Aluminum-Magnesium Hydroxycarbonate/Azo Dye Hybrids as Novel Multifunctional Colorants for Elastomer Composites

Abstract

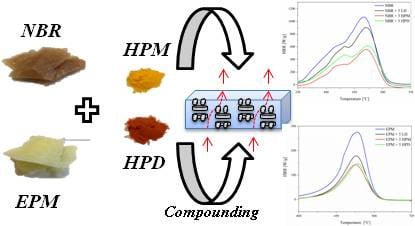

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hybrid Pigment Synthesis

2.3. Composite Preparation

2.4. Studies of Hybrid Pigments

2.5. Kinetics of Curing

2.6. Crossslink Density of Vulcanizates

2.7. Mechanical Strength of Composites

2.8. Dynamic Mechanical Analysis (DMA)

2.9. Air Permeability Measurement

2.10. Flammability of Composites (Microscale Combustion Calorimetry)

3. Results and Discussion

3.1. Hybrid Pigment Characterization

3.2. Kinetics of Curing

3.3. Crosslink Density of Vulcanizates

3.4. Mechanical Strength of Composites

3.5. Dynamic Mechanical Analysis

3.6. Composite Morphology

3.7. Barrier Properties

3.8. Flammability of Composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mohammad, S.; ul-Islam, S.; Mohammad, F. Recent advancements in natural dye applications: A review. J. Clean Prod. 2013, 53, 310–331. [Google Scholar] [CrossRef]

- Mahmud-Ali, A.; Fitz-Binder, C.; Bechtold, T. Aluminium based dye lakes from plant extracts for textile coloration. Dyes Pigment. 2012, 94, 533–540. [Google Scholar] [CrossRef]

- Jesionowski, T.; Binkowski, S.; Krysztafkiewicz, A. Adsorption of the selected organic dyes on the functionalized surface of precipitated silica via emulsion route. Dyes Pigment. 2005, 65, 267–279. [Google Scholar] [CrossRef]

- Andrzejewska, A.; Krysztafkiewicz, A.; Jesionowski, T. Adsorption of organic dyes on the aminosilane modified TiO2 surface. Dyes Pigment. 2004, 62, 121–130. [Google Scholar] [CrossRef]

- Cao, L.; Fei, X.; Zhao, H.; Gu, Y. Inorganic–organic hybrid pigment fabricated in the preparation process of organic pigment: Preparation and characterization. Dyes Pigment. 2015, 119, 75–83. [Google Scholar] [CrossRef]

- Tang, P.; Feng, Y.; Li, D. Facile synthesis of multicolor organic–inorganic hybrid pigments based on layered double hydroxides. Dyes Pigment. 2014, 104, 131–136. [Google Scholar] [CrossRef]

- Polette-Niewold, L.A.; Manciu, F.S.; Torres, B.; Alvarado, M., Jr.; Chianelli, R.R. Organic/inorganic complex pigments: Ancient colors Maya Blue. J. Inorg. Biochem. 2007, 101, 1958–1973. [Google Scholar] [CrossRef] [PubMed]

- Messina, P.V.; Schulz, P.C. Adsorption of reactive dyes on titania–silica mesoporous materials. J. Colloid Interface Sci. 2006, 299, 305–320. [Google Scholar] [CrossRef]

- Fournier, F.; de Viguerie, L.; Balme, S.; Janot, J.M.; Walter, P.; Jaber, M. Physico-chemical characterization of lake pigments based on montmorillonite and carminic acid. Appl. Clay Sci. 2016, 130, 12–17. [Google Scholar] [CrossRef]

- Raha, S.; Quazi, N.; Ivanov, I.; Bhattacharya, S. Dye/Clay intercalated nanopigments using commercially available non-ionic dye. Dyes Pigment. 2012, 93, 1512–1518. [Google Scholar] [CrossRef]

- Pardo, R.; Zayat, M.; Levy, D. Photochromic organic–inorganic hybrid materials. Chem. Soc. Rev. 2011, 40, 672–687. [Google Scholar] [CrossRef] [PubMed]

- Illaik, A.; Vuillermoz, C.; Commereuc, S.; Taviot-Gueho, C.; Verney, V.; Leroux, F. Reactive and functionalized LDH fillers for polymer. J. Phys. Chem. Solids 2008, 69, 1362–1366. [Google Scholar] [CrossRef]

- Wiyantoko, B.; Kurniawati, P.; Purbaningtias, T.E.; Fatimah, I. Synthesis and characterization of hydrotalcite at different Mg/Al molar ratios. Procedia Chem. 2015, 17, 21–26. [Google Scholar] [CrossRef]

- Arizaga, G.; Satyanarayana, K.; Wypych, F. Layered hydroxide salts: Synthesis, properties and potential applications. Solid State Ion. 2007, 178, 1143–1162. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, F.; Zhang, C.; Zeng, G.; Tan, X.; Yu, Z.; Cui, F. Utilization of LDH-based materials as potential adsorbents and photocatalysts for the decontamination of dyes wastewater: A review. RSC Adv. 2016, 6, 79415–79436. [Google Scholar] [CrossRef]

- Basu, D.; Das, A.; Stöckelhuber, K.W.; Wagenknecht, U.; Heinrich, G. Advances in layered double hydroxide (LDH)-based elastomer composites. Prog. Polym. Sci. 2014, 39, 594–626. [Google Scholar] [CrossRef]

- Guo, S.; Li, D.; Zhang, W.; Pu, M.; Evans, D.G.; Duan, X. Preparation of an anionic azo pigment-pillared layered double hydroxide and the thermo-and photostability of the resulting intercalated material. J. Solid State Chem. 2004, 177, 4597–4604. [Google Scholar] [CrossRef]

- Costantino, U.; Coletti, N.; Nocchetti, M.; Aloisi, G.G.; Elisei, F.; Latterini, L. Surface uptake and intercalation of fluorescein anions into Zn−Al−hydrotalcite. Photophysical characterization of materials obtained. Langmuir 2000, 16, 10351–10358. [Google Scholar] [CrossRef]

- Stawiński, W.; Węgrzyn, A.; Freitas, O.; Chmielarz, L.; Figueiredo, S. Dual-function hydrotalcite-derived adsorbents with sulfur storage properties: Dyes and hydrotalcite fate in adsorption-regeneration cycles. Microporous Mesoporous Mater. 2017, 250, 72–87. [Google Scholar] [CrossRef]

- dos Santos, R.M.M.; Gonçalves, R.G.L.; Constantino, V.R.L.; Santilli, C.V.; Borges, P.D.; Tronto, J.; Pinto, F.G. Adsorption of Acid Yellow 42 dye on calcined layered double hydroxide: Effect of time, concentration, pH and temperature. Appl. Clay Sci. 2017, 130, 132–139. [Google Scholar] [CrossRef]

- Nagendra, B.; Rosely, C.S.; Leuteritz, A.; Reuter, U.; Gowd, E.B. Polypropylene/layered double hydroxide nanocomposites: Influence of LDH intralayer metal constituents on the properties of polypropylene. ACS Omega 2017, 2, 20–31. [Google Scholar] [CrossRef]

- Kutlu, B.; Leuteritz, A.; Häußler, L.; Oertel, U.; Heinrich, G. Stabilization of polypropylene using dye modified layered double hydroxides. Polym. Degrad. Stab. 2014, 102, 9–14. [Google Scholar] [CrossRef]

- Zimmermann, A.; Jaerger, S.; Zawadzki, S.F.; Wypych, F. Synthetic zinc layered hydroxide salts intercalated with anionic azo dyes as fillers into high-density polyethylene composites: First insights. J. Polym. Res. 2013, 20, 224. [Google Scholar] [CrossRef]

- Marangoni, R.; Taviot-Guého, C.; Illaik, A.; Wypych, F.; Leroux, F. Organic inorganic dye filler for polymer: Blue-coloured layered double hydroxides into polystyrene. J. Colloid Interface Sci. 2008, 326, 366–373. [Google Scholar] [CrossRef] [PubMed]

- Taviot-Gueho, C.; Illaik, A.; Vuillermoz, C.; Commereuc, S.; Verney, V.; Leroux, F. LDH–dye hybrid material as coloured filler into polystyrene: Structural characterization and rheological properties. J. Phys. Chem. Solids 2007, 68, 1140–1146. [Google Scholar] [CrossRef]

- Marangoni, R.; Ramos, L.P.; Wypych, F. New multifunctional materials obtained by the intercalation of anionic dyes into layered zinc hydroxide nitrate followed by dispersion into poly (vinyl alcohol)(PVA). J. Colloid Interface Sci. 2009, 330, 303–309. [Google Scholar] [CrossRef] [PubMed]

- Marangoni, R.; Mikowski, A.; Wypych, F. Effect of adsorbed/intercalated anionic dyes into the mechanical properties of PVA: Layered zinc hydroxide nitrate nanocomposites. J. Colloid Interface Sci. 2010, 351, 384–391. [Google Scholar] [CrossRef]

- Hajibeygi, M.; Omidi-Ghallemohamadi, M. One-step synthesized azo-dye modified Mg-Al LDH reinforced biobased semi-aromatic polyamide containing naphthalene ring; study on thermal stability and optical properties. J. Polym. Res. 2017, 24, 61. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Kim, J.-H.; Bae, J.-H.; Yoon, C.; Kim, J.-P.; Choi, J.-H. The Synthesis and Characterizations of Thermally-Stable Yellow Metal Complex Dyes for LCD Color Filters. Mol. Cryst. Liq. Cryst. 2013, 583, 60–69. [Google Scholar] [CrossRef]

- Roy, M.; Devi, S.S.; Roy, S.; Singh, C.B.; Singh, K.S. Synthesis, characterization, crystal structures and in vitro antimicrobial activities of triorganotin(IV) complexes of azo-dicarboxylates. Inorg. Chim. Acta 2015, 426, 89–98. [Google Scholar] [CrossRef]

- Flory, P.J. Statistical mechanics of swelling of network structures. J. Chem. Phys. 1950, 18, 108–111. [Google Scholar] [CrossRef]

- Maciejewska, M.; Zaborski, M. Effect of ionic liquids on the dispersion of zinc oxide and silica nanoparticles, vulcanisation behaviour and properties of NBR composites. Express Polym. Lett. 2014, 8, 932–940. [Google Scholar] [CrossRef]

- Masek, A.; Zaborski, M.; Kosmalska, A. Derivatives of flavonoids as anti-ageing substances in elastomers. C. R. Chim. 2011, 14, 483–488. [Google Scholar] [CrossRef]

- Marzec, A.; Szadkowski, B.; Rogowski, J.; Maniukiewicz, W.; Zaborski, M. New organic-inorganic hybrids as multifunctional additives to improve ethylene-norbornene (EN) composite stability. Polym. Degrad. Stab. 2018. [Google Scholar] [CrossRef]

- Bera, P.; Rajamathi, P.; Hedge, M.S.; Kamath, P.V. Thermal behaviour of hydroxides, hydroxysalts and hydrotalcites. Bull. Mater. Sci. 2000, 23, 141–145. [Google Scholar] [CrossRef] [Green Version]

- Marzec, A.; Szadkowski, B.; Rogowski, J.; Maniukiewicz, W.; Moszyński, D.; Kozanecki, M.; Zaborski, M. Characterization and properties of new color-tunable hybrid pigments based on layered double hydroxides (LDH) and 1,2-dihydroxyanthraquinone dye. J. Ind. Eng. Chem. 2018. [Google Scholar] [CrossRef]

- Christie, R.M.; Mackay, J.L. Metal salt azo pigments. Color. Technol. 2008, 124, 133–144. [Google Scholar] [CrossRef]

- Bokobza, L. The reinforcement of elastomeric networks by fillers. Macromol. Mater. Eng. 2004, 289, 607–621. [Google Scholar] [CrossRef]

- Das, A.; Wang, D.Y.; Leuteritz, A.; Subramaniam, K.; Greenwell, H.C.; Wagenknecht, U.; Heinrich, G. Preparation of zinc oxide free, transparent rubber nanocomposites using layered double hydroxide filler. J. Mater. Chem. 2011, 21, 7194–7200. [Google Scholar] [CrossRef]

- Ismail, H.; Osman, H.; Ariffin, A. A comparative study on curing characteristics, mechanical properties, swelling behavior, thermal stability, and morphology of feldspar and morphology of feldspar and silica in SMRL vulcanizates. Polym. Plast. Technol. Eng. 2004, 43, 1323–1344. [Google Scholar] [CrossRef]

- Mouse, A.; Karger Kocsis, C. Rheological and thermodynamical behavior of styrene/butadiene rubber-organoclay nanocomposites. Macromol. Mater. Eng. 2001, 286, 260–266. [Google Scholar] [CrossRef]

- Li, Y.; Han, B.; Liu, L.; Zhang, F.; Zhang, L.; Wen, S. Surface modification of silica by two-step method and properties of solution styrene butadiene rubber (SSBR) nanocomposites filled with modified silica. Compos. Sci. Technol. 2013, 88, 69–75. [Google Scholar] [CrossRef]

- Kosmalska, A.; Zaborski, M.; Sokołowska, J. Adsorption of curatives and activity of silica towards elastomers. Macromol. Symp. 2003, 194, 269–276. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Q.; Zhang, Q.; Lu, Y. Gas barrier properties of natural rubber/kaolin composites prepared by melt blending. Appl. Clay Sci. 2010, 50, 255–259. [Google Scholar] [CrossRef]

- Laskowska, A.; Zaborski, M.; Boiteux, G.; Gain, O.; Marzec, A.; Maniukiewicz, W. Ionic elastomers based on carboxylated nitrile rubber (XNBR) and magnesium aluminium layered double hydroxide (hydrotalcite). Express Polym. Lett. 2014, 8, 374–386. [Google Scholar] [CrossRef]

- Wang, D.-Y.; Das, A.; Leuteritz, A.; Mahaling, R.N.; Jehnichen, D.; Wagenknecht, U.; Heinrich, G. Structural characteristics and flammability of fire retarding EPDM/layered double hydroxide (LDH) nanocomposites. RSC Adv. 2012, 2, 3927–3933. [Google Scholar] [CrossRef]

- Basu, D.; Das, A.; Wang, D.-Y.; George, J.J.; Stockelhuber, K.W.; Boldt, R.; Leuteritz, A.; Heinrich, G. Fire-safe and environmentally friendly nanocomposites based on layered double hydroxides and ethylene propylene diene elastomer. RSC Adv. 2016, 6, 26425–26436. [Google Scholar] [CrossRef]

| Materials | Content [phr 1] |

|---|---|

| NBR | 100 |

| Sulfur | 2 |

| Mercaptobenzothiazole | 2 |

| Zinc oxide | 5 |

| Stearic acid | 1 |

| EPM | 100 |

| Dicumyl peroxide | 2 |

| 1,3,5-triallyl-1,3,5-triazine-2,4,6(1H,3H,5H)-trione | 0.5 |

| Hybrid pigment HPM (LH modified with MCD) Hybrid pigment HPD (LH modified with DCD) | 0, 5, 10 |

| Rubber | μ0 | β |

|---|---|---|

| NBR | 0.381 | 0.671 |

| EPM | 0.501 | 0.273 |

| Sample | %N | %C | %H |

|---|---|---|---|

| LH | - | 1.55; 1.54; 1.52 | 3.20; 3.24; 3.25 |

| HPM | 2.15; 2.18; 2.17 | 9.22; 9.18; 9.25 | 3.37; 3.40; 3.41 |

| HPD | 0.77; 0.83; 0.80 | 7.51; 7.52; 7.50 | 3.40; 3.45; 3.48 |

| Elastomer Compound | Mmin1 [dNm] | ΔM 2 [dNm] | τ02 3 [min] | τ09 4 [min] |

|---|---|---|---|---|

| NBR | 0.41 ± 0.02 | 7.34 ± 0.01 | 3.57 ± 0.02 | 30.51 ± 0.02 |

| NBR + 5 HPM | 0.50 ± 0.01 | 7.49 ± 0.02 | 3.68 ± 0.02 | 33.61 ± 0.02 |

| NBR + 10 HPM | 0.51 ± 0.02 | 7.01 ± 0.02 | 3.67 ± 0.01 | 34.22 ± 0.01 |

| NBR + 5 HPD | 0.51 ± 0.01 | 8.74 ± 0.01 | 2.60 ± 0.01 | 27.84 ± 0.01 |

| NBR + 10 HPD | 0.63 ± 0.01 | 9.17 ± 0.03 | 2.50 ± 0.02 | 29.98 ± 0.02 |

| EPM | 0.77 ± 0.01 | 6.81 ± 0.01 | 1.54 ± 0.02 | 15.75 ± 0.01 |

| EPM + 5 HPM | 0.86 ± 0.02 | 7.87 ± 0.01 | 1.22 ± 0.02 | 13.23 ± 0.01 |

| EPM+ 10 HPM | 0.93 ± 0.02 | 8.34 ± 0.02 | 1.21 ± 0.03 | 12.59 ± 0.02 |

| EPM + 5 HPD | 0.86 ± 0.01 | 7.34 ± 0.01 | 1.36 ± 0.02 | 14.32 ± 0.01 |

| EPM + 10 HPD | 0.99 ± 0.03 | 8.43 ± 0.02 | 1.24 ± 0.03 | 13.09 ± 0.02 |

| Parameter | NBR | 5 HPM | 10 HPM | 5 HPD | 10 HPD |

|---|---|---|---|---|---|

| GTR 1 | 2.24×10−7 | 1.69×10−7 | 4.87×10−8 | 6.49×10−8 | 3.67×10−8 |

| P 2 | 2.46×10−10 | 1.83×10−10 | 5.41×10−11 | 7.14×10−11 | 4.15×10−11 |

| - | EPM | 5 HPM | 10 HPM | 5 HPD | 10 HPD |

| GTR | 8.13×10−8 | 7.76×10−8 | 7.03×10−8 | 7.91×10−8 | 6.17×10−8 |

| P | 1.10×10−10 | 9.16×10−11 | 7.73×10−11 | 9.49×10−11 | 7.71×10−11 |

| Elastomer Compound | HRRmax1 [W×g−1] | Total HR2 [kJ×g−1] | HR Capacity3 [J×g−1×K−1] |

|---|---|---|---|

| NBR | 1091 ± 55 | 95.5 ± 4.8 | 1059 ± 64 |

| NBR + 5 LH | 894 ± 45 | 66.3 ± 2.7 | 865 ± 29 |

| NBR + 10 LH | 481 ± 29 | 68.0 ± 4.1 | 612 ± 31 |

| NBR + 5 HPM | 599 ± 24 | 49.1 ± 2.5 | 580 ± 23 |

| NBR + 10 HPM | 524 ± 31 | 39.2 ± 1.8 | 509 ± 25 |

| NBR + 5 HPD | 612 ± 31 | 47.6 ± 2.4 | 599 ± 30 |

| NBR + 10 HPD | 384 ± 12 | 46.5 ± 2.3 | 378 ± 15 |

| EPM | 275 ± 8 | 14.8 ± 0.7 | 268 ± 11 |

| EPM + 5 LH | 181 ± 7 | 7.3 ± 0.4 | 177 ± 9 |

| EPM + 10 LH | 112 ± 7 | 4.8 ± 0.2 | 110 ± 6 |

| EPM + 5 HPM | 146 ± 10 | 6.3 ± 0.3 | 142 ± 9 |

| EPM+ 10 HPM | 93 ± 5 | 4.1 ± 0.2 | 91 ± 5 |

| EPM + 5 HPD | 149 ± 6 | 6.2 ± 0.3 | 146 ± 7 |

| EPM + 10 HPD | 93 ± 6 | 3.9 ± 0.2 | 91 ± 4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szadkowski, B.; Marzec, A.; Rybiński, P.; Maniukiewicz, W.; Zaborski, M. Aluminum-Magnesium Hydroxycarbonate/Azo Dye Hybrids as Novel Multifunctional Colorants for Elastomer Composites. Polymers 2019, 11, 43. https://doi.org/10.3390/polym11010043

Szadkowski B, Marzec A, Rybiński P, Maniukiewicz W, Zaborski M. Aluminum-Magnesium Hydroxycarbonate/Azo Dye Hybrids as Novel Multifunctional Colorants for Elastomer Composites. Polymers. 2019; 11(1):43. https://doi.org/10.3390/polym11010043

Chicago/Turabian StyleSzadkowski, Bolesław, Anna Marzec, Przemysław Rybiński, Waldemar Maniukiewicz, and Marian Zaborski. 2019. "Aluminum-Magnesium Hydroxycarbonate/Azo Dye Hybrids as Novel Multifunctional Colorants for Elastomer Composites" Polymers 11, no. 1: 43. https://doi.org/10.3390/polym11010043

APA StyleSzadkowski, B., Marzec, A., Rybiński, P., Maniukiewicz, W., & Zaborski, M. (2019). Aluminum-Magnesium Hydroxycarbonate/Azo Dye Hybrids as Novel Multifunctional Colorants for Elastomer Composites. Polymers, 11(1), 43. https://doi.org/10.3390/polym11010043