Exploration of Chitinous Scaffold-Based Interfaces for Glucose Sensing Assemblies

Abstract

:1. Introduction

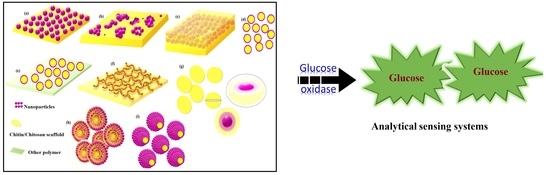

2. Composites of Chitin and Chitosan

3. Nanocomposites of Chitin and Chitosan

4. Method of Preparation of Chitinous Nano-Structures

5. Chitinous Scaffold for Immobilization

5.1. Chitin as an Enzyme Matrix

5.2. Chitosan as an Enzyme Scaffold

5.3. Chitosan Cryogel

5.4. GOx-Chitosan Electrochemistry

6. Innovative Strategies for Sensor Interface

6.1. Electrode Material/Refilling Matrix

6.2. Bare Electrode Modification

6.2.1. Electrode Surface Coating

Sol-Gel Casting

Electrochemical Deposition

6.2.2. Various Geometrical CS-Based Interfaces

Self-Assembled Monolayers

Layer by Layer

Sandwich Configuration

6.2.3. Microelectrode Arrays/Printing

6.3. Nano-Chitinous Material for Glucose Sensors

6.3.1. Nanochitin

6.3.2. Nanochitosan

7. Future Prospectus

Funding

Conflicts of Interest

References

- Bagal-Kestwal, D.R.; Kestwal, R.M.; Hsieh, W.T.; Chiang, B.H. Chitosan–guar gum–silver nanoparticles hybrid matrix with immobilized enzymes for fabrication of beta-glucan and glucose sensing photometric flow injection system. J. Pharm. Biomed. Anal. 2014, 88, 571–578. [Google Scholar] [CrossRef] [PubMed]

- Bagal-Kestwal, D.R.; Kestwal, R.M.; Chiang, B.H.; Morlanes, V. Chapter 8: Bio based nanomaterials and their bio-nanocomposites. In Nanomaterials and Nanocomposites, Zero-to Three-Dimensional Materials and Their Composites; Morlanes, V., Ed.; Wiley-VCH Verlag GmbH and Co.: Weinheim, Germany, 2016; pp. 255–329. ISBN 978-3-527-33780-4. [Google Scholar]

- Jayakumar, R.; Menon, D.; Manzoor, K.; Nair, S.V.; Tamura, H. Biomedical applications of chitin and chitosan based nanomaterials-A short review. Carbohydr. Polym. 2010, 82, 227–232. [Google Scholar] [CrossRef]

- Dash, M.; Chiellini, F.; Ottenbrite, R.M.; Chiellini, E. Chitosan-A versatile semi-synthetic polymer in biomedical applications. Prog. Polym. Sci. 2011, 36, 981–1094. [Google Scholar] [CrossRef]

- Pereda, M.; Dufresne, A.; Aranguren, M.I.; Marcovich, N.E. Polyelectrolyte films based on chitosan/olive oil and reinforced with cellulose nanocrystals. Carbohydr. Polym. 2014, 101, 1018–1026. [Google Scholar]

- Hudson, S.M.; Smith, C. Polysaccharides: Chitin and chitosan: Chemistry and technology of their use as structural materials. In Biopolymers from Renewable Resources; Kaplan, D.L., Ed.; Springer: Berlin, Germany, 1998; pp. 96–118. [Google Scholar]

- Krajewska, B. Chitin and its derivatives as supports for immobilization of enzymes. Acta Biotechnol. 1991, 11, 269–277. [Google Scholar] [CrossRef]

- Krajewska, B. Application of chitin- and chitosan-based materials for enzyme immobilizations: A review. Enzyme Microb. Technol. 2004, 35, 126–139. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, W.R.; Zhang, Y.; Li, W.; Hu, J.; Zheng, F.; Wu, Y. Liquefied chitin/polyvinyl alcohol based blend membranes: Preparation and characterization and antibacterial activity. Carbohydr. Polym. 2018, 180, 175–181. [Google Scholar] [CrossRef]

- Divya, K.; Jisha, M.S. Chitosan nanoparticles preparation and applications. Environ. Chem. Lett. 2018, 16, 101–112. [Google Scholar] [CrossRef]

- Benhabiles, M.S.; Abdi, N.; Drouiche, N.; Lounici, H.; Pauss, A.; Goosen, M.F.A.; Mameri, M. Protein recovery by ultrafiltration during isolation of chitin from shrimp shells Parapenaeus longirostris. Food Hydrocoll. 2013, 32, 28–34. [Google Scholar] [CrossRef]

- Benhabiles, M.S.; Abdi, N.; Drouiche, N.; Lounici, H.; Pauss, A.; Goosen, M.F.A.; Mameri, M. Effect of shrimp chitosan coatings as affected by chitosan extraction processes on postharvest quality of strawberry. J. Food Meas. Charact. 2013, 7, 215–221. [Google Scholar] [CrossRef]

- Bahasan, S.H.O.; Satheesh, S.; Abdulaziz Ba-akdah, M. Extraction of chitin from the shell wastes of two shrimp species fenneropenaeus semisulcatus and fenneropenaeus indicus using microorganisms. J. Aquat. Food Prod. Technol. 2017, 26, 390–405. [Google Scholar] [CrossRef]

- Aranaz, I.; Acosta, N.; Civera, C.; Elorza, B.; Mingo, J.; Castro, C.; Gandía, M.D.L.; Heras Caballero, A. Cosmetics and Cosmeceutical Applications of Chitin, Chitosan and Their Derivatives. Polymers 2018, 10, 213. [Google Scholar] [CrossRef] [PubMed]

- Wawrzkiewicz, M.; Bartczak, P.; Jesionowski, T. Enhanced removal of hazardous dye form aqueous solutions and real textile wastewater using bifunctional chitin/lignin biosorbent. Int. J. Biol. Macromol. 2017, 99, 754–764. [Google Scholar] [CrossRef] [PubMed]

- Panariello, L.; Coltelli, M.B.; Buchignani, M.; Lazzeri, A. Chitosan and nano-structured chitin for biobased anti-microbial treatments onto cellulose based materials. Eur. Polym. J. 2019, 113, 328–339. [Google Scholar] [CrossRef]

- Kasiri, M.B. Chapter14-Application of chitosan derivatives as promising adsorbents for treatment of textile wastewater. In The Impact and Prospects of Green Chemistry for Textile Technology, 1st ed.; Butola, B.S., Ed.; The Textile Institute Book Series, Shahid-ul-Islam; Woodhead Publishing: Cambridge, UK, 2019; pp. 417–469. ISBN 978-0-08-102491-1. [Google Scholar]

- Díaz-Hernández, A.; Gracida, J.; García-Almendárez, B.E.; Regalado, C.; Núñez, R.; Amaro-Reyes, A. Characterization of magnetic nanoparticles coated with chitosan: A potential approach for enzyme immobilization. J. Nanomater. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Khan, F.I.; Rahman, S.; Queen, A.; Ahamad, S.; Ali, S.; Kim, J.; Hassan, M.I. Implications of molecular diversity of chitin and its derivatives. Appl. Microbiol. Biotechnol. 2017, 101, 3513–3536. [Google Scholar] [CrossRef]

- Picheth, G.F.; Pirich, C.L.; Sierakowski, M.R.; Woehl, M.A.; Sakakibara, C.N.; de Souza, C.F.; Martin, A.A.; Da, S.R.; de Freitas, R.A. Bacterial cellulose in biomedical applications: A review. Int. J. Biol. Macromol. 2017, 104, 97–106. [Google Scholar] [CrossRef]

- Verlee, A.; Mincke, S.; Stevens, C.V. Recent developments in antibacterial and antifungal chitosan and its derivatives. Carbohydr. Polym. 2017, 164, 268–283. [Google Scholar] [CrossRef]

- Volova, T.G.; Shumilova, A.A.; Shidlovskiy, I.P.; Nikolaeva, E.D.; Sukovatiy, A.G.; Vasiliev, A.D.; Shishatskaya, E.I. Antibacterial properties of films of cellulose composites with silver nanoparticles and antibiotics. Polym. Test. 2018, 65, 54–68. [Google Scholar] [CrossRef]

- Bagal-Kestwal, D.R.; Pan, M.H.; Chiang, B.H. Electrically nanowired-enzymes for probe modification and sensor fabrication. Biosens. Bioelectron. 2018, 121, 223–235. [Google Scholar] [CrossRef]

- Badhe, R.V.; Bijukumar, D.; Chejara, D.R.; Mabrouk, M.; Choonara, Y.E.; Kumar, P.; du Toit, L.C.; Kondiah, P.P.D.; Pillay, V. A composite chitosan-gelatin bi-layered, biomimetic macroporous scaffold for blood vessel tissue engineering. Carbohydr. Polym. 2017, 157, 1215–1225. [Google Scholar] [CrossRef] [PubMed]

- Malhotra, S.K.; Goda, K.; Sreekala, M.S. Polymer Composites, 1st ed.; Thomas, S., Joseph, K., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2012; Volume 3, pp. 1–270. [Google Scholar]

- Bagal-Kestwal, D.R.; Pan, M.H.; Chiang, B.H. Chapter 3: Processing methods for the bio nanocomposites. In Bio Monomers for Green Polymeric Composites Materials; Morlanes, V., Bayraktar, O., Menon, G., Eds.; Wiley-VCH Verlag GmbH and Co: Weinheim, Germany, 2019; ISBN 978-1-119-30164-6. [Google Scholar]

- Bagal-Kestwal, D.R.; Pan, M.H.; Chiang, B.H. Chapter 7: Properties and applications of gelatins, pectins, carrageenans gels. In Bio Monomers for Green Polymeric Composites Materials; Morlanes, V., Bayraktar, O., Menon, G., Eds.; Wiley-VCH Verlag GmbH and Co: Weinheim, Germany, 2019; ISBN 978-1-119-30164-6. [Google Scholar]

- Yavuz, A.G.; Uygun, A.; Bhethanabotla, V.R. Preparation of substituted polyaniline/chitosan composites by in situ electropolymerization and their application to glucose sensing. Carbohydr. Polym. 2010, 81, 712–719. [Google Scholar] [CrossRef]

- Koev, S.T.; Dykstra, P.H.; Luo, X.; Rubloff, G.W.; Bentley, W.E.; Payne, G.F.; Ghodssi, R. Chitosan: An integrative biomaterial for lab-on-a-chip devices. Lab Chip 2010, 10, 3026–3042. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, M.; Machado, A.V. Preparation of polymer-based nanocomposites by different routes. In Nanocomposites: Synthesis, Characterization and Applications; Wang, X., Ed.; NEW Publishers: Zurich, Switzerland, 2013; pp. 1–22. ISBN 978-1-62948-227-9. [Google Scholar]

- Ahmad, R.; Wolfbeis, O.S.; Hahn, Y.-B.; Alshareef, H.N.; Torsi, L.; Salama, K.N. Deposition of nanomaterials: A crucial step in biosensor fabrication. Mater. Today Commun. 2018, 17, 289–321. [Google Scholar] [CrossRef]

- Hangarter, C.M.; Chartuprayoon, N.; Hernández, S.C.; Choa, Y.; Myung, N.V. Hybridized conducting polymer chemiresistive nano-sensors. Nano Today 2013, 8, 39–55. [Google Scholar] [CrossRef]

- Shukla, S.K.; Mishra, A.K.; Arotiba, O.A.; Mamba, B.B. Chitosan-based nanomaterials: A state-of-the-art review. Int. J. Biol. Macromol. 2013, 59, 46–58. [Google Scholar] [CrossRef]

- Zargar, V.; Asghari, M.; Dashti, A. A Review on Chitin and chitosan polymers: Structure, chemistry, solubility, derivatives, and applications. ChemBioEng Rev. 2015, 2, 204–226. [Google Scholar] [CrossRef]

- Vlăsceanu, G.M.; Amărandi, R.M.; Ioniță, M.; Tite, T.; Iovu, H.; Pilan, L.; Burns, J.S. Versatile graphene biosensors for enhancing human cell therapy. Biosens. Bioelectron. 2018, 117, 283–302. [Google Scholar] [CrossRef]

- Kickelbick, G. Hybrid Materials: Synthesis, Characterization, and Applications; Kickelbick, G., Ed.; Wiley-VCH: Weinheim, Germany, 2007; pp. 1–516. ISBN 978-3-527-61048-8. [Google Scholar]

- Ariga, K.; Nalwa, H.S. Functional Supramolecular Nanostructures. In Bottom-Up Nanofabrication: Supramolecules-I (Supramolecules, Self-Assemblies, and Organized Films); Ariga, K., Nalwa, H.S., Eds.; American Scientific Publishers: Los Angeles, CA, USA, 2009; ISBN 1-58883-079-9. [Google Scholar]

- Ruiz-Hitzky, E.; Aranda, P.; Darder, M.; Ogawa, M. Hybrid and biohybrid silicate based materials: Molecular vs block-assembling bottom-up processes. Chem. Soc. Rev. 2011, 40, 801–828. [Google Scholar] [CrossRef]

- Rahaman, M.; Aldalbahi, A.; Bhagabati, P. Preparation/Processing of Polymer–Carbon Composites by Different Techniques. In Carbon-Containing Polymer Composites; Rahaman, M., Khastgir, D., Aldalbahi, A., Eds.; Springer Series on Polymer and Composite Materials; Springer: Singapore, 2019. [Google Scholar]

- Mushi, N.E.; Butchosa, N.; Salajkova, M.; Zhou, Q.; Berglund, L.A. Nanostructured membranes based on native chitin nanofibers prepared by mild process. Carbohydr. Polym. 2014, 112, 255–263. [Google Scholar] [CrossRef]

- Mincea, M.; Negrulescu, A.; Ostafe, V. Preparation, modification, and applications of chitin nanowhiskers: A review. Rev. Adv. Mater. Sci. 2012, 30, 225–242. [Google Scholar]

- Kadokawa, J.; Takegawa, A.; Mine, S.; Prasad, K. Preparation of chitin nanowhiskers using an ionic liquid and their composite materials with poly (vinyl alcohol). Carbohydr. Polym. 2011, 84, 1408–1412. [Google Scholar] [CrossRef]

- Zhou, C.; Wu, Q. Chapter 6, Nanocrystals–Synthesis, characterization and applications. In Recent Development in Applications of Cellulose Nanocrystals for Advanced Polymer-Based Nanocomposites by Novel Fabrication Strategies; Neralla, S., Ed.; InTech: Gdańsk, Poland, 2012; pp. 103–120. [Google Scholar]

- Wu, B.Y.; Hou, S.H.; Yin, F.; Li, J.; Zhao, Z.X.; Huang, J.D.; Chen, Q. Amperometric glucose biosensor based on layer-by-layer assembly of multilayer films composed of chitosan, gold nanoparticles and glucose oxidase modified Pt electrode. Biosens. Bioelectron. 2007, 22, 838–844. [Google Scholar] [CrossRef] [PubMed]

- Ifuku, S.; Nogi, M.; Abe, K.; Yoshioka, M.; Morimoto, M.; Saimoto, H.; Yano, H. Synthesis of silver nanoparticles templated by TEMPO-mediated oxidized bacterial cellulose nanofibers. Biomacromolecules 2009, 10, 2714–2717. [Google Scholar] [CrossRef] [PubMed]

- Ifuku, S.; Nogi, M.; Yoshioka, M.; Morimoto, M.; Yano, H.; Saimoto, H. Fibrillation of dried chitin into 10–20 nm nanofibers by a simple grinding method under acidic conditions. Carbohydr. Polym. 2010, 81, 134–139. [Google Scholar] [CrossRef]

- Ifuku, S.; Nogi, M.; Abe, K.; Yoshoka, M.; Morimoto, M.; Saimoto, H.; Yano, H. Simple preparation method of chitin nanofibers with a uniform width of 10–20 nm from prawn shell under neutral conditions. Carbohydr. Polym. 2011, 84, 762–764. [Google Scholar] [CrossRef]

- Ifuku, S.; Shervani, Z.; Saimoto, H. Chitin Nanofibers, Preparations and Applications. In Advances in Nanofibers; Maguire, R., Ed.; IntechOpen: London, UK, 2013; pp. 85–101. [Google Scholar] [CrossRef] [Green Version]

- Tzoumaki, M.V.; Moschakis, T.; Biliaderis, C.G. Mixed aqueous chitin nanocrystal-whey protein dispersions: Microstructure and rheological behavior. Food Hydrocoll. 2011, 25, 935–942. [Google Scholar] [CrossRef]

- Vignati, E.; Piazza, R. Pickering emulsions: Interfacial tension, colloidal layer morphology, and trapped-particle motion. Langmuir 2003, 19, 6650–6656. [Google Scholar] [CrossRef]

- Fan, Y.; Saito, T.; Isogai, A. Chitin nanocrystals prepared by TEMPO-mediated oxidation of α-chitin. Biomacromolecules 2008, 9, 192–198. [Google Scholar] [CrossRef]

- Fan, Y.; Saito, T.; Isogai, A. Preparation of chitin nanofibers from squid pen β-chitin by simple mechanical treatment under acid conditions. Biomacromolecules 2008, 9, 1919–1923. [Google Scholar] [CrossRef]

- Fan, Y.; Saito, T.; Isogai, A. Individual chitin nano-whiskers prepared from partially deacetylated α-chitin by fibril surface cationization. Carbohydr. Polym. 2010, 79, 1046–1051. [Google Scholar] [CrossRef]

- Huang, K.S.; Sheu, Y.R.; Chao, I.C. Preparation and properties of nanochitosan. Polym. Plast. Technol. Eng. 2009, 48, 1239–1243. [Google Scholar] [CrossRef]

- Kocak, N.; Sahin, M.; Akin, I.; Kus, M.; Yilmaz, M. Microwave Assisted Synthesis of Chitosan Nanoparticles. J. Macromol. Sci. Part A Pure Appl. Chem. 2011, 48, 776–779. [Google Scholar] [CrossRef]

- Zhao, L.M.; Shi, L.E.; Zhang, Z.L.; Chen, J.M.; Shi, D.D.; Yang, J.; Tang, Z.X. Preparation and application of chitosan nanoparticles and nanofibers. Braz. J. Chem. Eng. 2011, 28, 353–362. [Google Scholar] [CrossRef]

- Cheung, R.C.F.; Ng, T.B.; Wong, J.H.; Chan, W.Y. Chitosan: An update on potential biomedical and pharmaceutical applications. Mar. Drugs 2015, 13, 5156–5186. [Google Scholar] [CrossRef] [PubMed]

- Taniai, T.; Sakuragawa, A.; Okutani, T. Fluorometric determination of glucose by flow injection analysis using immobilized enzyme-reactor columns prepared by coupling glucose oxidase and peroxidase onto chitosan beads. Anal. Sci. 2000, 16, 517–521. [Google Scholar] [CrossRef] [Green Version]

- Sugawara, K.; Takano, T.; Fukushi, H.; Hoshi, S.; Akatsuka, K.; Kuramitz, H.; Tanaka, S. Glucose sensing by a carbon-paste electrode containing chitin modified with glucose oxidase. J. Electroanal. Chem. 2000, 482, 81–86. [Google Scholar] [CrossRef]

- Sugawara, K.; Fukushi, H.; Hoshi, S.; Akatsuka, K.; Kuramitz, H. Electrochemical sensing of glucose at a platinum electrode with a chitin/glucose oxidase film. Anal. Sci. 2000, 16, 1139–1143. [Google Scholar] [CrossRef] [Green Version]

- Patel, H.; Rawtani, D.; Agrawal, Y.K. Anewly emerging trend of chitosan-based sensing platform for the organophosphate pesticide detection using acetylcholinesterase- a review. Trends Food Sci. Technol. 2019, 85, 78–91. [Google Scholar] [CrossRef]

- Bayramoğlu, G. Methacrylated chitosan based UV curable support for enzyme immobilization. Mater. Res. 2017, 20, 452–459. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.N.V.R. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Jafarizadeh-Malmiri, H.; Ghaz Jahanian, M.A.; Berenjian, A. Potential applications of chitosan nanoparticles as novel support in enzyme immobilization. Am. J. Biochem. Biotechnol. 2012, 8, 203–219. [Google Scholar]

- Biro, E.; Nemeth, A.S.; Sisak, C.; Feczko, T.; Gyenis, J. Preparation of chitosan particles suitable for enzyme immobilization. J. Biochem. Biophys. Methods 2008, 70, 1240–1246. [Google Scholar] [CrossRef] [PubMed]

- Yang, K.; Xu, N.S.; Su, W.W. Co-immobilized enzymes in magnetic chitosan beads for improved hydrolysis of macromolecular substrates under a time-varying magnetic field. J. Biotechnol. 2010, 148, 119–127. [Google Scholar] [CrossRef]

- Liu, C.G.; Desai, K.G.H.; Chen, X.G.; Park, H.J. Preparation and characterization of nanoparticles containing trypsin based on hydrophobically modified chitosan. J. Agric. Food Chem. 2005, 53, 1728–1733. [Google Scholar] [CrossRef]

- Ghadi, A.; Tabandeh, F.; Mahjoub, S.; Mohsenifar, A.; Roshan, F.T.; Alavije, R.S. Fabrication and characterization of core-shell magnetic chitosan nanoparticles as a novel carrier for immobilization of Burkholderia cepacia lipase. J. Oleo Sci. 2015, 64, 423–430. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Zhu, K.X.; Zhou, H.M. Immobilization of glucose oxidase in alginate-chitosan microcapsules. Int. J. Mol. Sci. 2011, 12, 3042–3054. [Google Scholar] [CrossRef]

- Rassas, I.; Bonhomme, A.; Bessueille, F.; Raffin, G.; Majdoub, H.; Jaffrezic-Renault, N. Voltammetric glucose biosensor based on glucose oxidase encapsulation in a chitosan-kappa-carrageenan polyelectrolyte complex. Mater. Sci. 2019, 95, 152–159. [Google Scholar] [CrossRef]

- Liu, L.M.; Wen, J.; Liu, L.; He, D.; Kuang, R.Y.; Shi, T. A mediator-free glucose biosensor based on glucose oxidase/chitosan/ α-zirconium phosphate ternary biocomposite. Anal. Biochem. 2014, 445, 24–29. [Google Scholar] [CrossRef]

- Rabti, A.; Argoubi, W.; Raouafi, N. Enzymatic sensing of glucose in artificial saliva using a flat electrode consisting of a nanocomposite prepared from reduced graphene oxide, chitosan, nafion and glucose oxidase. Microchim. Acta 2016, 183, 1227–1233. [Google Scholar] [CrossRef]

- Abellán-Llobregat, A.; Jeerapan, I.; Bandodkar, A.; Vidal, L.; Canals, A.; Wang, J.; Morallón, E. A stretchable and screen-printed electrochemical sensor for glucose determination in human perspiration. Biosens. Bioelectron. 2017, 91, 885–891. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fatoni, A.; Numnuam, A.; Kanatharana, P.; Limbut, W.; Thammakhet, C.; Thavarungkul, P. A highly stable oxygen-independent glucose biosensor based on a chitosan-albumin cryogel incorporated with carbon nanotubes and ferrocene. Sens. Actuator B Chem. 2013, 185, 725–734. [Google Scholar] [CrossRef]

- Demir, D.; Bölgen, N. Synthesis and characterization of injectable chitosan cryogel microsphere scaffolds. Int. J. Polym. Mater. Polym. Biomater. 2017, 66, 686–696. [Google Scholar] [CrossRef]

- Nikonorov, V.V.; Ivanov, R.V.; Kil’deeva, N.R.; Bulatnikova, L.N.; Lozinsky, V.I. Synthesis and characteristics of chitosan cryogels crosslinked by glutaric aldehyde. Polym. Sci. A 2010, 52, 828–834. [Google Scholar] [CrossRef]

- Fatoni, A.; Anggraeni, M.D.; Dwiasi, D.W. Simple colorimetric glucose biosensor using chitosan cryogel supporting material. AIP Conf. Proc. 2016, 1746, 020029. [Google Scholar]

- Yilmaz, O.; Demirkol, D.O.; Gulcemal, S.; Kılınc, A.; Timur, S.; Cetinkaya, B. Chitosan-ferrocene film as a platform for flow injection analysis applications of glucose oxidase and Gluconobacter oxydans biosensors. Colloids Surf. B Biointerfaces 2012, 100, 62–68. [Google Scholar] [CrossRef]

- Kim, J.; Sempionatto, J.R.; Imani, S.; Hartel, M.C.; Barfidokht, A.; Tang, G.; Campbell, A.S.; Mercier, P.P.; Wang, J. Simultaneous monitoring of sweat and interstitial fluid using a single wearable biosensor platform. Adv. Sci. 2018, 5, 1800880. [Google Scholar] [CrossRef] [Green Version]

- Goycoolea, F.; Argüelles-Monal, W.; Lizardi, J.; Peniche, C.; Heras, A.; Galed, G.; Díaz, E.I. Temperature and pH-sensitive chitosan hydrogels: DSC, rheological and swelling evidence of a volume phase transition. Polym. Bull. 2007, 58, 225–234. [Google Scholar] [CrossRef]

- Wei, X.; Cruz, J.; Gorski, W. Integration of enzymes and electrodes: Spectroscopic and electrochemical studies of chitosan-enzyme films. Anal. Chem. 2002, 74, 5039–5046. [Google Scholar] [CrossRef]

- Ozyilmaz, G.; Ozyilmaz, A.; Rağibe, H.; Akyürekoğlu, R.H. Poly (N-methylpyrrole)-chitosan layers for glucose oxidase immobilization for amperometric glucose biosensor design. Nat. Eng. Sci. 2017, 2, 123–134. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.M.; Wang, J.W.; Tan, R.X. Immobilization of glucose oxidase on chitosan-SiO2 gel. Enzym. Microb. Technol. 2004, 34, 126–131. [Google Scholar] [CrossRef]

- Chen, X.; Jia, J.B.; Dong, S.J. Organically modified sol–gel/chitosan composite based glucose. Electroanalysis 2003, 15, 608–612. [Google Scholar] [CrossRef]

- Tan, X.C.; Tian, Y.X.; Cai, P.X.; Zou, X.Y. Glucose biosensor based on glucose oxidase immobilized in sol-gel chitosan/silica hybrid composite film on Prussian blue modified glass carbon electrode. Anal. Bioanal. Chem. 2005, 381, 500–507. [Google Scholar] [CrossRef] [PubMed]

- Anusha, J.R.; Fleming, A.T.; Kim, H.J.; Kim, B.C.; Yu, K.H.; Raj, C.J. Effective immobilization of glucose oxidase on chitosan submicron particles from gladius of Todarodes pacificus for glucose sensing. Bioelectrochemistry 2015, 104, 44–50. [Google Scholar] [CrossRef]

- Bagal-Kestwal, D.R.M.; Chiang, B.H. Recent advances in enzyme based glucose biosensors for biomedical applications. Curr. Trends Biomed. Eng. Biosci. 2017, 3. [Google Scholar] [CrossRef]

- Gao, X.; Yang, W.; Pang, P.; Liao, S.; Cai, Q.; Zeng, K.; Grimes, C.A. A wireless magnetoelastic biosensor for rapid detection of glucose concentrations in urine samples. Sens. Actuators B Chem. 2007, 128, 161–167. [Google Scholar] [CrossRef]

- Alim, S.; Kafi, A.K.M.; Rajan, J.; Yusoff, M.M. Application of polymerized multiporous nanofiber of SnO2 for designing a bienzyme glucose biosensor based on HRP/GOx. Int. J. Biol. Macromol. 2019, 123, 1028–1034. [Google Scholar] [CrossRef]

- Wang, S.; Yoshimoto, M.; Fukunaga, K.; Nakao, K. Optimal covalent immobilization of glucose oxidase-contaiing liposomes for highly stable biocatalyst in bioreactor. Biotechnol. Bioeng. 2003, 83, 444–453. [Google Scholar] [CrossRef]

- Chen, Q.; Han, J.; Shi, H.; Wu, B.; Xu, X.; Osa, T. Use of chitosan for developing layer-by-layer multilayer thin films containing glucose oxidase for biosensor applications. Sens. Lett. 2004, 2, 102–105. [Google Scholar] [CrossRef]

- Miscoria, S.A.; Desbrieres, J.; Barrera, G.D.; Labbe, P.; Rivas, G.A. Glucose biosensor based on the layer-by-layer self-assembling of glucose oxidase and chitosan derivatives on a thiolated gold surface. Anal. Chim. Acta 2006, 578, 137–144. [Google Scholar] [CrossRef]

- Gu, T.; Zhang, Y.; Deng, F.; Zhang, J.; Hasebe, Y. Direct electrochemistry of glucose oxidase and biosensing for glucose based on DNA/chitosan film. J. Environ. Sci. 2011, 23, 66–69. [Google Scholar] [CrossRef]

- Kang, Z.; Jiao, K.; Yu, C.; Dong, J.; Peng, R.; Hu, Z.; Jiao, S. Direct electrochemistry and bioelectrocatalysis of glucose oxidase in CS/CNC film and its application in glucose biosensing and biofuel cells. RSC Adv. 2017, 7, 4572–4579. [Google Scholar] [CrossRef] [Green Version]

- Smith, S.K.; Lugo-Morales, L.Z.; Tang, C.; Gosrani, S.P.; Lee, C.A.; Roberts, J.G.; Morton, S.W.; McCarty, G.S.; Khan, S.A.; Sombers, L.A. Quantitative comparison of enzyme immobilization strategies for glucose biosensing in real-time using fast-scan cyclic voltammetry coupled with carbon-fiber microelectrodes. Chem. Phys. Chem. 2018, 19, 1197–1204. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Fang, H.Y.; Chen, W.C. Amperometric glucose biosensor based on screen-printed carbon electrodes mediated with hexacyanoferrate–chitosan oligomers mixture. Sens. Actuators B Chem. 2006, 117, 236–243. [Google Scholar] [CrossRef]

- Lee, S.H.; Chung, J.H.; Park, H.K.; Lee, G.J. A simple and facile glucose biosensor based on prussian blue modified graphite string. J. Sens. 2016, 2016, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhu, J.; Zhu, R.; Zhu, Z.; Lai, Z.; Chen, Z. Chitosan/Prussian blue-based biosensors. Meas. Sci. Technol. 2003, 14, 831–836. [Google Scholar] [CrossRef]

- Yang, M.H.; Yang, Y.H.; Liu, B.; Shen, G.L.; Yu, R.Q. Amperometric glucose biosensor based on chitosan with improved selectivity and stability. Sens. Actuators B 2004, 101, 269–276. [Google Scholar] [CrossRef]

- Miao, Y.; Chia, L.S.; Goh, N.K.; Tan, S.N. Amperometric glucose biosensor based on immobilization of glucose oxidase in chitosan matrix cross-linked with glutaraldehyde. Electroanalysis 2001, 13, 347–349. [Google Scholar] [CrossRef]

- Kumar-Krishnan, S.; Chakaravarthy, S.; Hernandez-Rangel, A.; Prokhorov, E.; Luna-Bárcenas, G.; Esparza, R.; Meyyappan, M. Chitosan supported silver nanowires as a platform for direct electrochemistry and highly sensitive electrochemical glucose biosensing. RSC Adv. 2016, 6, 20102–20108. [Google Scholar] [CrossRef]

- Krishnan, S.K.; Prokhorov, E.; Bahena, D.; Esparza, R.; Meyyappan, M. Chitosan-covered Pd@Pt core-shell nanocubes for direct electron transfer in electrochemical enzymatic glucose biosensor. ACS Omega 2017, 2, 1896–1904. [Google Scholar] [CrossRef] [Green Version]

- Li, F.; Wang, Z.; Feng, Y. Construction of bienzyme biosensors based on combination of the one-step electrodeposition and covalent-coupled sol-gel process. Sci. China Ser. B Chem. 2009, 52, 2269–2274. [Google Scholar] [CrossRef]

- Yoo, E.H.; Lee, S.Y. Glucose biosensors: An overview of use in clinical practice. Sensors 2010, 10, 4558–4576. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.; Wang, J. Improved design for the glucose biosensor. Food Technol. Biotechnol. 2001, 39, 55–58. [Google Scholar]

- Ronkainen, N.J.; Halsall, H.B.; Heineman, W.R. Electrochemical biosensors. Chem. Soc. Rev. 2010, 39, 1747–1763. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Li, X.; Zou, R.; Wu, H.; Shi, H.; Yu, S.; Liu, Y. Multifunctional glucose biosensors from Fe3O4 nanoparticles modified chitosan/graphene nanocomposites. Sci. Rep. 2015, 5, 11129. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bagal-Kestwal, D.; Karve, M.S.; Kakade, B.; Pillai, V.K. Invertase inhibition based electrochemical sensor for the detection of heavy metal ions in aqueous system: Application of ultra-microelectrode to enhance sucrose biosensor’s sensitivity. Biosens. Bioelectron. 2008, 24, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Putzbach, W.; Ronkainen, N.J. Immobilization techniques in the fabrication of nanomaterial-based electrochemical biosensors: A review. Sensors 2013, 13, 4811–4840. [Google Scholar] [CrossRef]

- Challa, S.S.R.K. Nanocomposites: Nanomaterials for the Life Sciences. In Gold Nanocomposite Biosensors; Wiley-VCH: Weinheim, Germany, 2010; pp. 139–162. [Google Scholar]

- Hedström, M.; Plieva, F.; Galaev, I.Y.; Mattiasson, B. Monolithic macroporous albumin/chitosan cryogel structure: A new matrix for enzyme immobilization. Anal. Bioanal. Chem. 2008, 390, 907–912. [Google Scholar] [CrossRef]

- Qiu, J.D.; Xie, H.Y.; Liang, R.P. Preparation of porous chitosan/carbon nanotubes film modified electrode for biosensor application. Microchim. Acta 2008, 162, 57–64. [Google Scholar] [CrossRef]

- Zhou, J.; Li, H.; Yang, H.; Cheng, H.; Lai, G. Immobilization of glucose oxidase on a carbon nanotubes/dendrimer-ferrocene modified electrode for reagentless glucose biosensing. J. Nanosci. Nanotechnol. 2017, 17, 212–216. [Google Scholar] [CrossRef]

- Qian, L.; Lu, L. Three dimensional porous graphene–chitosan composites from ice-induced assembly for direct electron transfer and electrocatalysis of glucose oxidase. RSC Adv. 2014, 4, 38273–38280. [Google Scholar] [CrossRef]

- Kang, X.; Wang, J.; Wu, H.; Aksay, I.A.; Liu, J.; Lin, Y. Glucose oxidase–graphene–chitosan modified electrode for direct electrochemistry and glucose sensing. Biosens. Bioelectron. 2009, 25, 901–905. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.G.; Huang, J.Y.; Zhou, Y.; Chen, Q.; Pan, X.H.; He, H.P.; Ye, Z.Z. A single mesoporous ZnO/chitosan hybrid nanostructure for a novel free nanoprobe type biosensor. Biosens. Bioelectron. 2013, 43, 226–230. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yuan, R.; Chai, Y. Simple construction of an enzymatic glucose biosensor based on a nanocomposite film prepared in one step from iron oxide, gold nanoparticles, and chitosan. Microchim. Acta 2011, 173, 369–374. [Google Scholar] [CrossRef]

- Song, Y.; Liu, H.; Tan, H.; Xu, F.; Jia, J.; Zhang, L.; Li, Z.; Wang, L. pH-switchable electrochemical sensing platform based on chitosan-reduced graphene oxide/concanavalin A layer for assay of glucose and urea. Anal. Chem. 2014, 86, 1980–1987. [Google Scholar] [CrossRef]

- Wang, L.; Yu, J.; Zhang, Y.; Yang, H.; Miao, L.; Song, Y. Simple and large-scale strategy to prepare flexible graphene tape electrode. ACS Appl. Mater. Interfaces 2017, 9, 9089–9095. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, R.; Xu, Y.; He, P.; Fang, Y. Direct electrochemistry study of glucose oxidase on Pt nanoparticle-modified aligned carbon nanotubes electrode by the assistance of chitosan–Cds and its biosensoring for glucose. Electrochem. Commun. 2008, 10, 1889–1892. [Google Scholar] [CrossRef]

- Bagal-Kestwal, D.R.; Chiang, B.H. Platinum nanoparticle-carbon nanotubes dispersed in gum Arabic-corn flour composite-enzymes for an electrochemical sucrose sensing in commercial juice. Ionics 2019, 25, 5551–5564. [Google Scholar] [CrossRef]

- El-Haleem, H.S.A.; Hefnawy, A.; Hassan, R.Y.A.; Badawi, A.H.; El-Sherbiny, I.M. Manganese diox nanostructure for a novel ide-core–shell hyperbranched chitosan (MnO2–HBCs) nano-structured screen printed electrode for enzymatic glucose biosensors. RSC Adv. 2016, 6, 109185–109191. [Google Scholar] [CrossRef]

- Shukla, S.K.; Deshpande, S.R.; Shukla, S.K.; Tiwari, A. Fabrication of tunable glucose biosensor based on zinc oxide/chitosan-graft-poly(vinyl alcohol) core-shell nanocomposite. Talanta 2012, 99, 283–287. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.; Kumar, A. Study of structural and electro-catalytic behaviour of amperometric biosensor based on chitosan/polypyrrole nanotubes-gold nanoparticles nanocomposites. Synth. Met. 2016, 220, 551–559. [Google Scholar] [CrossRef]

- Li, Z.; Sheng, L.; Meng, A.; Xie, C.; Zhao, K. A glassy carbon electrode modified with a composite consisting of reduced graphene oxide, zinc oxide and silver nanoparticles in a chitosan matrix for studying the direct electron transfer of glucose oxidase and for enzymatic sensing of glucose. Microchim. Acta 2016, 183, 1625–1632. [Google Scholar] [CrossRef]

- Qiu, J.D.; Huang, J.; Liang, R.P. Nanocomposite film based on graphene oxide for high performance flexible glucose biosensor. Sens. Actuators B 2011, 160, 287–294. [Google Scholar] [CrossRef]

- Wu, H.; Wang, J.; Kang, X.; Wang, C.; Wang, D.; Liu, J.; Aksay, I.A.; Lin, Y. Glucose biosensor based on immobilization of glucose oxidase in platinum nanoparticles/graphene/chitosan nanocomposite film. Talanta 2009, 80, 403–406. [Google Scholar] [CrossRef]

- Anusha, J.R.; Kim, H.J.; Fleming, A.T.; Das, S.J.; Yu, K.H.; Kim, B.C.; Raj, C.J. Simple fabrication of ZnO/Pt/chitosan electrode for enzymatic glucose biosensor. Sens. Actuators B Chem. 2014, 202, 827–833. [Google Scholar] [CrossRef]

- Zhou, Y.; Xiang, C.; Sun, L.X.; Xu, F. Glucose biosensor based on electrodeposition of platinum nanoparticles onto carbon nanotubes and immobilizing enzyme with chitosan-SiO2 sol–gel. Biosens. Bioelectron. 2008, 23, 1010–1016. [Google Scholar] [CrossRef]

- Peng, H.; Huang, Z.; Zheng, Y.; Chen, W.; Liu, A.; Lin, X. A novel nanocomposite matrix based on graphene oxide and ferrocene–branched organically modified sol–gel/chitosan for biosensor application. J. Solid State Electrochem. 2014, 18, 1941–1949. [Google Scholar] [CrossRef]

- Shan, C.; Yang, H.; Han, D.; Zhang, Q.; Ivaska, A.; Niu, L. Graphene/AuNPs/chitosan nanocomposites film for glucose biosensing. Biosens. Bioelectron. 2010, 25, 1070–1074. [Google Scholar] [CrossRef]

- Kulys, J.; Stupak, R. Glucose biosensor based on chitosan-gold and Prussian blue-gold nanoparticles. Open Nanosci. J. 2008, 2, 34–38. [Google Scholar] [CrossRef] [Green Version]

- Qiu, J.D.; Wang, R.; Liang, R.P.; Xia, X.H. Electrochemically deposited nanocomposite film of CS-Fc/Au NPs/GOx for glucose biosensor application. Biosens. Bioelectron. 2009, 24, 2920–2925. [Google Scholar] [CrossRef]

- Onay, A.; Dogan, Ü.; Ciftci, H.; Cetin, D.; Suludere, Z.; Tamer, U. Amperometric glucose sensor based on the glucose oxidase enzyme immobilized on graphite rod electrode modified with Fe3O4-CS-Au magnetic nanoparticles. Ionics 2018, 24, 4015–4022. [Google Scholar] [CrossRef]

- Khun, K.; Ibupoto, Z.H.; Lu, J.; AlSalhi, M.S.; Atif, M.; Ansari, A.A.; Willander, M. Potentiometric glucose sensor based on the glucose oxidase immobilized iron ferrite magnetic particle/chitosan composite modified gold coated glass electrode. Sens. Actuators B Chem. 2012, 173, 698–703. [Google Scholar] [CrossRef]

- Xu, X.; Ren, G.; Cheng, J.; Liu, Q.; Li, D.; Chen, Q. Self-assembly of polyaniline-grafted chitosan/glucose oxidase nanolayered films for electrochemical biosensor applications. J. Mater. Sci. 2006, 41, 4974–4977. [Google Scholar] [CrossRef]

- Kaushik, A.; Khan, R.; Solanki, P.R.; Pandey, P.; Alam, J.; Ahmad, S.; Malhotra, B. Iron oxide nanoparticles–chitosan composite based glucose biosensor. Biosens. Bioelectron. 2008, 24, 676–683. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Liang, Y.; Su, Y.; Shang, Q.; Zhang, C. Sensitivity enhancement of cloth-based closed bipolar electrochemiluminescence glucose sensor via electrode decoration with chitosan/multi-walled carbon nanotubes/graphene quantum dots-gold nanoparticles. Biosens. Bioelectron. 2019, 130, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Asrami, P.N.; Mozaffari, S.A.; Tehrani, M.S.; Azar, P.A. A novel impedimetric glucose biosensor based on immobilized glucose oxidase on a CuO-Chitosan nanobiocomposite modified FTO electrode. Int. J. Biol. Macromol. 2018, 118, 649–660. [Google Scholar] [CrossRef]

- Shrestha, B.K.; Ahmad, R.; Mousa, H.M.; Kim, I.G.; Kim, J.I.; Neupane, M.P.; Park, C.H.; Kim, C.S. High-performance glucose biosensor based on chitosan-glucose oxidase immobilized polypyrrole/Nafion/functionalized multi-walled carbon nanotubes bio-nanohybrid film. J. Colloid Interface Sci. 2016, 482, 39–47. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, H.; Yang, M.; Ilu, Y.; Shen, G.; Yu, R. Amperometric glucose biosensor based on a surface treated nanoporous ZrO2/Chitosan composite film as immobilization matrix. Anal. Chim. Acta 2004, 525, 213–220. [Google Scholar] [CrossRef]

- Xu, J.J.; Luo, X.L.; Du, Y.; Chen, H.Y. Application of MnO2 nanoparticles as an eliminator of ascorbate interference to amperometric glucose biosensors. Electrochem. Commun. 2004, 6, 1169–1173. [Google Scholar] [CrossRef]

- Barsan, M.M.; David, M.; Florescu, M.; Ţugulea, L.; Brett, C.M. A new self-assembled layer-by-layer glucose biosensor based on chitosan biopolymer entrapped enzyme with nitrogen doped graphene. Bioelectrochemistry 2014, 99, 46–52. [Google Scholar] [CrossRef]

- Qiu, J.; Peng, H.; Liang, R. Ferrocene-modified Fe3O4@SiO2 magnetic nanoparticles as building blocks for construction of reagentless enzyme-based biosensors. Electrochem. Commun. 2007, 9, 2734–2738. [Google Scholar] [CrossRef]

- Guan, H.; Gong, D.; Song, Y.; Han, B.; Zhang, N. Biosensor composed of integrated glucose oxidase with liposome microreactors/chitosan nanocomposite for amperometric glucose sensing. Colloid Surf. A Physicochem. Eng. Asp. 2019, 574, 260–267. [Google Scholar] [CrossRef]

- Kang, X.; Mai, Z.; Zou, X.; Cai, P.; Mo, J. A novel glucose biosensor based on immobilization of glucose oxidase in chitosan on a glassy carbon electrode modified with gold–platinum alloy nanoparticles/multiwall carbon nanotubes. Anal. Biochem. 2007, 369, 71–79. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Luo, X.-L.; Xu, J.-J.; Chen, H.-Y. A simple method to fabricate a chitosan-gold nanoparticles film and its application in glucose biosensor. Bioelectrochemistry 2007, 70, 342–347. [Google Scholar] [CrossRef] [PubMed]

- Xue, M.-H.; Xu, Q.; Zhou, M.; Zhu, J.-J. In situ immobilization of glucose oxidase in chitosan–gold nanoparticle hybrid film on prussian blue modified electrode for high-sensitivity glucose detection. Electrochem. Commun. 2006, 8, 1468–1474. [Google Scholar] [CrossRef]

- Luo, X.L.; Xu, J.J.; Du, Y.; Chen, H.Y. A glucose biosensor based on chitosan-glucose oxidase gold nanoparticles biocomposite formed by one-step electrodeposition. Anal. Biochem. 2004, 334, 284–289. [Google Scholar] [CrossRef]

- Paik, E.S.; Kim, Y.R.; Hong, H.G. Amperometric glucose biosensor utilizing zinc oxide-chitosan-glucose oxidase hybrid composite films on electrodeposited Pt-Fe (III). Anal. Sci. 2018, 34, 1271–1276. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Xie, Q.; Fu, Y.; Su, Z.; Jai, X.; Yao, S. Electrodeposition of carbon nanotubes-chitosan-glucose oxidase biosensing composite films triggered by reduction of p-benzoquinone or H2O2. J. Phys. Chem. B 2007, 111, 11276–11284. [Google Scholar] [CrossRef]

- Guo, M.; Fang, H.; Wang, R.; Yang, Z.; Xu, X. Electrodeposition of chitosan-glucose oxidase biocomposite onto Pt–Pb nanoparticles modified stainless steel needle electrode for amperometric glucose biosensor. Mater. Sci. Mater. Med. 2011, 22, 1985–1992. [Google Scholar] [CrossRef]

- Zeng, X.; Li, X.; Xing, L.; Liu, X.; Luo, S.; Wei, W.; Kong, B.; Li, Y. Electrodeposition of chitosan–ionic liquid–glucose oxidase biocomposite onto nano-gold electrode for amperometric glucose sensing. Biosens. Bioelectron. 2009, 24, 2898–2903. [Google Scholar] [CrossRef]

- Wang, L.; Gao, X.; Jin, L.; Wu, Q.; Chen, Z.; Lin, X. Amperometric glucose biosensor based on silver nanowires and glucose oxidase. Sens. Actuators B Chem. 2013, 176, 9–14. [Google Scholar] [CrossRef]

- Kang, X.; Mai, Z.; Zou, X.; Cai, P.; Mo, J. Glucose biosensors based on platinum nanoparticles-deposited carbon nanotubes in sol-gel chitosan/silica hybrid. Talanta 2008, 74, 879–886. [Google Scholar] [CrossRef] [PubMed]

- Anusha, J.R.; Raj, C.J.; Cho, B.B.; Fleming, A.T.; Yu, K.H.; Kim, B.C. Amperometric glucose biosensor based on glucose oxidase immobilized over chitosan nanoparticles from gladius of Uroteuthis duvauceli. Sens. Actuators B Chem. 2015, 215, 536–543. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Wu, W.; Jiang, Y.; Hu, B. Chitosan coated on the layers’ glucose oxidase immobilized on cysteamine/Au electrode for use as glucose biosensor. Biosens. Bioelectron. 2014, 60, 271–276. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, W.; Zeng, J.; Liu, X.; Zeng, X. Fabrication of a copper nanoparticle/chitosan/carbon nanotube-modified glassy carbon electrode for electrochemical sensing of hydrogen peroxide and glucose. Microchim. Acta 2008, 160, 253–260. [Google Scholar] [CrossRef]

- Costa, R.R.; Mano, J.F. Layer-by-layer self-assembly techniques for nanostructured devices in tissue engineering. In Nanomaterials in Tissue Engineering: Characterization, Fabrication and Applications, 1st ed.; Gaharwar, A.K., Sant, S., Hancock, M.J., Hacking, S.A., Eds.; Woodhead Publishing Ltd.: Cambridge, UK, 2013; pp. 88–118. [Google Scholar]

- Ragupathy, D.; Iyengar Gopalan, A.; Pill Lee, K. Synergistic contributions of multiwall carbon nanotubes and gold nanoparticles in a chitosan–ionic liquid matrix towards improved performance for a glucose sensor. Electrochem. Commun. 2009, 11, 397–401. [Google Scholar] [CrossRef]

- Donahue, C.E.T.; Miller, D.R., Jr.; Beger, T.W.; Johann, T.W.; Keithley, R.B. Improved formation of electrically-deposited enzyme-embedded chitosan coatings onto carbon fiber microelectrodes. Anal. Methods 2018, 10, 1565–1576. [Google Scholar] [CrossRef]

- Xin, H.X.; Bo, H.; Ying, S.F. Preparation of chitosan/glucose oxidase nanolayered films for electrode modification by the technique of layer-by-layer self-assembly. J. Mater. Sci. Lett. 2003, 22, 695–697. [Google Scholar]

- Pandey, P.C.; Upadhyay, S.; Pathak, H.C.; Pandey, C.M.D. A new glucose biosensor based on sandwich configuration of organically modified sol-gel glass. Electroanalysis 1999, 1, 59–64. [Google Scholar] [CrossRef]

- Ang, L.F.; Por, L.Y.; Yam, M.F. Development of an amperometric-based glucose biosensor to measure the glucose content of fruit. PLoS ONE 2015, 10, e0111859. [Google Scholar] [CrossRef] [Green Version]

- Huang, H.M.; Huang, P.K.; Kuo, W.H.; Ju, Y.H.; Wang, M.J. Sol–gel immobilized enzymatic glucose biosensor on gold interdigitated array (IDA) microelectrode. J. Sol Gel Sci. Technol. 2013, 67, 492–500. [Google Scholar] [CrossRef]

- Yang, H.; Chung, T.D.; Kim, Y.T.; Choi, C.A.; Jun, C.H.; Kim, H.C. Glucose sensor using a microfabricated electrode and electropolymerized bilayer films. Biosens. Bioelectron. 2002, 17, 251–259. [Google Scholar] [CrossRef]

- Wu, L.Q.; Gadre, A.P.; Yi, H.; Kastantin, M.J.; Rubloff, G.W.; Bentley, W.E.; Payne, G.F.; Ghodssi, R. Voltage-dependent assembly of the polysaccharide chitosan onto an electrode surface. Langmuir 2002, 18, 8620–8625. [Google Scholar] [CrossRef]

- Fernandes, R.; Wu, L.Q.; Chen, T.; Yi, H.; Rubloff, G.W.; Ghodssi, R.; Bentley, W.E.; Payne, G.F. Electrochemically induced deposition of a polysaccharide hydrogel onto a patterned surface. Langmuir 2003, 19, 4058–4062. [Google Scholar] [CrossRef]

- Su, X.; Ren, J.; Meng, X.; Rena, X.; Tang, F. A novel platform for enhanced biosensing based on the synergy effects of electrospun polymer nanofibers and graphene oxides. Analyst 2013, 138, 1459–1466. [Google Scholar] [CrossRef] [PubMed]

- Artigues, M.; Abellà, J.; Colominas, S. Analytical parameters of an amperometric glucose biosensor for fast analysis in food samples. Sensors 2017, 17, 2620. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sheng, Q.; Luo, K.; Li, L.; Zheng, J. Direct electrochemistry of glucose oxidase immobilized on ndpo4 nanoparticles/chitosan composite film on glassy carbon electrodes and its biosensing application. Bioelectrochemistry 2009, 74, 246–253. [Google Scholar] [CrossRef]

- Nakorn, N. Chitin Nanowhisker and Chitosan Nanoparticles in Protein Immobilization for Biosensor Applications. J. Met. Mater. Miner. 2008, 18, 73–77. [Google Scholar]

- Ding, F.; Deng, H.; Du, Y.; Shi, X.; Wang, Q. Emerging chitin and chitosan nanofibrous materials for biomedical applications. Nanoscale 2014, 6, 9477–9493. [Google Scholar] [CrossRef]

- Haghju, S.; Bari, M.R.; Khaled-Abad, M.A. Affecting parameters on fabrication of β-D-galactosidase immobilized chitosan/poly (vinyl alcohol) electrospun nanofibers. Carbohydr. Polym. 2018, 200, 137–143. [Google Scholar] [CrossRef]

- Bösiger, P.; Tegl, G.; Richard, I.M.; Le Gat, L.; Huber, L.; Stagl, V.; Mensah, A.; Guebitz, G.M.; Rossi, R.M.; Fortunato, G. Enzyme functionalized electrospun chitosan mats for antimicrobial treatment. Carbohydr. Polym. 2018, 181, 551–559. [Google Scholar] [CrossRef] [PubMed]

- Wan, D.; Yuan, S.; Li, G.L.; Neoh, K.G.; Kang, E.T. Glucose biosensor from covalent immobilization of chitosan-coupled carbon nanotubes on polyaniline-modified gold electrode. ACS Appl. Mater. Interfaces 2010, 2, 3083–3091. [Google Scholar] [CrossRef] [PubMed]

- Ignatova, M.; Manolova, N.; Rashkov, I. Novel antibacterial fibers of quaternized chitosan and poly (vinyl pyrrolidone) prepared by electrospinning. Eur. Polym. J. 2007, 43, 1112–1122. [Google Scholar] [CrossRef]

- Huang, X.; Ge, D.; Xu, Z. Preparation and characterization of stable chitosan nanofibrous membrane for lipase immobilization. Eur. Polym. J. 2007, 43, 3710–3718. [Google Scholar] [CrossRef]

- Gomathi, P.; Ragupathy, D.; Choi, J.H.; Yeum, J.H.; Lee, S.C.; Kim, J.C.; Lee, S.H.; Ghim, H.D. 2011 Fabrication of novel chitosan nanofiber/gold nanoparticles composite towards improved performance for a cholesterol sensor. Sens. Actuators. B 2011, 153, 44–49. [Google Scholar] [CrossRef]

- Huang, W.-C.; Wang, W.; Xue, C.; Mao, X. Effective enzyme immobilization onto a magnetic chitin nanofiber composite. ACS Sustain. Chem. Eng. 2018, 6, 8118–8124. [Google Scholar] [CrossRef]

- Demirkan, E.; Avci, T.; Aykut, Y. Protease immobilization on cellulose monoacetate/chitosan-blended nanofibers. J. Ind. Text. 2018, 47, 2092–2111. [Google Scholar] [CrossRef]

- Thomas, M.S.; Koshy, R.R.; Mary, S.K.; Thomas, S.; Pothan, L.A. Applications of Polysaccharide Based Composites. In Starch, Chitin and Chitosan Based Composites and Nanocomposites; Navard, P., Antipolis, S., Eds.; Springer Briefs in Molecular Science, Biobased Polymers; Springer: Cham, Germany, 2019; pp. 43–55. [Google Scholar]

- Kim, K.; Ha, M.; Choi, B.; Joo, S.H.; Kang, H.S.; Park, J.H.; Gu, B.; Park, C.; Park, C.; Kim, J.; et al. Biodegradable, electro-active chitin nanofiber films for flexible piezoelectric transducers. Nano Energy 2018, 48, 275–283. [Google Scholar] [CrossRef]

- Solairaj, D.; Rameshthangam, P.; Muthukumaran, P.; Wilson, J. Studies on electrochemical glucose sensing, antimicrobial activity and cytotoxicity of fabricated copper nanoparticle immobilized chitin nanostructure. Int. J. Biol. Macromol. 2017, 101, 668–679. [Google Scholar] [CrossRef]

- Tang, Z.X.; Qian, J.Q.; Shi, L.E. Preparation of chitosan nanoparticles as carrier for immobilized enzyme. Appl. Biochem. Biotechnol. 2007, 136, 77–96. [Google Scholar] [CrossRef]

- Huang, Y.; Qin, X.; Li, Z.; Fu, Y.; Qin, C.; Wu, F.; Su, Z.; Ma, M.; Xie, Q.; Yao, S.; et al. Fabrication of a chitosan/glucose oxidase-poly (anilineboronic acid)-Au(nano)/Au-plated Au electrode for biosensor and biofuel cell. Biosens. Bioelectron. 2012, 31, 357–362. [Google Scholar] [CrossRef] [PubMed]

- Grenha, A. Chitosan nanoparticles: A survey of preparation methods. J. Drug Target. 2012, 20, 291–300. [Google Scholar] [CrossRef] [PubMed]

- Hubbe, M.A.; Tyagi, P.; Pal, L. Nanopolysaccharides in Barrier Composites. In Advanced Functional Materials from Nanopolysaccharides; Lin, N., Tang, J., Dufresne, A., Tam, M., Eds.; Springer Series in Biomaterials Science and Engineering; Springer: Singapore, 2019; Volume 15, pp. 321–366. [Google Scholar]

- Senel, M. Simple method for preparing glucose biosensor based on in-situ polypyrrole cross-linked chitosan/glucose oxidase/gold bionanocomposite film. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 48, 287–293. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Gu, S.-X.; Jin, L.; Zhou, Y.-E.; Yang, Z.; Wang, W.; Hu, X. Graphene/polyaniline/gold nanoparticles nanocomposite for the direct electron transfer of glucose oxidase and glucose biosensing. Sens. Actuators B Chem. 2014, 190, 562–569. [Google Scholar] [CrossRef]

| Immobilization Matrix Composition | Method of Preparation | Sensing System | Characteristic Features/Application | Reference | |

|---|---|---|---|---|---|

| Primary Phase | Secondary Phase | ||||

| Chitin | GOx | Adsorption based on electrostatic interactions | CS-GOx/CPE | Glucose detection in sports drink | [59] |

| Chitin | GOx | Adsorption based on electrostatic interactions | CS-GOx/PtE | Glucose detection in sports drink | [60] |

| Chitosan | GDI-AY9-GOx | Cross-linking | CS-GDI-GOx-AY9/PtE | New composite composition for CS-film, simple, efficient, and cost-effective enzyme immobilization, Standard glucose detection with linear range = 10 µM–5.0 mM and LOD = 10 µM | [81] |

| Chitosan | CS-PNMP-GOx | Cross-linking | CS-PNMP-GOx/PtE | Standard glucose detection | [82] |

| Chitosan | TOES | Sol-gel encapsulation | CS-GOx-TOES/GCE | Standard glucose detection | [84] |

| Chitosan | SiO2-GOx | Sol-gel entrapment | CS-SiO2-GOx/PB-NF/GCE | Glucose detection in human blood samples | [85] |

| Chitosan & pH sensitive polymer | GOx-CAT | Cross-linking | Urine glucose detection | [88] | |

| Chitosan | GOx | Absorption | CT-GOx/PtE | Layer-by-layer thin films, Standard glucose detection | [91] |

| Chitosan | Thiolated gold-GOx | Adsorption | CS-GOx-MPS/ CHIT/Naf/AuE | Human Serum glucose detection | [92] |

| Chitosan | GOx-DNA | Adsorption | CS-GOx-DNA/GCE | Standard glucose detection | [93] |

| Chitosan | GOx-CNCs | Adsorption | CS-GOx/CNCs/GCE | Standard glucose detection | [94] |

| Chitosan | GOx | Adsorption Hydrogel entrapment Nanofibers entrapment | CS-GOx CS-GOx CS-PVA-GOx | Brain glucose detection | [95] |

| Chitosan | Cos-GOx | Physical mixing | Cos-GOx-Ferri/SPCE | Standard glucose detection | [96] |

| Chitosan | Pb-G-GOx | Sol-gel adsorption | CS-GOx/PB-G/PS-StE | string sensor with PB modified graphite and CS, linear range = 0.03 to 1.0 mM, LOD =10 µM Glucose detection in spiked human serum samples | [97] |

| Chitosan | PB-GOx PB-GalOD PB-GluOD | Cross-linking | CS-GOx-PB/PtE CS-GalOD-PB/PtE CS-GluOD-PB/PtE | Human blood serum and fermented solution Glucose, galactose glutamate detection | [98] |

| Chitosan | GOx | Cross-linking | CT-GOx/PtE | Amperometric biosensor Glucose detection in beverage drink samples | [99] |

| Chitosan | Fc-GOx | Sandwich configuration with cross-linking | CS-Fc:GA-GOx-CS/CPE | Fast response time, Linear range = 8 × 10−4 to 1.7 × 10−2 M, LOD = 8 × 10−4 M, Glucose in soft drink samples | [100] |

| Chitosan | AgNWs-GOx | Covalent linkage | CS-AgNWs-GOx/GCE | Standard glucose detection | [101] |

| Chitosan | Pd@PtNC-GOx | Covalent immobilization | CS-GOx/Pd@Pt NC/GCE | Standard glucose detection | [102] |

| Chitosan | HRP-GOx | Electrodeposition and Covalent coupling sol-gel | CS-GPTMS-GOx- HRP/AuE | Standard glucose detection | [103] |

| Conjugation Method | Chitinous Sensing System | Reinforced Secondary Phase | Linear Dynamic Range | LOD | Target Sample | Reference |

|---|---|---|---|---|---|---|

| Electrostatic adsorption | CS-GOx/AuNPs/PAA/PtE | AuNPs-GOx | 0.5–16 mM | 7.0 µM | Human serum glucose | [44] |

| Encapsulation | CS-κ-Cg-GOx/AuNPs/AuE CS-κ-Cg-GOx/AuE | CNT-PtNP-MTOS | 10 µM–7.0 mM 10 µM–7.0 mM | 5.0 µM 5.0 µM | Spiked saliva glucose | [70] |

| Adsorption | GCSPs-GOx-(ZnO-Pt) NPs/FTOE SCS-GOx-(ZnO-Pt)NPs/FTOE | GCSP-GOx | 0.05–1.0 mM 0.05–1.0 mM | 0.22 mM 0.31 mM | Standard glucose | [86] |

| Cross-linking | CS-GOx /PtNPs/SCS/ZnO CS-GOx/PtNPs/GCSP/ZnO | PtNPs-GOx | 0.05–1.0 mM 0.05–1.0 mM | 0.09 mM 0.053 mM | Standard glucose | [87] |

| Absorption | PANI-SnO2-NF/GOx-HRP-CS/GCE | GOx-HRP-CS | 5.0–100 μM | 1.8 μM | Spiked human urine glucose | [89] |

| Adsorption | CS-GOx-DNA/GCE | GOx-DNA | 0.04–2.28 mmol L−1 | 0.04 mmol·L−1 | Standard glucose | [93] |

| Covalent bonding | GOx-CDI/CS-CNTs-GA/PANI-AuE | GOx-CS-CNTs | 1.0–20 mM | 1.0 mM | Standard glucose | [105] |

| Covalent linkage | CS-G-MNPs-GOx/Pt-ITOE | MNPs-GOx | 16 μM–26 mM | 16 μM | Standard glucose | [107] |

| Entrapment & cross linking | CS-GOx-SWNTs/E | GOx-SWNTs | 10 µM–35 mM | 2.5 µM | Standard glucose | [112] |

| Covalent linking | CS-CNT-GOx-Fc-RD/E | GNPs-GOx | 0.02–2.91 mM | 7.5 μM | Human blood glucose | [113] |

| Entrapment | CS-GR70-GOx-NF/GCE | CS-GR70-GOx | 0.14–7.0 mM | 17.5 mM | Standard glucose | [114] |

| Adsorption | CS-G-GOx/GCE | G-GOx | 0.08–12 mM | 0.02 mM | Standard glucose | [115] |

| Electrostatic adsorption | CS-ZnONF-GOx/E | ZnONF-GOx | 0.2–12 mM | 0.2 mM | Intra cellular glucose | [116] |

| Electrochemical deposition | CS-GOx/Fe3O4NPs-AuNPs/AuE | Fe3O4Nps-AuNPS-GOx | 3.0 μM–0.57 mM | 1.2 μM | Human blood glucose | [117] |

| Electrostatic interactions | CS-rGO-Con A/GCE | Con A-rGO | 1.0−10.0 mM | 1.0 mM | Glucose, Urea | [118] |

| Electrochemical deposition | CS-AuNPs-GOx/GTE | AuNPs-GOx | 0.616–14.0 mM | 0.202 mM | Blood serum glucose | [119] |

| Encapsulation | CS-gPVA-ZnONPs/GOx/ITOE | gPVA-ZnONPs-GOx | 2.0 μM–1.2 mM | 0.2 µM | Blood serum, urine glucose | [123] |

| Entrapment | CS-PPyNTs-AuNPs-GOx/ITOE | PPyNTs-AuNPs-GOx | 3.0–230 μM | 3.10 μM | Standard glucose | [124] |

| Adsorption | CS-GOx-rGO(HHA)-ZnO-AgNPs/GCE | GOx-rGO(HHA)-ZnO-AgNPs | 0.1–12 mM | 10.6 μM | Blood serum glucose | [125] |

| Electrostatic adsorption | CS-Fc-GONS-GOx/GCE | Fc-GONS-GOx | 0.02–6.78 mM | 7.6 μM | Standard glucose | [126] |

| Adsorption | CS-FGS-PtNPs/CS-GOx/GCE | FGS-PtNPs-GOx | 0.3 μM–5.0 mM | 0.6 μM | Blood glucose | [127] |

| Electrostatic adsorption | CS-GOx-PtNPs/ZnO-FTOE CS-GOx/ZnO-FTOE | CS-GOx-PtNPs CS-GOx | 16.6 µM–2.0 mM 31.19 µM–2.0 mM | 16.60 µM 31.19 µM | Standard glucose | [128] |

| Entrapment | CS-SiO2-GOx-Nf-Pt/MWNTs/GCE | SiO2-GOx | 1.0 μM–23 mM | 1.0 μM | Standard glucose | [129] |

| Entrapment | CS-GOx/TEOS-APTES-Fc-GONS/GCE | GOx/TEOS-APTES-Fc-GONS | 0.02–5.39 mM | 6.5 mM | Blood serum glucose | [130] |

| Adsorption | CS-G-AuNPs-GOx/AuE | G-AuNPs-GOx | 2.0–14 mM | 180 μM | Blood glucose | [131] |

| Electrochemical deposition | CS-GOx-(Au-PB) NPs/GCE (Au-PB)NPs-GOx/GCE | GOx-(Au-PB)NPs | 0.2–3.0 × 10−3 M 0.2–1.9 × 10−3 M | 0.2 mM 0.2 mM | Standard glucose | [132] |

| Electrochemical deposition | CS-Fc/AuNPs/GOx/GCE | Fc-GOx | 0.02–8.66 mM | 5.6 µM | Serum glucose | [133] |

| Cross-linking | CS-Fe3O4-AuNPs-GOx/GrE | Fe3O4-AuNPs-GOx | 5.0–30 mM | 0.55 mM | Blood glucose | [134] |

| Adsorption | CS-GOx-Fe3O4NPs/ Au-coated glass E | GOx-Fe3O4NPs | 1.0 × 10−6–3.0 × 10−2 M | 0.04 mmol·L−1 | Standard glucose | [135] |

| Electrodeposition | CS-g-PAN-GOx/PtE | g-PAN-GOx | 0.5–16 mM | 0.5 mM | Standard glucose | [136] |

| Adsorption | CS-GOx/Fe3O4/ITOE | Fe3O4NPs-GOx | 10–400 mg dL−1 | 0.5 mM | Standard glucose | [137] |

| Adsorption | Cathode; CS-GQDs-AuNPs/PDDA-MWCNTs/CS/CBC and Anode: GOx-CBA | CS-GQDs-AuNPs-PDDA-MWCNTs | 0.1–5000 μM | 64 nM | Blood glucose | [138] |

| Cross linking | CS-GOx/Nano-CuO-FTOE | CS-GOx | 0.2–15 mM | 27 μM | Blood serum glucose | [139] |

| Electrostatic adsorption | CS/GOx/GNPs/Ppy-Nf-fMWCNTs/GCE | FMCNTs-GOx | 5.0 µM–4.7 mM | 5.0 µM | Human serum glucose | [140] |

| Cross-linking | CS-GOx/ZrO2/NF/PtE | ZrO2-GOx | 1.25 × 10−5–9.5 × 10−3 M | 1.0 × 10−5 M | Blood glucose | [141] |

| Entrapment | CS-GOx/ MnO4NPs/AuDE | GOx-MnO4NPs | NA | NA | Standard glucose | [142] |

| Entrapment | CS-NG-GOx-PSS/AuQC CS-GOx-PSS/AuQC | NG-GOx GOx-PSS | 0.2–1.8 mM 0.2–1.8 mM | 64 μM 112 μM | Standard glucose | [143] |

| Entrapment | CS-GOx-FMC-AFSNPs/MCPE | GOx-FMC-AFSNPs | 1.0 × 10−5 –4.0 × 10−3 M | 3.2 μM | Standard glucose | [144] |

| Encapsulation and entrapment | CS-GOx-LM/GCE | CS-GOx-LM | 0.01–10 mmol·L−1 | 1.31 μmol·L−1 | Food sample-Fruit juice glucose | [145] |

| Electrodeposition | CS-GOx/Au-PtNPs-CNTs/GCE | Au-PtNPs-CNTs-GOx | 0.001–7.0 mM | 0.2 μM | Human blood, urine | [146] |

| Electrochemical deposition | CS-GOx/AuNPs/GCE | AuNPs-GOx | 5.0 × 10−5–1.30 × 10−3 M | 13 μM | Standard glucose | [147] |

| Electrochemical deposition | CS-AuNPs-GOx/PB-GCE | AuNPs-GOx | 1.0 × 10−6–1.6 × 10−3 M | 6.9 × 10−7 M | Human serum glucose | [148] |

| Electrodeposition | CS-GOx/AuNPs/AuE | AuNPs-GOx | 5.0 μM–2.4 mM | 2.7 µM | Serum glucose | [149] |

| Cross-linking | GOx-(CS-ZnO)NS-NF/PtFe(III) | ZnONS-GOx | 10 μM–11.0 mM | 1.0 µM | Standard glucose | [150] |

| Electrodeposition | CS-GOx-MWCNTs/AuE | GOx-MWCNTs | 5.0 µM–8.0 mM | 6.8 mM | Standard glucose | [151] |

| Electrodeposition | CS-GOx-Pt–PbNPs/SSNE | GOx- Pt–PbNPs | 0.03–9.0 mM | 0.03 mM | Standard glucose | [152] |

| Electrodeposition | CS-GOx-IL-MWCNTs/nanoAuE | GOx-IL-MWCNTs | 3.0 µM–9.0 mM | 1.5µM | Serum glucose | [153] |

| Adsorption | CS-GOx-AgNWs/GCE | GOx-CS-AgNWs | 10 μM–0.8 mM | 2.83 µM | Spiked serum glucose | [154] |

| Encapsulation | CS-GOx/CNT-PtNP-MTOS/GCE | CNT-PtNP-MTOS | 1.2 × 10−6–6.0 × 10−3 M | 3.0×10−7 M | Human serum glucose | [155] |

| Encapsulation | 1. CSNPs-GOx/AuE 2. CS-GOx/AuE | CSNPs-GOx | 0.001–1.0 mM | 1.1 mM | Standard glucose | [156] |

| Covalent bonding | CS-Cys-GOx/AuE | Cys-GOxc126 | 10.5–27 mM | 316.8 μM | Standard glucose | [157] |

| Sensing System | Method of Preparation | Linear Dynamic Range | Sensitivity | LOD | Target Sample | Reference |

|---|---|---|---|---|---|---|

| (CS-PVA)-GOx | Nanofibers entrapment | 0.2–50 mM | ~0.4–15 nA·mM−1 | ~0.6–1.0 mM | Brain glucose | [95] |

| CS-GOx-CdS/ACNTs-Ptnano/GCE | Electrodeposition and encapsulation | 400 μM–21.2 mM | 1.0 µA·mM−1 | 46.8 μM | Standard glucose | [120] |

| CS-BQ-GOx/Au-µE CS-CFM0-GOx/ Au-µE | Covalent bonding | 0–1.6 mM | 14.4 nA·mM−1 13.5 nA·mM−1 | 8.9 µM 11.5 µM | Standard glucose | [160] |

| (CT-GOx)n = 6/PtE | Absorption Layer-by-layer thin films | NA | NA | NA | Standard glucose detection | [162] |

| CS-TEOS-GOx/Au-SiO2µE | Entrapment-So-gel | 0–35 mM | 8.74 µA·mM−1·cm2 | 1.0 mM | Standard glucose | [165] |

| (CS-PVA-GO)Nf-GOx/PtE | Cross-linking & co-electrospinning | 5.0 μM–3.5 mM | 11.98 µA·cm−1·mM−1 | 5.0 μM | Human serum glucose | [169] |

| (CS-GOx)/TiO2NTAsE | Physical entrapment-hydrogel | 0.3–1.5 mM | 5.46 µA·mM−1 | 0.07 mM | Soft drinks, Dairy products, tomato & soy sauces | [170] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bagal-Kestwal, D.R.; Chiang, B.-H. Exploration of Chitinous Scaffold-Based Interfaces for Glucose Sensing Assemblies. Polymers 2019, 11, 1958. https://doi.org/10.3390/polym11121958

Bagal-Kestwal DR, Chiang B-H. Exploration of Chitinous Scaffold-Based Interfaces for Glucose Sensing Assemblies. Polymers. 2019; 11(12):1958. https://doi.org/10.3390/polym11121958

Chicago/Turabian StyleBagal-Kestwal, Dipali R., and Been-Huang Chiang. 2019. "Exploration of Chitinous Scaffold-Based Interfaces for Glucose Sensing Assemblies" Polymers 11, no. 12: 1958. https://doi.org/10.3390/polym11121958

APA StyleBagal-Kestwal, D. R., & Chiang, B. -H. (2019). Exploration of Chitinous Scaffold-Based Interfaces for Glucose Sensing Assemblies. Polymers, 11(12), 1958. https://doi.org/10.3390/polym11121958