Lignocellulose-Chitosan-Multiwalled Carbon Nanotube Composites with Improved Mechanical Strength, Dimensional Stability and Fire Retardancy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Crosslinked Chitosan/Multiwalled Carbon Nanotube Hydrogel

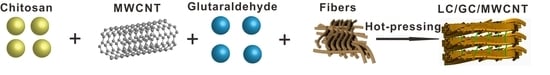

2.3. Preparation of Lignocellulose-Chitosan-Multiwalled Carbon Nanotube Composite

2.4. Physical and Mechanical Properties Test

2.5. Characterization

3. Results and Discussion

3.1. Micromorphology of Composites

3.2. X-ray Diffraction Analysis

3.3. FTIR Analysis

3.4. XPS Analysis

3.5. TG Analysis

3.6. Mechanical Properties Analysis

3.7. Dimensional Stability Analysis

3.8. Combustion Test

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kusumah, S.S.; Umemura, K.; Yoshioka, K.; Miyafuji, H.; Kanayama, K. Utilization of sweet sorghum bagasse and citric acid for manufacturing of particleboard I: Effects of pre-drying treatment and citric acid content on the board properties. Ind. Crop. Prod. 2016, 84, 34–42. [Google Scholar] [CrossRef]

- Hu, J.-P.; Guo, M.-H. Influence of ammonium lignosulfonate on the mechanical and dimensional properties of wood fiber biocomposites reinforced with polylactic acid. Ind. Crop. Prod. 2015, 78, 48–57. [Google Scholar] [CrossRef]

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol. 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Gravitis, J.; Abolins, J.; Veveris, A.; Andzs, M.; Liitia, T.; Tamminen, T. Utilization of lignin powder for manufacturing self-binding HDF. Holzforschung 2017, 71, 555–561. [Google Scholar] [CrossRef]

- Li, D.-L.; Ge, S.-B.; Peng, W.-X.; Wu, Q.-D.; Wu, J.-G. Chemical structure characteristics of wood/lignin composites during mold pressing. Polym. Compos. 2017, 38, 955–965. [Google Scholar] [CrossRef]

- Geng, X.; Li, K. Investigation of wood adhesives from kraft lignin and polyethylenimine. J. Adhes. Sci. Technol. 2006, 20, 847–858. [Google Scholar] [CrossRef]

- Theng, D.; Arbat, G.; Delgado-Aguilar, M.; Vilaseca, F.; Ngo, B.; Mutjé, P. All-lignocellulosic fiberboard from corn biomass and cellulose nanofibers. Ind. Crop. Prod. 2015, 76, 166–173. [Google Scholar] [CrossRef]

- Robles, E.; Czubak, E.; Kowaluk, G.; Labidi, J. Lignocellulosic-based multilayer self-bonded composites with modified cellulose nanoparticles. Compos. Part B Eng. 2016, 106, 300–307. [Google Scholar] [CrossRef]

- Li, N.; Qi, G.; Sun, X.S.; Stamm, M.J.; Wang, D. Physicochemical Properties and Adhesion Performance of Canola Protein Modified with Sodium Bisulfite. J. Am. Oil Chem. Soc. 2011, 89, 897–908. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Zhong, Z.; Wang, D.; Ratto, J.A.; Sheng, K.; Sun, X.S. Mechanical and water soaking properties of medium density fiberboard with wood fiber and soybean protein adhesive. Bioresour. Technol. 2009, 100, 3556–3562. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wu, J.; Bernard, G.M. Preparation and characterization of canola protein isolate–poly(glycidyl methacrylate) conjugates: A bio-based adhesive. Ind. Crop. Prod. 2014, 57, 124–131. [Google Scholar] [CrossRef]

- Nordqvist, P.; Nordgren, N.; Khabbaz, F.; Malmström, E. Plant proteins as wood adhesives: Bonding performance at the macro- and nanoscale. Ind. Crop. Prod. 2013, 44, 246–252. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Z.; Gu, Z.; Hong, Y.; Cheng, L. Preparation, characterization and properties of starch-based wood adhesive. Carbohydr. Polym. 2012, 88, 699–706. [Google Scholar] [CrossRef]

- Zhang, Y.; Ding, L.; Gu, J.; Tan, H.; Zhu, L. Preparation and properties of a starch-based wood adhesive with high bonding strength and water resistance. Carbohydr. Polym. 2015, 115, 32–37. [Google Scholar] [CrossRef] [PubMed]

- Umemura, K.; Kawai, S. Modification of chitosan by the Maillard reaction using cellulose model compounds. Carbohydr. Polym. 2007, 68, 242–248. [Google Scholar] [CrossRef]

- Rinaudo, M. New way to crosslink chitosan in aqueous solution. Eur. Polym. J. 2010, 46, 1537–1544. [Google Scholar] [CrossRef]

- Zang, J.; Jia, S.; Liu, Y.; Wu, S.; Zhang, Y. A facile method to prepare chemically crosslinked and efficient polyvinyl alcohol/chitosan beads for catalase immobilization. Catal. Commun. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Patel, A.K. Chitosan: Emergence as potent candidate for green adhesive market. Biochem. Eng. J. 2015, 102, 74–81. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; Elchinger, P.-H.; de Baynast, H.; Pierre, G.; Delattre, C.; Michaud, P. Chitosan as an adhesive. Eur. Polym. J. 2014, 60, 198–212. [Google Scholar] [CrossRef]

- Peshkova, S.; Li, K. Investigation of chitosan–phenolics systems as wood adhesives. J. Biotechnol. 2003, 102, 199–207. [Google Scholar] [CrossRef]

- Umemura, K.; Mihara, A.; Kawai, S. Development of new natural polymer-based wood adhesives III: Effects of glucose addition on properties of chitosan. J. Wood Sci. 2010, 56, 387–394. [Google Scholar] [CrossRef]

- Patel, A.K.; Michaud, P.; Petit, E.; de Baynast, H.; Grédiac, M.; Mathias, J.-D. Development of a chitosan-based adhesive. Application to wood bonding. J. Appl. Polym. Sci. 2013, 127, 5014–5021. [Google Scholar] [CrossRef]

- Montazer, M.; Afjeh, M.G. Simultaneous x-linking and antimicrobial finishing of cotton fabric. J. Appl. Polym. Sci. 2007, 103, 178–185. [Google Scholar] [CrossRef]

- Gao, H.; Zhou, W.; Jang, J.-H.; Goodenough, J.B. Cross-Linked Chitosan as a Polymer Network Binder for an Antimony Anode in Sodium-Ion Batteries. Adv. Energy Mater. 2016, 6, 1502130. [Google Scholar] [CrossRef]

- Chen, C.; Lee, S.H.; Cho, M.; Kim, J.; Lee, Y. Cross-Linked Chitosan as an Efficient Binder for Si Anode of Li-ion Batteries. ACS Appl. Mater. Interfaces 2016, 8, 2658–2665. [Google Scholar] [CrossRef] [PubMed]

- Ji, X.; Li, B.; Yuan, B.; Guo, M. Preparation and characterizations of a chitosan-based medium-density fiberboard adhesive with high bonding strength and water resistance. Carbohydr. Polym. 2017, 176, 273–280. [Google Scholar] [CrossRef] [PubMed]

- Kong, L.; Tu, K.; Guan, H.; Wang, X. Growth of high-density ZnO nanorods on wood with enhanced photostability, flame retardancy and water repellency. Appl. Surf. Sci. 2017, 407, 479–484. [Google Scholar] [CrossRef]

- Guo, B.; Liu, Y.; Zhang, Q.; Wang, F.; Wang, Q.; Liu, Y.; Li, J.; Yu, H. Efficient Flame-Retardant and Smoke-Suppression Properties of Mg-Al-Layered Double-Hydroxide Nanostructures on Wood Substrate. ACS Appl. Mater. Interfaces 2017, 9, 23039–23047. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Liu, J.; Lv, W. Thermal degradation and fire performance of wood treated with PMUF resin and boron compounds. Fire Mater. 2017, 41, 1051–1057. [Google Scholar] [CrossRef]

- Wang, Q.; Li, J.; Winandy, J. Chemical mechanism of fire retardance of boric acid on wood. Wood Sci. Technol. 2004, 38, 375–389. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, N.; Wang, Q.; Xiao, Z.; Wang, F.; Zhang, Y.; Militz, H. Combustion behavior of oak wood (Quercus mongolica L.) modified by 1,3-dimethylol-4,5-dihydroxyethyleneurea (DMDHEU). Holzforschung 2014, 68, 881–887. [Google Scholar] [CrossRef]

- Wang, X.; Kalali, E.N.; Wan, J.-T.; Wang, D.-Y. Carbon-family materials for flame retardant polymeric materials. Prog. Polym. Sci. 2017, 69, 22–46. [Google Scholar] [CrossRef]

- Aschberger, K.; Campia, I.; Pesudo, L.Q.; Radovnikovic, A.; Reina, V. Chemical alternatives assessment of different flame retardants—A case study including multi-walled carbon nanotubes as synergist. Environ. Int. 2017, 101, 27–45. [Google Scholar] [CrossRef] [PubMed]

- Dittrich, B.; Wartig, K.-A.; Hofmann, D.; Mülhaupt, R.; Schartel, B. Flame retardancy through carbon nanomaterials: Carbon black, multiwall nanotubes, expanded graphite, multi-layer graphene and graphene in polypropylene. Polym. Degrad. Stab. 2013, 98, 1495–1505. [Google Scholar] [CrossRef]

- Demczyk, B.G.; Wang, Y.M.; Cumings, J.; Hetman, M.; Han, W.; Zettl, A.; Ritchie, R.O. Direct Mechanical Measurement of the Tensile Strength and Elastic Modulus of Multiwalled Carbon Nanotubes. Microsc. Microanal. 2006, 12, 934–935. [Google Scholar] [CrossRef]

- Dervishi, E.; Li, Z.; Xu, Y.; Saini, V.; Biris, A.R.; Lupu, D.; Biris, A.S. Carbon Nanotubes: Synthesis, Properties, and Applications. Part. Sci. Technol. 2009, 27, 107–125. [Google Scholar] [CrossRef]

- Coleman, J.N.; Khan, U.; Gun’ko, Y.K. Mechanical Reinforcement of Polymers Using Carbon Nanotubes. Adv. Mater. 2006, 18, 689–706. [Google Scholar] [CrossRef]

- Chatterjee, S.; Lee, M.W.; Woo, S.H. Enhanced mechanical strength of chitosan hydrogel beads by impregnation with carbon nanotubes. Carbon 2009, 47, 2933–2936. [Google Scholar] [CrossRef]

- Luo, X.-F.; Yang, C.-H.; Peng, Y.-Y.; Pu, N.-W.; Ger, M.-D.; Hsieh, C.-T.; Chang, J.-K. Graphene nanosheets, carbon nanotubes, graphite, and activated carbon as anode materials for sodium-ion batteries. J. Mater. Chem. A 2015, 3, 10320–10326. [Google Scholar] [CrossRef]

- Salam, M.A.; Burk, R. Synthesis and characterization of multi-walled carbon nanotubes modified with octadecylamine and polyethylene glycol. Arab. J. Chem. 2017, 10, S921–S927. [Google Scholar] [CrossRef]

- Li, B.; Shan, C.-L.; Zhou, Q.; Fang, Y.; Wang, Y.-L.; Xu, F.; Han, L.-R.; Ibrahim, M.; Guo, L.-B.; Xie, G.-L. Synthesis, characterization, and antibacterial activity of cross-linked chitosan-glutaraldehyde. Mar. Drugs 2013, 11, 1534–1552. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Zheng, Z.; Qin, X.; Li, M.; Li, H.; Wang, X. The thermal and mechanical properties of a polyurethane/multi-walled carbon nanotube composite. Carbon 2006, 44, 2701–2707. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, H.; Dang, B.; Xiong, Y.; Yao, Q.; Wang, C.; Sun, Q.; Jin, C. Bio-Inspired nacre-like nanolignocellulose-poly (vinyl alcohol)-TiO2 composite with superior mechanical and photocatalytic properties. Sci. Rep. 2017, 7, 1823. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Dong, Y.; Yan, Y.; Zhang, S.; Li, J. Mussel-inspired chemistry for preparation of superhydrophobic surfaces on porous substrates. RSC Adv. 2017, 7, 29149–29158. [Google Scholar] [CrossRef]

- Meng, F.-D.; Yu, Y.-L.; Zhang, Y.-M.; Yu, W.-J.; Gao, J.-M. Surface chemical composition analysis of heat-treated bamboo. Appl. Surf. Sci. 2016, 371, 383–390. [Google Scholar] [CrossRef]

- Sa, R.; Wei, Z.; Yan, Y.; Wang, L.; Wang, W.; Zhang, L.; Ning, N.; Tian, M. Catechol and epoxy functionalized ultrahigh molecular weight polyethylene (UHMWPE) fibers with improved surface activity and interfacial adhesion. Compos. Sci. Technol. 2015, 113, 54–62. [Google Scholar] [CrossRef]

- Chen, S.; Cao, Y.; Feng, J. Polydopamine as an efficient and robust platform to functionalize carbon fiber for high-performance polymer composites. ACS Appl. Mater. Interfaces 2014, 6, 349–356. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Jin, C.; Sun, Q.; Zhang, Q. Fabrication of nanocrystalline anatase TiO2 in a graphene network as a bamboo coating material with enhanced photocatalytic activity and fire resistance. J. Alloy. Compd. 2017, 702, 418–426. [Google Scholar] [CrossRef]

- Jin, C.; Yao, Q.; Li, J.; Fan, B.; Sun, Q. Fabrication, superhydrophobicity, and microwave absorbing properties of the magnetic γ-Fe2O3/bamboo composites. Mater. Des. 2015, 85, 205–210. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, J.; Wang, R.; Lu, H.; Li, L.; Kong, Y.; Qi, K.; Xin, J.H. Artificial lotus leaf structures from assembling carbon nanotubes and their applications in hydrophobic textiles. J. Mater. Chem. 2007, 17, 1071–1078. [Google Scholar] [CrossRef]

- Lee, C.H.; Johnson, N.; Drelich, J.; Yap, Y.K. The performance of superhydrophobic and superoleophilic carbon nanotube meshes in water–oil filtration. Carbon 2011, 49, 669–676. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Du, F.; Winey, K.I.; Groth, K.M.; Shields, J.R.; Bellayer, S.P.; Kim, H.; Douglas, J.F. Flammability properties of polymer nanocomposites with single-walled carbon nanotubes: Effects of nanotube dispersion and concentration. Polymer 2005, 46, 471–481. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuan, L.; Liang, G.; Gu, A.; Qiang, Z.; Yang, C.; Chen, X. Unique hybridized carbon nanotubes and their high performance flame retarding composites with high smoke suppression, good toughness and low curing temperature. J. Mater. Chem. A 2014, 2, 4975–4988. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, L.; Tang, Y.; Jia, Z. Adsorption of nicotine and tar from the mainstream smoke of cigarettes by oxidized carbon nanotubes. Appl. Surf. Sci. 2006, 252, 2933–2937. [Google Scholar] [CrossRef]

- Zhao, J.; Buldum, A.; Han, J.; Lu, J.P. Gas molecule adsorption in carbon nanotubes and nanotube bundles. Nanotechnology 2002, 13, 3394–3400. [Google Scholar] [CrossRef]

- Santucci, S.; Picozzi, S.; Di Gregorio, F.; Lozzi, L.; Cantalini, C.; Valentini, L.; Kenny, J.; Delley, B. NO2 and CO gas adsorption on carbon nanotubes: Experiment and theory. J. Chem. Phys. 2003, 119, 10904–10910. [Google Scholar] [CrossRef]

| Samples | PHRR a | THR a | TSP a | PSPR a | Residue a |

|---|---|---|---|---|---|

| (kW/m2) | (MJ/m2) | (m2/kg) | (m2/s) | (wt %) | |

| LC | 535.8 ± 8.6 | 27.0 ± 1.1 | 1.1 ± 0.1 | 0.029 ± 0.002 | 12.5 ± 1.3 |

| LC/GC/MWCNT | 450.9 ± 9.2 | 24.1 ± 0.9 | 0.6 ± 0.1 | 0.022 ± 0.002 | 19.7 ± 1.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Yan, Y.; Shen, X.; Qian, T.; Wang, J.; Sun, Q.; Jin, C. Lignocellulose-Chitosan-Multiwalled Carbon Nanotube Composites with Improved Mechanical Strength, Dimensional Stability and Fire Retardancy. Polymers 2018, 10, 341. https://doi.org/10.3390/polym10030341

Wang Z, Yan Y, Shen X, Qian T, Wang J, Sun Q, Jin C. Lignocellulose-Chitosan-Multiwalled Carbon Nanotube Composites with Improved Mechanical Strength, Dimensional Stability and Fire Retardancy. Polymers. 2018; 10(3):341. https://doi.org/10.3390/polym10030341

Chicago/Turabian StyleWang, Zhe, Yutao Yan, Xiaoping Shen, Temeng Qian, Junjie Wang, Qingfeng Sun, and Chunde Jin. 2018. "Lignocellulose-Chitosan-Multiwalled Carbon Nanotube Composites with Improved Mechanical Strength, Dimensional Stability and Fire Retardancy" Polymers 10, no. 3: 341. https://doi.org/10.3390/polym10030341

APA StyleWang, Z., Yan, Y., Shen, X., Qian, T., Wang, J., Sun, Q., & Jin, C. (2018). Lignocellulose-Chitosan-Multiwalled Carbon Nanotube Composites with Improved Mechanical Strength, Dimensional Stability and Fire Retardancy. Polymers, 10(3), 341. https://doi.org/10.3390/polym10030341