Synthesizing Iron Oxide Nanostructures: The Polyethylenenemine (PEI) Role

Abstract

:1. Introduction

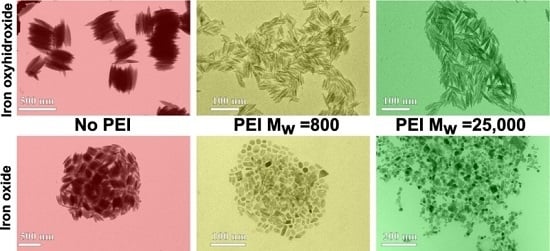

2. Results

2.1. Synthesis of the Materials

2.1.1. Preparation of β-FeOOH NRs

No PEI Addition

PEI Addition

2.1.2. Reduction of β-FeOOH NRs

3. Characterization of the Materials by XRD, TEM, HRTEM, and SQUID Magnetometry

3.1. Characterization of β-FeOOH NRs

3.2. Characterization of Iron Oxide Nanostructures

4. Discussion

5. Materials and Methods

5.1. Synthesis of the Materials: General Notes

5.2. XRD Analysis

5.3. TEM HRTEM Imaging and Size Analysis

5.4. Magnetic Behavior Investigation

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rossi, L.M.; Costa, N.J.S.; Silva, F.P.; Wojcieszak, R. Magnetic nanomaterials in catalysis: Advanced catalysts for magnetic separation and beyond. Green Chem. 2014, 16, 2906. [Google Scholar] [CrossRef]

- Frey, N.A.; Peng, S.; Cheng, K.; Sun, S. Magnetic nanoparticles: Synthesis, functionalization, and applications in bioimaging and magnetic energy storage. Chem. Soc. Rev. 2009, 38, 2532–2542. [Google Scholar] [CrossRef] [PubMed]

- Yoon, T.J.; Lee, H.; Shao, H.; Weissleder, R. Highly magnetic core–shell nanoparticles with a unique magnetization mechanism. Angew. Chem. Int. Ed. 2011, 50, 4663–4666. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Li, Y.; Guo, C.; Wang, J.; Ma, J.; Liang, X.; Yang, L.R.; Liu, H.Z. Temperature-responsive magnetite/PEO–PPO–PEO block copolymer nanoparticles for controlled drug targeting delivery. Langmuir 2007, 23, 12669–12676. [Google Scholar] [CrossRef] [PubMed]

- Laurent, S.; Dutz, S.; Hafeli, U.O.; Mahmoudi, M. Magnetic fluid hyperthermia: Focus on superparamagnetic iron oxide nanoparticles. Adv. Colloid Interface Sci. 2011, 166, 8–23. [Google Scholar] [CrossRef] [PubMed]

- Suh, S.K.; Yuet, K.; Hwang, D.K.; Bong, K.W.; Doyle, P.S.; Hatton, T.A. Synthesis of nonspherical superparamagnetic particles: In situ coprecipitation of magnetic nanoparticles in microgels prepared by stop-flow lithography. J. Am. Chem. Soc. 2012, 134, 7337–7343. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Yu, B.; Li, X.; Li, K. Facile solvothermal synthesis of monodisperse Fe3O4 nanocrystals with precise size control of one nanometre as potential MRI contrast agents. J. Mater. Chem. 2011, 21, 2476–2481. [Google Scholar] [CrossRef]

- Lemine, O.M.; Omri, K.; Zhang, B.; El Mir, L.; Sajieddine, M.; Alyamani, A.; Bououdina, M. Sol–gel synthesis of 8 nm magnetite (Fe3O4) nanoparticles and their magnetic properties. Superlattices Microstruct. 2012, 52, 793–799. [Google Scholar] [CrossRef]

- Park, J.; An, K.; Hwang, Y.; Park, J.G.; Noh, H.J.; Kim, K.Y.; Park, J.H.; Hwang, N.M.; Hyeon, T. Ultra-large-scale syntheses of monodisperse nanocrystals. Nat. Mater. 2004, 3, 891–895. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Zhu, X.; Wu, D.; Chen, Q.; Huang, D.; Sun, C.; Xin, J.; Ni, K.; Gao, J. Anisotropic shaped iron oxide nanostructures: Controlled synthesis and proton relaxation shortening effects. Chem. Mater. 2015, 27, 3505–3515. [Google Scholar] [CrossRef]

- Muraliganth, T.; Murugan, A.V.; Manthiram, A. Facile synthesis of carbon-decorated single-crystalline Fe3O4 nanowires and their application as high performance anode in lithium ion batteries. Chem. Commun. 2009, 7360–7362. [Google Scholar] [CrossRef] [PubMed]

- Bao, L.; Low, W.-L.; Jiang, J.; Ying, J.Y. Colloidal synthesis of magnetic nanorods with tuneable aspect ratios. J. Mater. Chem. 2012, 22, 7117–7120. [Google Scholar] [CrossRef]

- Si, J.-C.; Xing, Y.; Peng, M.-L.; Zhang, C.; Buske, N.; Chen, C.; Cui, Y.-L. Solvothermal synthesis of tunable iron oxide nanorods and their transfer from organic phase to water phase. Cryst. Eng. Commun. 2014, 16, 512–516. [Google Scholar] [CrossRef]

- Tadic, M.; Milosevic, I.; Kralj, S.; Saboungi, M.-L.; Motte, L. Ferromagnetic behavior and exchange bias effect in akaganeite nanorods. Appl. Phys. Lett. 2015, 106, 183706. [Google Scholar] [CrossRef]

- Guo, H.; Barnard, A.S. Naturally occurring iron oxide nanoparticles: Morphology, surface chemistry and environmental stability. J. Mat. Chem. A 2013, 1, 27–42. [Google Scholar] [CrossRef]

- Chaudhari, N.K.; Yu, J.-S. Size control synthesis of uniform β-FeOOH to high coercive field porous magnetic. J. Phys. Chem. C 2008, 112, 19957–19962. [Google Scholar] [CrossRef]

- Chen, M.; Tang, B.; Nikles, D.E. Preparation of iron nanoparticles by reduction of acicular β-FeOOH particles. IEEE Trans. Magn. 1998, 34, 1141–1143. [Google Scholar] [CrossRef]

- Peng, Z.; Wu, M.; Xiong, Y.; Wang, J.; Chen, Q. Synthesis of magnetite nanorods through reduction of β-FeOOH. Chem. Lett. 2005, 34, 636–637. [Google Scholar] [CrossRef]

- Yue, J.; Jiang, X.; Yu, A. Experimental and theoretical study on the β-FeOOH nanorods: Growth and conversion. J. Nanopart. Res. 2011, 13, 3961–3974. [Google Scholar] [CrossRef]

- Milosevic, I.; Jouni, H.; David, C.; Warmont, F.; Bonnin, D.; Motte, L. Facile microwave process in water for the fabrication of magnetic nanorods. J. Phys. Chem. C 2011, 115, 18999–19004. [Google Scholar] [CrossRef]

- Chen, S.; Feng, J.; Guo, X.; Hong, J.; Ding, W. One-step wet chemistry for preparation of magnetite nanorods. Mater. Lett. 2005, 59, 985–988. [Google Scholar] [CrossRef]

- Piao, Y.; Kim, J.; Na, H.B.; Kim, D.; Baek, J.S.; Ko, M.K.; Lee, J.H.; Shokouhimehr, M.; Hieon, T. Wrap–bake–peel process for nanostructural transformation from β-FeOOH nanorods to biocompatible iron oxide nanocapsules. Nat. Mater. 2008, 7, 242–247. [Google Scholar] [CrossRef] [PubMed]

- Bomati-Miguel, O.; Rebolledo, A.F.; Tartaj, P. Controlled formation of porous magnetic nanorods via a liquid/liquid solvothermal method. Chem. Commun. 2008, 4168–4170. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.; Cha, J.; Lee, J.K. Synthesis of various magnetite nanoparticles through simple phase transformation and their shape-dependent magnetic properties. RSC Adv. 2013, 3, 8365–8371. [Google Scholar] [CrossRef]

- Mohapatra, J.; Mitra, A.; Tyagi, H.; Bahadur, D.; Aslam, M. Iron oxide nanorods as high-performance magnetic resonance imaging contrast agents. Nanoscale 2015, 7, 9174–9184. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.-M.; Wei, A. Uniform gold nanorod from polyethylenimine-coated alumina templates. J. Phys. Chem. B 2005, 109, 23336–23341. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.-Y.; Yin, Y.-T.; Chen, C.-H.; Chiou, J.-W. Influence of polyethyleneimine and ammonium on the growth of ZnO nanowires by hydrothermal method. J. Phys. Chem. C 2011, 115, 20913–20919. [Google Scholar] [CrossRef]

- Prozorov, R.; Prozorov, T.; Mallapragada, S.K.; Narasimhan, B.; Williams, T.J.; Bazylinski, D.A. Magnetic irreversibility and the Verwey transition in nanocrystalline bacterial magnetite. Phys. Rev. B 2007, 76, 054406. [Google Scholar] [CrossRef]

- Yang, J.B.; Zhou, X.D.; Yelon, W.B.; James, W.J.; Cai, Q.; Gopalakrishnan, K.V.; Malik, S.K.; Sun, X.C.; Nikles, D.E. Magnetic and structural studies of the Verwey transition in Fe3−δO4 nanoparticles. J. Appl. Phys. 2004, 95, 7540. [Google Scholar] [CrossRef]

- Bhowmik, R.N.; Saravanan, A. Surface magnetism, Morin transition, and magnetic dynamics in antiferromagnetic α-Fe2O3 (hematite) nanograins. J. Appl. Phys. 2010, 107, 053916. [Google Scholar] [CrossRef]

- Wu, C.; Yin, P.; Zhu, X.; OuYang, C.; Xie, Y. Synthesis of hematite (α-Fe2O3) nanorods: Diameter-size and shape effects on their applications in magnetism, lithium ion battery, and gas sensors. J. Phys. Chem. B 2006, 110, 17806–17812. [Google Scholar] [CrossRef] [PubMed]

- Guardia, P.; Pérez, N.; Labarta, A.; Batlle, X. Controlled synthesis of iron oxide nanoparticles over a wide size range. Langmuir 2010, 26, 5843–5847. [Google Scholar] [CrossRef] [PubMed]

- André-Filho, J.; León-Félix, L.; Coaquira, J.A.H.; Garg, V.K.; Oliveira, A.C. Size dependence of the magnetic and hyperfine properties of nanostructured hematite (α-Fe2O3) powders prepared by the ball milling technique. In Proceedings of the 13th Latin American Conference on the Applications of the Mössbauer Effect (LACAME 2012), Medellin, Colombia, 11–16 November 2012.

- Zhao, Y.; Dunnill, C.W.; Zhu, Y.; Gregory, D.H.; Kockenberger, W.; Li, Y.; Hu, W.; Ahmad, I.; McCartney, D.G. Low-temperature magnetic properties of hematite nanorods. Chem. Mater. 2007, 19, 916–921. [Google Scholar] [CrossRef]

- Mikhaylova, M.; Kim, D.Y.; Bobrysheva, N.; Osmolowsky, M.; Semenov, V.; Tsakalakos, T.; Muhammed, M. Superparamagnetism of magnetite nanoparticles: Dependence on surface modification. Langmuir 2004, 20, 2472–2477. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Wu, Z.; Yu, T.; Jiang, C.; Kim, W.-S. Recent progress on magnetic iron oxide nanoparticles: Synthesis, surface functional strategies and biomedical applications. Sci. Technol. Adv. Mater. 2015, 16, 023501. [Google Scholar] [CrossRef] [PubMed]

| Sample | FeO_800 | FeO_25000 | FeO_nopei |

|---|---|---|---|

| HC (Oe) | 511 | 497 | 789 |

| MSAT (emu/g) | 83 | 69 | 15 |

| MR (emu/g) | 20 | 19 | 2 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lentijo Mozo, S.; Zuddas, E.; Casu, A.; Falqui, A. Synthesizing Iron Oxide Nanostructures: The Polyethylenenemine (PEI) Role. Crystals 2017, 7, 22. https://doi.org/10.3390/cryst7010022

Lentijo Mozo S, Zuddas E, Casu A, Falqui A. Synthesizing Iron Oxide Nanostructures: The Polyethylenenemine (PEI) Role. Crystals. 2017; 7(1):22. https://doi.org/10.3390/cryst7010022

Chicago/Turabian StyleLentijo Mozo, Sergio, Efisio Zuddas, Alberto Casu, and Andrea Falqui. 2017. "Synthesizing Iron Oxide Nanostructures: The Polyethylenenemine (PEI) Role" Crystals 7, no. 1: 22. https://doi.org/10.3390/cryst7010022

APA StyleLentijo Mozo, S., Zuddas, E., Casu, A., & Falqui, A. (2017). Synthesizing Iron Oxide Nanostructures: The Polyethylenenemine (PEI) Role. Crystals, 7(1), 22. https://doi.org/10.3390/cryst7010022