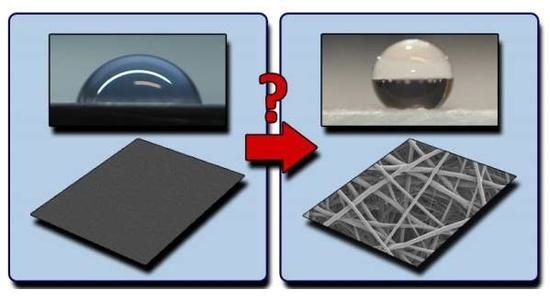

Roughness and Fiber Fraction Dominated Wetting of Electrospun Fiber-Based Porous Meshes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polymer Solutions

2.2. Electrospinning

2.3. Spin-Coating

2.4. Surface Profilometry

2.5. SEM Parameters and Image Analysis

2.6. Contact Angle and Surface Free Energy

2.7. X-ray Photoelectron Spectroscopy

2.8. Experimental Summary

- Investigation of fibers and films morphology using SEM; fiber diameter comparison to surface roughness and fiber fraction for all meshes.

- Wetting contact angle on films and meshes made of seven types of polymer (including PMMA, PLGA, PC, PCL, PS, PVDF, and most hydrophilic PA6), without any surface modifications; meshes were divided to four groups by their average fiber diameter below 0.5 µm, 1–2 µm, 2–3 µm, and 4–6 µm.

- The varying fiber diameter of the same polymer (PMMA) for the three groups: below 0.5 µm, between 1–2 µm, and 2–3 µm, and keeping the same thickness of the meshes to validate wetting contact angle.

- Analyzing the effect of thickness of 3D meshes on wetting contact angles.

- Calculations of surface free energy and its changes with fiber fraction in the meshes, with additional surface chemistry analysis using XPS.

3. Results

3.1. Contact Angle versus Fiber Diameter, Roughness and Fiber Fraction

3.2. The Surface Free Energy of Polymer Films

3.3. Surface Chemistry

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Kubiak, K.J.; Wilson, M.C.T.; Mathia, T.G.; Carval, P. Wettability versus roughness of engineering surfaces. Wear 2011, 271, 523–528. [Google Scholar] [CrossRef] [Green Version]

- Guo, Z.; Liu, W.; Su, B.L. Superhydrophobic surfaces: From natural to biomimetic to functional. J. Colloid Interface Sci. 2011, 353, 335–355. [Google Scholar] [CrossRef] [PubMed]

- Bhushan, B.; Jung, Y.C.; Koch, K. Micro-, nano- and hierarchical structures for superhydrophobicity, self-cleaning and low adhesion. Philos. Trans. A Math. Phys. Eng. Sci. 2009, 367, 1631–1672. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Azad, M.A.K.; Barthlott, W.; Koch, K. Hierarchical Surface Architecture of Plants as an Inspiration for Biomimetic Fog Collectors. Langmuir 2015, 31, 13172–13179. [Google Scholar] [CrossRef]

- Brown, P.S.; Bhushan, B. Bioinspired materials for water supply and management: Water collection, water purification and separation of water from oil. Philos. Trans. A Math. Phys. Eng. Sci. 2016, 374, 20160135. [Google Scholar] [CrossRef]

- Tuteja, A.; Choi, W.; Ma, M.; Mabry, J.M.; Mazzella, S.A.; Rutledge, G.C.; McKinley, G.H.; Cohen, R.E. Designing Superoleophobic Surfaces. Science 2007, 318, 1618–1622. [Google Scholar] [CrossRef] [PubMed]

- Yohe, S.T.; Freedman, J.D.; Falde, E.J.; Colson, Y.L.; Grinstaff, M.W. A Mechanistic Study of Wetting Superhydrophobic Porous 3D Meshes. Adv. Funct. Mater. 2013, 23, 3628–3637. [Google Scholar] [CrossRef] [Green Version]

- Gopal, R.; Kaur, S.; Ma, Z.; Chan, C.; Ramakrishna, S.; Matsuura, T. Electrospun nanofibrous filtration membrane. J. Membr. Sci. 2006, 281, 581–586. [Google Scholar] [CrossRef]

- Zhang, C.; Li, P.; Cao, B. Electrospun Microfibrous Membranes Based on PIM-1/POSS with High Oil Wettability for Separation of Oil–Water Mixtures and Cleanup of Oil Soluble Contaminants. Ind. Eng. Chem. Res. 2015, 54, 8772–8781. [Google Scholar] [CrossRef]

- Zhang, C.; Li, P.; Cao, B. Fabrication of superhydrophobic-superoleophilic fabrics by an etching and dip-coating two-step method for oil-water separation. Ind. Eng. Chem. Res. 2016, 55, 5030–5035. [Google Scholar] [CrossRef]

- Li, X.; Yu, X.; Cheng, C.; Deng, L.; Wang, M.; Wang, X. Electrospun Superhydrophobic Organic/Inorganic Composite Nanofibrous Membranes for Membrane Distillation. ACS Appl. Mater. Interfaces 2015, 7, 21919–21930. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Steckl, A.J. Selective pH-Responsive Core-Sheath Nanofiber Membranes for Chem/Bio/Med Applications: Targeted Delivery of Functional Molecules. ACS Appl. Mater. Interfaces 2017, 9, 42653–42660. [Google Scholar] [CrossRef] [PubMed]

- Park, A.M.; Turley, F.E.; Wycisk, R.J.; Pintauro, P.N. Electrospun and cross-linked nanofiber composite anion exchange membranes. Macromolecules 2014, 47, 227–235. [Google Scholar] [CrossRef]

- Stachewicz, U.; Modaresifar, F.; Bailey, R.J.; Peijs, T.; Barber, A.H. Manufacture of Void-Free Electrospun Polymer Nanofiber Composites with Optimized Mechanical Properties. ACS Appl. Mater. Interfaces 2012, 4, 2577–2582. [Google Scholar] [CrossRef]

- Enayati, M.S.; Behzad, T.; Sajkiewicz, P.; Bagheri, R.; Ghasemi-Mobarakeh, L.; Pierini, F. Theoretical and experimental study of the stiffness of electrospun composites of poly(vinyl alcohol), cellulose nanofibers, and nanohydroxy apatite. Cellulose 2018, 25, 65–75. [Google Scholar] [CrossRef]

- Morello, G.; Camposeo, A.; Moffa, M.; Pisignano, D. Electrospun amplified fiber optics. ACS Appl. Mater. Interfaces 2015, 7, 5213–5218. [Google Scholar] [CrossRef] [PubMed]

- Ganesh, V.A.; Ranganath, A.S.; Baji, A.; Raut, H.K.; Sahay, R.; Ramakrishna, S. Hierarchical Structured Electrospun Nanofibers for Improved Fog Harvesting Applications. Macromol. Mater. Eng. 2017, 302, 1600387. [Google Scholar] [CrossRef]

- Park, K.C.; Chhatre, S.S.; Srinivasan, S.; Cohen, R.E.; McKinley, G.H. Optimal design of permeable fiber network structures for fog harvesting. Langmuir 2013, 29, 13269–13277. [Google Scholar] [CrossRef]

- Liang, M.; Chen, X.; Xu, Y.; Zhu, L.; Jin, X.; Huang, C. Double-grooved nanofibre surfaces with enhanced anisotropic hydrophobicity. Nanoscale 2017, 9, 16214–16222. [Google Scholar] [CrossRef]

- Varagnolo, S.; Raccanello, F.; Pierno, M.; Mistura, G.; Moffa, M.; Persano, L.; Pisignano, D. Highly sticky surfaces made by electrospun polymer nanofibers. RSC Adv. 2017, 7, 5836–5842. [Google Scholar] [CrossRef] [Green Version]

- Lavielle, N.; Hébraud, A.; Thöny-Meyer, L.; Rossi, R.M.; Schlatter, G. 3D Composite Assemblies of Microparticles and Nanofibers for Tailored Wettability and Controlled Drug Delivery. Macromol. Mater. Eng. 2017, 302, 1–8. [Google Scholar] [CrossRef]

- Agarwal, S.; Wendorff, J.H.; Greiner, A. Use of electrospinning technique for biomedical applications. Polymer 2008, 49, 5603–5621. [Google Scholar] [CrossRef] [Green Version]

- Haider, A.; Haider, S.; Kang, I.-K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Zhou, Q.; Xie, J.; Bao, M.; Yuan, H.; Ye, Z.; Lou, X.; Zhang, Y. Engineering aligned electrospun PLLA microfibers with nano-porous surface nanotopography for modulating the responses of vascular smooth muscle cells. J. Mater. Chem. B 2015, 3, 4439–4450. [Google Scholar] [CrossRef]

- Ahmed, F.; Choudhury, N.R.; Dutta, N.K.; Zannettino, A.; Knott, R. Near superhydrophobic fibrous scaffold for endothelialization: Fabrication, characterization and cellular activities. Biomacromolecules 2013, 14, 3850–3860. [Google Scholar] [CrossRef]

- Stachewicz, U.; Qiao, T.; Rawlinson, S.C.F.; Almeida, F.V.; Li, W.-Q.Q.; Cattell, M.; Barber, A.H. 3D imaging of cell interactions with electrospun PLGA nanofiber membranes for bone regeneration. Acta Biomater. 2015, 27, 88–100. [Google Scholar] [CrossRef]

- Terpilowski, K.; Rymuszka, D.; Holysz, L.; Chibowski, E. Changes in Wettability of Polycarbonate and Polypropylene Pretreated With Oxygen and Argon Plasma. In Proceedings of the 8th International Conference MMT-20142, Ariel, Israel, 28 July–01 August 01 2014; pp. 155–165. [Google Scholar]

- Squires, T.M. Drops on soft surfaces learn the hard way. Proc. Natl. Acad. Sci. USA 2013, 110, 12505–12506. [Google Scholar] [CrossRef] [Green Version]

- Ma, M.; Gupta, M.; Li, Z.; Zhai, L.; Gleason, K.K.; Cohen, R.E.; Rubner, M.F.; Rutledge, G.C. Decorated electrospun fibers exhibiting superhydrophobicity. Adv. Mater. 2007, 19, 255–259. [Google Scholar] [CrossRef]

- Pai, C.L.; Boyce, M.C.; Rutledge, G.C. Morphology of porous and wrinkled fibers of polystyrene electrospun from dimethylformamide. Macromolecules 2009, 42, 2102–2114. [Google Scholar] [CrossRef]

- Wang, L.; Pai, C.L.; Boyce, M.C.; Rutledge, G.C. Wrinkled surface topographies of electrospun polymer fibers. Appl. Phys. Lett. 2009, 94, 92–95. [Google Scholar] [CrossRef]

- Scheffler, R.; Bell, N.S.; Sigmund, W. Electrospun Teflon AF fibers for superhydrophobic membranes. J. Mater. Res. 2010, 25, 1595–1600. [Google Scholar] [CrossRef]

- Muthiah, P.; Hsu, S.H.; Sigmund, W. Coaxially electrospun PVDF-teflon AF and teflon AF-PVDF core-sheath nanofiber mats with superhydrophobic properties. Langmuir 2010, 26, 12483–12487. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Burghaus, U.; Besenbacher, F.; Wang, Z.L. Preparation and Characterization of Nanomaterials for Sustainable Energy Production. ACS Nano 2010, 4, 5517–5526. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stachewicz, U.; Bailey, R.J.; Zhang, H.; Stone, C.A.; Willis, C.R.; Barber, A.H. Wetting Hierarchy in Oleophobic 3D Electrospun Nanofiber Networks. ACS Appl. Mater. Interfaces 2015, 7, 16645–16652. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, Z.; Hou, X.; Zhang, L.; Wu, S. Enhancing crystallinity and orientation by hot-stretching to improve the mechanical properties of electrospun partially aligned polyacrylonitrile (PAN) nanocomposites. Materials 2010, 4, 621–632. [Google Scholar] [CrossRef] [PubMed]

- Stachewicz, U.; Bailey, R.J.; Wang, W.; Barber, A.H. Size dependent mechanical properties of electrospun polymer fibers from a composite structure. Polymer 2012, 53, 5132–5137. [Google Scholar] [CrossRef]

- Camposeo, A.; Greenfeld, I.; Tantussi, F.; Moffa, M.; Fuso, F.; Allegrini, M.; Zussman, E.; Pisignano, D. Conformational evolution of elongated polymer solutions tailors the polarization of light-emission from organic nanofibers. Macromolecules 2014, 47, 4704–4710. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Yamaguchi, K.; Nagaishi, T.; Murai, M.; Kim, M.; Wei, K.; Zhang, K.Q.; Kim, I.S. Enhancement of mechanical properties of polymeric nanofibers by controlling crystallization behavior using a simple freezing/thawing process. RSC Adv. 2017, 7, 43994–44000. [Google Scholar] [CrossRef] [Green Version]

- Duprat, C.; Protière, S.; Beebe, A.Y.; Stone, H.A. Wetting of flexible fibre arrays. Nature 2012, 482, 510–513. [Google Scholar] [CrossRef] [PubMed]

- Sauret, A.; Bick, A.D.; Duprat, C.; Stone, H.A. Wetting of crossed fibers: Multiple steady states and symmetry breaking. Europhys. Lett. 2014, 105, 56006. [Google Scholar] [CrossRef] [Green Version]

- Chaudhury, M.K. Interfacial interaction between low-energy surfaces. Mater. Sci. Eng. R Rep. 1996, 16, 97–159. [Google Scholar] [CrossRef]

- Stachewicz, U.; Stone, C.A.; Willis, C.R.; Barber, A.H. Charge assisted tailoring of chemical functionality at electrospun nanofiber surfaces. J. Mater. Chem. 2012, 22, 22935–22941. [Google Scholar] [CrossRef]

- Stachewicz, U.; Barber, A.H. Enhanced wetting behavior at electrospun polyamide nanofiber surfaces. Langmuir 2011, 27, 3024–3029. [Google Scholar] [CrossRef] [PubMed]

- Stachewicz, U.; Hang, F.; Barber, A.H. Adhesion anisotropy between contacting electrospun fibers. Langmuir 2014, 30, 6819–6825. [Google Scholar] [CrossRef]

- Ma, M.; Mao, Y.; Gupta, M.; Gleason, K.K.; Rutledge, G.C. Superhydrophobic fabrics produced by electrospinning and chemical vapor deposition. Macromolecules 2005, 38, 9742–9748. [Google Scholar] [CrossRef]

- Wang, J.; Raza, A.; Si, Y.; Cui, L.; Ge, J.; Ding, B.; Yu, J. Synthesis of superamphiphobic breathable membranes utilizing SiO2 nanoparticles decorated fluorinated polyurethane nanofibers. Nanoscale 2012, 4, 7549–7556. [Google Scholar] [CrossRef] [PubMed]

- Stachewicz, U.; Benett, C.; Barber, A.H. Wetting of polyamide film surfaces with electrospun nanofibers. Mater. Res. Soc. Symp. Proc. 2012, 1403, 47–51. [Google Scholar] [CrossRef]

- Qin, X.H.; Xin, D.P. The study on the air volume fraction of electrospun nanofiber nonwoven mats. Fibers Polym. 2010, 11, 632–637. [Google Scholar] [CrossRef]

- Sadeghi, P.; Tavanai, H.; Khoddami, A. Hydrophobicity of fluorocarbon-finished electrospun poly (acrylonitrile) nanofibrous webs. J. Text. Inst. 2017, 108, 189–195. [Google Scholar] [CrossRef]

- Koysuren, O.; Koysuren, H.N. Characterization of poly(methyl methacrylate) nanofiber mats by electrospinning process. J. Macromol. Sci. Part A Pure Appl. Chem. 2016, 53, 691–698. [Google Scholar] [CrossRef]

- Konosu, Y.; Matsumoto, H.; Tsuboi, K.; Minagawa, M.; Tanioka, A. Enhancing the Effect of the Nanofiber Network Structure on Thermoresponsive Wettability Switching. Langmuir 2011, 27, 14716–14720. [Google Scholar] [CrossRef] [PubMed]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Metwally, S.; Karbowniczek, J.E.; Szewczyk, P.K.; Marzec, M.M.; Bernasik, A.; Stachewicz, U. Single-Step Approach to Tailor Surface Chemistry and Potential on Electrospun PCL Fibers for Tissue Engineering Application. Adv. Mater. Interfaces 2018, 1801211, 1801211. [Google Scholar] [CrossRef]

- Cha, B.G.; Kwak, H.W.; Park, A.R.; Kim, S.H.; Park, S.Y.; Kim, H.J.; Kim, I.S.; Lee, K.H.; Park, Y.H. Structural characteristics and biological performance of silk fibroin nanofiber containing microalgae spirulina extract. Biopolymers 2014, 101, 307–318. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Chen, Q.; Ayres, V.M.; Baczewski, A.D.; Udpa, L.; Kumar, S. Scanning probe recognition microscopy investigation of tissue scaffold properties. Int. J. Nanomed. 2007, 2, 651–661. [Google Scholar] [CrossRef]

- Stachewicz, U.; Szewczyk, P.K.; Kruk, A.; Barber, A.H.; Czyrska-Filemonowicz, A. Pore shape and size dependence on cell growth into electrospun fiber scaffolds for tissue engineering: 2D and 3D analyses using SEM and FIB-SEM tomography. Mater. Sci. Eng. C 2019, 95, 397–408. [Google Scholar] [CrossRef]

- Heller, W.; Cheng, M.H.; Greene, B.W. Surface tension measurements by means of the “microcone tensiometer”. J. Colloid Interface Sci. 1966, 22, 179–194. [Google Scholar] [CrossRef]

- Van Oss, C.J. Interfacial Forces in Aqueous Media; CRC Press: Boca Raton, FL, USA, 1995; Volume 26, ISBN 1420015761. [Google Scholar]

- Pagliaro, M.; Rossi, M. The Future of Glycerol; Green Chemistry Series; Royal Society of Chemistry: Cambridge, UK, 2008; ISBN 978-0-85404-124-4. [Google Scholar]

- Rulison, C. Two-Component Surface Energy Characterization as a Predictor of Wettability and Dispersability; KRÜSS GmbH: Hamburg, Germany, 2000; pp. 1–22. [Google Scholar]

- Rico, I.; Lattes, A. Formamide, a water substitute. 12. Krafft temperature and micelle formation of ionic surfactants in formamide. J. Phys. Chem. 1986, 90, 5870–5872. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Stachewicz, U.; Li, S.; Bilotti, E.; Barber, A.H. Dependence of surface free energy on molecular orientation in polymer films. Appl. Phys. Lett. 2012, 100, 094104. [Google Scholar] [CrossRef]

- Stachewicz, U.; Dijksman, J.F.; Soudani, C.; Tunnicliffe, L.B.; Busfield, J.J.C.; Barber, A.H. Surface free energy analysis of electrospun fibers based on Rayleigh-Plateau/Weber instabilities. Eur. Polym. J. 2017, 91, 368–375. [Google Scholar] [CrossRef]

- Busolo, T.; Ura, D.P.; Kim, S.K.; Marzec, M.M.; Bernasik, A.; Stachewicz, U.; Kar-Narayan, S. Surface potential tailoring of PMMA fibers by electrospinning for enhanced triboelectric performance. Nano Energy 2018. [Google Scholar] [CrossRef]

- Szewczyk, P.K.; Knapczyk-Korczak, J.; Ura, D.P.; Metwally, S.; Gruszczyński, A.; Stachewicz, U. Biomimicking wetting properties of spider web from Linothele megatheloides with electrospun fibers. Mater. Lett. 2018, 233, 211–214. [Google Scholar] [CrossRef]

- Choi, G.R.; Park, J.; Ha, J.W.; Kim, W.D.; Lim, H. Superamphiphobic web of PTFEMA fibers via simple electrospinning without functionalization. Macromol. Mater. Eng. 2010, 295, 995–1002. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Bianco, A.; Iardino, G.; Bertarelli, C.; Miozzo, L.; Papagni, A.; Zerbi, G. Modification of surface properties of electrospun polyamide nanofibers by means of a perfluorinated acridine. Appl. Surf. Sci. 2007, 253, 8360–8364. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, R.; Fane, A.G. Fabrication of bioinspired composite nanofiber membranes with robust superhydrophobicity for direct contact membrane distillation. Environ. Sci. Technol. 2014, 48, 6335–6341. [Google Scholar] [CrossRef]

- Can-Herrera, L.A.; Ávila-Ortega, A.; de la Rosa-García, S.; Oliva, A.I.; Cauich-Rodríguez, J.V.; Cervantes-Uc, J.M. Surface modification of electrospun polycaprolactone microfibers by air plasma treatment: Effect of plasma power and treatment time. Eur. Polym. J. 2016, 84, 502–513. [Google Scholar] [CrossRef]

- Russo, V.; Tammaro, L.; Di Marcantonio, L.; Sorrentino, A.; Ancora, M.; Valbonetti, L.; Turriani, M.; Martelli, A.; Cammà, C.; Barboni, B. Amniotic epithelial stem cell biocompatibility for electrospun poly(lactide-co-glycolide), poly(ε-caprolactone), poly(lactic acid) scaffolds. Mater. Sci. Eng. C 2016, 69, 321–329. [Google Scholar] [CrossRef]

- Kang, M.; Jung, R.; Kim, H.S.; Jin, H.J. Preparation of superhydrophobic polystyrene membranes by electrospinning. Colloids Surf. A Physicochem. Eng. Asp. 2008, 313–314, 411–414. [Google Scholar] [CrossRef]

- Li, S.; Barber, A.H. Creating superhydrophobic polycarbonate fiber network from hydrophilic polycarbonate through electrospinning. Mater. Res. Soc. Symp. Proc. 2012, 1403, 53–58. [Google Scholar] [CrossRef]

- Chen, J.-T.; Chen, W.-L.; Fan, P.-W.; Yao, I.-C. Effect of Thermal Annealing on the Surface Properties of Electrospun Polymer Fibers. Macromol. Rapid Commun. 2014, 35, 360–366. [Google Scholar] [CrossRef] [PubMed]

- Hejda, F.; Solař, P.; Kousal, J. Surface free energy determination by contact angle measurements—A comparison of various approaches. In WDS’10 Proceedings of Contributed Papers, Part III; Charles University: Prague, Czech Republic, 1969; pp. 25–30. [Google Scholar]

- Dalet, P.; Papon, E.; Villenave, J.J. Surface free energy of polymeric materials: Relevancy of conventional contact angle data analyses. J. Adhes. Sci. Technol. 1999, 13, 857–870. [Google Scholar] [CrossRef]

- Wu, S. Polymer Interface and Adhesion; CRC Press: Boca Raton, FL, USA, 1982; ISBN 9780824715335. [Google Scholar]

- Wu, S. Calculation of interfacial tension in polymer systems. J. Polym. Sci. Part C Polym. Symp. 2007, 34, 19–30. [Google Scholar] [CrossRef]

- Luk, J.Z.; Cork, J.; Cooper-White, J.; Grøndahl, L. Use of two-step grafting to fabricate dual-functional films and site-specific functionalized scaffolds. Langmuir 2015, 31, 1746–1754. [Google Scholar] [CrossRef]

- Cho, D.; Chen, S.; Jeong, Y.; Joo, Y.L. Surface hydro-properties of electrospun fiber mats. Fibers Polym. 2015, 16, 1578–1586. [Google Scholar] [CrossRef]

| Polymer | Supplier | Mw [g·mol−1] | Solvents | C [%] | t [h] | vr [rpm] | T [°C] |

|---|---|---|---|---|---|---|---|

| PA6 | BASF, Ludwigshafen, Germany | 24,000 | Formic Acid:Acetic Acid 1:1 | 12 | 4 | 500 | 25 |

| PVDF | Sigma Aldrich | 275,000 | DMAc:Acetone 1:1 | 22 | 4 | 1500 | 60 |

| PMMA 1 | Sigma Aldrich | 150,000 | Formic Acid:(DMF) 7:3 | 12 | 3 | 750 | 45 |

| PMMA 2 | Sigma Aldrich | 350,000 | DMF | 12 | 2.5 | 500 | 55 |

| PMMA 3 | Sigma Aldrich | 150,000 | DMF | 30 | 3 | 750 | 45 |

| PLGA | Sigma Aldrich | 66,000–107,000 | Chloroform:DMF 85:15 | 15 | 2 | 500 | 25 |

| PC | Goodfellow, Huntingdon, UK | - | DMF:THF 1:1 | 20 | 4 | 900 | 50 |

| PCL | Perstorp, Warrington, UK | 50,000 | Chloroform | 12 | 2 | 700 | 25 |

| PS | Sigma Aldrich | 350,000 | DMF | 25 | 6 | 500 | 25 |

| Polymer | Electrospinning | Spin-Coating | ||||

|---|---|---|---|---|---|---|

| U [kV] | Q [ml·h−1] | D [cm] | H [%] | ts [s] | vs [rpm] | |

| PA6 | 16 | 0.2 | 15 | 40 | 10 | 1000 |

| PVDF | 15 | 4.2 | 18 | 60 | 40 | 3500 |

| PMMA 1 | 11 | 0.3 | 10 | 40 | - | - |

| PMMA 2 | 12 | 4.0 | 15 | 35 | 20 | 3500 |

| PMMA 3 | 12 | 3 | 15 | 40 | - | - |

| PLGA | 17 | 9.5 | 15 | 60 | 60 | 3000 |

| PC | 12 | 3.0 | 15 | 50 | 20 | 5000 |

| PCL | 14 | 0.001 | 20 | 50 | 60 | 3000 |

| PS | 11 | 1.5 | 15 | 40 | 10 | 2000 |

| Liquid | [mJm−2] | [mJm−2] | [mJm−2] |

|---|---|---|---|

| Water | 72.8 | 51.0 | 21.8 |

| Glycerol | 64.0 | 30.0 | 34.0 |

| Formamide | 58.2 | 18.7 | 39.5 |

| Fibers Deposition Time [min] | Sample Thickness [μm] | Df [μm] | Ra [µm] | Ff [%] | Contact Angle [°] | ||

|---|---|---|---|---|---|---|---|

| Water | Glycerol | Formamide | |||||

| 15 | 35.32 | 1.43 ± 0.25 | 7.10 ± 0.91 | 45.20 ± 15.55 | 131.9 ± 3.3 | 129.1 ± 3.0 | 118.2 ± 3.1 |

| 30 | 67.90 | 1.55 ± 0.25 | 6.76 ± 0.52 | 45.41 ± 3.14 | 125.2 ± 4.2 | 126.1 ± 5.8 | 119.6 ± 2.3 |

| 45 | 134.68 | 1.70 ± 0.20 | 10.18 ± 0.82 | 41.18 ± 10.75 | 130.3 ± 5.0 | 126.7 ± 2.8 | 118.6 ± 3.1 |

| Polymer Fibers | Water Contact Angle [°] | Df [μm] | ||

|---|---|---|---|---|

| Measured | Literature Data with References | Measured | Literature Data with References | |

| PA6 | 51.7 ± 4.9 | 50.0 [71] | 0.12 ± 0.02 | 0.15 ± 0.03 [71] |

| PVDF | 136.3 ± 3.9 | 142.8 ± 1.4 [72] | 1.23 ± 0.50 | ~0.17 [72] |

| PMMA 1 | 116.0 ± 4.2 | 134.6 ± 3.0 [51] | 0.34 ± 0.09 | 0.34 ± 0.05 [51] |

| PMMA 2 | 125.2 ± 4.2 | 132.2 ± 4.1 [51] | 1.43 ± 0.19 | 1.42 ± 0.14 [51] |

| PMMA 3 | 118.8 ± 5.8 | 135.0 [77] | 2.57 ± 0.92 | 5.00 - 5.50 [77] |

| PLGA | 121.6 ± 8.5 | 125.0 [74] | 1.81 ± 0.90 | 0.80 - 1.60 [74] |

| PC | 145.1 ± 2.6 | 122.0 ± 0.7 [76] | 2.35 ± 0.53 | ~0.75 [76] |

| PCL | 129.4 ± 3.3 | 128.0 ± 6.0 [73] | 4.08 ± 1.71 | 1.30 ± 0.60 [73] |

| PS | 124.8 ± 4.9 | 138.1 ± 0.7 [75] | 5.48 ± 0.47 | 12.70 ± 1.60 [75] |

| Polymer | Surface Free Energy [mJm−2] | ||||||

|---|---|---|---|---|---|---|---|

| Calculated | Literature Data | ||||||

| Ref. | |||||||

| PA6 | 45.9 | 22.9 | 23.0 | 40.3 | 5.50 | 34.9 | [44] |

| PVDF | 24.2 | 7.20 | 17.1 | 30.3 | 7.00 | 23.3 | [80] |

| PMMA | 35.9 | 12.8 | 23.1 | 32.0 | 9.00 | 23.0 | [81] |

| PLGA | 31.7 | 15.7 | 16.0 | - | - | - | - |

| PC | 39.3 | 0.90 | 38.5 | 44.0 | 1.00 | 43.0 | [27] |

| PCL | 40.7 | 7.40 | 33.3 | 33.0 | 10.0 | 22.0 | [82] |

| PS | 25.3 | 9.10 | 16.2 | 32.1 | 5.40 | 26.7 | [81] |

| Polymer Sample | C | O | F | N | O/C | |

|---|---|---|---|---|---|---|

| PA6 | fibers | 75.2 | 11.9 | - | 12.9 | 0.16 |

| film | 78.0 | 10.2 | - | 11.8 | 0.13 | |

| PVDF | fibers | 51.1 | 0.70 | 48.1 | - | - |

| film | 53.2 | - | 46.8 | - | - | |

| PMMA 2 | fibers | 69.5 | 29.9 | - | - | 0.43 |

| film | 73.4 | 26.6 | - | - | 0.36 | |

| PLGA | fibers | 60.1 | 39.9 | - | - | 0.66 |

| film | 61.6 | 38.4 | - | - | 0.62 | |

| PC | fibers | 82.9 | 17.1 | - | - | 0.21 |

| film | 85.2 | 14.8 | - | - | 0.17 | |

| PCL | fibers | 78.0 | 22.0 | - | - | 0.28 |

| film | 77.5 | 22.5 | - | - | 0.29 | |

| PS | fibers | 100.0 | 0.00 | - | - | 0.00 |

| film | 100.0 | 0.00 | - | - | 0.00 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szewczyk, P.K.; Ura, D.P.; Metwally, S.; Knapczyk-Korczak, J.; Gajek, M.; Marzec, M.M.; Bernasik, A.; Stachewicz, U. Roughness and Fiber Fraction Dominated Wetting of Electrospun Fiber-Based Porous Meshes. Polymers 2019, 11, 34. https://doi.org/10.3390/polym11010034

Szewczyk PK, Ura DP, Metwally S, Knapczyk-Korczak J, Gajek M, Marzec MM, Bernasik A, Stachewicz U. Roughness and Fiber Fraction Dominated Wetting of Electrospun Fiber-Based Porous Meshes. Polymers. 2019; 11(1):34. https://doi.org/10.3390/polym11010034

Chicago/Turabian StyleSzewczyk, Piotr K., Daniel P. Ura, Sara Metwally, Joanna Knapczyk-Korczak, Marcin Gajek, Mateusz M. Marzec, Andrzej Bernasik, and Urszula Stachewicz. 2019. "Roughness and Fiber Fraction Dominated Wetting of Electrospun Fiber-Based Porous Meshes" Polymers 11, no. 1: 34. https://doi.org/10.3390/polym11010034

APA StyleSzewczyk, P. K., Ura, D. P., Metwally, S., Knapczyk-Korczak, J., Gajek, M., Marzec, M. M., Bernasik, A., & Stachewicz, U. (2019). Roughness and Fiber Fraction Dominated Wetting of Electrospun Fiber-Based Porous Meshes. Polymers, 11(1), 34. https://doi.org/10.3390/polym11010034