Deterioration in the Physico-Mechanical and Thermal Properties of Biopolymers Due to Reprocessing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Polymer Processing

2.3. Compression Molding

2.4. Gel Permeation Chromatography (GPC)

2.5. Melt Flow Index (MFI)

2.6. Differential Scanning Calorimetry (DSC)

2.7. Dynamic Mechanical Analyzer (DMA)

2.8. Thermogravimetric Analysis (TGA)

2.9. Flexural Testing

2.10. Izod Impact Testing

2.11. Statistical Analysis

3. Results

3.1. Gel Permeation Chromatography (GPC)

3.2. Effect of Recycling on Flow Characteristics

3.3. Differential Scanning Calorimetry (DSC)

3.3.1. PLA

3.3.2. Bioflex

3.3.3. Solanyl

3.3.4. PHBV

3.4. Dynamic Mechanical Analyzer (DMA)

3.4.1. PLA

3.4.2. Bioflex

3.4.3. Solanyl

3.4.4. PHBV

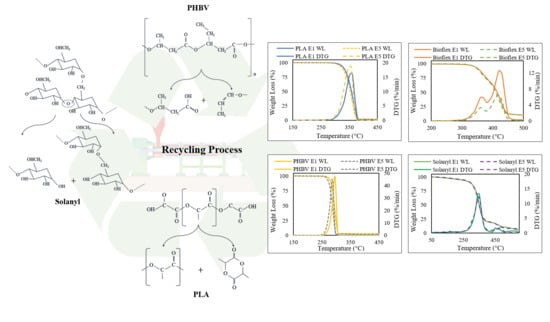

3.5. Thermogravimetric Analysis (TGA)

3.5.1. PLA

3.5.2. Bioflex

3.5.3. Solanyl

3.5.4. PHBV

3.6. Effect of Recycling on Mechanical Properties

4. Conclusions

- PHBV and PLA exhibited a considerable reduction in molecular weight after five times of undergoing extrusion cycles.

- DMA results showed a higher storage modulus for virgin polymers and a more viscoelastic behavior in the recycled polymers.

- Solanyl exhibited better thermal processability compared to the other biopolymers studied in this work. The molecular structure of Solanyl possessed lower recycling sensitivity.

- The maximum flexural strength in all polymers except Solanyl declined as the number of extrusion cycles increased.

Author Contributions

Funding

Conflicts of Interest

References

- Koller, M.; Maršálek, L.; de Sousa Dias, M.M.; Braunegg, G. Producing microbial polyhydroxyalkanoate (PHA) biopolyesters in a sustainable manner. New Biotechnol. 2017, 37, 24–38. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Lai, M.; Liu, J. Control and development of crystallinity and morphology in poly (β-hydroxybutyrate-co-β-hydroxyvalerate)/poly (propylene carbonate) blends. J. Appl. Polym. Sci. 2005, 98, 1427–1436. [Google Scholar] [CrossRef]

- Scaffaro, R.; Morreale, M.; Mirabella, F.; La Mantia, F.P. Preparation and recycling of plasticized PLA. Macromol. Mater. Eng. 2011, 296, 141–150. [Google Scholar] [CrossRef]

- Martín-Alfonso, J.; Valencia, C.; Sánchez, M.; Franco, J.; Gallegos, C. Rheological modification of lubricating greases with recycled polymers from different plastics waste. Ind. Eng. Chem. Res. 2009, 48, 4136–4144. [Google Scholar] [CrossRef]

- Beyler, C.L.; Hirschler, M.M. Thermal decomposition of polymers. In SFPE Handbook of Fire Protection Engineering; National Fire Protection Association: Quincy, MA, USA, 2002; Volume 2, pp. 111–131. [Google Scholar]

- Abe, H. Thermal degradation of environmentally degradable poly (hydroxyalkanoic acid)s. Macromol. Biosci. 2006, 6, 469–486. [Google Scholar] [CrossRef]

- Xiang, H.; Wen, X.; Miu, X.; Li, Y.; Zhou, Z.; Zhu, M. Thermal depolymerization mechanisms of poly (3-hydroxybutyrate-co-3-hydroxyvalerate). Prog. Nat. Sci. Mater. Int. 2016, 26, 58–64. [Google Scholar] [CrossRef]

- Dai, X.; Cao, Y.; Shi, X.; Wang, X. Non-isothermal crystallization kinetics, thermal degradation behavior and mechanical properties of poly (lactic acid)/MOF composites prepared by melt-blending methods. RSC Adv. 2016, 6, 71461–71471. [Google Scholar] [CrossRef]

- Nicolae, C.-A.; Grigorescu, M.A.; Gabor, R.A. An Investigation of Thermal Degradation of Poly (Lactic Acid). Eng. Lett. 2008, 16, 568–571. [Google Scholar]

- Kale, G.; Auras, R.; Singh, S.P. Degradation of commercial biodegradable packages under real composting and ambient exposure conditions. J. Polym. Environ. 2006, 14, 317–334. [Google Scholar] [CrossRef]

- Mano, J.; Koniarova, D.; Reis, R. Thermal properties of thermoplastic starch/synthetic polymer blends with potential biomedical applicability. J. Mater. Sci. Mater. Med. 2003, 14, 127–135. [Google Scholar] [CrossRef]

- Collins, E.; Metzger, A. Polyvinylchloride melt rheology II—the influence of molecular weight on flow activation energy. Polym. Eng. Sci. 1970, 10, 57–65. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, X.; Gu, Q.; Chen, W.; Sun, P.; Xue, G. Confinement-induced deviation of chain mobility and glass transition temperature for polystyrene/Au nanoparticles. Macromolecules 2013, 46, 2292–2297. [Google Scholar] [CrossRef]

- Pedroso, A.G.; Rosa, D.S. Mechanical, thermal and morphological characterization of recycled LDPE/corn starch blends. Carbohydr. Polym. 2005, 59, 1–9. [Google Scholar] [CrossRef]

- Thermal Degradation of Plastics. Technical Whitepaper; Zeus, Ed.; Zeus Industrial Products, Inc.: Orangeburg, SC, USA, 2005; pp. 3–5. [Google Scholar]

- Suksut, B.; Deeprasertkul, C. Effect of nucleating agents on physical properties of poly (lactic acid) and its blend with natural rubber. J. Polym. Environ. 2011, 19, 288–296. [Google Scholar] [CrossRef]

- Morreale, M.; Liga, A.; Mistretta, M.C.; Ascione, L.; Mantia, F.P.L. Mechanical, thermomechanical and reprocessing behavior of green composites from biodegradable polymer and wood flour. Materials 2015, 8, 7536–7548. [Google Scholar] [CrossRef] [PubMed]

- Kömmling, A.; Jaunich, M.; Wolff, D. Revealing effects of chain scission during ageing of EPDM rubber using relaxation and recovery experiment. Polym. Test. 2016, 56, 261–268. [Google Scholar] [CrossRef]

- Sherwood, C.H. The Effect of Shear on Polymer Crystallization Kinetics. Ph.D. Thesis, University of Massachusetts Amherst, Amherst, MA, USA, 1977. [Google Scholar]

- Najafi, S.K. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef]

- Gunaseelan, S.; Rao, R.; Manimaran, A.; Ramu, E.; Sivakumar, B. Determination of traces of amorphous cefuroxime axetil content in cefuroxime axetil crystalline drug substance using modulated differential scanning calorimetry (MDSC). J. Chem. Pharm. Res. 2012, 4, 4743–4751. [Google Scholar]

- Li, H.; Huneault, M.A. Effect of nucleation and plasticization on the crystallization of poly (lactic acid). Polymer 2007, 48, 6855–6866. [Google Scholar] [CrossRef]

- Thiré, R.M.d.S.M.; Arruda, L.C.; Barreto, L.S. Morphology and thermal properties of poly (3-hydroxybutyrate-co-3-hydroxyvalerate)/attapulgite nanocomposites. Mater. Res. 2011, 14, 340–344. [Google Scholar] [CrossRef]

- Wang, K.; Bahlouli, N.; Addiego, F.; Ahzi, S.; Rémond, Y.; Ruch, D.; Muller, R. Effect of talc content on the degradation of re-extruded polypropylene/talc composites. Polym. Degrad. Stab. 2013, 98, 1275–1286. [Google Scholar] [CrossRef]

- Cheng, S.; Lau, K.-T.; Liu, T.; Zhao, Y.; Lam, P.-M.; Yin, Y. Mechanical and thermal properties of chicken feather fiber/PLA green composites. Compos. Part B Eng. 2009, 40, 650–654. [Google Scholar] [CrossRef]

- Bourmaud, A.; Le Duigou, A.; Baley, C. What is the technical and environmental interest in reusing a recycled polypropylene–hemp fibre composite? Polym. Degrad. Stab. 2011, 96, 1732–1739. [Google Scholar] [CrossRef]

- Prasad, D.S.; Shoba, C.; Varma, K.R. Damping behavior of commonly used reinforcement powders–an experimental approach. Eng. Sci. Technol. Int. J. 2015, 18, 674–679. [Google Scholar] [CrossRef]

- Bandzierz, K.; Reuvekamp, L.; Dryzek, J.; Dierkes, W.; Blume, A.; Bielinski, D. Influence of network structure on glass transition temperature of elastomers. Materials 2016, 9, 607. [Google Scholar] [CrossRef] [PubMed]

- Shojaeiarani, J.; Bajwa, D.; Stark, N. Green esterification: A new approach to improve thermal and mechanical properties of poly (lactic acid) composites reinforced by cellulose nanocrystals. J. App. Polym. Sci. 2018, 135, 46468. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly (lactic acid)(PLA) composites: a comparative study. Compos. Sci. Technol. 2006, 66, 1813–1824. [Google Scholar] [CrossRef]

- Carrasco, F.; Pagès, P.; Gámez-Pérez, J.; Santana, O.; Maspoch, M.L. Processing of poly (lactic acid): Characterization of chemical structure, thermal stability and mechanical properties. Polym. Degrad. Stab. 2010, 95, 116–125. [Google Scholar] [CrossRef]

- Crompton, T.R. Thermal Stability of Polymers; Smithers Rapra: Akron, OH, USA, 2012. [Google Scholar]

- Peng, Y.; Gardner, D.J.; Han, Y.; Kiziltas, A.; Cai, Z.; Tshabalala, M.A. Influence of drying method on the material properties of nanocellulose I: thermostability and crystallinity. Cellulose 2013, 20, 2379–2392. [Google Scholar] [CrossRef]

- Jiun, Y.L.; Tze, C.T.; Moosa, U.; Tawawneh, M. Effects of Recycling Cycle on Used Thermoplastic Polymer and Thermoplastic Elastomer Polymer. Polym. Polym. Compos. 2016, 24, 735. [Google Scholar] [CrossRef]

- Jahani, B.; Brooks, A.; Azarmi, F. Development of antibacterial surfaces via thermal spray coating techniques. Biomed. Sci. Instrum. 2018, 54, 1. [Google Scholar]

- Kuram, E.; Ozcelik, B.; Yilmaz, F.; Timur, G.; Sahin, Z.M. The effect of recycling number on the mechanical, chemical, thermal, and rheological properties of PBT/PC/ABS ternary blends: With and without glass-fiber. Polym. Compos. 2014, 35, 2074–2084. [Google Scholar] [CrossRef]

| Polymer | Grade | Mw (g/mol) * | Supplier |

|---|---|---|---|

| PLA | 2003D | 200,000 | NatureWorks LLC (Minnetonka, MN, USA) |

| Bioflex | F-2110 | 53,000 | FKuR Kunststoff GmbH (Willich, Germany) |

| Solanyl | C2201 | NA | Rodenburg Biopolymers (Oosterhout, Netherlands) |

| PHBV | Y1000P | 300,000 | TianAn Biopolymer (Ningbo, China) |

| Extruder Temperature at Different Zones (°C) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Polymer | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | Zone 6 | Zone 7 | Gate Adaptor | Die | Screw RPM |

| PLA | 152 | 154 | 157 | 160 | 160 | 163 | 166 | 168 | 160 | 180 |

| Bioflex | 154 | 160 | 166 | 171 | 177 | 179 | 182 | 185 | 170 | 200 |

| Solanyl | 93 | 121 | 132 | 135 | 138 | 141 | 143 | 146 | 140 | 120 |

| PHBV | 177 | 166 | 160 | 154 | 149 | 143 | 138 | 132 | 125 | 200 |

| Polymer | Extrusion Cycles | Molecular Weight (g/mol) | Molecular Number (g/mol) | (Mw/Mn) | nt |

|---|---|---|---|---|---|

| PLA | 1 | 203,500 | 152,245 | 1.3 | 1.9 × 10−5 |

| 5 | 44,149 | 39,663 | 1.1 | ||

| Bioflex | 1 | 52,132 | 39,759 | 1.3 | 7.2 × 10−6 |

| 5 | 49,276 | 30,891 | 1.5 | ||

| Solanyl | 1 | 61,109 | 31,047 | 1.9 | 2.4 × 10−6 |

| 5 | 59,695 | 28,885 | 2.0 | ||

| PHBV | 1 | 298,500 | 176,383 | 1.6 | 1.5 × 10−5 |

| 5 | 52,262 | 48,525 | 1.1 |

| Polymer | Extrusion Cycles | Melt Flow Index (g/10 min) |

|---|---|---|

| PLA | 1 | 10.60 |

| 5 | 18.20 | |

| Bioflex | 1 | 6.37 |

| 5 | 9.18 | |

| Solanyl | 1 | 12.73 |

| 5 | 14.51 | |

| PHBV | 1 | 18.18 |

| 5 | 37.90 |

| Polymer | Extrusion Cycles | Tg (°C) | Tc (°C) | Tm (°C) | X% |

|---|---|---|---|---|---|

| PLA | 1 | 60.36 | 90.87 | 150.86 | 33.17 |

| 5 | 55.04 | 91.23 | 151.87 | 7.01 | |

| Bioflex | 1 | 65.73 | 85.34 | 151.36 | 2.72 |

| 5 | 64.23 | 80.24 | 148.12 | 2.67 | |

| Solanyl | 1 | 45.23 | - | 141.22 | - |

| 5 | 44.40 | - | 140.53 | - | |

| PHBV | 1 | - | - | 168.57 | 55.91% |

| 5 | - | - | 175.62 | 54.46% |

| Polymer | Extrusion Cycles | Flexural Strength (MPa) | Flexural Modulus (GPa) | Impact Strength (kJ/m2) |

|---|---|---|---|---|

| PLA | 1 | 77.7 ± 7.4 a | 2.5 ± 0.7 a | 7.7 ± 0.2 a |

| 5 | 75.0 ± 3.4 b | 2.2 ± 0.1 b | 7.0 ± 0.1 b | |

| Bioflex | 1 | 9.0 ± 0.8 a | 0.3 ± 0.0 a | 9.1 ± 0.5 a |

| 5 | 8.2 ± 0.2 b | 0.2 ± 0.0 b | 8.7 ± 0.2 b | |

| Solanyl | 1 | 15.1 ± 0.4 a | 1.4 ± 0.0 a | 2.1 ± 0.4 a |

| 5 | 15.2 ± 0.1 a | 1.3 ± 0.1 b | 2.1 ± 0.3 a | |

| PHBV | 1 | 47.4 ± 3.6 a | 3.2 ± 0.3 a | 3.7 ± 0.1 a |

| 5 | 46.5 ± 4.9 b | 2.7 ± 0.2 b | 2.6 ± 0.1 b |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shojaeiarani, J.; Bajwa, D.S.; Rehovsky, C.; Bajwa, S.G.; Vahidi, G. Deterioration in the Physico-Mechanical and Thermal Properties of Biopolymers Due to Reprocessing. Polymers 2019, 11, 58. https://doi.org/10.3390/polym11010058

Shojaeiarani J, Bajwa DS, Rehovsky C, Bajwa SG, Vahidi G. Deterioration in the Physico-Mechanical and Thermal Properties of Biopolymers Due to Reprocessing. Polymers. 2019; 11(1):58. https://doi.org/10.3390/polym11010058

Chicago/Turabian StyleShojaeiarani, Jamileh, Dilpreet S. Bajwa, Chad Rehovsky, Sreekala G. Bajwa, and Ghazal Vahidi. 2019. "Deterioration in the Physico-Mechanical and Thermal Properties of Biopolymers Due to Reprocessing" Polymers 11, no. 1: 58. https://doi.org/10.3390/polym11010058

APA StyleShojaeiarani, J., Bajwa, D. S., Rehovsky, C., Bajwa, S. G., & Vahidi, G. (2019). Deterioration in the Physico-Mechanical and Thermal Properties of Biopolymers Due to Reprocessing. Polymers, 11(1), 58. https://doi.org/10.3390/polym11010058