25BFA | 234.00 | 2201.83 | 0.75 |

| 50C-45FA-5BFA | 231.95 | 2145.83 | 0.80 |

| 50C-49.5FA-0.25BFA-0.25HL | 234.27 | 2191.40 | 0.50 |

| 50C-48.75FA-0.625BFA-0.625HL | 231.41 | 2152.33 | 1.25 |

| 50C-45FA-2.5BFA-2.5HL | 230.36 | 2200.57 | 0.85 |

| 50C-25BFA-25CFA | 223.64 | 2173.23 | 0.80 |

| Mortar Formulation | Coefficient | R2 | Coefficient | R2 | Coefficient | R2 |

|---|---|---|---|---|---|---|

| 28 Days | 90 Days | 180 Days | ||||

| 100C | 1.67 × 10−4 | 0.98 | 8.94 × 10−5 | 0.96 | 1.04 × 10−4 | 0.98 |

| 50C-50FA | 1.08 × 10−4 | 0.81 | 8.44 × 10−5 | 0.86 | 7.71 × 10−5 | 0.94 |

| 50C-50BFA | 2.79 × 10−4 | 0.96 | 1.20 × 10−4 | 0.93 | 1.19 × 10−4 | 0.96 |

| 50C-49.5FA-0.5HL | 1.64 × 10−4 | 0.99 | 1.26 × 10−4 | 0.97 | 1.20 × 10−4 | 0.96 |

| 50C-48.75FA-1.25HL | 1.74 × 10−4 | 0.99 | 1.28 × 10−4 | 0.94 | 1.23 × 10−4 | 0.98 |

| 50C-45FA-5HL | 1.62 × 10−4 | 0.99 | 1.21 × 10−4 | 0.91 | 1.18 × 10−4 | 0.95 |

| 50C-49.5BFA-0.5HL | 1.74 × 10−4 | 1.00 | 1.65 × 10−4 | 0.98 | 2.17 × 10−4 | 0.99 |

| 50C-48.75BFA-1.25HL | 1.37 × 10−4 | 0.94 | 1.71 × 10−4 | 0.96 | 1.34 × 10−4 | 1.00 |

| 50C-45BFA-5HL | 2.29 × 10−4 | 0.97 | 2.07 × 10−4 | 0.98 | 1.52 × 10−4 | 0.99 |

| 50C-49.5FA-0.5BFA | 2.00 × 10−4 | 0.98 | 1.91 × 10−4 | 0.97 | 1.40 × 10−4 | 1.00 |

| 50C-48.75FA-1.25BFA | 1.61 × 10−4 | 0.99 | 1.41 × 10−4 | 0.99 | 1.33 × 10−4 | 1.00 |

| 50C-45FA-5BFA | 1.68 × 10−4 | 0.99 | 1.26 × 10−4 | 0.94 | 1.44 × 10−4 | 0.99 |

| 50C-49.5FA-0.25BFA-0.25HL | 1.78 × 10−4 | 0.98 | 1.61 × 10−4 | 0.98 | 1.33 × 10−4 | 0.99 |

| 50C-48.75FA-0.625BFA-0.625HL | 1.82 × 10−4 | 0.97 | 1.29 × 10−4 | 0.99 | 1.34 × 10−4 | 0.99 |

| 50C-45FA-2.5BFA-2.5HL | 1.76 × 10−4 | 0.95 | 1.58 × 10−4 | 0.98 | 1.52 × 10−4 | 1.00 |

| 50C-25BFA-25CFA | 2.19 × 10−4 | 0.96 | 1.65 × 10−4 | 0.94 | 1.47 × 10−4 | 0.99 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teixeira, E.R.; Camões, A.; Branco, F.G.; Matos, J.C. Effect of Biomass Fly Ash on Fresh and Hardened Properties of High Volume Fly Ash Mortars. Crystals 2021, 11, 233. https://doi.org/10.3390/cryst11030233

Teixeira ER, Camões A, Branco FG, Matos JC. Effect of Biomass Fly Ash on Fresh and Hardened Properties of High Volume Fly Ash Mortars. Crystals. 2021; 11(3):233. https://doi.org/10.3390/cryst11030233

Chicago/Turabian StyleTeixeira, Elisabete R., Aires Camões, Fernando G. Branco, and José Campos Matos. 2021. "Effect of Biomass Fly Ash on Fresh and Hardened Properties of High Volume Fly Ash Mortars" Crystals 11, no. 3: 233. https://doi.org/10.3390/cryst11030233

APA StyleTeixeira, E. R., Camões, A., Branco, F. G., & Matos, J. C. (2021). Effect of Biomass Fly Ash on Fresh and Hardened Properties of High Volume Fly Ash Mortars. Crystals, 11(3), 233. https://doi.org/10.3390/cryst11030233