Poplar Hot Water Extract Enhances Barrier and Antioxidant Properties of Chitosan/Bentonite Composite Film for Packaging Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Hot Water Wood Extract (HWE)

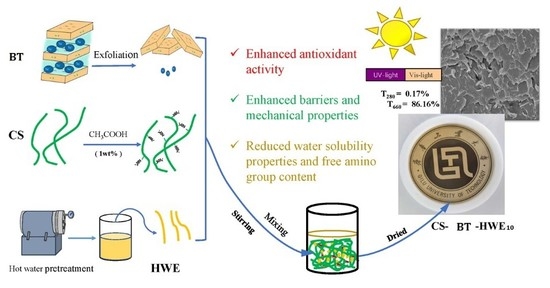

2.3. CS-BT-HWE Composite Film Preparation

2.4. Color Properties

2.5. Optical Property

2.6. Antioxidant Activity

2.7. Water Vapor Permeability (WVP) and Oxygen Permeability (OP)

2.8. Water Solubility (WS) and Free Amino Group

2.9. Mechanical Properties

2.10. Scanning Electron Microscopy (SEM) and Scanning Probe Microscope (SPM)

2.11. XRD

2.12. FT-IR

2.13. 13C-NMR

2.14. Statistical Analysis

3. Results

3.1. Physical Appearance and Color

3.2. UV Light Barrier Property

3.3. Antioxidant Activity

3.4. Water Vapor and Oxygen Permeability

3.5. Water Solubility Property and Free Amino Group

3.6. Mechanical Properties

3.7. Microstructure

3.8. XRD

3.9. FTIR

3.10. 13C-NMR

4. Conclusions

Supplementary Materials

) and mixing for 10 h (

) and mixing for 10 h (  ) (n = 3).

) (n = 3).Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ni, S.; Zhang, H.; Dai, H.; Xiao, H. Starch-based flexible coating for food packaging paper with exceptional hydrophobicity and antimicrobial activity. Polymers 2018, 10, 1260. [Google Scholar] [CrossRef] [PubMed]

- Nouri, A.; Yaraki, M.T.; Ghorbanpour, M.; Agarwal, S.; Gupta, V.K. Enhanced antibacterial effect of chitosan film using montmorillonite/CuO nanocomposite. Int. J. Biol. Macromol. 2018, 109, 1219–1231. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Yong, H.; Gao, L.; Li, L.; Jin, M.; Liu, J. Preparation and characterization of antioxidant and pH-sensitive films based on chitosan and black soybean seed coat extract. Food Hydrocoll. 2019, 89, 56–66. [Google Scholar] [CrossRef]

- Liang, J.; Wang, R.; Chen, R. The impact of cross-linking mode on the physical and antimicrobial properties of a chitosan/bacterial cellulose composite. Polymers 2019, 11, 491. [Google Scholar] [CrossRef] [PubMed]

- Nunes, C.; Coimbra, M.A.; Ferreira, P. Tailoring functional chitosan-based composites for food applications. Chem. Rec. 2018, 18, 1138–1149. [Google Scholar] [CrossRef]

- Giannakas, A.; Grigoriadi, K.; Leontiou, A.; Barkoula, N.M.; Ladavos, A. Preparation, characterization, mechanical and barrier properties investigation of chitosan-clay nanocomposites. Carbohydr. Polym. 2014, 108, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Guan, Y.; Qi, X.M.; Chen, G.G.; Peng, F.; Sun, R.C. Facile approach to prepare drug-loading film from hemicelluloses and chitosan. Carbohydr. Polym. 2016, 153, 542–548. [Google Scholar] [CrossRef]

- Peng, X.W.; Ren, J.L.; Zhong, L.X.; Sun, R.C. Nanocomposite films based on xylan-rich hemicelluloses and cellulose nanofibers with enhanced mechanical properties. Biomacromolecules 2011, 12, 3321–3329. [Google Scholar] [CrossRef]

- Xing, Y.; Xu, X.; Gui, X.; Cao, Y.; Xu, M. Effect of kaolinite and montmorillonite on fine coal flotation. Fuel 2017, 195, 284–289. [Google Scholar] [CrossRef]

- Cesur, S.; Köroğlu, C.; Yalçın, H.T. Antimicrobial and biodegradable food packaging applications of polycaprolactone/organo nanoclay/chitosan polymeric composite films. J. Vinyl. Addit. Techn. 2018, 24, 376–387. [Google Scholar] [CrossRef]

- Devi, N.; Dutta, J. Preparation and characterization of chitosan-bentonite nanocomposite films for wound healing application. Int. J. Biol. Macromol. 2017, 104, 1897–1904. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Zhao, Y.; Yi, H.; Chen, T.; Kang, S.; Li, H.; Song, S. Preparation and characterization of self-assembly hydrogels with exfoliated montmorillonite nanosheets and chitosan. Nanotechnology 2017, 29, 025605–025616. [Google Scholar] [CrossRef] [PubMed]

- Merino, D.; Mansilla, A.Y.; Casalongue, C.A.; Alvarez, V.A. Preparation, characterization, and in vitro testing of nanoclay antimicrobial activities and elicitor capacity. J. Agr. Food Chem. 2018, 66, 3101–3109. [Google Scholar] [CrossRef] [PubMed]

- Gallina, G.; Cabeza, Á.; Grénman, H.; Biasi, P.; García-Serna, J.; Salmi, T. Hemicellulose extraction by hot pressurized water pretreatment at 160 °C for 10 different woods: Yield and molecular weight. J. Supercrit. Fluids 2018, 133, 716–725. [Google Scholar] [CrossRef]

- Li, X.; Shi, X.; Wang, M.; Du, Y. Xylan chitosan conjugate—A potential food preservative. Food Chem. 2011, 126, 520–525. [Google Scholar] [CrossRef]

- Li, X.; Shi, X.; Jin, Y.; Ding, F.; Du, Y. Controllable antioxidative xylan–chitosan Maillard reaction products used for lipid food storage. Carbohydr. Polym. 2013, 91, 428–433. [Google Scholar] [CrossRef]

- Edlund, U.; Ryberg, Y.Z.; Albertsson, A.C. Barrier Films from Renewable Forestry Waste. Biomacromolecules 2010, 11, 2532–2538. [Google Scholar] [CrossRef]

- Wan, C.; Li, Y. Effect of hot water extraction and liquid hot water pretreatment on the fungal degradation of biomass feedstocks. Bioresour. Technol. 2011, 102, 9788–9793. [Google Scholar] [CrossRef]

- Fatehi, P.; Ni, Y.H.; Zhu, J.Y.; Zhang, X.; Pan, X.J. Integrated forest biorefinery–prehydrolysis/dissolving pulping process. ACS 2011, 1067, 475–506. [Google Scholar]

- Garrote, G.; Kabel, M.A.; Schols, H.A.; Falqué, E.; Domínguez, H.; Parajó, J.C. Effects of eucalyptus globulus wood autohydrolysis conditions on the reaction products. J. Agr. Food Chem. 2007, 55, 9006–9013. [Google Scholar] [CrossRef]

- Larsson, S.; Palmqvist, E.; Hahn-Hägerdal, B.; Tengborg, C.; Stenberg, K.; Zacchi, G.; Nilvebrant, N.O. The generation of fermentation inhibitors during dilute acid hydrolysis of softwood. Enzyme Microb. Tech. 1999, 24, 151–159. [Google Scholar] [CrossRef]

- Walton, S.; Heiningen, A.V.; Walsum, P.V. Inhibition effects on fermentation of hardwood extracted hemicelluloses by acetic acid and sodium. Bioresour. Technol. 2010, 101, 1935–1940. [Google Scholar] [CrossRef] [PubMed]

- Khazraie, T.; Zhang, Y.; Tarasov, D.; Gao, W.; Price, J.; DeMartini, N.; Hupa, L.; Fatehi, P. A process for producing lignin and volatile compounds from hydrolysis liquor. Biotechnol. Biofuels 2017, 10, 47–61. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.G.; Hu, Y.J.; Peng, F.; Bian, J.; Li, M.F.; Yao, C.L.; Sun, R.C. Fabrication of strong nanocomposite films with renewable forestry waste/montmorillonite/reduction of graphene oxide for fire retardant. Chem. Eng. J. 2018, 337, 436–445. [Google Scholar] [CrossRef]

- Heitz, M.; Capek-Ménard, E.; Koeberle, P.G.; Gagné, J.; Chornet, E.; Overend, R.P.; Taylor, J.D.; Yu, E. Fractionation of Populus tremuloides at the pilot plant scale: Optimization of steam pretreatment conditions using the STAKE II technology. Bioresour. Technol. 1991, 35, 23–32. [Google Scholar] [CrossRef]

- Blois, M.S. Antioxidant determinations by the use of a stable free radical. Nature 1958, 181, 1199–1200. [Google Scholar] [CrossRef]

- Gennadiosa, A. Measurement errors in water vapor permeability of highly permeable, hydrophilic edible films. J. Food Eng. 1994, 21, 395–409. [Google Scholar] [CrossRef]

- Souza, V.G.L.; Pires, J.R.A.; Rodrigues, P.F.; Lopes, A.A.S.; Fernandes, F.M.B.; Duarte, M.P.; Coelhoso, I.M.; Fernando, A.L. Bionanocomposites of chitosan/montmorillonite incorporated with rosmarinus officinalis essential oil: Development and physical characterization. Food Packag. Shelf 2018, 16, 148–156. [Google Scholar] [CrossRef]

- Umemura, K.; Kawai, S. Preparation and characterization of Maillard reacted chitosan films with hemicellulose model compounds. J. Appl. Polym.Sci. 2008, 108, 2481–2487. [Google Scholar] [CrossRef]

- Martins, S.I.F.S.; Jongen, W.M.F.; Boekel, M.A.J.S.V. A review of Maillard reaction in food and implications to kinetic modelling. Trends food sci. tech. 2001, 11, 364–373. [Google Scholar] [CrossRef]

- Kanmani, P.; Rhim, J.W. Development and characterization of carrageenan/grapefruit seed extract composite films for active packaging. Int. J. Biol. Macromol. 2014, 68, 258–266. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Gao, Y.; Zuo, C.; Deng, Y.; Dai, H. Thermally-induced cellulose nanofibril films with near-complete ultraviolet-blocking and improved water resistance. Carbohydr. Polym. 2019, 223, 115050–115057. [Google Scholar] [CrossRef] [PubMed]

- Yang, W.; Wang, X.; Gogoi, P.; Bian, H.; Dai, H. Highly transparent and thermally stable cellulose nanofibril films functionalized with colored metal ions for ultraviolet blocking activities. Carbohydr. Polym. 2019, 213, 10–16. [Google Scholar] [CrossRef] [PubMed]

- Morales, F.J.; Romero, C.; Salvi, J.P. Chromatographic determination of bound hydroxymethylfurfural as an index of milk protein glycosylation. J. Agr. Food Chem. 1997, 45, 1570–1573. [Google Scholar] [CrossRef]

- Zhu, K.X.; Li, J.; Li, M.; Guo, X.N.; Peng, W.; Zhou, H.M. Functional properties of chitosan-xylose Maillard reaction products and their application to semi-dried noodle. Carbohydr. Polym. 2013, 92, 1972–1977. [Google Scholar] [CrossRef] [PubMed]

- Rubilar, J.F.; Rui, M.S.C.; Silva, H.D.; Vicente, A.A.; Khmelinskii, I.; Vieira, M.C. Physico-mechanical properties of chitosan films with carvacrol and grape seed extract. J. Food Eng. 2013, 115, 466–474. [Google Scholar] [CrossRef] [Green Version]

- Jutaporn, C.; Suphitchaya, C.; Thawien, W. Antimicrobial activity and characteristics of edible films incorporated with phayom wood (shorea tolura) extract. Inter. Food Resear. J. 2011, 18, 39–53. [Google Scholar]

- Enayat, S.; Banerjee, S. Comparative antioxidant activity of extracts from leaves, bark and catkins of salix aegyptiaca sp. Food Chem. 2009, 116, 23–28. [Google Scholar] [CrossRef]

- Um, M.; Shin, G.J.; Lee, J.W. Extraction of total phenolic compounds from yellow poplar hydrolysate and evaluation of their antioxidant activities. Ind. Crop. Prod. 2017, 97, 574–581. [Google Scholar] [CrossRef]

- Yen, M.T.; Yang, J.H.; Mau, J.L. Antioxidant properties of chitosan from crab shells. Carbohydr. Polym. 2008, 74, 840–844. [Google Scholar] [CrossRef]

- Kanatt, S.R.; Rao, M.; Chawla, S.; Sharma, A. Active chitosan–polyvinyl alcohol films with natural extracts. Food Hydrocoll. 2012, 29, 290–297. [Google Scholar] [CrossRef]

- Siripatrawan, U.; Harte, B.R. Physical properties and antioxidant activity of an active film from chitosan incorporated with green tea extract. Food Hydrocoll. 2010, 24, 770–775. [Google Scholar] [CrossRef]

- Nunes, C.; Maricato, E.; Cunha, A.; Nunes, A.; da Silva, J.A.; Coimbra, M.A. Chitosan-caffeic acid-genipin films presenting enhanced antioxidant activity and stability in acidic media. Carbohydr. Polym. 2013, 91, 236–243. [Google Scholar] [CrossRef] [PubMed]

- Alboofetileh, M.; Rezaei, M.; Hosseini, H.; Abdollahi, M. Effect of montmorillonite clay and biopolymer concentration on the physical and mechanical properties of alginate nanocomposite films. J. Food Eng. 2013, 117, 26–33. [Google Scholar] [CrossRef]

- Liu, L.; Tang, X.; Wang, Y.; Guo, S. Smart gelation of chitosan solution in the presence of NaHCO3 for injectable drug delivery system. Int. J. Pharm. 2011, 414, 6–15. [Google Scholar] [CrossRef] [PubMed]

- Van Boekel, M.A. Formation of flavour compounds in the Maillard reaction. Biotechnol. Adv. 2006, 24, 230–233. [Google Scholar] [CrossRef]

- Bian, H.; Gao, Y.; Wang, R.; Liu, Z.; Wu, W.; Dai, H. Contribution of lignin to the surface structure and physical performance of cellulose nanofibrils film. Cellulose 2018, 25, 1309–1318. [Google Scholar] [CrossRef]

- Silva, S.M.; Braga, C.R.; Fook, M.V.; Raposo, C.M.; Carvalho, L.H.; Canedo, E.L. Application of Infrared Spectroscopy to Analysis of Chitosan Clay Nanocomposites. Infrared Spectroscopy 2012, 43–62. [Google Scholar]

- Lewandowska, K.; Sionkowska, A.; Kaczmarek, B.; Furtos, G. Characterization of chitosan composites with various clays. Int. J. Biol. Macromol. 2014, 65, 534–541. [Google Scholar] [CrossRef] [PubMed]

- Rhim, J.W.; Hong, S.I.; Park, H.M.; Ng, P.K. Preparation and characterization of chitosan-based nanocomposite films with antimicrobial activity. J. Agr. Food Chem. 2006, 54, 5814–5822. [Google Scholar] [CrossRef]

- Sharma, S.; Sanpui, P.; Chattopadhyay, A.; Ghosh, S.S. Fabrication of antibacterial silver nanoparticle—sodium alginate–chitosan composite films. RSC Adv. 2012, 2, 5837–5843. [Google Scholar] [CrossRef]

- Wang, S.F.S.L.; Zhang, W.D.; Tong, Y.J. Preparation and mechanical properties of chitosan/carbon nanotubes composites. Biomacromolecules 2005, 6, 3067–3072. [Google Scholar] [CrossRef] [PubMed]

- Qiao, C.; Ma, X.; Zhang, J.; Yao, J. Molecular interactions in gelatin/chitosan composite films. Food Chem. 2017, 235, 45–50. [Google Scholar] [CrossRef] [PubMed]

- Samuels, R.J. Solid state characterization of the structure of chitosan films. J. Polym.Sci. Pol. Chem. 2010, 19, 1083–1105. [Google Scholar] [CrossRef]

- Brugnerotto, J.; Lizardi, J.; Goycoolea, F.M.; Argüelles-Monal, W.; Desbrieres, J.; Rinaudo, M. An infrared investigation in relation with chitin and chitosan characterization. Polymers 2001, 42, 3569–3580. [Google Scholar] [CrossRef]

- Chen, X.; Gao, H.; Ploehn, H.J. Montmorillonite–levan nanocomposites with improved thermal and mechanical properties. Carbohydr. Polym. 2014, 101, 565–573. [Google Scholar] [CrossRef]

- Osman, Z.; Arof, A.K. FTIR studies of chitosan acetate based polymer electrolytes. Electrochim. Acta 2003, 48, 993–999. [Google Scholar] [CrossRef]

- Hu, Y.; Niu, Y.; Fu, G.; Yue, P.; Li, M.; Peng, F.; Sun, R. Turning wood autohydrolysate directly into food packing composite films with good toughness. Int. J. Polym. Sci. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Crouvisier-Urion, K.; Bodart, P.R.; Winckler, P.; Raya, J.; Gougeon, R.D.; Cayot, P.; Domenek, S.; Debeaufort, F.; Karbowiak, T. Biobased composite films from chitosan and lignin: antioxidant activity related to structure and moisture. ACS Sustain. Chem. Eng. 2016, 4, 6371–6381. [Google Scholar] [CrossRef]

- Epure, V.; Griffon, M.; Pollet, E.; Avérous, L. Structure and properties of glycerol-plasticized chitosan obtained by mechanical kneading. Carbohydr. Polym. 2011, 83, 947–952. [Google Scholar] [CrossRef]

| HWE/CS (w/w) | L* | a* | b* | ΔE | T280 | T660 |

|---|---|---|---|---|---|---|

| 0% | 84.03 ± 0.31 a | 0.92 ± 0.08 a | –2.14 ± 0.37 a | 7.58 ± 0.31 a | 26.37 ± 1.52 a | 90.70 ± 0.16 a |

| 10% | 66.12 ± 1.82 b | 3.69 ± 1.63 b | 51.93 ± 2.96 b | 54.57 ± 3.56 b | 0.17 ± 0.01 b | 86.16 ± 0.31 b |

| 20% | 57.90 ± 1.66 c | 17.69 ± 1.86 c | 69.22 ± 0.49 c | 75.77 ± 0.99 c | 0.09 ± 0.00 bc | 78.89 ± 0.35 c |

| 30% | 52.22 ± 3.41 d | 25.59 ± 2.56 d | 64.77 ± 1.18 d | 76.96 ± 1.30 c,d | 0.09 ± 0.00 b,c,d | 70.52 ± 0.38 d |

| 40% | 46.42 ± 1.68 e | 27.75 ± 1.64 e | 63.12 ± 2.06 d,e | 79.35 ± 0.97 e | 0.09 ± 0.00 b,c,d,e | 68.52 ± 0.66 e |

| Sample Code | WVP × 10−13 (g·cm·cm−2·s−1·Pa−1) | OP × 10−7 (cm3·cm·cm−2· s−1·Pa−1) | WS (%) | Relative Amount of Free Amino Groups (%) | TS (MPa) | EB (%) | Thickness (μm) |

|---|---|---|---|---|---|---|---|

| CS | 8.71 ± 0.20 a | 0.95 ± 0.05 a | 17.84 ± 0.76 a | -- | 39.32 ± 2.22 a | 11.74 ± 1.70 a | 45.14 ± 1.35 a |

| CS-BT | 6.72 ± 0.40 b | 0.46 ± 0.02 b | 15.24 ± 0.33 b | 93.26 ± 0.32 b | 52.96 ± 4.73 b | 7.95 ± 1.23 b | 46.43 ± 1.72 a,b |

| CS-HWE10 | 7.91 ± 0.37 c | 0.92 ± 0.02 c | 11.44 ± 0.38 c | 32.28 ± 0.61 c | 49.07 ± 3.46 b,c | 5.14 ± 1.09 c | 48.86 ± 1.07 c |

| CS-BT-HWE10 | 7.13 ± 0.08 b,d | 0.68 ± 0.01 d | 10.03 ± 0.15 c,d | 26.05 ± 1.38 d | 59.07 ± 5.22 d | 5.51 ± 1.04 b,d | 51.71 ± 1.11 d |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Liu, N.; Ni, S.; Bian, H.; Fu, Y.; Chen, X. Poplar Hot Water Extract Enhances Barrier and Antioxidant Properties of Chitosan/Bentonite Composite Film for Packaging Applications. Polymers 2019, 11, 1614. https://doi.org/10.3390/polym11101614

Sun M, Liu N, Ni S, Bian H, Fu Y, Chen X. Poplar Hot Water Extract Enhances Barrier and Antioxidant Properties of Chitosan/Bentonite Composite Film for Packaging Applications. Polymers. 2019; 11(10):1614. https://doi.org/10.3390/polym11101614

Chicago/Turabian StyleSun, Mengya, Na Liu, Shuzhen Ni, Huiyang Bian, Yingjuan Fu, and Xiaoqian Chen. 2019. "Poplar Hot Water Extract Enhances Barrier and Antioxidant Properties of Chitosan/Bentonite Composite Film for Packaging Applications" Polymers 11, no. 10: 1614. https://doi.org/10.3390/polym11101614

APA StyleSun, M., Liu, N., Ni, S., Bian, H., Fu, Y., & Chen, X. (2019). Poplar Hot Water Extract Enhances Barrier and Antioxidant Properties of Chitosan/Bentonite Composite Film for Packaging Applications. Polymers, 11(10), 1614. https://doi.org/10.3390/polym11101614