Fundamentals of Global Modeling for Polymer Extrusion

Abstract

:1. Introduction

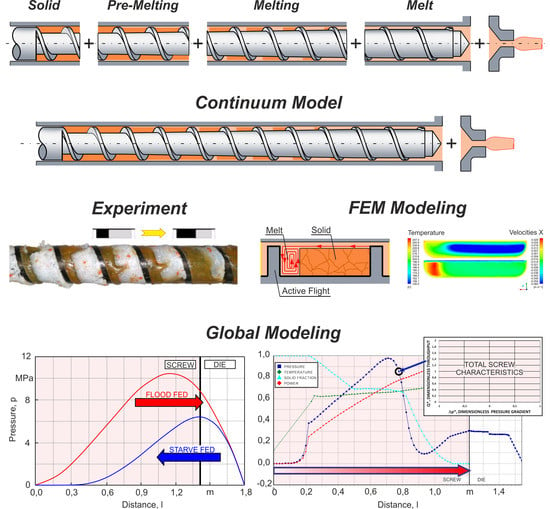

2. Modeling of the Extrusion Process

2.1. Solid Conveying Section

2.2. Melting Section

2.3. Melt Conveying Section

3. Computer Models of Extrusion

4. Global Modeling of the Extrusion Process

5. Future Concepts

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- McKelvey, J.M. Polymer Processing; John Wiley & Sons Inc.: New York, NY, USA, 1962; ISBN 978-0471584438. [Google Scholar]

- Tadmor, Z.; Klein, I. Engineering Principles of Plasticating Extrusion; Van Nostrand Reinhold, Co.: New York, NY, USA, 1970; ISBN 978-0442156350. [Google Scholar]

- White, J.L. Rubber Processing; Hanser Publishers: Munich, Germany, 1995; ISBN 978-3446166004. [Google Scholar]

- White, J.L.; Potente, H. Screw Extrusion. Science and Technology; Hanser Publishers: Munich, Germany, 2003; ISBN 978-3-446-19624-7. [Google Scholar]

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing, 2nd ed.; John Wiley & Sons Inc.: New York, NY, USA, 2006; ISBN 978-0-471-38770-1. [Google Scholar]

- White, J.L.; Kim, E.K. Twin Screw Extrusion. Technology and Principles, 2nd ed.; Hanser Publishers: Munich, Germany, 2010; ISBN 978-1569904718. [Google Scholar]

- Hensen, F.; Knappe, W.; Potente, H. Handbuch der Kunststoff-Extrusiontechnik. Grundlagen; Carl Hanser Verlag: Munich, Germany, 1989; ISBN 978-3446143395. [Google Scholar]

- Rauwendaal, C. Polymer Extrusion, 5th ed.; Carl Hanser Verlag: Munich, Germany, 2014; ISBN 978-1-56990-516-6. [Google Scholar]

- Campbell, G.A.; Spalding, M.A. Analyzing and Troubleshooting Single-Screw Extruders; Carl Hanser Verlag: Munich, Germany, 2013; ISBN 978-3-446-41371-9. [Google Scholar]

- Chung, C.I. Extrusion of Polymers. Theory and Practice, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2010; ISBN 978-1-569-904596. [Google Scholar]

- Agassant, J.F.; Avenas, P.; Carreau, P.J.; Vergnes, B.; Vincent, M. Polymer Processing. Principles and Modelling, 2nd ed.; Carl Hanser Verlag: Munich, Germany, 2017; ISBN 978-1-56990-605-7. [Google Scholar]

- Agassant, J.F.; Andersen, P.G.; Anderson, P.D.; Ban, K.; Bousmina, M.; Bumm, S.H.; Canedo, E.L.; Elemans, P.H.M.; Feke, D.L.; Feng, L.-F.; et al. Mixing and Compounding of Polymers. Theory and Practice, 2nd ed.; Manas-Zloczower, I., Ed.; Carl Hanser Verlag: Munich, Germany, 2009; ISBN 978-3-446-40773-2. [Google Scholar]

- Osswald, T.; Hernandez-Ortiz, J.P. Polymer Processing. Modeling and Simulation; Carl Hanser Verlag: Munich, Germany, 2006; ISBN 978-3-446-40381-9. [Google Scholar]

- Fisher, E.G. Extrusion of Plastics, 1st ed.; Iliffe Books Ltd.: London, UK, 1958. [Google Scholar]

- Bergen, J.T.; Bernhardt, E.C.; Beyer, C.S.; Carley, J.F.; Cash, F.M.; Dahl, R.B.; Darnell, W.H.; Hearst, T.M.; Kovach, G.P.; Marshall, D.I.; et al. Processing of Thermoplastic Materials; Bernhardt, E.C., Ed.; Reinhold Publishing Corporation: New York, NY, USA, 1959. [Google Scholar]

- Schenkel, G. Kunststoff—Extrudertechnik; Carl Hanser Verlag: Munich, Germany, 1963. [Google Scholar]

- Pearson, J.R.A. Mechanical Principles of Polymer Melt Processing; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Fenner, R.T. Extruder Screw Design; Iliffe Books Ltd.: London, UK, 1970. [Google Scholar]

- Torner, R.V. Grundprozesse der Verarbeitung von Polymeren; VEB Deutscher Verlag: Leipzig, Germany, 1974. [Google Scholar]

- Middleman, S. Fundamentals of Polymer Processing; McGraw-Hill: New York, NY, USA, 1977; ISBN 978-0070418516. [Google Scholar]

- Potente, H. Auslegen von Schneckenmaschinen Baureihen; Carl Hanser Verlag: Munich, Germany, 1981; ISBN 978-3446133846. [Google Scholar]

- Pearson, J.R.A.; Crochet, M.J.; Walters, K.; Tanner, R.I.; Fenner, R.T.; Richardson, S.M.; Denn, M.M.; Petrie, C.J.S.; Kistler, S.F.; Scriven, L.E.; et al. Computational Analysis of Polymer Processing; Pearson, J.R.A., Richardson, S.M., Eds.; Elsevier Publisher: London, UK, 1983; ISBN 978-94-009-6634-5. [Google Scholar]

- Barone, M.R.; Forger, R.D.; Bernhardt, E.C.; Tucker, C.L.; Kamal, M.R.; Michael, E.R.; Lee, C.-C.; Castro, J.M.; Richardson, S.M.; Güceri, S.I.; et al. Fundamentals of Computer Modeling for Polymer Processing; Tucker, C.T., Ed.; Hanser Publishers: New York, NY, USA, 1989; ISBN 978-3446147041. [Google Scholar]

- Rao, N.S. Computer Aided Design of Plasticating Screws: Programs in Fortran and Basic; Hanser Publishers: New York, NY, USA, 1986; ISBN 978-1569900826. [Google Scholar]

- Erwin, L.; Elmendorp, J.J.; Tucker, C.L.; Rauwendaal, C.; Dreiblatt, A.; Eise, K.; Jansen, L.P.B.M.; Nichols, R.; Manas-Zloczower, I.; Kearney, M.R.; et al. Mixing in Polymer Processing; Rauwendaal, C., Ed.; M. Dekker: New York, NY, USA, 1991; ISBN 978-0824785215. [Google Scholar]

- Bernhardt, E.C.; Bertacchi, G.; Crochet, M.J.; Debbaut, B.; Harms, R.; Mitsoulis, E.; O’Brien, K.T.; Rao, N.S.; Vlachopoulos, J.; Silvi, N.; et al. Computer Modeling for Extrusion and Other Continuous Polymer Processes; O’Brien, K.T., Ed.; Hanser Publishers: New York, NY, USA, 1992; ISBN 978-1569900680. [Google Scholar]

- Baird, D.G.; Collias, D.I. Polymer Processing: Principles and Design; Butterworth-Heinemann: Oxford, UK, 1995; ISBN 978-0750691055. [Google Scholar]

- Kohlgrüber, K. Co-Rotating Twin-Screw Extruders; Hanser Publisher: New York, NY, USA, 2008; ISBN 978-1569904220. [Google Scholar]

- Vlachopoulos, J. Polymer Rheology and Extrusion; McMaster University: Hamilton, ON, Canada, 2011. [Google Scholar]

- Hopmann, C.; Michaeli, W. Extrusion Dies for Plastics and Rubber, 4th ed.; Hanser Publisher: New York, NY, USA, 2016; ISBN 978-1-56990-623-1. [Google Scholar]

- Martelli, F. Twin–Screw Extruders: A Basic Understanding; Van Nostrand Reinhold Co.: New York, NY, USA, 1983; ISBN 978-146-841-466-0. [Google Scholar]

- Todd, D.B. Plastics Compounding; Carl Hanser Verlag: Munich, Germany, 1998; ISBN 978-344-615-861-0. [Google Scholar]

- Kramer, W.; Stewart, E.; Martin, C.; Griff, A.; Wagner, J.R.; Fisher, T.; Smith, D.; Stoughton, P.; Morgan, C.; Hovis, G.; et al. The SPE Guide on Extrusion Technology and Troubleshooting; Wagner, J.R., Vlachopoulos, J., Eds.; Society of Plastic Engineers: Brookfield, CT, USA, 2001; ISBN 978-097-221-592-3. [Google Scholar]

- Darnell, W.H.; Mol, E.A.J. Solids Conveying in Extruders. SPE J. 1956, 20, 20–29. [Google Scholar]

- Schneider, K. Der Fördervorgang in der Einzugszone eines Extruders. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, October 1968. [Google Scholar]

- Tadmor, Z.; Broyer, E. Solids Conveying in Screw Extruders—Part I: A Modified Isothermal Model. Polym. Eng. Sci. 1972, 12, 12–24. [Google Scholar] [CrossRef]

- Tadmor, Z.; Broyer, E. Solids Conveying in Screw Extruders—Part II: A Modified Non-Isothermal Model. Polym. Eng. Sci. 1972, 12, 376–378. [Google Scholar] [CrossRef]

- Campbell, G.A.; Dontula, N. Solids Transport in Extruders. Int. Polym. Proc. 1995, 10, 30–35. [Google Scholar] [CrossRef]

- Hyun, K.S.; Spalding, M.A.; Hinton, C.E. Theoretical and Experimental Analysis of Solids Conveying in Single-Screw Extruders. J. Reinf. Plast. Compos. 1997, 16, 1210–1219. [Google Scholar] [CrossRef]

- Chung, C.I. Maximum Pressure Developed by Solid Conveying Force in Screw Extruders. Polym. Eng. Sci. 1975, 15, 29–34. [Google Scholar] [CrossRef]

- Chung, C.I. Conveying in Screw Extruders. SPE-J. 1970, 26, 33–44. [Google Scholar]

- Spalding, M.A.; Hyun, K.S. Coefficients of Dynamic Friction as a Function of Temperature, Pressure, and Velocity for Several Polyethylene Resins. Polym. Eng. Sci. 1995, 35, 557–563. [Google Scholar] [CrossRef]

- Leßmann, J.-S.; Weddige, R.; Schöppner, V.; Porsch, A. Modelling the Solids Throughput of Single Screw Smooth Barrel Extruders as a Function of the Feed Section Parameters. Int. Polym. Proc. 2012, 27, 469–477. [Google Scholar] [CrossRef]

- Trippe, J.; Schöppner, V. Modeling of Solid Conveying Pressure Throughput Behavior of Single Screw Smooth Barrel Extruders under Consideration of Backpressure and High Screw Speeds. Int. Polym. Process. 2018, 33, 486–496. [Google Scholar] [CrossRef]

- Fang, S.; Chen, L.; Zhu, F. Studies on the Theory of Single Screw Plasticating Extrusion. Part II: Non-Plug Flow Solid Conveying. Polym. Eng. Sci. 1991, 31, 1117–1122. [Google Scholar] [CrossRef]

- Pohl, T.C.; Potente, H. Simulation and Analyses of the Polymer-Pellet-Flow into the First Section of a Single Screw. SPE ANTEC Tech. Papers 2001, 59, 185–189. [Google Scholar]

- Moysey, P.A.; Thompson, M.R. Investigation of Solids Transport in a Single-Screw Extruder Using a 3-D Discrete Particle Simulation. Polym. Eng. Sci. 2004, 44, 2203–2215. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Modelling the Solids Inflow and Solids Conveying of Single-Screw Extruders Using the Discrete Element Method. Powder Technol. 2005, 153, 95–107. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Determining the Collision Properties of Semi-Crystalline and Amorphous Thermoplastics for DEM Simulations of Solids Transport in an Extruder. Chem. Eng. Sci. 2007, 62, 3699–3709. [Google Scholar] [CrossRef]

- Moysey, P.A.; Thompson, M.R. Discrete Particle Simulations of Solids Compaction and Conveying in a Single-Screw Extruder. Polym. Eng. Sci. 2008, 48, 62–73. [Google Scholar] [CrossRef]

- Carrot, C.; Guillet, J.; May, J.F.; Puaux, J.-P. Modeling of the Conveying of Solid Polymer in the Feeding Zone of Intermeshing Co-Rotating Twin Screw Extruders. Polym. Eng. Sci. 1993, 33, 700–708. [Google Scholar] [CrossRef]

- Bawiskar, S.; White, J.L. Solids Conveying and Melting in a Starve Fed Self-wiping Co-Rotating Twin Screw Extruder. Int. Polym. Proc. 1995, 10, 105–110. [Google Scholar] [CrossRef]

- Potente, H.; Melisch, U.; Palluch, K.P. A Physico-Mathematical Model for Solids Conveying in Co-Rotating Twin Screw Extruders. Int. Polym. Proc. 1996, 11, 29–41. [Google Scholar] [CrossRef]

- Wong, A.C.-Y.; Liu, T.; Zhu, F. Solid Transportation in the Feeding Zone of Intermeshing Co-rotating Twin-Screw Extruders. J. Polym. Res. 2000, 7, 135–147. [Google Scholar] [CrossRef]

- Doboczky, Z. Theoretische and wirkliche Ausstoßleistung der Doppelschnecken Extruder. Plastverarbeiter 1965, 16, 395–400. [Google Scholar]

- Wilczyński, K.; White, J.L. Experimental Study of Melting in an Intermeshing Counter-Rotating Twin Screw Extruder. Int. Polym. Proc. 2001, 16, 257–262. [Google Scholar] [CrossRef]

- Maddock, B.H. A Visual Analysis of Flow and Mixing in Extruder Screws. SPE ANTEC Tech. Papers 1959, 15, 383. [Google Scholar]

- Street, L.F. Plastifying Extrusion. Intern. Plast. Eng. 1961, 1, 289–296. [Google Scholar]

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental Study for Starve-Fed Single Screw Extrusion of Thermoplastics. Polym. Eng. Sci. 2012, 52, 1258–1270. [Google Scholar] [CrossRef]

- Tadmor, Z. Fundamentals of Plasticating Extrusion. I. A Theoretical Model for Melting. Polym. Eng. Sci. 1966, 6, 185–190. [Google Scholar] [CrossRef]

- Marshall, D.I.; Klein, I. Fundamentals of Plasticating Extrusion. II. Experiments. Polym. Eng. Sci. 1966, 6, 191–197. [Google Scholar] [CrossRef]

- Tadmor, Z.; Duvdevani, I.J.; Klein, I. Melting in Plasticating Extruders Theory and Experiments. Polym. Eng. Sci. 1967, 7, 198–217. [Google Scholar] [CrossRef]

- Tadmor, Z.; Klein, I. Computer Programs for Plastic Engineers; Reinhold Book Corporation: New York, NY, USA, 1968. [Google Scholar]

- Kacir, L.; Tadmor, Z. Solids Conveying in Screw Extruders. Part III: The Delay Zone. Polym. Eng. Sci. 1972, 12, 387–395. [Google Scholar] [CrossRef]

- Menges, G.; Klenk, K.P. Melting and Plasticating of Unplasticized PVC Powder in the Screw Extruder. Kunststoffe 1967, 57, 598–603. [Google Scholar]

- Mennig, G. Observations Made in the Extrusion of Wall-Slipping Rigid PVC. Kunststoffe 1981, 71, 359–362. [Google Scholar]

- Dekker, J. Improved Screw Design for the Extrusion of Polypropylene. Kunststoffe 1976, 66, 5–7. [Google Scholar]

- Donovan, R.C. A Theoretical Melting Model for Plasticating Extruders. Polym. Eng. Sci. 1971, 11, 247–257. [Google Scholar] [CrossRef]

- Edmondson, I.R.; Fenner, R.T. Melting of Thermoplastics in Single Screw Extruders. Polymer 1975, 16, 49–56. [Google Scholar] [CrossRef]

- Cox, A.P.D.; Fenner, R.T. Melting Performance in the Single Screw Extrusion of Thermoplastics. Polym. Eng. Sci. 1980, 20, 562–571. [Google Scholar] [CrossRef]

- Lindt, J.T. A Dynamic Melting Model for a Single-Screw Extruder. Polym. Eng. Sci. 1976, 16, 284–290. [Google Scholar] [CrossRef]

- Lindt, J.T. Pressure Development in the Melting Zone of a Single-Screw Extruder. Polym. Eng. Sci. 1981, 21, 1162–1166. [Google Scholar] [CrossRef]

- Elbirli, B.; Lindt, J.T.; Gottgetreu, S.R.; Baba, S.M. Mathematical Modeling of Melting of Polymers in a Single-Screw Extruder. Polym. Eng. Sci. 1984, 24, 988–999. [Google Scholar] [CrossRef]

- Lindt, J.T.; Elbirli, B. Effect of the Cross-Channel Flow on the Melting Performance of a Single-Screw Extruder. Polym. Eng. Sci. 1985, 25, 412–418. [Google Scholar] [CrossRef]

- Shapiro, J.; Halmos, A.L.; Pearson, J.R.A. Melting in Single Screw Extruders. Polymer 1976, 17, 905–918. [Google Scholar] [CrossRef]

- Halmos, A.L.; Pearson, J.R.A.; Trottnow, R. Melting in Single Screw Extruders. Polymer 1978, 19, 1199–1216. [Google Scholar] [CrossRef]

- Vermeulen, J.R.; Gerson, P.M.; Beek, W.J. The Melting of a Bed of Polymer Granules on a Hot Moving Surface. Chem. Eng. Sci. 1971, 26, 1445–1455. [Google Scholar] [CrossRef]

- Pearson, J.R.A. On the Melting of Solids Near a Hot Moving Interface, with Particular Reference to Beds of Granular Polymers. Int. J. Heat Mass Tran. 1976, 19, 405–411. [Google Scholar] [CrossRef]

- Mount, E.M.; Watson, J.G.; Chung, C.I. Analytical Melting Model for Extrusion: Melting Rate of Fully Compacted Solid Polymers. Polym. Eng. Sci. 1982, 22, 729–737. [Google Scholar] [CrossRef]

- Potente, H. An Analytical Model of Partial and Thorough Melting in Single-Screw Extruders. Int. Polym. Proc. 1991, 6, 297–303. [Google Scholar] [CrossRef]

- Ingen Housz, J.F.; Meijer, H.E.H. The Melting Performance of Single Screw Extruders. Polym. Eng. Sci. 1981, 21, 352–359. [Google Scholar] [CrossRef]

- Ingen Housz, J.F.; Meijer, H.E.H. The Melting Performance of Single Screw Extruders. II. Polym. Eng. Sci. 1981, 21, 1156–1161. [Google Scholar] [CrossRef] [Green Version]

- Elbirli, B.; Lindt, J.T.; Gottgetreu, S.R.; Baba, S.M. Mathematical Modeling of Melting of Polymers in Barrier-Screw Extruders. Polym. Eng. Sci. 1983, 23, 86–94. [Google Scholar] [CrossRef]

- Amellal, K.; Elbirli, B. Performance Study of Barrier Screws in the Transition Zone. Polym. Eng. Sci. 1988, 28, 311–320. [Google Scholar] [CrossRef]

- Han, C.D.; Lee, K.Y.; Wheeler, N.C. A Study on the Performance of Barrier-Screw Extruders. Polym. Eng. Sci. 1991, 31, 831–841. [Google Scholar] [CrossRef]

- Rauwendaal, C. Extruder Screws with Barrier Sections. Polym. Eng. Sci. 1986, 26, 1245–1253. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A.; Covas, J.A. The Plasticating Sequence in Barrier Extrusion Screws Part I: Modeling. Polym. Eng. Sci. 2014, 54, 1791–1803. [Google Scholar] [CrossRef]

- Gaspar-Cunha, A.; Covas, J.A. The Plasticating Sequence in Barrier Extrusion Screws Part II: Experimental Assessment. Polym. Plast. Technol. 2014, 53, 1456–1466. [Google Scholar] [CrossRef]

- Grünschloß, E. A New Style Single Screw Extruder with Improved Plastification and Output Power. Int. Polym. Proc. 2002, 17, 291–300. [Google Scholar] [CrossRef]

- Grünschloß, E. A Powerful Universal Plasticating System for Single-Screw Extruders and Injection-Molding Machines. Int. Polym. Proc. 2003, 18, 226–234. [Google Scholar] [CrossRef]

- Chung, C.I.; Choi, M.; Yoon, D.; Gunning, L.; Grünschloß, E. Performance of a HELIBAR Extruder Using a Grooved Barrel. SPE ANTEC Tech. Papers 2009, 2, 1192–1196. [Google Scholar]

- Jin, X.-M.; Jia, M.-Y.; Xue, P.; Cai, J.-C.; Pan, L.; Yu, D.-Q. Study on the Melting Performance of Single Screw Extruder with Grooved Melting Zone and Barr Screw. J. Mater. Process. Tech. 2014, 12, 2834–2842. [Google Scholar] [CrossRef]

- Avila-Alfaro, J.A.; Grünschloß, E.; Epple, S.; Bonten, C. Analysis of a Single Screw Extruder with a Grooved Plasticating Barrel—Part I: The Melting Model. Int. Polym. Proc. 2015, 30, 284–296. [Google Scholar] [CrossRef]

- Kettemann, J.; Avila-Alfaro, J.A.; Bonten, C. Analysis of a Single-Screw Extruder with a Grooved Plasticizing Barrel—Experimental Investigation. Int. Polym. Proc. 2019, 34, 143–150. [Google Scholar] [CrossRef]

- Liu, T.; Wong, A.C.-Y.; Zhu, F. Prediction of Screw Length Required for Polymer Melting and Melting Characteristics. Int. Polym. Proc. 2001, 16, 113–123. [Google Scholar] [CrossRef]

- Zhu, F. Extrusion Theory and Application; China Light Industry Press: Beijing, China, 2001. [Google Scholar]

- Noriega, M.D.P.; Osswald, A.T.; Ferrier, N. In Line Measurement of the Polymer Melting Behavior in Single Screw Extruders. J. Polym. Eng. 2004, 24, 557–578. [Google Scholar] [CrossRef]

- Wang, D.; Min, K. In-Line Monitoring and Analysis of Polymer Melting Behavior in an Intermeshing Counter-Rotating Twin-Screw Extruder by Ultrasound Waves. Polym. Eng. Sci. 2005, 45, 998–1010. [Google Scholar] [CrossRef]

- Aigner, M.; Praher, B.; Kneidinger, C.; Miethlinger, J.; Steinbichler, G. Verifying the Melting Behavior in Single-Screw Plasticization Units Using a Novel Simulation Model and Experimental Method. Int. Polym. Proc. 2014, 29, 624–634. [Google Scholar] [CrossRef]

- Yu, H.; Xu, B.; Wu, H.; Turng, L.-S.; Wang, M. A Visualization of Flow Patterns of Viscoelastic Fluid Partially Filled in a Co-Rotating Nontwin Screw Extruder. Polym. Eng. Sci. 2019, 59, E24–E32. [Google Scholar] [CrossRef]

- Viriyayuthakorn, M.; Kassahun, B. A Three Dimensional Model for Plasticating Extrusion Screw Design. SPE-ANTEC Tech. Papers 1985, 30, 81–84. [Google Scholar]

- Syrjala, S. A New Approach for the Simulation of Melting in Extruders. Int. Commun. Heat Mass 2000, 27, 623–634. [Google Scholar] [CrossRef]

- Altinkaynak, A.; Gupta, M.; Spalding, M.A.; Crabtree, S.L. Melting in a Single Screw Extruder: Experiments and 3D Finite Element Simulations. Int. Polym. Proc. 2011, 26, 182–196. [Google Scholar] [CrossRef]

- Hopmann, C.; Kremer, C.; Grammel, S. Predicting the Melting Behavior Within a Single Screw Extruder Using 3D FVM simulation. In Proceedings of the Polymer Processing Society 28th Annual Meeting (PPS-28), Pattaya, Thailand, 11–15 December 2012. [Google Scholar]

- Kazmer, D.O.; Grosskopf, C.M.; Venoor, V. Vortical Fountain Flows in Plasticating Screws. Polymers 2018, 10, 823. [Google Scholar] [CrossRef] [Green Version]

- Lewandowski, A.; Wilczyński, K. General Model of Polymer Melting in Extrusion Process. Polimery 2018, 63, 444–452. [Google Scholar] [CrossRef]

- Todd, D.B. Melting of Plastics in Kneading Blocks. SPE ANTEC Tech. Papers 1992, 39, 2528–2536. [Google Scholar] [CrossRef]

- Sakai, T. The Development of On-line Techniques and Novel Processing Systems for the Monitoring and Handling of the Evolution of Microstructure in Nonreactive and Reactive Polymer Systems. Adv. Polym. Technol. 1995, 14, 277–290. [Google Scholar] [CrossRef]

- Gogos, C.G.; Tadmor, Z.; Kim, M.H. Melting Phenomena and Mechanisms in Polymer Processing Equipment. Adv. Polym. Technol. 1998, 17, 285–305. [Google Scholar] [CrossRef]

- Qian, B.; Gogos, C.G. The Importance of Plastic Energy Dissipation (PED) to the Heating and Melting of Polymer Particulates in Intermeshing Co-Rotating Twin-Screw Extruders. Adv. Polym. Technol. 2000, 19, 287–299. [Google Scholar] [CrossRef]

- Qian, B.; Todd, D.B.; Gogos, C.G. Plastic Energy Dissipation and its Role on Heating/Melting of Single-Component Polymers and Multi-Component Polymer Blends. Adv. Polym. Technol. 2003, 22, 85–95. [Google Scholar] [CrossRef]

- Potente, H.; Melisch, U. Theoretical and Experimental Investigations of the Melting of Pellets in Co-Rotating Twin-Screw Extruders. Int. Polym. Proc. 1996, 11, 101–108. [Google Scholar] [CrossRef]

- Bawiskar, S.; White, J.L. Melting Model for Modular Self Wiping Co-Rotating Twin Screw Extruders. Polym. Eng. Sci. 1998, 38, 727–740. [Google Scholar] [CrossRef]

- Vergnes, B.; Delacour, M.L.; Souveton, G.; Bouvier, J.M. A Study of Polymer Melting in a Co-Rotating Twin Screw Extruder. In Proceedings of the International Polymer Processing Society 15th Annual Meeting (PPS-15), Hertogenbosch, The Netherlands, 31 May–4 June 1999. [Google Scholar]

- Vergnes, B.; Souveton, G.; Delacour, M.L.; Ainser, A. Experimental and Theoretical Study of Polymer Melting in a Co-rotating Twin Screw Extruder. Int. Polym. Proc. 2001, 16, 351–362. [Google Scholar] [CrossRef]

- Zhu, L.; Narh, K.A.; Geng, X. Modeling of Particle-Dispersed Melting Mechanism and its Application in Corotating Twin-Screw Extrusion. J. Polym. Sci. B Polym. Phys. 2001, 39, 2461–2468. [Google Scholar] [CrossRef]

- Janssen, L.P.B.M. Twin Screw Extrusion; Elsevier Scientific Pub. Co.: Amsterdam, The Netherlands, 1978; ISBN 978-0444416292. [Google Scholar]

- Lim, S.; White, J.L. Flow Mechanisms, Material Distributions and Phase Morphology Development in a Modular Intermeshing Counter-Rotating Twin Screw Extruder of Leistritz Design. Int. Polym. Proc. 1994, 9, 33–45. [Google Scholar] [CrossRef]

- Cho, J.W.; White, J.L. Melting and Blending in a Modular Co-Rotating/Counter-Rotating Twin Screw Extruder. Int. Polyrn Proc. 1996, 11, 21–28. [Google Scholar] [CrossRef]

- Wilczyński, K.; White, J.L. Melting Model for Intermeshing Counter-Rotating Twin-Screw Extruders. Polym. Eng. Sci. 2003, 43, 1715–1726. [Google Scholar] [CrossRef]

- Wang, D.; Min, K. Experiments and Analysis of Effect of Calender Gaps on Melting of PVC Powders in an Intermeshing Counter-Rotating Twin-Screw Extruder. Int. Polym. Proc. 2006, 21, 17–23. [Google Scholar] [CrossRef]

- Wilczyński, K.; Lewandowski, A.; Wilczyński, K.J. Experimental Study of Melting of LDPE/PS Polyblend in an Intermeshing Counter-Rotating Twin Screw Extruder. Polym. Eng. Sci. 2012, 52, 449–458. [Google Scholar] [CrossRef]

- Lopez-Latorre, L.; McKelvey, J.M. Melting and Pressurization in Starve Feed Extrusion. Adv. Polym. Technol. 1984, 3, 355–364. [Google Scholar] [CrossRef]

- Isherwood, D.P.; Pieris, R.N.; Kassatly, J. The Effect of Metered Starve Feeding on the Performance of a Small Extruder. J. Eng. Ind. 1984, 106, 132–136. [Google Scholar] [CrossRef]

- Strand, S.R.; Spalding, M.A.; Hyun, S.K. Modeling of the Solids-Conveying Section of a Starve Fed Single Screw Plasticating Extruder. SPE ANTEC Tech. Papers 1992, 38, 2537–2541. [Google Scholar]

- Thompson, M.R.; Donoian, G.; Christiano, J.P. Melting Mechanism of a Starved-Fed Single-Screw Extruder for Calcium Carbonate Filled Polyethylene. Polym. Eng. Sci. 2000, 40, 2014–2026. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Wilczyński, K.J. Melting Model for Starve Fed Single Screw Extrusion of Thermoplastics. Int. Polym. Proc. 2013, 28, 34–42. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A.; Lewandowski, A.; Wilczyński, K. A Composite Model for Starve Fed Single Screw Extrusion of Thermoplastics. Polym. Eng. Sci. 2014, 54, 2362–2374. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Experimental Study for Extrusion of Polypropylene/Wood Flour Composites. Int. Polym. Proc. 2015, 30, 113–120. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Buziak, K. Study on the Flow of Wood Plastic Composites in the Starve Fed Single Screw Extrusion. Polimery 2017, 62, 680–685. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Wilczyński, K. Experimental Study of Melting of Polymer Blends in a Starve Fed Single Screw Extruder. Polym. Eng. Sci. 2016, 56, 1349–1356. [Google Scholar] [CrossRef]

- Donovan, R.C.; Thomas, D.E.; Leversen, L.D. An Experimental Study of Plasticating in a Reciprocating-Screw Injection Molding Machine. Polym. Eng. Sci. 1971, 11, 353–360. [Google Scholar] [CrossRef]

- Donovan, R.C. A Theoretical Melting Model for a Reciprocating-Screw Injection Molding Machine. Polym. Eng. Sci. 1971, 11, 361–368. [Google Scholar] [CrossRef]

- Donovan, R.C. The Plasticating Process in Injection Molding. Polym. Eng. Sci. 1974, 14, 101–111. [Google Scholar] [CrossRef]

- Lipshitz, S.D.; Lavie, R.; Tadmor, Z. A Melting Model for Reciprocating Screw Injection-Molding Machines. Polym. Eng. Sci. 1974, 14, 553–559. [Google Scholar] [CrossRef]

- Potente, H.; Schulte, H.; Effen, N. Simulation of Injection Molding and Comparison with Experimental Values. Int. Polym. Proc. 1993, 8, 224–235. [Google Scholar] [CrossRef]

- Potente, H.; Bornemann, M. Non-Isothermal Model for the Drive Power Calculation of Single-screw Plasticating Units. Int. Polym. Proc. 2008, 23, 345–350. [Google Scholar] [CrossRef]

- Iwko, J.; Steller, R.; Wróblewski, R.; Kaczmar, J. Experimental Verification of Computer Model for Polymer Plastication Process in Injection Molding. Polimery 2015, 60, 644–656. [Google Scholar] [CrossRef] [Green Version]

- Iwko, J.; Steller, R.; Wróblewski, R. Experimentally Verified Mathematical Model of Polymer Plasticization Process in Injection Molding. Polymers 2018, 10, 968. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, C.; Pontes, A.J.; Viana, J.C.; Nóbrega, J.M.; Gaspar-Cunha, A. Modeling of Plasticating Injection Molding—Experimental Assessment. Int. Polym. Proc. 2014, 29, 558–569. [Google Scholar] [CrossRef]

- Wilczyński, K.; Narowski, P. Simulation Studies on the Effect of Material Characteristics and Runner Layout Geometry on the Filling Imbalance in Geometrically Balanced Injection Molds. Polymers 2019, 11, 639. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rowell, H.S.; Finlayson, D. Screw Viscous Pumps. Engineering 1928, 126, 249. [Google Scholar]

- Carley, J.F.; Mallouk, R.S.; McKelvey, J.M. Simplified Flow Theory for Screw Extruders. Ind. Eng. Chem. 1953, 45, 974–978. [Google Scholar] [CrossRef]

- Maillefer, C. Etude Theorique et Experimentale sur le Fonctionnement des Boudineuses. Ph.D. Thesis, University of Lausanne, Lausanne, Switzerland, 1952. [Google Scholar]

- Carley, J.F.; Strub, R.A. Basic Concepts of Extrusion. Ind. Eng. Chem. 1953, 45, 970–974. [Google Scholar] [CrossRef]

- Squires, P.H. Screw Extruder Pumping Efficiency. SPE J. 1958, 14, 24–30. [Google Scholar]

- Booy, M.L. Influence of Channel Curvature on Flow, Pressure Distribution, and Power Requirements of Screw Pumps and Melt Extruders. Polym. Eng. Sci. 1963, 3, 176–185. [Google Scholar] [CrossRef]

- Squires, P.H. Screw Extrusion—Flow Patterns and Recent Theoretical Developments. Polym. Eng. Sci. 1964, 4, 7–16. [Google Scholar] [CrossRef]

- Mallouk, R.S.; McKelvey, J.M. Power Requirements of Melt Extruder. Ind. Eng. Chem. 1953, 45, 987–989. [Google Scholar] [CrossRef]

- Maddock, B.H. Effect of Wear on the Delivery Capacity of Extruder Screw. SPE J. 1959, 15, 433–434. [Google Scholar]

- Kroesser, F.W.; Middleman, S. The Calculation of Screw Characteristics for the Extrusion of Non-Newtonian Melts. Polym. Eng. Sci. 1965, 5, 230. [Google Scholar] [CrossRef]

- Middleman, S. Flow of Power Law Fluids in Rectangular Ducts. Trans. Soc. Rheol. 1965, 9, 83–93. [Google Scholar] [CrossRef]

- Colwell, R.E.; Nickolls, K.R. The Screw Extruder. Ind. Eng. Chem. 1959, 51, 841–843. [Google Scholar] [CrossRef]

- Griffith, R.M. Fully Developed Flow in Screw Extryders. Theoretical and Experimental Study. Ind. Eng. Chem. Fundam. 1962, 1, 180–187. [Google Scholar] [CrossRef]

- Zamodits, H.J.; Pearson, J.R.A. Flow of Polymer Melts in Extruders. Part I. The Effect of Transverse Flow and of a Superposed Steady Temperature Profile. Trans. Soc. Rheol. 1969, 13, 357–385. [Google Scholar] [CrossRef]

- Fenner, R.T. The Design of Large Hot Melt Extruders. Polymer 1975, 16, 298–304. [Google Scholar] [CrossRef]

- Elbirli, B.; Lindt, J.T. A Note on the Numerical Treatment of the Thermally Developing Flow in Screw Extruders. Polym. Eng. Sci. 1984, 24, 482–487. [Google Scholar] [CrossRef]

- Lindt, J.T. Flow of a Temperature Dependent Power-Law Model Fluid Between Parallel Plates: An Approximation for Flow in a Screw extruder. Polym. Eng. Sci. 1989, 29, 471–478. [Google Scholar] [CrossRef]

- Spalding, M.A.; Dooley, J.; Hyun, K.S.; Strand, S.R. Three-Dimensional Numerical Analysis of a Single-Screw Extruder. SPE ANTEC Tech. Papers 1993, 39, 1533–1541. [Google Scholar]

- Lawal, A.; Kalyon, D.M. Nonisothermal Model of Single Screw Extrusion of Generalized Newtonian Fluids. Numer. Heat Transf. A Appl. 1994, 26, 103–121. [Google Scholar] [CrossRef]

- Syrjala, S. On the Analysis of Fluid Flow and Heat Transfer in the Melt Conveying Section of a Single-Screw Extruder. Numer. Heat Transf. A Appl. 1999, 35, 25–47. [Google Scholar] [CrossRef]

- Syrjala, S. Numerical Simulation of Nanisothermal Flow of Polymer Melt in a Single-Screw Extruder. Numer. Heat Transf. A Appl. 2000, 37, 897–915. [Google Scholar] [CrossRef]

- Ilinca, F.; Hétu, J.-F. Three-Dimensional Finite Element Solution of the Flow in Single and Twin-Screw Extruders. Int. Polym. Proc. 2010, 25, 275–286. [Google Scholar] [CrossRef] [Green Version]

- Pachner, S.; Löw-Baselli, B.; Affenzeller, M.; Miethlinger, J. A Generalized 2D Output Model of Polymer Melt Flow in Single-Screw Extrusion. Int. Polym. Proc. 2017, 32, 209–216. [Google Scholar] [CrossRef]

- Marschik, C.; Roland, W.; Löw-Baselli, B.; Miethlinger, J. A Heuristic Method for Modeling Three-Dimensional Non-Newtonian Flows of Polymer Melts in Single-Screw Extruders. J. Non Newton Fluid 2017, 248, 27–39. [Google Scholar] [CrossRef]

- Marschik, C.; Roland, W.; Miethlinger, J. A Network-Theory-Based Comparative Study of Melt-Conveying Models in Single-Screw Extrusion: A. Isothermal Flow. Polymers 2018, 10, 929. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Polychronopoulos, N.D.; Vlachopoulos, J. Computer Flow Simulation of Moffatt Eddies in Single Screw Extrusion. Int. Polym. Proc. 2018, 33, 662–668. [Google Scholar] [CrossRef]

- Erdmenger, R. Mehrwellen-Schnecken in der Verfahrenstechnik. Chem. Ing. Tech. 1964, 36, 175–185. [Google Scholar] [CrossRef]

- Erdmenger, R. Schneckenmaschinen fur die Hochviskos-Verfahrenstechnik; Bayer AG: Leverkusen, Germany, 1978. [Google Scholar]

- Booy, M.L. Geometry of Fully Wiped Twin-Screw Equipment. Polym. Eng. Sci. 1978, 18, 973–984. [Google Scholar] [CrossRef]

- Booy, M.L. Isothermal Flow of Viscous Liquids in Corotating Twin Screw Devices. Polym. Eng. Sci. 1980, 20, 1220–1228. [Google Scholar] [CrossRef]

- Denson, C.D.; Hwang, B.K. The Influence of the Axial Pressure Gradient on Flow Rate for Newtonian Liquids in a Self Wiping, Co-Rotating Twin Screw Extruder. Polym. Eng. Sci. 1980, 20, 965–971. [Google Scholar] [CrossRef]

- Szydłowski, W.; White, J.L. An Improved Theory of Metering in an Intermeshing Corotating Twin-Screw Extruder. Adv. Polym. Technol. 1987, 7, 177–183. [Google Scholar] [CrossRef]

- White, J.L.; Szydłowski, W. Composite Models of Modular Intermeshing Corotating and Tangential Counter-Rotating Twin Screw Extruders. Adv. Polym. Technol. 1987, 7, 419–426. [Google Scholar] [CrossRef]

- Tayeb, J.; Vergnes, B.; Della Valle, G. Theoretical Computation of the Isothermal Flow Through the Reverse Screw Element of a Twin Screw Extrusion Cooker. J. Food Sci. 1988, 53, 616–625. [Google Scholar] [CrossRef]

- Tayeb, J.; Vergnes, B.; Della Valle, G. A Basic Model for a Twin-Screw Extruder. J. Food Sci. 1989, 54, 1047–1056. [Google Scholar] [CrossRef]

- Wang, Y.; White, J.L. Non-Newtonian Flow Modelling in the Screw Regions of an Intermeshing Corotating Twin Screw Extruder. J. Non Newton. Fluid 1989, 32, 19–38. [Google Scholar] [CrossRef]

- Wang, Y.; White, J.L.; Szydłowski, W. Flow in a Modular Intermeshing Co-Rotating Twin Screw Extruder. Int. Polym. Proc. 1989, 4, 262–269. [Google Scholar] [CrossRef]

- Chen, Z.; White, J.L. Dimensionless Non-Newtonian Isothermal Simulation and Scale-up Considerations for Modular Intermeshing Corotating Twin Screw Extruders. Int. Polym. Proc. 1991, 6, 304–310. [Google Scholar] [CrossRef]

- White, J.L.; Chen, Z. Simulation of Non-Isothermal Flow in Modular Co-Rotating Twin Screw Extrusion. Polym. Eng. Sci. 1994, 34, 229–237. [Google Scholar] [CrossRef]

- Potente, H.; Ansalh, J.; Wittemeier, R. Throughput Characteristics of Tightly Intermeshing Co-rotating Twin Screw Extruders. Int. Polym. Proc. 1990, 5, 208–216. [Google Scholar] [CrossRef]

- Todd, D.B. Drag and Pressure Flow in Twin Screw Extruders. Int. Polym. Proc. 1991, 6, 143–147. [Google Scholar] [CrossRef]

- Malik, M.; Kalyon, D.M.; Golba, J.C., Jr. Simulation of Co-Rotating Twin Screw Extrusion Process Subject to Pressure-Dependent Wall Slip at Barrel and Screw Surfaces: 3D FEM Analysis for Combinations of Forward- and Reverse-Conveying Screw Elements. Int. Polym. Proc. 2014, 29, 51–62. [Google Scholar] [CrossRef]

- Durin, A.; De Micheli, P.; Nguyen, H.-C.; David, C.; Valette, R.; Vergnes, B. Comparison between 1D and 3D Approaches for Twin-Screw Extrusion Simulation. Int. Polym. Proc. 2014, 29, 641–648. [Google Scholar] [CrossRef]

- Bravo, V.L.; Hrymak, A.N.; Wright, J.D. Numerical Simulation of Pressure and Velocity Profiles in Kneading Elements of a Co-Rotating Twin Screw Extruder. Polym. Eng. Sci. 2000, 40, 525–541. [Google Scholar] [CrossRef]

- Martin, C. Twin Screw Extruders as Continuous Mixers for Thermal Processing: A Technical and Historical Perspective. AAPS Pharm. Sci. Tech. 2016, 17, 3–19. [Google Scholar] [CrossRef]

- Martin, C. A Typical Twin Screw Extrusion Compounding Systems for Polyolefins. In Proceedings of the SPE International Polyolefins Conference, Houston, TX, USA, 26 February–1 March 2017. [Google Scholar]

- Utracki, A. Simulation of Co-Rotating Fully Intermeshing Twin-Screw Compounding Extruders. In Proceedings of the SPE International Polyolefins Conference, Houston, TX, USA, 26 February–1 March 2017. [Google Scholar]

- Martin, C. Optimum Twin Screw Extrusion Process Designs for PLA formulations. In Proceedings of the PPS Americas Regional Conference, Boston, MA, USA, 5–9 November 2018. [Google Scholar]

- Nakayama, Y.; Takemitsu, H.; Kajiwara, T.; Kimura, K.; Takeuchi, T.; Tomiyama, H. Improving Mixing Characteristics with a Pitched Tip in Kneading Elements in Twin-Screw Extrusion. AIChE J. 2018, 64, 1424–1434. [Google Scholar] [CrossRef] [Green Version]

- Kimura, Y.; Chaudhary, A.K.; Spalding, M.A. Twin-Screw Extrusion of Polyethylene. In Handbook of Industrial Polyethylene and Technology; Spalding, M.A., Chatterjee, A.M., Eds.; Scrivener Publishing LLC: Beverly, MA, USA, 2018; pp. 357–380. ISBN 978-111-915-976-6. [Google Scholar]

- Kiesskalt, S. Untersuchungen an einer Kapsel Pumpe. VDI Zeitschr. 1927, 71, 453. [Google Scholar]

- Montelius, C.O.J. Der Kogelige Danske Videnscabernes Selscabs Skrifter. Teknist Tidskaift. 1933, 6, 61–63. [Google Scholar]

- Doboczky, Z. Einschnecke–Doppelschnecke. Plastverarbeiter 1965, 16, 57–67. [Google Scholar]

- Janssen, L.P.B.M.; Mulders, L.H.R.M.; Smith, J.M. A Model from the Output of the Pump Zone of the Double Screw Processor or Extruder. Plastics Polym. 1975, 43, 93–98. [Google Scholar]

- Speur, J.A.; Mavridis, H.; Vlachopoulos, J.; Janssen, L.P.B.M. Flow Patterns in the Calender Gap of a Counterrotating Twin Screw Extruder. Adv. Polym. Technol. 1987, 7, 39–48. [Google Scholar] [CrossRef]

- White, J.L.; Adewale, A. A Unified View of Modeling Flow in Counter-rotating Twin Screw Extruders. Int. Polym. Proc. 1993, 8, 210–217. [Google Scholar] [CrossRef]

- Li, T.; Manas-Zloczower, I. Flow Field Analysis of an Intermeshing Counter-Rotating Twin Screw Extruder. Polym. Eng. Sci. 1994, 34, 551–558. [Google Scholar] [CrossRef]

- Kajiwara, T.; Nagashima, Y.; Nakano, Y.; Funatsu, K. Numerical Study of Twin-Screw Extruders by Three-Dimensional Flow Analysis-Development of Analysis Technique and Evaluation of Mixing Performance for Full Flight Screws. Polym. Eng. Sci. 1996, 36, 2142–2152. [Google Scholar] [CrossRef]

- Hong, M.-H.; White, J.L. Fluid Mechanics of Intermeshing Counter-Rotating Twin Screw Extruders. Int. Polym. Proc. 1998, 13, 342–346. [Google Scholar] [CrossRef]

- Hong, M.H.; White, J.L. Simulation of Flow in an Intermeshing Modular Counter-Rotating Twin Screw Extruder: Non-Newtonian and Non-Isothermal Behavior. Int. Polym. Proc. 1999, 14, 136–143. [Google Scholar] [CrossRef]

- Schneider, H.-P. The Historical Development of the Counter-Rotating Twin-Screw Extruder. Kunstoffe Plast. Eur. 2005, 1, 1–6. [Google Scholar]

- Wilczyński, K.; Lewandowski, A. Study on the Polymer Melt Flow in a Closely Intermeshing Counter-Rotating Twin Screw Extruder. Int. Polym. Proc. 2014, 29, 649–659. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Polyflow, CDF for Extrusion, Forming and Molding; ANSYS Inc.: Canonsburg, PA, USA, 2019. [Google Scholar]

- Wilczyński, K.J.; Lewandowski, A.; Nastaj, A.; Wilczyński, K. Modeling for Starve Fed/Flood Fed Mixing Single-Screw Extruders. Int. Polym. Proc. 2016, 31, 82–91. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Lewandowski, A.; Nastaj, A.; Wilczyński, K. A Global Model for Starve-Fed Nonconventional Single-Screw Extrusion of Thermoplastics. Adv. Polym. Technol. 2017, 36, 23–35. [Google Scholar] [CrossRef]

- Ariffin, A.; Ahmad, M.S.B. Review: Single Screw Extruder in Particulate Filler Composite. Polym. Plast. Technol. 2011, 50, 395–403. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J. Multipurpose Computer Model for Screw Processing of Plastics. Polym. Plast. Technol. 2012, 51, 626–633. [Google Scholar] [CrossRef]

- Teixeira, C.; Gaspar-Cunha, A.; Covas, J.A. Flow and Heat Transfer Along the Length of a Co-rotating Twin Screw Extruder. Polym. Plast. Technol. 2012, 51, 1567–1577. [Google Scholar] [CrossRef]

- Klein, I.; Klein, R.J. The SPR System of CAE Software. In Computer Modeling for Extrusion and Other Continuous Polymer Processes; O’Brien, K.T., Ed.; Hanser Publishers: New York, NY, USA, 1992; pp. 103–252. ISBN 978-1569900680. [Google Scholar]

- Agur, E.E.; Vlachopoulos, J. Numerical Simulation of a Single-Screw Plasticating Extruder. Polym. Eng. Sci. 1982, 22, 1084–1094. [Google Scholar] [CrossRef]

- Potente, H.; Hanhart, W.; Schöppner, V. Potential Applications for Computer-aided Extruder Design. Int. Polym. Proc. 1993, 8, 335–344. [Google Scholar] [CrossRef]

- Potente, H.; Hanhart, W.; Reski, T. Design and Processing Optimization of Extruder Screws. Polym. Eng. Sci. 1994, 34, 937–945. [Google Scholar] [CrossRef]

- Sebastian, D.H.; Rakos, R. Extrusion Process Analysis with PASS. In Computer Modeling for Extrusion and Other Continuous Polymer Processes; O’Brien, K.T., Ed.; Hanser Publishers: New York, NY, USA, 1992; pp. 331–448. ISBN 978-1569900680. [Google Scholar]

- Wilczyński, K. A Computer Model for Single-Screw Plasticating Extrusion. Polym. Plast. Technol. 1996, 35, 449–477. [Google Scholar] [CrossRef]

- Wilczyński, K. Single Screw Extrusion Model for Plasticating Extruders. Polym. Plast. Technol. 1999, 38, 581–608. [Google Scholar] [CrossRef]

- Fukase, H.; Kunio, T.; Shinya, S.; Nomura, A. A Plasticating Model for Single-Screw Extruders. Polym. Eng. Sci. 1982, 22, 578–586. [Google Scholar] [CrossRef]

- Zawadsky, E.; Karnis, J. Mathematical Model of a Single-Screw Plasticating Extruder. J. Rheol. Acta 1985, 24, 556–565. [Google Scholar] [CrossRef]

- Vincelette, A.R.; Guerrero, C.S.; Carreau, P.J.; Lafleur, P.G. A Model for Single-Screw Plasticating Extruders. Int. Polym. Proc. 1989, 4, 232–241. [Google Scholar] [CrossRef]

- Amellal, K.; Lafleur, P.G. Computer Simulation of Conventional and Barrier Screw Extruders. Plast. Rubber Compos. Process. 1993, 19, 227–239. [Google Scholar]

- Wilczyński, K.; Buziak, K.; Wilczyński, K.J.; Lewandowski, A.; Nastaj, A. Computer Modeling for Single-Screw Extrusion of Wood-Plastic Composites. Polymers 2018, 10, 295. [Google Scholar] [CrossRef] [Green Version]

- Bawiskar, S.; White, J.L. A Composite Model for Solid Conveying, Melting, Pressure and Fill Factor Profiles in Modular Co-Rotating Twin Screw Extruders. Int. Polym. Proc. 1997, 12, 331–340. [Google Scholar] [CrossRef]

- White, J.L.; Kim, B.-J.; Bawiskar, S.; Keum, J.M. Development of a Global Computer Software for Modular Self-Wiping Corotating Twin Screw Extruders. Polym. Plast. Technol. 2001, 40, 385–405. [Google Scholar] [CrossRef]

- White, J.L.; Keum, J.; Jung, H.; Ban, K.; Bumm, S. Corotating Twin-Screw Extrusion Reactive Extrusion-Devolatilization Model and Software. Polym. Plast. Technol. 2006, 45, 539–548. [Google Scholar] [CrossRef]

- Potente, H.; Ansalh, J.; Klarholz, B. Design of Tightly Intermeshing Co-Rotating Twin Screw Extruders. Int. Polym. Proc. 1994, 9, 11–25. [Google Scholar] [CrossRef]

- Potente, H.; Bastian, M.; Flecke, J. Design of a Compounding Extruder by Means of the SIGMA Simulation Software. Adv. Polym. Technol. 1999, 18, 147–170. [Google Scholar] [CrossRef]

- Vergnes, B.; Valle, G.D.; Delamare, L. A Global Computer Software for Polymer Flows in Corotating Twin Screw Extruders. Polym. Eng. Sci. 1998, 38, 1781–1792. [Google Scholar] [CrossRef]

- Canedo, E.L. Computer Simulation of Plastics Compounding Operations in Twin-Screw Extruders. SPE ANTEC Tech. Papers 1999, 45, 310–316. [Google Scholar]

- Wilczyński, K.; Jiang, Q.; White, J.L. A Composite Model for Melting, Pressure and Fill Factor Profiles in a Metered Fed Closely Intermeshing Counter-Rotating Twin Screw Extruder. Int. Polym. Proc. 2007, 22, 198–203. [Google Scholar] [CrossRef]

- Jiang, Q.; White, J.L.; Yang, J. A Global Model for Closely Intermeshing Counter-Rotating Twin Screw Extruders with Flood Feeding. Int. Polym. Proc. 2010, 25, 223–235. [Google Scholar] [CrossRef]

- Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J. Modeling of the Polymer Melt Flow in a Twin Screw Counter-Rotating Extrusion Process. Part II. Simulation and Experimental Studies—Verification of the Adopted Model. Polimery 2011, 56, 45–50. [Google Scholar] [CrossRef]

- Lewandowski, A.; Wilczyński, K.J.; Nastaj, A.; Wilczyński, K. A Composite Model for an Intermeshing Counter-Rotating Twin-Screw Extruder and its Experimental Verification. Polym. Eng. Sci. 2015, 55, 2838–2848. [Google Scholar] [CrossRef]

- Wilczyński, K.J.; Nastaj, A.; Wilczyński, K. A Computer Model for Starve-Fed Single-Screw Extrusion of Polymer Blends. Adv. Polym. Technol. 2018, 37, 2142–2151. [Google Scholar] [CrossRef]

- Wilczyński, K.; Buziak, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J. Modeling for Single Screw Extrusion of Wood Plastic Composites. In Proceedings of the Polymer Processing Society Conference (PPS2015), Graz, Austria, 21–25 September 2015; p. 170. [Google Scholar]

- Mooney, M. Explicit Formulas for Slip and Fluidity. J. Rheol. 1931, 2, 210–222. [Google Scholar] [CrossRef]

- Potente, H.; Bornemann, M.; Kurte-Jardin, M. Analytical Model for the Throughput and Drive Power Calculation in the Melting Section of Single Screw Plasticizing Units Considering Wall-Slippage. Int. Polym. Proc. 2009, 24, 23–30. [Google Scholar] [CrossRef]

- Worth, R.A.; Parnaby, J.; Helmy, H.A. Wall Slip and its Implications in the Design of Single Screw Melt-Fed Extruders. Polym. Eng. Sci. 1977, 17, 257–265. [Google Scholar] [CrossRef]

- Meijer, H.E.H.; Verbraak, C.P.J.M. Modeling of Extrusion with Slip Boundary Conditions. Polym. Eng. Sci. 1988, 28, 758–771. [Google Scholar] [CrossRef] [Green Version]

- Lawal, A.; Kalyon, D.M.; Yilmazer, U. Extrusion and Lubrication Flows of Viscoplastic Fluids with Wall Slip. Chem. Eng. Commun. 1993, 122, 127–150. [Google Scholar] [CrossRef]

- Lawal, A.; Kalyon, D.M. Single Screw Extrusion of Viscoplastic Fluids Subject to Different Slip Coefficients at Screw and Barrel Surfaces. Polym. Eng. Sci. 1994, 34, 1471–1479. [Google Scholar] [CrossRef]

- Kalyon, D.M.; Lawal, A.; Yazici, R.; Yaras, P.; Railkar, S. Mathematical Modeling and Experimental Studies of Twin-Screw Extrusion of Filled Polymers. Polym. Eng. Sci. 1999, 39, 1139–1151. [Google Scholar] [CrossRef]

- Potente, H.; Ridder, H. Pressure/Throughput Behavior of a Single-Screw Plasticising Unit in Consideration of Wall Slippage. Int. Polym. Proc. 2002, 17, 102–107. [Google Scholar] [CrossRef]

- Potente, H.; Ridder, H.; Cunha, R.V. Global Concept for Describing and Investigation of Wall Slip Effects in the Extrusion Process. Macromol. Mater. Eng. 2002, 287, 836–842. [Google Scholar] [CrossRef]

- Potente, H.; Kurte, M.; Ridder, H. Influence of Non-Newtonian Behaviour on the Processing Characteristics of Wall-Slipping Materials. Int. Polym. Proc. 2003, 18, 115–121. [Google Scholar] [CrossRef]

- Potente, H.; Kurte–Jardin, M.; Klus, S.; Timmermann, K. Two Dimensional Description of Pressure-Throughput Behaviour of Newtonian Materials Considering Wall Slippage Effects. Int. Polym. Proc. 2005, 20, 312–321. [Google Scholar] [CrossRef]

- Potente, H.; Timmermann, K.; Kurte-Jardin, M. Description of the Pressure/Throughput Behavior of a Single-Screw Plasticating Unit in Consideration of Wall Slippage Effects for Non-Newtonian Material and 1-D Flow. Int. Polym. Proc. 2006, 21, 272–282. [Google Scholar] [CrossRef]

- Ferras, L.L.; Nobrega, J.M.; Pinho, F.T.; Carneiro, O.S. Profile Extrusion Die Design: The Effect of Wall Slip. In Proceedings of the Polymer Processing Society 23rd Annual Meeting (PPS-23), Salvador, Brazil, 27–31 May 2007. [Google Scholar]

- Hatzikiriakos, S.G.; Mitsoulis, E. Slip Effects in Tapered Dies. Polym. Eng. Sci. 2009, 49, 1960–1969. [Google Scholar] [CrossRef]

- Gupta, M. Effect of Wall Slip on the Flow in a Flat Die for Sheet Extrusion. SPE ANTEC Tech. Papers 2011, 57, 1191–1196. [Google Scholar]

- Lewandowski, A.; Wilczyński, K. Global Modeling of Single Screw Extrusion with Slip Effects. Int. Polym. Proc. 2019, 34, 81–90. [Google Scholar] [CrossRef]

- Wilczyński, K.; Buziak, K.; Lewandowski, A.; Wilczyński, K.J.; Nastaj, A. Proceedings of the AIP 35th International Conference of the Polymer Processing Society, Izmir-Cesma, Turkey, 26–30 May 2019. in press.

- Bingham, E.C. Fluidity and Plasticity; McGraw-Hill: New York, NY, USA, 1922. [Google Scholar]

- Bird, R.B.; Dai, G.C.; Yarusso, B.J. The Rheology and Flow of Viscoplastic Materials. Rev. Chem. Eng. 1983, 1, 1–70. [Google Scholar] [CrossRef]

- Mitsoulis, E. Flows of Viscoplastic Materials: Models and Computations. In Rheology Reviews 2007; Binding, D.M., Hudson, N.E., Keunings, R., Eds.; The British Society of Rheology: London, UK, 2007; pp. 135–178. [Google Scholar]

- Lewandowski, A.; Wilczyński, K. Global Modeling for Single Screw Extrusion of Viscoplastics. Int. Polym. Proc. 2020, 35. in press. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilczyński, K.; Nastaj, A.; Lewandowski, A.; Wilczyński, K.J.; Buziak, K. Fundamentals of Global Modeling for Polymer Extrusion. Polymers 2019, 11, 2106. https://doi.org/10.3390/polym11122106

Wilczyński K, Nastaj A, Lewandowski A, Wilczyński KJ, Buziak K. Fundamentals of Global Modeling for Polymer Extrusion. Polymers. 2019; 11(12):2106. https://doi.org/10.3390/polym11122106

Chicago/Turabian StyleWilczyński, Krzysztof, Andrzej Nastaj, Adrian Lewandowski, Krzysztof J. Wilczyński, and Kamila Buziak. 2019. "Fundamentals of Global Modeling for Polymer Extrusion" Polymers 11, no. 12: 2106. https://doi.org/10.3390/polym11122106

APA StyleWilczyński, K., Nastaj, A., Lewandowski, A., Wilczyński, K. J., & Buziak, K. (2019). Fundamentals of Global Modeling for Polymer Extrusion. Polymers, 11(12), 2106. https://doi.org/10.3390/polym11122106