Effect of Thermal Ageing on the Impact Damage Resistance and Tolerance of Carbon-Fibre-Reinforced Epoxy Laminates

Abstract

:1. Introduction

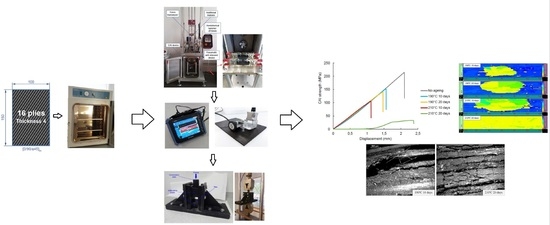

2. Materials and Methods

2.1. Materials and Specimen Preparation

2.2. Low Velocity Impact Testing

2.3. Phased Array Ultrasonic Testing

2.4. Compression after Impact (CAI) Test

3. Results and Discussion

3.1. Effect of Ageing on the Impact Damage Resistance of CFRP Composite Laminates

3.2. Effect of Ageing on the Impact Damage Tolerance of CFRP Composite Laminates

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rivallant, S.; Bouvet, C.; Abi Abdallah, E.; Broll, B.; Barrau, J.-J. Experimental analysis of CFRP laminates subjected to compression after impact: The role of impact-induced cracks in failure. Compos. Struct. 2014, 111, 147–157. [Google Scholar] [CrossRef] [Green Version]

- Rhead, A.T.; Hua, S.; Butler, R. Damage resistance and damage tolerance of hybrid carbon-glass laminates. Compos. A Appl. Sci. Manuf. 2015, 76, 224–232. [Google Scholar] [CrossRef] [Green Version]

- Caminero, M.A.; García-Moreno, I.; Rodríguez, G.P. Damage resistance of carbon fibre reinforced epoxy laminates subjected to low velocity impact: Effects of laminate thickness and ply-stacking sequence. Polym. Test. 2017, 63, 530–541. [Google Scholar] [CrossRef]

- Pavlopoulou, S.; Grammatikos, S.A.; Kordatos, E.Z.; Worden, K.; Paipetis, A.S.; Matikas, T.E.; Soutis, C. Continuous debonding monitoring of a patch repaired helicopter stabilizer: Damage assessment and analysis. Compos. Struct. 2015, 127, 231–244. [Google Scholar] [CrossRef] [Green Version]

- Caminero, M.A.; Rodríguez, G.P.; Muñoz, V. Effect of stacking sequence on Charpy impact and flexural damage behavior of composite laminates. Compos. Struct. 2016, 136, 345–357. [Google Scholar] [CrossRef]

- Shi, Y.; Soutis, C. Modelling transverse matrix cracking and splitting of cross-ply composite laminates under four point bending. Theor. Appl. Fract. Mech. 2016, 83, 73–81. [Google Scholar] [CrossRef]

- Shi, Y.; Swait, T.; Soutis, C. Modelling damage evolution in composite laminates subjected to low velocity impact. Compos. Struct. 2012, 94, 2902–2913. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Hallett, S.R. The role of delamination in strength, failure mechanism and hole size effect in open hole tensile test on quasi-isotropic laminates. Compos. A 2009, 40, 335–342. [Google Scholar] [CrossRef]

- Ostré, B.; Bouvet, C.; Minot, C.; Aboissière, J. Experimental analysis of CFRP laminates subjected to compression after edge impact. Compos. Struct. 2016, 152, 767–778. [Google Scholar] [CrossRef] [Green Version]

- Hawyes, V.J.; Curtis, P.T.; Soutis, C. Effect of impact damage on the compressive response of composite laminates. Compos. A Appl. Sci. Manuf. 2001, 32, 1263–1270. [Google Scholar] [CrossRef]

- Farooq, U.; Myler, P. Prediction of load threshold of fibre-reinforced laminated composite panels subjected to low velocity drop-weight impact using efficient data filtering techniques. Results Phys. 2015, 5, 206–221. [Google Scholar] [CrossRef] [Green Version]

- Selver, E.; Potluri, P.; Hogg, P.; Soutis, C. Impact damage tolerance of thermoset composites reinforced with hybrid commingled yarns. Compos. B Eng. 2016, 91, 522–538. [Google Scholar] [CrossRef] [Green Version]

- Aktaş, A.; Aktaş, M.; Turan, F. The effect of stacking sequence on the impact and post-impact behavior of woven/knit fabric glass/epoxy hybrid composites. Compos. Struct. 2013, 103, 119–135. [Google Scholar] [CrossRef]

- Saeed, M.U.; Chen, Z.; Chen, Z.; Li, B. Compression behavior of laminated composites subjected to damage induced by low velocity impact and drilling. Compos. B Eng. 2014, 56, 815–820. [Google Scholar] [CrossRef]

- Han, G.; Guan, Z.; Li, X.; Du, S. Failure analysis of carbon fiber reinforced composite subjected to low velocity impact and compression after impact. J. Reinf. Plast. Compos. 2016, 35, 727–746. [Google Scholar] [CrossRef]

- Remacha, M.; Sánchez-Sáez, S.; López-Romano, B.; Barbero, E. A new device for determining the compression after impact strength in thin laminates. Compos. Struct. 2015, 127, 99–107. [Google Scholar] [CrossRef] [Green Version]

- D7136 ASTM. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event. Annu. B ASTM Stand. 2012, 10, 1–16. [Google Scholar]

- Sanchez-Saez, S.; Barbero, E.; Zaera, R.; Navarro, C. Compression after impact of thin composite laminates. Compos. Sci. Technol. 2005, 65, 1911–1919. [Google Scholar] [CrossRef] [Green Version]

- Caminero, M.A.; García-Moreno, I.; Rodríguez, G.P. Experimental study of the influence of thickness and ply-stacking sequence on the compression after impact strength of carbon fibre reinforced epoxy laminates. Polym. Test. 2018, 66. [Google Scholar] [CrossRef]

- Vieille, B.; Albouy, W.; Bouscarrat, D.; Taleb, L. High-temperature fatigue behaviour of notched quasi-isotropic thermoplastic and thermoset laminates: Influence of matrix ductility on damage mechanisms and stress distribution. Compos. Struct. 2016, 153, 311–320. [Google Scholar] [CrossRef]

- Soutis, C. Fibre reinforced composites in aircraft construction. Prog. Aerosp. Sci. 2005, 41, 143–151. [Google Scholar] [CrossRef]

- Ernault, E.; Richaud, E.; Fayolle, B. Origin of epoxies embrittlement during oxidative ageing. Polym. Test. 2017, 63, 448–454. [Google Scholar] [CrossRef] [Green Version]

- Smirnova, V.E.; Popova, E.N.; Svetlichnyi, V.M.; Myagkova, L.A.; Orekhov, A.N.; Yudin, V.E.; Muzafarov, A.M.; Tatarinova, E.A. Effect of thermal aging on the mechanical characteristics of a composite of a polyimide with an organosilicon resin. Russ. J. Appl. Chem. 2011, 84, 1800–1804. [Google Scholar] [CrossRef]

- Belaid, S.; Chabira, S.F.; Balland, P.; Sebaa, M.; Belhouideg, S. Thermal aging effect on the mechanical properties of polyester fiberglass composites. J. Mater. Environ. Sci 2015, 6, 2795–2803. [Google Scholar]

- Barbosa, A.P.C.; Fulco, A.P.P.; Guerra, E.S.; Arakaki, F.K.; Tosatto, M.; Costa, M.C.B.; Melo, J.D.D. Accelerated aging effects on carbon fiber/epoxy composites. Compos. B Eng. 2017, 110, 298–306. [Google Scholar] [CrossRef]

- Merino-Pérez, J.L.; Ayvar-Soberanis, S.; Merson, E.; Hodzic, A. The influence of heat during short ageing periods on the mechanical properties of cfrp composites. In Proceedings of the 16th European Conference on Composite Materials, Seville, Spain, 22–26 June 2014. [Google Scholar]

- Wang, Z.; Xian, G.; Zhao, X.-L. Effects of hydrothermal aging on carbon fibre/epoxy composites with different interfacial bonding strength. Constr. Build. Mater. 2018, 161, 634–648. [Google Scholar] [CrossRef]

- Park, J.-M.; Shin, P.-S.; Kim, J.-H.; Baek, Y.-M.; Park, H.-S.; DeVries, L.K. Evaluation of thermally-aged carbon fiber/epoxy composites using acoustic emission, electrical resistance, contact angle and thermogram. In Behavior and Mechanics of Multifunctional Materials and Composites XII; Naguib, H.E., Ed.; SPIE: Bellingham, WA, USA, 2018; Volume 10596, p. 54. [Google Scholar]

- Barile, C.; Casavola, C.; Pappalettere, F.T. RFI composite materials behaviour. Struct. Integr. Life 2010, 10, 209–213. [Google Scholar]

- Zhang, D.; He, M.; He, W.; Zhou, Y.; Qin, S.; Yu, J. Influence of Thermo-Oxidative Ageing on the Thermal and Dynamical Mechanical Properties of Long Glass Fibre-Reinforced Poly(Butylene Terephthalate) Composites Filled with DOPO. Materials 2017, 10. [Google Scholar] [CrossRef]

- Abenojar, J.; Pantoja, M.; Martínez, M.A.; del Real, J.C. Aging by moisture and/or temperature of epoxy/SiC composites: Thermal and mechanical properties. J. Compos. Mater. 2015, 49, 2963–2975. [Google Scholar] [CrossRef]

- Lévêque, D.; Schieffer, A.; Mavel, A.; Maire, J.-F. Analysis of how thermal aging affects the long-term mechanical behavior and strength of polymer–matrix composites. Compos. Sci. Technol. 2005, 65, 395–401. [Google Scholar] [CrossRef]

- Tcharkhtchi, A.; Farzaneh, S.; Abdallah-Elhirtsi, S.; Esmaeillou, B.; Nony, F.; Baron, A. Thermal Aging Effect on Mechanical Properties of Polyurethane. Int. J. Polym. Anal. Charact. 2014, 19. [Google Scholar] [CrossRef]

- Guo, J.; Wang, M.; Li, L.; Wang, J.; He, W.; Chen, X. Effects of thermal-oxidative aging on the flammability, thermal degradation kinetics and mechanical properties of DBDPE flame retardant long glass fiber reinforced polypropylene composites. Polym. Compos. 2018, 39, E1733–E1741. [Google Scholar] [CrossRef]

- Riccio, A.; Di Felice, G.; Saputo, S.; Scaramuzzino, F. Stacking Sequence Effects on Damage Onset in Composite Laminate Subjected to Low Velocity Impact. Procedia Eng. 2014, 88, 222–229. [Google Scholar] [CrossRef] [Green Version]

- Sebaey, T.A.; González, E.V.; Lopes, C.S.; Blanco, N.; Maimí, P.; Costa, J. Damage resistance and damage tolerance of dispersed CFRP laminates: Effect of the mismatch angle between plies. Compos. Struct. 2013, 101, 255–264. [Google Scholar] [CrossRef]

- Sebaey, T.A.; González, E.V.; Lopes, C.S.; Blanco, N.; Costa, J. Damage resistance and damage tolerance of dispersed CFRP laminates: Effect of ply clustering. Compos. Struct. 2013, 106, 96–103. [Google Scholar] [CrossRef]

- Hazzard, M.K.; Hallett, S.; Curtis, P.T.; Iannucci, L.; Trask, R.S. Effect of fibre orientation on the low velocity impact response of thin Dyneema® composite laminates. Int. J. Impact Eng. 2017, 100, 35–45. [Google Scholar] [CrossRef] [Green Version]

- Suvarna, R.; Arumugam, V.; Bull, D.J.; Chambers, A.R.; Santulli, C. Effect of temperature on low velocity impact damage and post-impact flexural strength of CFRP assessed using ultrasonic C-scan and micro-focus computed tomography. Compos. B Eng. 2014, 66, 58–64. [Google Scholar] [CrossRef]

- Al-Salehi, F.A.R.; Al-Hassani, S.T.S.; Haftchenari, H.; Hinton, M.J. Temperature and Rate Effects on GRP Tubes Under Tensile Hoop Loading. Appl. Compos. Mater. 2001, 8, 1–24. [Google Scholar] [CrossRef]

- Im, K.-H.; Cha, C.-S.; Kim, S.-K.; Yang, I.-Y. Effects of temperature on impact damages in CFRP composite laminates. Compos. B Eng. 2001, 32, 669–682. [Google Scholar] [CrossRef]

- Gómez-del Rı́o, T.; Zaera, R.; Barbero, E.; Navarro, C. Damage in CFRPs due to low velocity impact at low temperature. Compos. B Eng. 2005, 36, 41–50. [Google Scholar] [CrossRef] [Green Version]

- García-Moreno, I.; Caminero, M.; Rodríguez, G.; López-Cela, J.; García-Moreno, I.; Caminero, M.Á.; Rodríguez, G.P.; López-Cela, J.J. Effect of Thermal Ageing on the Impact and Flexural Damage Behaviour of Carbon Fibre-Reinforced Epoxy Laminates. Polymers 2019, 11, 80. [Google Scholar] [CrossRef]

- Resources, H. Prepeg Data Sheets. Hexply M21E Epoxy Matrix. Product Data. Available online: www.hexcel.com (accessed on 2 May 2016).

- Slattery, P.G.; McCarthy, C.T.; O’Higgins, R.M. Assessment of residual strength of repaired solid laminate composite materials through mechanical testing. Compos. Struct. 2016, 147, 122–130. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.M.; Boffa, N.D.; Monaco, E.; Ricci, F. Nondestructive evaluation of carbon fibre reinforced composites with infrared thermography and ultrasonics. Compos. Struct. 2015, 134, 845–853. [Google Scholar] [CrossRef]

- Gaudenzi, P.; Bernabei, M.; Dati, E.; De Angelis, G.; Marrone, M.; Lampani, L. On the evaluation of impact damage on composite materials by comparing different NDI techniques. Compos. Struct. 2014, 118, 257–266. [Google Scholar] [CrossRef]

- Hassen, A.A.; Taheri, H.; Vaidya, U.K. Non-destructive investigation of thermoplastic reinforced composites. Compos. B Eng. 2016, 97, 244–254. [Google Scholar] [CrossRef] [Green Version]

- Caminero, M.A.; García-Moreno, I.; Rodríguez, G.P.; Chacón, J.M. Internal damage evaluation of composite structures using phased array ultrasonic technique: Impact damage assessment in CFRP and 3D printed reinforced composites. Compos. B Eng. 2019, 165, 131–142. [Google Scholar] [CrossRef]

- Mlyniec, A.; Korta, J.; Kudelski, R.; Uhl, T. The influence of the laminate thickness, stacking sequence and thermal aging on the static and dynamic behavior of carbon/epoxy composites. Compos. Struct. 2014, 118, 208–216. [Google Scholar] [CrossRef]

- Boominathan, R.; Arumugam, V.; Santulli, C.; Adhithya Plato Sidharth, A.; Anand Sankar, R.; Sridhar, B.T.N. Acoustic emission characterization of the temperature effect on falling weight impact damage in carbon/epoxy laminates. Compos. B Eng. 2014, 56, 591–598. [Google Scholar] [CrossRef]

- Marouani, S.; Curtil, L.; Hamelin, P. Ageing of carbon/epoxy and carbon/vinylester composites used in the reinforcement and/or the repair of civil engineering structures. Compos. B Eng. 2012, 43, 2020–2030. [Google Scholar] [CrossRef]

- Shaoquan, W.; Shangli, D.; Yu, G.; Yungang, S. Thermal ageing effects on mechanical properties and barely visible impact damage behavior of a carbon fiber reinforced bismaleimide composite. Mater. Des. 2017, 115, 213–223. [Google Scholar] [CrossRef]

- Lv, X.; Wang, R.; Liu, W.; Jiang, L. Surface and interface properties of carbon fiber composites under cyclical aging. Appl. Surf. Sci. 2011, 257, 10459–10464. [Google Scholar] [CrossRef]

- Akay, M.; Spratt, G.R. Evaluation of thermal ageing of a carbon fibre reinforced bismalemide. Compos. Sci. Technol. 2008, 68, 3081–3086. [Google Scholar] [CrossRef]

- Luo, H.; Roy, S.; Lu, H. Dynamic compressive behavior of unidirectional IM7/5250-4 laminate after thermal oxidation. Compos. Sci. Technol. 2012, 72, 159–166. [Google Scholar] [CrossRef]

| E11T (GPa) | E22T (GPa) | G12 (GPa) | (MPa) | (MPa) | (MPa) |

| 177.5 | 11.8 | 5.2 | 3050.8 | 56.1 | 94.2 |

| E11C (GPa) | E22C (GPa) | ν12 | (MPa) | (MPa) | |

| 146.1 | 7.4 | 0.39 | 1500.5 | 200.4 |

| Temperature (°C) | Time (days) | Fmax (N) | Eabsorbed (J) | Damage extension (mm × mm) |

|---|---|---|---|---|

| Non-aged * | - | 9212.25 (68.90) | 8.23(0.30) | 90.25 (0.24) × 67.84 (0.19) |

| 190 | 10 | 7955.93 | 7.64 | 56.09 × 51.05 |

| 7898.06 | 7.63 | 69.00 × 60.52 | ||

| 8129.51 | 6.25 | 53.72 × 51.71 | ||

| 20 | 8036.93 | 7.68 | 78.05 × 68.93 | |

| 8742.84 | 6.79 | 82.50 × 63.82 | ||

| 8291.52 | 7.72 | 69.04 × 62.37 | ||

| 210 | 10 | 7793.91 | 8.38 | 91.49 × 52.48 |

| 7799.70 | 8.39 | 81.88 × 67.93 | ||

| 8146.87 | 7.86 | 90.82 × 64.63 | ||

| 20 | 3847.78 | 16.24 | Failure | |

| 3841.99 | 16.83 | Failure | ||

| 3552.68 | 16.47 | Failure |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Moreno, I.; Caminero, M.Á.; Rodríguez, G.P.; López-Cela, J.J. Effect of Thermal Ageing on the Impact Damage Resistance and Tolerance of Carbon-Fibre-Reinforced Epoxy Laminates. Polymers 2019, 11, 160. https://doi.org/10.3390/polym11010160

García-Moreno I, Caminero MÁ, Rodríguez GP, López-Cela JJ. Effect of Thermal Ageing on the Impact Damage Resistance and Tolerance of Carbon-Fibre-Reinforced Epoxy Laminates. Polymers. 2019; 11(1):160. https://doi.org/10.3390/polym11010160

Chicago/Turabian StyleGarcía-Moreno, Irene, Miguel Ángel Caminero, Gloria Patricia Rodríguez, and Juan José López-Cela. 2019. "Effect of Thermal Ageing on the Impact Damage Resistance and Tolerance of Carbon-Fibre-Reinforced Epoxy Laminates" Polymers 11, no. 1: 160. https://doi.org/10.3390/polym11010160

APA StyleGarcía-Moreno, I., Caminero, M. Á., Rodríguez, G. P., & López-Cela, J. J. (2019). Effect of Thermal Ageing on the Impact Damage Resistance and Tolerance of Carbon-Fibre-Reinforced Epoxy Laminates. Polymers, 11(1), 160. https://doi.org/10.3390/polym11010160