Effect of Modified Tapioca Starch on Mechanical, Thermal, and Morphological Properties of PBS Blends for Food Packaging

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. PBS and Starch Preparation

2.3. Characterization

2.3.1. Mechanical Properties

2.3.2. Fourier Transform Infrared Spectroscopy

2.3.3. Morphological Analysis

2.3.4. Thermal Analysis

3. Results and Discussion

3.1. Mechanical Properties

3.2. FTIR Analysis

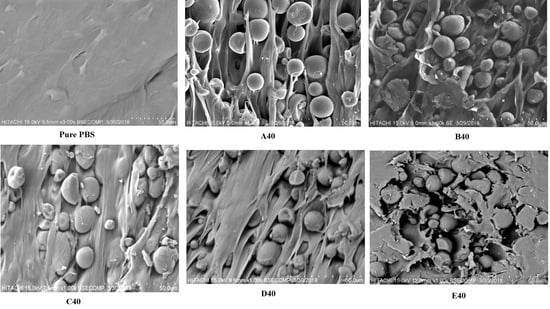

3.3. Morphology Analysis of Starch/PBS Blends

3.4. Thermal Properties

4. Conclusions

5. Data Availability

Author Contributions

Funding

Conflicts of Interest

References

- Karmaus, A.L.; Osborn, R.; Krishan, M. Scientific advances and challenges in safety evaluation of food packaging materials: Workshop proceedings. Regul. Toxicol. Pharmacol. 2018, 98, 80–87. [Google Scholar] [CrossRef] [PubMed]

- Dilkes-Hoffman, L.S.; Lane, J.L.; Grant, T.; Pratt, S.; Lant, P.A.; Laycock, B. Environmental impact of biodegradable food packaging when considering food waste. J. Clean. Prod. 2018, 180, 325–334. [Google Scholar] [CrossRef]

- Kim, S.; Yang, S.Y.; Chun, H.H.; Song, K.B. High hydrostatic pressure processing for the preparation of buckwheat and tapioca starch films. Food Hydrocoll. 2018, 81, 71–76. [Google Scholar] [CrossRef]

- Agustin, M.B.; Ahmmad, B.; Alonzo, S.M.M.; Patriana, F.M. Bioplastic based on starch and cellulose nanocrystals from rice straw. J. Reinf. Plast. Compos. 2014, 33, 2205–2213. [Google Scholar] [CrossRef]

- Zhou, X.-Y.; Jia, D.-M.; Cui, Y.-F.; Xie, D. Kinetics Analysis of Thermal Degradation Reaction of PVA and PVA/Starch Blends. J. Reinf. Plast. Compos. 2009, 28, 2771–2780. [Google Scholar] [CrossRef]

- Araújo, A.; Galvão, A.; Filho, C.S.; Mendes, F.; Oliveira, M.; Barbosa, F.; Filho, M.S.; Bastos, M. Okra mucilage and corn starch bio-based film to be applied in food. Polym. Test. 2018, 71, 352–361. [Google Scholar] [CrossRef]

- Campos, A.; Marconcini, J.; Imam, S.; Klamczynski, A.; Ortis, W.; Wood, D.; Williams, T.; Martins-Franchetti, S.; Mattoso, L. Morphological, mechanical properties and biodegradability of biocomposite thermoplastic starch and polycaprolactone reinforced with sisal fibers. J. Reinf. Plast. Compos. 2012, 31, 573–581. [Google Scholar] [CrossRef]

- Homayouni, H.; Kavoosi, G.; Nassiri, S.M. Physicochemical, antioxidant and antibacterial properties of dispersion made from tapioca and gelatinized tapioca starch incorporated with carvacrol. LWT Food Sci. Technol. 2017, 77, 503–509. [Google Scholar] [CrossRef]

- Makmoon, T.; Foungfuchat, A.; Jiratumnukul, N. Modified tapioca starch as a rheology modifier in acrylic dispersion system. Prog. Org. Coat. 2013, 76, 959–962. [Google Scholar] [CrossRef]

- Marvizadeh, M.M.; Oladzadabbasabadi, N.; Mohammadi Nafchi, A.; Jokar, M. Preparation and characterization of bionanocomposite film based on tapioca starch/bovine gelatin/nanorod zinc oxide. Int. J. Boil. Macromol. 2017, 99, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Peelman, N.; Ragaert, P.; De Meulenaer, B.; Adons, D.; Peeters, R.; Cardon, L.; Van Impe, F.; Devlieghere, F. Application of bioplastics for food packaging. Trends Food Sci. Technol. 2013, 32, 128–141. [Google Scholar] [CrossRef] [Green Version]

- Jabeen, N.; Majid, I.; Nayik, G.A. Bioplastics and food packaging: A review. Cogent Food Agric. 2015, 1, 1117749. [Google Scholar] [CrossRef]

- Bautista, M.; Martínez De Ilarduya, A.; Alla, A.; Vives, M.; Morató, J.; Muñoz-Guerra, S. Cationic poly(butylene succinate) copolyesters. Eur. Polym. J. 2016, 75, 329–342. [Google Scholar] [CrossRef] [Green Version]

- Lancuški, A.; Abu Ammar, A.; Avrahami, R.; Vilensky, R.; Vasilyev, G.; Zussman, E. Design of starch-formate compound fibers as encapsulation platform for biotherapeutics. Carbohydr. Polym. 2017, 158, 68–76. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.H.; Sapuan, S.M.; Lee, J.H.; Hassan, M.R. Mechanical properties of kenaf fibre reinforced floreon biocomposites with magnesium hydroxide filler. J. Mech. Eng. Sci. 2016, 10, 2234–2248. [Google Scholar] [CrossRef]

- Maubane, L.; Ray, S.S.; Jalama, K. The effect of starch amylose content on the morphology and properties of melt-processed butyl-etherified starch/poly[(butylene succinate)-co-adipate] blends. Carbohydr. Polym. 2017, 155, 89–100. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, T.A.; Oliveira, R.R.; Barbosa, R.; Azevedo, J.B.; Alves, T.S. Effect of reprocessing cycles on the degradation of PP/PBAT-thermoplastic starch blends. Carbohydr. Polym. 2017, 168, 52–60. [Google Scholar] [CrossRef] [PubMed]

- Patel, H.; Royall, P.G.; Gaisford, S.; Williams, G.R.; Edwards, C.H.; Warren, F.J.; Flanagan, B.M.; Ellis, P.R.; Butterworth, P.J. Structural and enzyme kinetic studies of retrograded starch: Inhibition of α-amylase and consequences for intestinal digestion of starch. Carbohydr. Polym. 2017, 164, 154–161. [Google Scholar] [CrossRef] [PubMed]

- Frollini, E.; Bartolucci, N.; Sisti, L.; Celli, A. Biocomposites based on poly(butylene succinate) and curaua: Mechanical and morphological properties. Polym. Test. 2015, 45, 168–173. [Google Scholar] [CrossRef]

- Negrin, M.; Macerata, E.; Consolati, G.; Quasso, F.; Genovese, L.; Soccio, M.; Giola, M.; Lotti, N.; Munari, A.; Mariani, M. Gamma radiation effects on random copolymers based on poly(butylene succinate) for packaging applications. Radiat. Phys. Chem. 2018, 142, 34–43. [Google Scholar] [CrossRef]

- Georgousopoulou, I.N.; Vouyiouka, S.; Dole, P.; Papaspyrides, C.D. Thermo-mechanical degradation and stabilization of poly(butylene succinate). Polym. Degrad. Stab. 2016, 128, 182–192. [Google Scholar] [CrossRef]

- Li, J.; Luo, X.; Lin, X.; Zhou, Y. Comparative study on the blends of PBS/thermoplastic starch prepared from waxy and normal corn starches. Starch/Staerke 2013, 65, 831–839. [Google Scholar] [CrossRef]

- Suttiruengwong, S.; Sotho, K.; Seadan, M. Effect of Glycerol and Reactive Compatibilizers on Poly(butylene succinate)/Starch Blends. J. Renew. Mater. 2014, 2, 85–92. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, G.; Zhang, W.; Guo, W.; Wang, J. Processing and Thermal Behaviors of Poly(Butylene Succinate) Blends with Highly-Filled Starch and Glycerol. J. Polym. Environ. 2013, 21, 46–53. [Google Scholar] [CrossRef]

- Jamaluddin, N.; Razaina, M.T.; Ishak, Z.A.M. Mechanical and Morphology Behaviours of Polybutylene (succinate)/Thermoplastic Polyurethaneblend. Procedia Chem. 2016, 19, 426–432. [Google Scholar] [CrossRef]

- Liu, L.; Yu, J.; Cheng, L.; Qu, W. Mechanical properties of poly(butylene succinate) (PBS) biocomposites reinforced with surface modified jute fibre. Compos. Part A 2009, 40, 669–674. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, C.; Xu, S. Mechanical, thermal and flame retardant properties of magnesium hydroxide filled poly(vinyl chloride) composites: The effect of filler shape. Compos. Part A 2018, 113, 1–11. [Google Scholar] [CrossRef]

- Santagata, G.; Valerio, F.; Cimmino, A.; Dal Poggetto, G.; Masi, M.; Di Biase, M.; Malinconico, M.; Lavermicocca, P.; Evidente, A. Chemico-physical and antifungal properties of poly(butylene succinate)/cavoxin blend: Study of a novel bioactive polymeric based system. Eur. Polym. J. 2017, 94, 230–247. [Google Scholar] [CrossRef]

- Lu, Z.-H.; Donner, E.; Yada, R.Y.; Liu, Q. Physicochemical properties and in vitro starch digestibility of potato starch/protein blends. Carbohydr. Polym. 2016, 154, 214–222. [Google Scholar] [CrossRef] [PubMed]

- Khatoon, S.; Sreerama, Y.N.; Raghavendra, D.; Bhattacharya, S.; Bhat, K.K. Properties of enzyme modified corn, rice and tapioca starches. Food Res. Int. 2009, 42, 1426–1433. [Google Scholar] [CrossRef]

- Whitney, K.; Reuhs, B.L.; Ovando Martinez, M.; Simsek, S. Analysis of octenylsuccinate rice and tapioca starches: Distribution of octenylsuccinic anhydride groups in starch granules. Food Chem. 2016, 211, 608–615. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, K.; Liu, Y.; Hu, X.; Su, T.; Li, P.; Wang, Z. Preparation, characterization, and biodegradation of poly(butylene succinate)/cellulose triacetate blends. Int. J. Boil. Macromol. 2018, 114, 373–380. [Google Scholar] [CrossRef] [PubMed]

- Espinel Villacrés, R.A.; Flores, S.K.; Gerschenson, L.N. Biopolymeric antimicrobial films: Study of the influence of hydroxypropyl methylcellulose, tapioca starch and glycerol contents on physical properties. Mater. Sci. Eng. C 2014, 36, 108–117. [Google Scholar] [CrossRef] [PubMed]

- Monroy, Y.; Rivero, S.; García, M.A. Microstructural and techno-functional properties of cassava starch modified by ultrasound. Ultrason. Sonochem. 2018, 42, 795–804. [Google Scholar] [CrossRef] [PubMed]

- Breuninger, W.F.; Piyachomkwan, K.; Sriroth, K. Tapioca/Cassava Starch: Production and Use. In Starch; Elsevier: Amsterdam, The Netherlands, 2009; pp. 541–568. [Google Scholar]

- Gao, J.; Vasanthan, T.; Hoover, R.; Li, J. Structural modification of waxy, regular, and high-amylose maize and hulless barley starches on partial acid hydrolysis and their impact on physicochemical properties and chemical modification. Starch/Staerke 2012, 64, 313–325. [Google Scholar] [CrossRef]

- Wang, N.; Yu, J.; Chang, P.R.; Ma, X. Influence of formamide and water on the properties of thermoplastic starch/poly(lactic acid) blends. Carbohydr. Polym. 2008, 71, 109–118. [Google Scholar] [CrossRef]

- De Paiva, J.M.F.; Frollini, E. Unmodified and modified surface sisal fibers as reinforcement of phenolic and lignophenolic matrices composites: Thermal analyses of fibers and composites. Macromol. Mater. Eng. 2006, 291, 405–417. [Google Scholar] [CrossRef]

- Lee, C.H.; Sapuan, S.M.; Hassan, M.R. Thermal analysis of kenaf fiber reinforced floreon biocomposites with magnesium hydroxide flame retardant filler. Polym. Compos. 2018, 39, 869–875. [Google Scholar] [CrossRef]

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers. Compos. Part B 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Tian, Y.; Li, Y.; Xu, X.; Jin, Z. Starch retrogradation studied by thermogravimetric analysis (TGA). Carbohydr. Polym. 2011, 84, 1165–1168. [Google Scholar] [CrossRef]

- Sánchez-Jiménez, P.E.; Pérez-Maqueda, L.A.; Perejón, A.; Criado, J.M. Generalized master plots as a straightforward approach for determining the kinetic model: The case of cellulose pyrolysis. Thermochim. Acta 2013, 552, 54–59. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Jiménez, P.E.; Pérez-Maqueda, L.A.; Perejón, A.; Pascual-Cosp, J.; Benítez-Guerrero, M.; Criado, J.M. An improved model for the kinetic description of the thermal degradation of cellulose. Cellulose 2011, 18, 1487–1498. [Google Scholar] [CrossRef]

- Colussi, R.; Pinto, V.Z.; El Halal, S.L.M.; Vanier, N.L.; Villanova, F.A.; Marques e Silva, R.; da Rosa Zavareze, E.; Dias, A.R.G. Structural, morphological, and physicochemical properties of acetylated high-, medium-, and low-amylose rice starches. Carbohydr. Polym. 2014, 103, 405–413. [Google Scholar] [CrossRef] [PubMed]

- Boonprasith, P.; Wootthikanokkhan, J.; Nimitsiriwat, N. Mechanical, thermal, and barrier properties of nanocomposites based on poly(butylene succinate)/thermoplastic starch blends containing different types of clay. J. Appl. Polym. Sci. 2013, 130, 1114–1123. [Google Scholar] [CrossRef]

| Properties | Starch Type A | Starch Type B | Starch Type C | Starch Type D | Starch Type E |

|---|---|---|---|---|---|

| Moisture, % | 11.1 | 8.1 | 7.2 | 8.6 | 11.2 |

| Bulk Density, g/cm3 | 0.63 | 0.62 | 0.59 | 0.53 | 0.54 |

| Beginning of gelatanization (Tg), °C | 51 | 45.2 | 44.9 | 60.3 | 69.4 |

| Maximum Brabender viscosity, BU | 1291 | 228 | 405 | 750 | 717 |

| Viscosity, Cp | 5.5 | 6.5 | 6.3 | 5.7 | 6.1 |

| Specimen | Tensile Strength (MPa) | Tensile Modulus (MPa) | Flexural Strength (MPa) | Flexural Modulus (MPa) |

|---|---|---|---|---|

| A40 | 17.59 ± 1.25 | 1082.24 ± 228.21 | 50.41 ± 4.20 | 2137.70 ± 260.59 |

| A50 | 13.49 ± 0.60 | 2040.13 ± 73.86 | 36.87 ± 1.06 | 2252.84 ± 181.69 |

| A60 | 12.57 ± 0.72 | 2655.27 ± 148.21 | 29.61 ± 2.77 | 3188.48 ± 323.42 |

| B40 | 16.59 ± 0.17 | 1284.82 ± 58.27 | 45.99 ± 1.70 | 1569.25 ± 122.82 |

| B50 | 12.89 ± 0.330 | 1945.16 ± 52.01 | 37.67 ± 1.69 | 2031.28 ± 176.94 |

| B60 | 11.32 ± 0.51 | 2142.13 ± 54.26 | 21.39 ± 1.64 | 1265.52 ± 69.70 |

| C40 | 16.02 ± 0.11 | 821.46 ± 42.64 | 19.02 ± 0.64 | 378.690 ± 42.30 |

| C50 | 14.97 ± 1.31 | 915.33 ± 32.98 | 17.58 ± 0.61 | 655.896 ± 14.63 |

| C60 | 13.76 ± 0.93 | 1042.12 ± 17.42 | 12.87 ± 1.05 | 727.07 ± 55.79 |

| D40 | 18.13 ± 0.64 | 586.48 ± 40.39 | 16.86 ± 1.25 | 397.87 ± 22.01 |

| D50 | 17.79 ± 0.51 | 736.21 ± 10.12 | 17.49 ± 1.24 | 562.11 ± 40.65 |

| D60 | 13.11 ± 0.42 | 764.39 ± 15.14 | 15.46 ± 1.63 | 395.57 ± 53.15 |

| E40 | 14.98 ± 1.23 | 534.77 ± 32.47 | 12.43 ± 0.40 | 663.304 ± 21.69 |

| E50 | 14.03 ± 1.08 | 745.18 ± 65.94 | 16.12 ± 0.62 | 594.282 ± 42.28 |

| E60 | 11.95 ± 0.84 | 885.01 ± 70.50 | 12.40 ± 1.35 | 770.02 ± 53.62 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayu, R.S.; Khalina, A.; Harmaen, A.S.; Zaman, K.; Jawaid, M.; Lee, C.H. Effect of Modified Tapioca Starch on Mechanical, Thermal, and Morphological Properties of PBS Blends for Food Packaging. Polymers 2018, 10, 1187. https://doi.org/10.3390/polym10111187

Ayu RS, Khalina A, Harmaen AS, Zaman K, Jawaid M, Lee CH. Effect of Modified Tapioca Starch on Mechanical, Thermal, and Morphological Properties of PBS Blends for Food Packaging. Polymers. 2018; 10(11):1187. https://doi.org/10.3390/polym10111187

Chicago/Turabian StyleAyu, Rafiqah S., Abdan Khalina, Ahmad Saffian Harmaen, Khairul Zaman, Mohammad Jawaid, and Ching Hao Lee. 2018. "Effect of Modified Tapioca Starch on Mechanical, Thermal, and Morphological Properties of PBS Blends for Food Packaging" Polymers 10, no. 11: 1187. https://doi.org/10.3390/polym10111187

APA StyleAyu, R. S., Khalina, A., Harmaen, A. S., Zaman, K., Jawaid, M., & Lee, C. H. (2018). Effect of Modified Tapioca Starch on Mechanical, Thermal, and Morphological Properties of PBS Blends for Food Packaging. Polymers, 10(11), 1187. https://doi.org/10.3390/polym10111187