Recent Advances on Properties and Utility of Nanomaterials Generated from Industrial and Biological Activities

Abstract

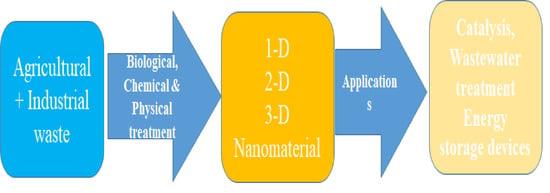

:1. Introduction

2. Classification of Nanostructured Materials

2.1. Zero-Dimensional Nanomaterial (0D Nanomaterial)

2.2. One Dimensional Nanomaterial (1D Nanomaterial)

2.3. Two-Dimensional Nanomaterials (2D Nanomaterials)

2.4. Three Dimensional Nanomaterials (3D Nanomaterials)

3. Different Methods of Nanomaterials Synthesis

3.1. Physical Methods for Synthesis of 2D NSMs

3.2. Chemical Methods for Synthesis of Nanomaterials

3.3. Biological Methods for the Synthesis of 2D NSMs

4. Carbon Nanomaterials

4.1. Synthesis of Fullerenes (OD NMs) from Fly Ash an Industrial Waste

4.2. Synthesis of GO from Agro Waste

4.3. Synthesis of Carbon Nanotubes/Carbon Nanofibers

4.4. Synthesis of CNTs from Fly Ash

4.5. Synthesis of CNTs from Plastic Waste and Tyres

4.6. Synthesis of CNTs from Agro Waste: Rice Husk

4.7. Synthesis of CNTs and Graphene from Oil

4.8. Synthesis of CNTs and Graphene from Poultry Waste

4.9. Carbon-Based Fullerene-Like (FL) Solid Compounds

4.10. Surface Functionalization and Modification of Graphene

4.11. D Carbon Nanomaterials

5. Applications of 2D Nanomaterials

5.1. Catalytic Applications of 2D Nanomaterials in Fuel Cells

5.2. Applications Related to Surface Plasmon Resonance

5.3. Nanotechnology and Solar Energy

6. Conclusions & Future Prospects

- Every year, tonnes of industrial wastes are produced with no use. Scientists are now starting to utilize the wastes for the synthesis of nanoparticles such as metals and metal oxide nanoparticles, nano-cellulose, carbon-based nanoparticles, and nano-fibres.

- These nanoparticles are further used to solve various environmental problems, especially nanoremediation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 0D | 0-dimensional |

| 1D | 1-dimensional |

| 2D | 2-dimensional |

| 3D | 3-dimensional |

| AFM | atomic force microscopy |

| AgNO3 | silver nitrate |

| Al2O3 | aluminum oxide |

| BaO | barium oxide |

| BET | Brunauer–Emmett–Teller |

| °C | degree Celsius |

| Ca | calcium |

| CaO | calcium Oxide |

| Cd | cadmium |

| CO | carbon monoxide |

| Co3O4 | cobalt(II,III) oxide |

| CNTs | carbon nanotubes |

| Cr | chromium |

| CVD | chemical vapor deposition |

| DMF | N,N-dimethylformamide |

| Fe | ferrous |

| Fe2O3 | ferric oxide |

| Fe3O4 | ferrous ferric oxide |

| Ga | gallium |

| GO | grapheme oxide |

| HER | hydrogen evolution reaction |

| HRTEM | high resolution transmission electron microscopy |

| InSe | indium selenide |

| K | kelvin |

| LCVD | laser chemical vapor deposition techniques |

| LEDs | light emitting diodes |

| Mg | magnesium |

| MgO | magnesium oxide |

| μm | micrometer |

| Mn | manganese |

| MnO | manganese oxide |

| Mo | molybdenum |

| MoO3 | molybdenum trioxide |

| MoS2 | molybdenum disulfide |

| MWCNT | multi walled carbon nanotubes |

| Na | sodium |

| Ni | nickel |

| Nm | nanometer |

| NMs | nanomaterials |

| NSMs | nano structured materials |

| NSs | nanosheets |

| NPs | nanoparticles |

| NSs | nanostructures |

| ORR | oxygen reduction reaction |

| Pb | lead |

| Pd | palladium |

| PEM | polymer electrolyte material |

| P2O5 | phosphorus pentoxide |

| Pt | platinum |

| PVP | polyvinyl pyrrolidone |

| QD | quantum dots |

| Rice Husk | rice husk |

| SB | sugarcane bagasse |

| Se | selenium |

| SEM | scanning electron microscopy |

| SERS | surface enhanced Raman scattering |

| SiO2 | silicon dioxide (silica) |

| SnO | stannous oxide |

| SnO2 | stannic oxide |

| SPR | surface plasmon resonance |

| SQUID | superconducting quantum interface device |

| SS | standard size |

| SVR | surface volume ratio |

| TEM | transmission electron microscopy |

| TGA | thermogravimetric analysis |

| TiO2 | titanium dioxide |

| TPPs | thermal power plants |

| WO3 | tungsten trioxide |

| WS3 | tungsten (VI) sulfide |

| XRD | X-ray diffraction |

| Zn | zinc |

| ZnO | zinc oxide |

| ZnS | zinc sulfide |

References

- Mansoori, G.A.; Soelaiman, T.A.F. Nanotechnology—An Introduction for the Standards. J. ASTM Int. 2005, 2, 1–21. [Google Scholar]

- Yadav, V.K.; Ali, D.; Khan, S.H.; Gnanamoorthy, G.; Choudhary, N.; Yadav, K.K.; Thai, V.N.; Hussain, S.A.; Manhrdas, S. Synthesis and Characterization of Amorphous Iron Oxide Nanoparticles by the Sonochemical Method and Their Application for the Remediation of Heavy Metals from Wastewater. Nanomaterials 2020, 10, 1551. [Google Scholar] [CrossRef] [PubMed]

- Malshe, A. Nanotechnology. In CIRP Encyclopedia of Production Engineering; The International Academy for Produ, Laperrière, L., Reinhart, G., Eds.; Springer: Berlin, Heidelberg, 2016. [Google Scholar] [CrossRef]

- Lošdorfer Božič, A.; Šiber, A.; Podgornik, R. Statistical analysis of sizes and shapes of virus capsids and their resulting elastic properties. J. Biol. Phys. 2013, 39, 215–228. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mansoori, G.A. Advances in Atomic and Molecular Nanotechnology. Available online: http://trl.lab.uic.edu/1.OnlineMaterials/nano.publications/AdvancesInAtomicNMolecularnanotech.pdf (accessed on 30 May 2021).

- Ali, S.; Abbas, Y.; Zuhra, Z.; Butler, I.S. Synthesis of γ-alumina (Al2O3) nanoparticles and their potential for use as an adsorbent in the removal of methylene blue dye from industrial wastewater. Nanoscale Adv. 2019, 1, 213–218. [Google Scholar] [CrossRef] [Green Version]

- Alam, J.; Yadav, V.K.; Yadav, K.K.; Cabral-Pinto, M.M.; Tavker, N.; Choudhary, N.; Shukla, A.K.; Ali, F.A.; Alhoshan, M.; Hamid, A.A. Recent Advances in Methods for the Recovery of Carbon Nanominerals and Polyaromatic Hydrocarbons from Coal Fly Ash and Their Emerging Applications. Crystals 2021, 11, 88. [Google Scholar] [CrossRef]

- Pyun, J.; Matyjaszewski, K. Synthesis of Nanocomposite Organic/Inorganic Hybrid Materials Using Controlled/“Living” Radical Polymerization. Chem. Mater. 2001, 13, 3436–3448. [Google Scholar] [CrossRef]

- Hanemann, T.; Szabó, D.V. Polymer-Nanoparticle Composites: From Synthesis to Modern Applications. Materials 2010, 3, 3468–3517. [Google Scholar] [CrossRef]

- Tavker, N.; Yadav, V.K.; Yadav, K.K.; Cabral-Pinto, M.M.; Alam, J.; Shukla, A.K.; Ali, F.A.; Alhoshan, M. Removal of Cadmium and Chromium by Mixture of Silver Nanoparticles and Nano-Fibrillated Cellulose Isolated from Waste Peels of Citrus Sinensis. Polymers 2021, 13, 234. [Google Scholar] [CrossRef]

- Marghussian, V. Nano-Glass Ceramics: Processing, Properties and Applications; Elsevier: Alpharetta, GA, USA, 2015; pp. 1–282. [Google Scholar]

- Yadav, V.K.; Fulekar, M.H. Advances in Methods for Recovery of Ferrous, Alumina, and Silica Nanoparticles from Fly Ash Waste. Ceramics 2020, 3, 34. [Google Scholar] [CrossRef]

- Yoriya, S.; Intana, T.; Tepsri, P. Separation of Cenospheres from Lignite Fly Ash Using Acetone–Water Mixture. Appl. Sci. 2019, 9, 3792. [Google Scholar] [CrossRef] [Green Version]

- Yadav, V.K.; Yadav, K.K.; Gnanamoorthy, G.; Choudhary, N.; Khan, S.H.; Gupta, N.; Kamyab, H.; Bach, Q.-V. A novel synthesis and characterization of polyhedral shaped amorphous iron oxide nanoparticles from incense sticks ash waste. Environ. Technol. Innov. 2020, 20, 101089. [Google Scholar] [CrossRef]

- Rana, S.; Fangueiro, R.; Thakur, V.K.; Joshi, M.; Thomas, S.; Fiedler, B. Nanomaterials from Natural Products for Industrial Applications. Available online: https://downloads.hindawi.com/journals/specialissues/743287.pdf (accessed on 30 May 2021).

- Dutta, T.; Kim, K.-H.; Deep, A.; Szulejko, J.; Vellingiri, K.; Kumar, S.; Kwon, E.; Yun, S.-T. Recovery of Nanomaterials from Battery and Electronic Wastes: A New Paradigm of Environmental Waste Management. Renew. Sustain. Energy Rev. 2017, 82, 3694–3704. [Google Scholar] [CrossRef]

- Ali, H.; Hassaan, M. Applications of Bio-waste Materials as Green Synthesis of Nanoparticles and Water Purification. Adv. Mater. 2017, 6, 85–101. [Google Scholar] [CrossRef] [Green Version]

- Yadav, V.K.; Fulekar, M.H. The current scenario of thermal power plants and fly ash production and utilization: With a focus in India. Int. J. Adv. Eng. Res. Dev. 2018, 5, 768–777. [Google Scholar]

- Sangeetha, J.; Thangadurai, D.; Hospet, R.; Purushotham, P.; Manowade, K.R.; Mujeeb, M.A.; Mundaragi, A.C.; Jogaiah, S.; David, M.; Thimmappa, S.C.; et al. Production of Bionanomaterials from Agricultural Wastes. In Nanotechnology: An Agricultural Paradigm; Springer: Singapore, 2017; pp. 33–58. [Google Scholar] [CrossRef]

- Cabral-Pinto, M.M.S.; Inácio, M.; Neves, O.; Almeida, A.A.; Pinto, E.; Oliveiros, B.; Ferreira da Silva, E.A. Human Health Risk Assessment Due to Agricultural Activities and Crop Consumption in the Surroundings of an Industrial Area. Expo. Health 2020, 12, 629–640. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, H.; Ge, S.; Song, J.; Wang, J.; Zhang, S. Synthesis of Carbon Nanotube Arrays with High Aspect Ratio via Ni-Catalyzed Pyrolysis of Waste Polyethylene. Nanomaterials 2018, 8, 556. [Google Scholar] [CrossRef] [Green Version]

- Cabral-Pinto, M.M.S.; Marinho-Reis, P.; Almeida, A.; Pinto, E.; Neves, O.; Inácio, M.; Gerardo, B.; Freitas, S.; Simões, M.R.; Dinis, P.A.; et al. Links between Cognitive Status and Trace Element Levels in Hair for an Environmentally Exposed Population: A Case Study in the Surroundings of the Estarreja Industrial Area. Int. J. Environ. Res. Public Health 2019, 16, 4560. [Google Scholar] [CrossRef] [Green Version]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Yadav, V.K.; Fulekar, M.H. Biogenic synthesis of maghemite nanoparticles (γ-Fe2O3) using Tridax leaf extract and its application for removal of fly ash heavy metals (Pb, Cd). Mater. Today Proc. 2018, 5, 20704–20710. [Google Scholar] [CrossRef]

- Nikalje, A. Nanotechnology and Its Applications in Medicine. Med. Chem. 2015, 5, 081–089. [Google Scholar] [CrossRef]

- Jeevanandam, J.; Barhoum, A.; Chan, Y.S.S.; Dufresne, A.; Danquah, M. Review on Nanoparticles and Nanostructured Materials: History, Sources, Toxicity, and Regulations. Beilstein J. Nanotechnol. 2018, 9, 1050–1074. [Google Scholar] [CrossRef] [Green Version]

- Edvinsson, T. Optical quantum confinement and photocatalytic properties in two-, one- and zero-dimensional nanostructures. R. Soc. Open Sci. 2018, 5, 180387. [Google Scholar] [CrossRef] [Green Version]

- Brehm, M.; Grydlik, M. Site-controlled and advanced epitaxial Ge/Si quantum dots: Fabrication, properties, and applications. Nanotechnology 2017, 28, 392001. [Google Scholar] [CrossRef]

- Patel, K.D.; Singh, R.K.; Kim, H.-W. Carbon-based nanomaterials as an emerging platform for theranostics. Mater. Horiz. 2019, 6, 434–469. [Google Scholar] [CrossRef]

- Singh, R.; Singh, K.R. A Review on Nano Materials of Carbon. J. Appl. Phys. 2017, 9, 42–57. [Google Scholar]

- Han, N.; Wang, F.; Ho, J. One-Dimensional Nanostructured Materials for Solar Energy Harvesting. Nanomater. Energy 2012, 1, 4–17. [Google Scholar] [CrossRef]

- Om, K.; Manjit, K. Single Electron Transistor: Applications & Problems. Int. J. VLSI Des. Commun. Syst. (VLSICS) 2010, 1, 24–29. [Google Scholar]

- Cao, H. Synthesis, Characterization, and Applications of Zero-Dimensional (0D) Nanostructures. In Synthesis and Applications of Inorganic Nanostructures; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Tiwari, J.N.; Tiwari, R.N.; Kim, K.S. Zero-dimensional, one-dimensional, two-dimensional and three-dimensional nanostructured materials for advanced electrochemical energy devices. Prog. Mater. Sci. 2012, 57, 724–803. [Google Scholar] [CrossRef]

- Mostofizadeh, A.; Li, Y.; Song, B.; Huang, Y. Synthesis, Properties, and Applications of Low-Dimensional Carbon-Related Nanomaterials. J. Nanomater. 2011, 2011, 685081. [Google Scholar] [CrossRef]

- Goyenola, C.; Stafström, S.; Hultman, L.; Gueorguiev, A.G. Structural Patterns Arising during Synthetic Growth of Fullerene-Like Sulfocarbide. J. Phys. Chem. C 2012, 116, 21124–21131. [Google Scholar] [CrossRef]

- Edelstein, A.S. Nanomaterials. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, UK, 2001; pp. 5916–5927. [Google Scholar] [CrossRef]

- Whitby, R.L.D.; Acquah, S.F.A.; Ma, R.; Zhu, Y. 1D Nanomaterials. J. Nanomater. 2010, 2010, 597851. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Hong, H.; Gong, Q.; Ji, L. 1D Nanomaterials: Synthesis, Properties, and Applications. Available online: https://downloads.hindawi.com/journals/jnm/2013/101836.pdf (accessed on 30 May 2021).

- Fang, X.; Zhang, L. One-Dimensional (1D) ZnS Nanomaterials and Nanostructures. J. Mater. Sci. Technol. 2006, 22, 721–736. [Google Scholar]

- Zhang, C.; Yan, Y.; Zhao, Y.; Yao, J. Synthesis and Applications of Organic Nanorods, Nanowires and Nanotubes. Annu. Rep. Sect. C Phys.Chem. 2013, 109, 211–239. [Google Scholar] [CrossRef]

- Guo, Z.; Tan, L. Fundamental and applications of Nanomaterials; Artech House: Norwood, MA, USA, 2009; pp. 1–241. [Google Scholar]

- Zhang, Z.; Zou, R.; Yu, L.; Hu, J. One-Dimensional Silicon-Based Semiconductor Nanomaterials: Synthesis, Structures, Properties and Applications. Crit. Rev. Solid State Mater. Sci. 2011, 36, 148–173. [Google Scholar] [CrossRef]

- Gnanamoorthy, G.; Yadav, V.K.; Latha, D.; Karthikeyan, V.; Narayanan, V. Enhanced photocatalytic performance of ZnSnO3/rGO nanocomposite. Chem. Phys. Lett. 2020, 739, 137050. [Google Scholar] [CrossRef]

- Gonsalves, K.E.; Rangarajan, S.P.; Wang, J. Chapter 1—Chemical synthesis of nanostructured metals, metal alloys, and semiconductors. In Handbook of Nanostructured Materials and Nanotechnology; Nalwa, H.S., Ed.; Academic Press: Burlington, NJ, USA, 2000; pp. 1–56. [Google Scholar] [CrossRef]

- Klein, E.; Lesyuk, R.; Klinke, C. Insights into the formation mechanism of two-dimensional lead halide nanostructures. Nanoscale 2018, 10, 4442–4451. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, P.K.; Kim, K.; Powell, M.A.; Equeenuddin, S.M. Recovery of metals and other beneficial products from coal fly ash: A sustainable approach for fly ash management. Int. J. Coal Sci. Technol. 2016, 3, 267–283. [Google Scholar] [CrossRef] [Green Version]

- Yin, P.T.; Shah, S.; Chhowalla, M.; Lee, K.-B. Design, synthesis, and characterization of graphene-nanoparticle hybrid materials for bioapplications. Chem. Rev. 2015, 115, 2483–2531. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, J.; Chen, X.; Huang, P. Graphene-based nanomaterials for bioimaging. Adv. Drug Deliv. Rev. 2016, 105, 242–254. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shah, M.; Fawcett, D.; Sharma, S.; Tripathy, S.; Poinern, G. Green Synthesis of Metallic Nanoparticles via Biological Entities. Materials 2015, 8, 7278–7308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koski, K.J.; Cui, Y. The New Skinny in Two-Dimensional Nanomaterials. ACS Nano 2013, 7, 3739–3743. [Google Scholar] [CrossRef] [PubMed]

- Gnanamoorthy, G.; Ramar, K.; Padmanaban, A.; Yadav, V.K.; Suresh Babu, K.; Karthikeyan, V.; Narayanan, V. Implementation of ZnSnO3 nanosheets and their RE (Er, Eu, and Pr) materials: Enhanced photocatalytic activity. Adv. Powder Technol. 2020, 31, 1209–1219. [Google Scholar] [CrossRef]

- Boroumand Moghaddam, A.; Namvar, F.; Moniri, M.; Md Tahir, P.; Azizi, S.; Mohamad, R. Nanoparticles Biosynthesized by Fungi and Yeast: A Review of Their Preparation, Properties, and Medical Applications. Molecules 2015, 20, 16540–16565. [Google Scholar] [CrossRef]

- Miró, P.; Audiffred, M.; Heine, T. An Atlas of Two-Dimensional Materials. Chem. Soc. Rev. 2014, 43, 6537–6554. [Google Scholar] [CrossRef]

- Van Gough, D.; Juhl, A.T.; Braun, P.V. Programming structure into 3D nanomaterials. Mater. Today 2009, 12, 28–35. [Google Scholar] [CrossRef]

- Yaya, A. Layered Nanomaterials—A Review. Glob. J. Eng. Des. and Technol. 2012, 1, 32–41. [Google Scholar]

- Korotcenkov, G. Current Trends in Nanomaterials for Metal Oxide-Based Conductometric Gas Sensors: Advantages and Limitations. Part 1: 1D and 2D Nanostructures. Nanomaterials 2020, 10, 1392. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Jaiswal, S.; Duffy, B.; Jaiswal, A. Nanostructured Materials for Food Applications: Spectroscopy, Microscopy and Physical Properties. Bioengineering 2019, 6, 26. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Gu, H. Novel Metal Nanomaterials and Their Catalytic Applications. Molecules 2015, 20, 17070–17092. [Google Scholar] [CrossRef] [Green Version]

- Julien, M.C.; Mauger, A. Nanostructured MnO2 as Electrode Materials for Energy Storage. Nanomaterials 2017, 7, 396. [Google Scholar] [CrossRef] [Green Version]

- Singh, P.; Jain, S. Biosynthesis of Nanomaterials: Growth and Properties. Rev. Adv. Sci. Eng. 2014, 3, 231–238. [Google Scholar] [CrossRef]

- Luther, W. Industrial Application of Nanomaterials—Chances and Risks. Technologiezentrum 2004, 54, 1–3. [Google Scholar]

- Gavagnin, M.; Wanzenboeck, H.D.; Wachter, S.; Shawrav, M.M.; Persson, A.; Gunnarsson, K.; Svedlindh, P.; Stöger-Pollach, M.; Bertagnolli, E. Free-Standing Magnetic Nanopillars for 3D Nanomagnet Logic. ACS Appl. Mater. Interfaces 2014, 6, 20254–20260. [Google Scholar] [CrossRef]

- Georgakilas, V.; Perman, J.A.; Tucek, J.; Zboril, R. Broad Family of Carbon Nanoallotropes: Classification, Chemistry, and Applications of Fullerenes, Carbon Dots, Nanotubes, Graphene, Nanodiamonds, and Combined Superstructures. Chem. Rev. 2015, 115, 4744–4822. [Google Scholar] [CrossRef]

- Semaltianos, N.G. Nanoparticles by Laser Ablation. Crit. Rev. Solid State Mater. Sci. 2010, 35, 105–124. [Google Scholar] [CrossRef]

- Sarkar, J.K.; Wang, Q. Different Pyrolysis Process Conditions of South Asian Waste Coconut Shell and Characterization of Gas, Bio-Char, and Bio-Oil. Energies 2020, 13, 1970. [Google Scholar] [CrossRef]

- Dhand, C.; Dwivedi, N.; Loh, X.J.; Ng, A.; Verma, N.; Beuerman, R.; Lakshminarayanan, R.; Ramakrishna, S. Methods and Strategies for the Synthesis of Diverse Nanoparticles and Their Applications: A Comprehensive Overview. RSC Adv. 2015, 5, 105003–105037. [Google Scholar] [CrossRef]

- Umadevi, S.; Umamaheswari, R.; Ganesh, V. Lyotropic liquid crystal-assisted synthesis of micro- and nanoparticles of silver. Liq. Cryst. 2017, 44, 1409–1420. [Google Scholar] [CrossRef]

- Tonelli, D.; Scavetta, E.; Gualandi, I. Electrochemical Deposition of Nanomaterials for Electrochemical Sensing. Sensors 2019, 19, 1186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tierno, P.; Goedel, W.A. Using Electroless Deposition for the Preparation of Micron Sized Polymer/Metal Core/Shell Particles and Hollow Metal Spheres. J. Phys. Chem. B 2006, 110, 3043–3050. [Google Scholar] [CrossRef]

- Hayashi, H.; Hakuta, Y. Hydrothermal Synthesis of Metal Oxide Nanoparticles in Supercritical Water. Materials 2010, 3, 3794–3817. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Wu, Q.; Wu, J. Synthesis of Nanoparticles via Solvothermal and Hydrothermal Methods. In Handbook of Nanoparticles; Aliofkhazraei, M., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 295–328. [Google Scholar] [CrossRef]

- Ramesh, S. Sol-Gel Synthesis and Characterization of Nanoparticles. J. Nanosci. 2013, 2013, 929321. [Google Scholar] [CrossRef] [Green Version]

- Kumar Yadav, V.; Fulekar, M.H. Green synthesis and characterization of amorphous silica nanoparticles from fly ash. Mater. Today Proc. 2019, 18, 4351–4359. [Google Scholar] [CrossRef]

- Essawy, H.; Fathy, N.; Tawfik, M.; El-Sabbagh, S.; Ismail, N.; Youssef, H. Fabrication of single-walled carbon nanotubes from vulcanized scrap rubber via thermal chemical vapor deposition. RSC Adv. 2017, 7, 12938–12944. [Google Scholar] [CrossRef] [Green Version]

- Piriyawong, V.; Thongpool, V.; Asanithi, P.; Limsuwan, P. Preparation and Characterization of Alumina Nanoparticles in Deionized Water Using Laser Ablation Technique. J. Nanomater. 2012, 2012, 819403. [Google Scholar] [CrossRef]

- Yadav, D.A. Synthesis of nanomaterials by physical and chemical methods. Int. Educ. Res. J. 2017, 3, 350–352. [Google Scholar]

- Fariq, A.; Khan, T.; Yasmin, A. Microbial synthesis of nanoparticles and their potential applications in biomedicine. J. Appl. Biomed. 2017, 15, 241–248. [Google Scholar] [CrossRef]

- Peralta-Videa, J.R.; Huang, Y.; Parsons, J.G.; Zhao, L.; Lopez-Moreno, L.; Hernandez-Viezcas, J.A.; Gardea-Torresdey, J.L. Plant-based green synthesis of metallic nanoparticles: Scientific curiosity or a realistic alternative to chemical synthesis? Nanotechnol. Environ. Eng. 2016, 1, 4. [Google Scholar] [CrossRef]

- Bansal, V.; Poddar, P.; Ahmad, A.; Sastry, M. Room-Temperature Biosynthesis of Ferroelectric Barium Titanate Nanoparticles. J. Am. Chem. Soc. 2006, 128, 11958–11963. [Google Scholar] [CrossRef]

- Castro, L.; Blázquez, M.L.; Muñoz, J.; González, F.; Ballester, A. Biological Synthesis of Metallic Nanoparticles Using Algae. IET Nanobiotechnol. 2013, 7, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Iravani, S. Bacteria in Nanoparticle Synthesis: Current Status and Future Prospects. Int. Sch. Res. Not. 2014, 2014, 59316. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, D.; Kanchi, S.; Bisetty, K. Biogenic synthesis of nanoparticles: A review. Arab. J. Chem. 2019, 12, 3576–3600. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Kim, K.H.; Bark, C.W. Two-Dimensional Nanomaterials: Their Structures, Synthesis, and Applications. Sci. Adv. Mater. 2017, 9, 1441–1457. [Google Scholar] [CrossRef]

- Zavabeti, A.; Jannat, A.; Zhong, L.; Haidry, A.A.; Yao, Z.; Ou, J.Z. Two-Dimensional Materials in Large-Areas: Synthesis, Properties and Applications. Nano-Micro Lett. 2020, 12, 66. [Google Scholar] [CrossRef] [Green Version]

- Colson, P.; Henrist, C.; Cloots, R. Nanosphere Lithography: A Powerful Method for the Controlled Manufacturing of Nanomaterials. J. Nanomater. 2013, 2013, 948510. [Google Scholar] [CrossRef] [Green Version]

- Pingali, K.C.; Deng, S.; Rockstraw, D.A. Synthesis of Nanowires by Spray Pyrolysis. J. Sens. 2009, 2009, 683280. [Google Scholar] [CrossRef] [Green Version]

- Suryanarayana, C.; Prabhu, B. Synthesis of Nanostructured Materials by Inert-Gas Condensation Methods; Nanostructured materials (second edition); William Andrew Publishing: Norwich, NY, USA, 2007; pp. 47–90. [Google Scholar]

- Habiba, K.; Makarov, V.; Weiner, B.; Morell, G. Fabrication of Nanomaterials by Pulsed Laser Synthesis; In book: Manufacturing Nanostructures, Chapter: 10. Available online: https://www.researchgate.net/publication/270583669_Fabrication_of_Nanomaterials_by_Pulsed_Laser_Synthesis (accessed on 30 May 2021).

- Xu, H.; Zeiger, B.W.; Suslick, K.S. Sonochemical synthesis of nanomaterials. Chem. Soc. Rev. 2013, 42, 2555–2567. [Google Scholar] [CrossRef] [Green Version]

- Ray, P.C.; Yu, H.; Fu, P.P. Toxicity and Environmental Risks of Nanomaterials: Challenges and Future Needs. J. Environ. Sci. Health Part C 2009, 27, 1–35. [Google Scholar] [CrossRef] [Green Version]

- Gnanamoorthy, G.; Ali, D.; Yadav, V.K.; Dhinagaran, G.; Venkatachalam, K.; Narayanan, V. New construction of Fe3O4/rGO/ZnSnO3 nanocomposites enhanced photoelectro chemical properties. Opt. Mater. 2020, 109, 110353. [Google Scholar] [CrossRef]

- Yang, J.; Hou, B.; Wang, J.; Tian, B.; Bi, J.; Wang, N.; Li, X.; Huang, X. Nanomaterials for the Removal of Heavy Metals from Wastewater. Nanomaterials 2019, 9, 424. [Google Scholar] [CrossRef] [Green Version]

- Dai, Z.R.; Pan, Z.W.; Wang, Z.L. Growth and Structure Evolution of Novel Tin Oxide Diskettes. J. Am. Chem. Soc. 2002, 124, 8673–8680. [Google Scholar] [CrossRef] [PubMed]

- Cha, C.; Shin, S.R.; Annabi, N.; Dokmeci, M.R.; Khademhosseini, A. Carbon-based nanomaterials: Multifunctional materials for biomedical engineering. ACS Nano 2013, 7, 2891–2897. [Google Scholar] [CrossRef]

- Savjani, K.T.; Gajjar, A.K.; Savjani, J.K. Drug solubility: Importance and enhancement techniques. ISRN Pharm. 2012, 2012, 195727. [Google Scholar] [CrossRef] [Green Version]

- Dubé, M.A.; Salehpour, S. Applying the Principles of Green Chemistry to Polymer Production Technology. Macromol. React. Eng. 2014, 8, 7–28. [Google Scholar] [CrossRef]

- Giurlani, W.; Zangari, G.; Gambinossi, F.; Passaponti, M.; Salvietti, E.; Di Benedetto, F.; Caporali, S.; Innocenti, M. Electroplating for Decorative Applications: Recent Trends in Research and Development. Coatings 2018, 8, 260. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Fan, Z.; Zhang, Z.; Niu, W.; Li, C.; Yang, N.; Chen, B.; Zhang, H. Two-Dimensional Metal Nanomaterials: Synthesis, Properties, and Applications. Chem. Rev. 2018, 118, 6409–6455. [Google Scholar] [CrossRef]

- Yang, F.; Song, P.; Ruan, M.; Xu, W. Recent progress in two-dimensional nanomaterials: Synthesis, engineering, and applications. FlatChem 2019, 18, 100133. [Google Scholar] [CrossRef]

- Paul, R.; Reifenberger, R.G.; Fisher, T.S.; Zemlyanov, D.Y. Atomic Layer Deposition of FeO on Pt(111) by Ferrocene Adsorption and Oxidation. Chem. Mater. 2015, 27, 5915–5924. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, H.; Yu, J.; Li, B.; Ding, B. Multi-functional flexible 2D carbon nanostructured networks. Nat. Commun. 2020, 11, 5134. [Google Scholar] [CrossRef] [PubMed]

- Rai, M.; Ingle, A.; Birla, S.; Yadav, A.; Santos, C. Strategic Role of Selected Noble Metal Nanoparticles in Medicine. Crit. Rev. Microbiol. 2016, 42, 696–719. [Google Scholar] [CrossRef] [PubMed]

- Khodashenas, B.; Ghorbani, H. Synthesis of Silver Nanoparticles with Different Shapes. Arab. J. Chem. 2015, 12, 1823–1838. [Google Scholar] [CrossRef] [Green Version]

- Jiang, X.; Yu, A.B.; Yang, W.R.; Ding, Y.; Xu, C.X.; Lam, S. Synthesis and Growth of Hematite Nanodiscs through a Facile Hydrothermal Approach. J. Nanopart. Res. 2009, 12, 877–893. [Google Scholar] [CrossRef]

- Fu, J.; Skrabalak, S.E. Aerosol synthesis of shape-controlled template particles: A route to Ta3N5 nanoplates and octahedra as photocatalysts. J. Mater. Chem. A 2016, 4, 8451–8457. [Google Scholar] [CrossRef]

- Swarnavalli, G.C.J.; Joseph, V.; Kannappan, V.; Roopsingh, D. A Simple Approach to the Synthesis of Hexagonal-Shaped Silver Nanoplates. J. Nanomater. 2011, 2011, 825637. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Zhao, X.; Li, Y.; Sui, X. Shape-Controlled Synthesis for Silver: Triangular/Hexagonal Nanoplates, Chain-Like Nanoplate Assemblies, and Nanobelts. J. Mater. Res. 2009, 24, 2200–2209. [Google Scholar] [CrossRef]

- Zeb Gul Sial, M.A.; Ud Din, M.A.; Wang, X. Multimetallic nanosheets: Synthesis and applications in fuel cells. Chem. Soc. Rev. 2018, 47, 6175–6200. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Chen, H.; Xing, C.; Guo, M.; Xu, F.; Wang, X.; Gruber, H.; Zhang, B.; Tang, J. Sodium Citrate: A Universal Reducing Agent for Reduction/Decoration of Graphene Oxide with Au Nanoparticles. Nano Res. 2011, 4, 599–611. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, G.; Yu, Y.; Yan, C.; Sun, J.; He, F. Synthesis of Metal Oxide Nanosheets through a Novel Approach for Energy Applications. J. Mater. Chem. A 2015, 4, 781–784. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H.; Xue, X. Preparation of Different Shaped α-Fe2O3 Nanoparticles with Large Particle of Iron Oxide Red. CrystEngComm 2019, 21, 1097–1101. [Google Scholar] [CrossRef]

- Dai, X.-C.; Hou, S.; Huang, M.-H.; Li, Y.-B.; Li, T.; Xiao, F.-X. Electrochemically anodized one-dimensional semiconductors: A fruitful platform for solar energy conversion. J. Phys. Energy 2019, 1, 022002. [Google Scholar] [CrossRef]

- Kawde, A.-N.; Aziz, M.A.; El-Zohri, M.; Baig, N.; Odewunmi, N. Cathodized Gold Nanoparticle-Modified Graphite Pencil Electrode for Non-Enzymatic Sensitive Voltammetric Detection of Glucose. Electroanalysis 2017, 29, 1214–1221. [Google Scholar] [CrossRef]

- Ghicov, A.; Schmuki, P. Self-ordering electrochemistry: A review on growth and functionality of TiO2 nanotubes and other self-aligned MOx structures. Chem. Commun. 2009, 2791–2808. [Google Scholar] [CrossRef] [PubMed]

- Syrek, K.; Kapusta-Kołodziej, J.; Jarosz, M.; Sulka, G.D. Effect of electrolyte agitation on anodic titanium dioxide (ATO) growth and its photoelectrochemical properties. Electrochim. Acta 2015, 180, 801–810. [Google Scholar] [CrossRef]

- Lawrence, M.J.; Celorrio, V.; Shi, X.; Wang, Q.; Yanson, A.; Adkins, N.J.E.; Gu, M.; Rodríguez-López, J.; Rodriguez, P. Electrochemical Synthesis of Nanostructured Metal-Doped Titanates and Investigation of Their Activity as Oxygen Evolution Photoanodes. ACS Appl. Energy Mater. 2018, 1, 5233–5244. [Google Scholar] [CrossRef]

- Yadav, V.K.; Khan, S.H.; Malik, P.; Thappa, A.; Suriyaprabha, R.; Ravi, R.K.; Choudhary, N.; Kalasariya, H.; Gnanamoorthy, G. Microbial Synthesis of Nanoparticles and Their Applications for Wastewater Treatment. In Microbial Biotechnology: Basic Research and Applications; Singh, J., Vyas, A., Wang, S., Prasad, R., Eds.; Springer: Singapore, 2020; pp. 147–187. [Google Scholar] [CrossRef]

- Tiwari, S.; Kumar, V.; Huczko, A.; Oraon, R.; De Adhikari, A.; Nayak, G. Magical Allotropes of Carbon: Prospects and Applications. Crit. Rev. Solid State Mater. Sci. 2015, 41, 257–317. [Google Scholar] [CrossRef]

- Zaytseva, O.; Neumann, G. Carbon nanomaterials: Production, impact on plant development, agricultural and environmental applications. Chem. Biol. Technol. Agric. 2016, 3, 17. [Google Scholar] [CrossRef] [Green Version]

- Hower, J.; Groppo, J.; Graham, U.; Ward, C.; Kostova, I.; Maroto-Valer, M.; Dai, S. Coal-Derived Unburned Carbons in Fly Ash: A Review. Int. J. Coal Geol. 2017, 179, 11–27. [Google Scholar] [CrossRef]

- Salah, N.; Al-Ghamdi, A.; Memic, A.; Habib, S.S.; Khan, Z.H. Formation of Carbon Nanotubes from Carbon Rich Fly Ash: Growth Parameters and Mechanism. Mater. Manuf. Process. 2016, 31, 146–156. [Google Scholar] [CrossRef]

- Loh, Y.R.; Sujan, D.; Rahman, M.E.; Das, C.A. Sugarcane bagasse—The future composite material: A literature review. Resour. Conserv. Recycl. 2013, 75, 14–22. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Gao, S.J.; Yang, Z.; Wu, N. Characteristics and Applications of Sugar Cane Bagasse Ash Waste in Cementitious Materials. Materials 2018, 12, 39. [Google Scholar] [CrossRef] [Green Version]

- Kroto, H.W.; Heath, J.R.; O’Brien, S.C.; Curl, R.F.; Smalley, R.E. buckminsterfullerene. Nature 1985, 318, 162–163. [Google Scholar] [CrossRef]

- Iijima, S. Helical Microtubules of Graphitic Carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Byrne, M.T.; Gun’ko, Y.K. Recent advances in research on carbon nanotube-polymer composites. Adv. Mater. 2010, 22, 1672–1688. [Google Scholar] [CrossRef]

- Arora, N.; Sharma, N.N. Arc Discharge Synthesis of Carbon Nanotubes: Comprehensive Review. Diam. Relat. Mater. 2014, 50, 135–150. [Google Scholar] [CrossRef]

- Vallejos, S.; Di Maggio, F.; Shujah, T.; Blackman, C. Chemical Vapour Deposition of Gas Sensitive Metal Oxides. Chemosensors 2016, 4, 4. [Google Scholar] [CrossRef] [Green Version]

- Tripathi, P.K.; Durbach, S.; Coville, N.J. Synthesis of Multi-Walled Carbon Nanotubes from Plastic Waste Using a Stainless-Steel CVD Reactor as Catalyst. Nanomaterials 2017, 7, 284. [Google Scholar] [CrossRef]

- Nguyen, H.; Jamali Moghadam, M.; Moayedi, H. Agricultural Wastes Preparation, Management, and Applications in Civil Engineering: A Review. J. Mater. Cycles Waste Manag. 2019, 21, 1039–1051. [Google Scholar] [CrossRef]

- Zhang, Y.; Williams, P.T. Carbon nanotubes and hydrogen production from the pyrolysis catalysis or catalytic-steam reforming of waste tyres. J. Anal. Appl. Pyrolysis 2016, 122, 490–501. [Google Scholar] [CrossRef] [Green Version]

- Gnanamoorthy, G.; Yadav, V.K.; Yadav, K.K. Fabrication of different SnO2 nanorods for enhanced photocatalytic degradation and antibacterial activity. Environ. Sci. Pollut. Res. 2021, 1, 1–11. [Google Scholar]

- Ramirez, A.; Royo, C.; Latorre, N.; Mallada, R.; Tiggelaar, R.; Monzon, A. Unraveling The Growth of Vertically Aligned Multi-Walled Carbon Nanotubes by Chemical Vapor Deposition. Mater. Res. Express 2014, 1, 045604. [Google Scholar] [CrossRef]

- Nessim, G.D. Properties, synthesis, and growth mechanisms of carbon nanotubes with special focus on thermal chemical vapor deposition. Nanoscale 2010, 2, 1306–1323. [Google Scholar] [CrossRef]

- MacKenzie, K.J.; Dunens, O.M.; Harris, A.T. An Updated Review of Synthesis Parameters and Growth Mechanisms for Carbon Nanotubes in Fluidized Beds. Ind. Eng. Chem. Res. 2010, 49, 5323–5338. [Google Scholar] [CrossRef]

- Zhuo, C.; Wang, X.; Nowak, W.; Levendis, Y. Oxidative Heat Treatment of 316L Stainless Steel for Effective Catalytic Growth of Carbon Nanotubes. Appl. Surf. Sci. 2014, 313, 227–236. [Google Scholar] [CrossRef]

- Azadi, M.; Bahrololoom, M.; Heidari, F. Enhancing the Mechanical Properties of an Epoxy Coating with Rice Husk Ash, a Green Product. J. Coat. Technol. Res. 2011, 8, 117–123. [Google Scholar] [CrossRef]

- Yalçin, N.; Sevinç, V. Studies on Silica Obtained from Rice Husk. Ceram. Int. 2001, 27, 219–224. [Google Scholar] [CrossRef]

- Yalçın, N.; Sevinç, V. Studies of the Surface Area and Porosity of Activated Carbons Prepared from Rice Husks. Carbon 2000, 38, 1943–1945. [Google Scholar] [CrossRef]

- Dalling, T. FAO Statistical yearbook 2013: World food and agriculture. In Food and Agriculture Organization of the United Nations; FAO Fiat Fanis: Rome, Italy, 2010; p. 189. [Google Scholar]

- Osman, A.I.; Farrell, C.; Al-Muhtaseb, A.a.H.; Harrison, J.; Rooney, D.W. The production and application of carbon nanomaterials from high alkali silicate herbaceous biomass. Sci. Rep. 2020, 10, 2563. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.R.; Singh, D.R.; Singh, D. Natural and Waste Hydrocarbon Precursors for the Synthesis of Carbon Based Nanomaterials: Graphene and CNTs. Renew. Sustain. Energy Rev. 2016, 58, 976–1006. [Google Scholar] [CrossRef]

- Chatterjee, A.K.; Sharon, M.; Banerjee, R.; Neumann-Spallart, M. CVD Synthesis of Carbon Nanotubes Using a Finely Dispersed Cobalt Catalyst and Their Use in Double Layer Electrochemical Capacitors. Electrochim. Acta 2003, 48, 3439–3446. [Google Scholar] [CrossRef]

- Myint, D.; Gilani, S.A.; Kawase, M.; Watanabe, K.N. Sustainable Sesame (Sesamum indicum L.) Production through Improved Technology: An Overview of Production, Challenges, and Opportunities in Myanmar. Sustainability 2020, 12, 3515. [Google Scholar] [CrossRef]

- Janas, D. From Bio to Nano: A Review of Sustainable Methods of Synthesis of Carbon Nanotubes. Sustainability 2020, 12, 4115. [Google Scholar] [CrossRef]

- Titirici, M.; White, R.; Brun, N.; Budarin, V.; Su, D.; Monte, F.; Clark, J.; MacLachlan, M. Sustainable carbon materials. Chem. Soc. Rev. 2014, 44, 250–290. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, X.; Zhang, L.; Lv, Y. Microwave-Assisted Synthesis of Carbon Nanodots through an Eggshell Membrane and Their Fluorescent Application. Analyst 2012, 137, 5392–5397. [Google Scholar] [CrossRef] [PubMed]

- Furlan, A.; Gueorguiev, G.K.; Högberg, H.; Stafström, S.; Hultman, L. Fullerene-like CPx: A first-principles study of the relative stability of precursors and defect energetics during synthetic growth. Thin Solid Film 2006, 515, 1028–1032. [Google Scholar] [CrossRef]

- Shi, S.; Chen, F.; Ehlerding, E.B.; Cai, W. Surface Engineering of Graphene-Based Nanomaterials for Biomedical Applications. Bioconjug. Chem. 2014, 25, 1609–1619. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ali, I.; Basheer, A.A.; Mbianda, X.Y.; Burakov, A.; Galunin, E.; Burakova, I.; Mkrtchyan, E.; Tkachev, A.; Grachev, V. Graphene based adsorbents for remediation of noxious pollutants from wastewater. Environ. Int. 2019, 127, 160–180. [Google Scholar] [CrossRef]

- Ghosal, K.; Sarkar, K. Biomedical Applications of Graphene Nanomaterials and Beyond. ACS Biomater. Sci. Eng. 2018, 4, 2653–2703. [Google Scholar] [CrossRef] [PubMed]

- Yadav, V.K.; Gnanamoorthy, G.; Cabral-Pinto, M.M.S.; Alam, J.; Ahamed, M.; Gupta, N.; Singh, B.; Choudhary, N.; Inwati, G.K.; Yadav, K.K. Variations and similarities in structural, chemical, and elemental properties on the ashes derived from the coal due to their combustion in open and controlled manner. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef] [PubMed]

- Paul, R.; Etacheri, V.; Pol, V.G.; Hu, J.; Fisher, T.S. Highly porous three-dimensional carbon nanotube foam as a freestanding anode for a lithium-ion battery. RSC Adv. 2016, 6, 79734–79744. [Google Scholar] [CrossRef]

- Paul, R.; Du, F.; Dai, L.; Ding, Y.; Wang, Z.L.; Wei, F.; Roy, A. 3D Heteroatom-Doped Carbon Nanomaterials as Multifunctional Metal-Free Catalysts for Integrated Energy Devices. Adv. Mater. 2019, 31. [Google Scholar] [CrossRef]

- Paul, R.; Roy, A.K. BN-codoped CNT based nanoporous brushes for all-solid-state flexible supercapacitors at elevated temperatures. Electrochim. Acta 2021, 365, 1805598. [Google Scholar] [CrossRef]

- Serrano, M.C.; Gutiérrez, M.C.; del Monte, F. Role of polymers in the design of 3D carbon nanotube-based scaffolds for biomedical applications. Prog. Polym. Sci. 2014, 39, 1448–1471. [Google Scholar] [CrossRef]

- Yadav, V.K.; Yadav, K.K.; Cabral-Pinto, M.M.S.; Choudhary, N.; Gnanamoorthy, G.; Tirth, V.; Prasad, S.; Khan, A.H.; Islam, S.; Khan, N.A. The Processing of Calcium Rich Agricultural and Industrial Waste for Recovery of Calcium Carbonate and Calcium Oxide and Their Application for Environmental Cleanup: A Review. Appl. Sci. 2021, 11, 4212. [Google Scholar] [CrossRef]

- Mei, L.; Zhu, S.; Yin, W.; Chen, C.; Nie, G.; Gu, Z.; Zhao, Y. Two-dimensional nanomaterials beyond graphene for antibacterial applications: Current progress and future perspectives. Theranostics 2020, 10, 757–781. [Google Scholar] [CrossRef] [PubMed]

- Alberto, N.; Domingues, M.F.; Marques, C.; Andre, P.; Antunes, P. Optical Fiber Magnetic Field Sensors Based on Magnetic Fluid: A Review. Sensors 2018, 18, 4325. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khan, K.; Tareen, A.K.; Aslam, M.; Sagar, R.U.R.; Zhang, B.; Huang, W.; Mahmood, A.; Mahmood, N.; Khan, K.; Zhang, H.; et al. Recent Progress, Challenges, and Prospects in Two-Dimensional Photo-Catalyst Materials and Environmental Remediation. Nano-Micro Lett. 2020, 12, 167. [Google Scholar] [CrossRef]

- Hong, J.W.; Kim, Y.; Wi, D.H.; Lee, S.; Lee, S.-U.; Lee, Y.W.; Choi, S.-I.; Han, S.W. Ultrathin Free-Standing Ternary-Alloy Nanosheets. Angew. Chem. 2016, 128, 2803–2808. [Google Scholar] [CrossRef]

- Ud Din, M.A.; Saleem, F.; Ni, B.; Yong, Y.; Wang, X. Porous Tetrametallic PtCuBiMn Nanosheets with a High Catalytic Activity and Methanol Tolerance Limit for Oxygen Reduction Reactions. Adv. Mater. 2017, 29, 1604994. [Google Scholar] [CrossRef]

- Paul, R.; Zhu, L.; Chen, H.; Qu, J.; Dai, L. Recent Advances in Carbon-Based Metal-Free Electrocatalysts. Adv. Mater. 2019, 31, 1806403. [Google Scholar] [CrossRef]

- Paul, R.; Roy, A.K.; Dai, L. Chapter 8—Nanoporous graphitic carbon for efficient supercapacitors and related energy applications. In Hybrid Atomic-Scale Interface Design for Materials Functionality; Roy, A.K., Ed.; Elsevier: Alpharetta, GA, USA, 2021; pp. 143–178. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, T.; Qian, F.; Chen, W.; Chandrasekaran, S.; Yao, B.; Song, Y.; Duoss, E.B.; Kuntz, J.D.; Spadaccini, C.M.; et al. 3D printed functional nanomaterials for electrochemical energy storage. Nano Today 2017, 15, 107–120. [Google Scholar] [CrossRef]

- Freitas, R.R.Q.; Rivelino, R.; de Brito Mota, F.; de Castilho, C.M.C.; Kakanakova-Georgieva, A.; Gueorguiev, G.K. Topological Insulating Phases in Two-Dimensional Bismuth-Containing Single Layers Preserved by Hydrogenation. J. Phys. Chem. C 2015, 119, 23599–23606. [Google Scholar] [CrossRef] [Green Version]

- Prasad, S.; Yadav, K.K.; Kumar, S.; Gupta, N.; Cabral-Pinto, M.M.S.; Rezania, S.; Radwan, N.; Alam, J. Chromium contamination and effect on environmental health and its remediation: A sustainable approaches. J. Environ. Manag. 2021, 285, 112194. [Google Scholar] [CrossRef]

- Zhao, F.; Slade Rc Fau-Varcoe, J.R.; Varcoe, J.R. Techniques for the study and development of microbial fuel cells: An electrochemical perspective. Chem. Soc. Rev. 2009, 38, 1926–1939. [Google Scholar] [CrossRef] [Green Version]

- Kannan, R.; Kakade, B.A.; Pillai, V.K. Polymer Electrolyte Fuel Cells Using Nafion-Based Composite Membranes with Functionalized Carbon Nanotubes. Angew. Chem. Int. Ed. 2008, 47, 2653–2656. [Google Scholar] [CrossRef]

- Huang, X.; Jain, P.; El-Sayed, I.; El-Sayed, M. Plasmonic PTT Therapy (PPTT) Using Gold Nanoparticles. Lasers Med. Sci. 2008, 23, 217–228. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, C.; Wei, W.; Xiao, G.; Ni, M. Performance Improvement of a Nanofluid Solar Collector Based on Direct Absorption Collection (DAC) Concepts. Int. J. Heat Mass Transf. 2014, 75, 262–271. [Google Scholar] [CrossRef]

- Thaker, R.; Patel, J.R. Application of Nano fluids in Solar Energy. J. Altern. Energy Sources Technol. 2015, 6, 1–11. [Google Scholar]

- Elsheikh, A.H.; Sharshir, S.W.; Mostafa, M.; Essa, F.; Ahmed Ali, M. Applications of Nanofluids in Solar Energy: A Review of Recent Advances. Renew. Sustain. Energy Rev. 2017, 82, 3483–3502. [Google Scholar] [CrossRef]

| Elements | Composition (wt. %) |

|---|---|

| SiO2 | 40–60% |

| Al2O3 | 20–40% |

| Fe2O3-Fe3O4 | 5–15% |

| TiO2 | 2–5% |

| Carbon | 5–20% |

| CaO, BaO, MgO, MnO, P2O5 | Traces |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yadav, V.K.; Malik, P.; Khan, A.H.; Pandit, P.R.; Hasan, M.A.; Cabral-Pinto, M.M.S.; Islam, S.; Suriyaprabha, R.; Yadav, K.K.; Dinis, P.A.; et al. Recent Advances on Properties and Utility of Nanomaterials Generated from Industrial and Biological Activities. Crystals 2021, 11, 634. https://doi.org/10.3390/cryst11060634

Yadav VK, Malik P, Khan AH, Pandit PR, Hasan MA, Cabral-Pinto MMS, Islam S, Suriyaprabha R, Yadav KK, Dinis PA, et al. Recent Advances on Properties and Utility of Nanomaterials Generated from Industrial and Biological Activities. Crystals. 2021; 11(6):634. https://doi.org/10.3390/cryst11060634

Chicago/Turabian StyleYadav, Virendra Kumar, Parth Malik, Afzal Husain Khan, Priti Raj Pandit, Mohd Abul Hasan, Marina M. S. Cabral-Pinto, Saiful Islam, R. Suriyaprabha, Krishna Kumar Yadav, Pedro A. Dinis, and et al. 2021. "Recent Advances on Properties and Utility of Nanomaterials Generated from Industrial and Biological Activities" Crystals 11, no. 6: 634. https://doi.org/10.3390/cryst11060634

APA StyleYadav, V. K., Malik, P., Khan, A. H., Pandit, P. R., Hasan, M. A., Cabral-Pinto, M. M. S., Islam, S., Suriyaprabha, R., Yadav, K. K., Dinis, P. A., Khan, S. H., & Diniz, L. (2021). Recent Advances on Properties and Utility of Nanomaterials Generated from Industrial and Biological Activities. Crystals, 11(6), 634. https://doi.org/10.3390/cryst11060634