Enhancement in the Physico-Mechanical Functions of Seaweed Biopolymer Film via Embedding Fillers for Plasticulture Application—A Comparison with Conventional Biodegradable Mulch Film

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microbially Induced Calcium Carbonate Precipitation (MICP)

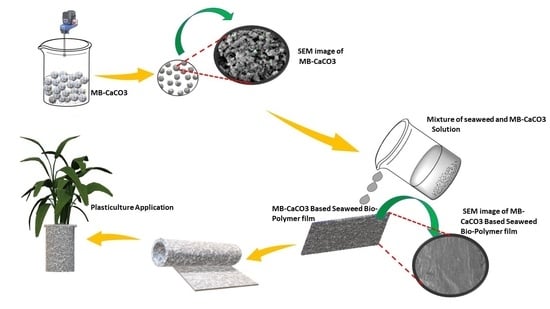

2.3. Preparation of MB–CaCO3/Seaweed and C–CaCO3/Seaweed Composite Films

2.4. Characterization Studies

2.4.1. Thickness

2.4.2. Contact Angles

2.4.3. Water Vapor Permeability

2.4.4. Optical Properties

2.4.5. Mechanical Properties

2.4.6. Thermal Properties

2.4.7. Structural Analysis-Fourier Transform Infrared (FTIR)

2.4.8. Morphological Property-Scanning Electron Microscope (SEM)

2.4.9. Soil Burial Test

2.4.10. Statistical Analysis

3. Results and Discussion

3.1. Characterization of Composite Films

3.1.1. Thickness

3.1.2. Contact Angles (CA)

3.1.3. Water Vapor Permeability

3.1.4. Mechanical Properties

3.1.5. Color and Opacity Properties

3.1.6. Thermal Properties

3.1.7. FTIR-ATR Analysis

3.1.8. Morphological Test-Scanning Electron Microscope (SEM)

3.1.9. Biodegradability: Soil Compost Test

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jafarzadeh, S.; Ariffin, F.; Mahmud, S.; Alias, A.K.; Hosseini, S.F.; Ahmad, M. Improving the physical and protective functions of semolina films by embedding a blend nanofillers (ZnO-nr and nano-kaolin). Food Packag. Shelf Life 2017, 12, 66–75. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Chong, E.W.N.; Owolabi, F.A.T.; Asniza, M.; Tye, Y.Y.; Tajarudin, H.A.; Paridah, M.T.; Rizal, S. Microbial-induced CaCO3 filled seaweed-based film for green plasticulture application. J. Clean. Prod. 2018, 199, 150–163. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Flury, M. Is Biodegradable Plastic Mulch the Solution to Agriculture’s Plastic Problem? Environ. Sci. Technol. 2017, 51, 1068–1069. [Google Scholar] [CrossRef] [PubMed]

- Vartiainen, J.; Vähä-Nissi, M.; Harlin, A. Biopolymer Films and Coatings in Packaging Applications—A Review of Recent Developments. Mater. Sci. Appl. 2014, 5, 708–718. [Google Scholar] [CrossRef]

- Hu, L.; Pan, H.; Zhou, Y.; Zhang, M. Methods to improve lignin’s reactivity as a phenol substitute and as replacement for other phenolic compounds: A brief review. BioResources 2011, 6, 3515–3525. [Google Scholar]

- Jafarzadeh, S.; Alias, A.K.; Ariffin, F.; Mahmud, S.; Najafi, A.; Sheibani, S. Characterization of a new biodegradable edible film based on semolina loaded with nano kaolin. Int. Food Res. J. 2017, 24, 304–309. [Google Scholar] [CrossRef]

- Peng, H.; Poovaiah, N.; Forrester, M.; Cochran, E.; Wang, Q. Ex Vivo Culture of Primary Intestinal Stem Cells in Collagen Gels and Foams. ACS Biomater. Sci. Eng. 2015, 1, 37–42. [Google Scholar] [CrossRef]

- Das, A.K.; Rajkumar, V.; Verma, A.K.; Swarup, D. Moringa oleiferia leaves extract: A natural antioxidant for retarding lipid peroxidation in cooked goat meat patties. Int. J. Food Sci. Technol. 2012, 48, 585–591. [Google Scholar] [CrossRef]

- Suresh Kumar, K.; Ganesan, K.; Subba Rao, P.V. Seasonal variation in nutritional composition of Kappaphycus alvarezii (Doty) Doty—An edible seaweed. J. Food Sci. Technol. 2015, 52, 2751–2760. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Tye, Y.Y.; Saurabh, C.K.; Leh, C.P.; Lai, T.K.; Chong, E.W.N.; Nurul Fazita, M.R.; Hafiidz, J.M.; Banerjee, A.; Syakir, M.I. Biodegradable polymer films from seaweed polysaccharides: A review on cellulose as a reinforcement material. Express Polym. Lett. 2017, 11, 244–265. [Google Scholar] [CrossRef]

- Siah, W.M.; Aminah, A.; Ishak, A. Edible films from seaweed (Kappaphycus alvarezii). Int. Food Res. J. 2015, 22, 2230–2236. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Saurabh, C.K.; Tye, Y.Y.; Lai, T.K.; Easa, A.M.; Rosamah, E.; Fazita, M.R.N.; Syakir, M.I.; Adnan, A.S.; Fizree, H.M.; et al. Seaweed based sustainable films and composites for food and pharmaceutical applications: A review. Renew. Sustain. Energy Rev. 2017, 77, 353–362. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Tye, Y.Y.; Chow, S.T.; Saurabh, C.K.; Tahir, P.M.; Dungani, R.; Syakir, M.I. Cellulosic pulp fiber as reinforcement materials in seaweed-based film. BioResources 2016, 12, 29–42. [Google Scholar] [CrossRef]

- Coelhoso, I.M.; Ferreira, A.R.V.; Alves, V.D. Biodegradable Barrier Membranes Based on Nanoclays and Carrageenan / Pectin Blends. Int. J. Membr. Sci. Technol. 2014, 4, 11. [Google Scholar] [CrossRef]

- Alboofetileh, M.; Rezaei, M.; Hosseini, H.; Abdollahi, M. Effect of montmorillonite clay and biopolymer concentration on the physical and mechanical properties of alginate nanocomposite films. J. Food Eng. 2013, 117, 26–33. [Google Scholar] [CrossRef]

- Maurya, S.D.; Purushothaman, M.; Krishnan, P.S.G.; Nayak, S.K. Effect of nano-calcium carbonate content on the properties of poly(urethane methacrylate) nanocomposites. J. Thermoplast. Compos. Mater. 2014, 27, 1711–1727. [Google Scholar] [CrossRef]

- Lu, D.R.; Xiao, C.M.; Xu, S.J. Starch-based completely biodegradable polymer materials. Express Polym. Lett. 2009, 3, 366–375. [Google Scholar] [CrossRef] [Green Version]

- Anbu, P.; Kang, C.H.; Shin, Y.J.; So, J.S. Formations of calcium carbonate minerals by bacteria and its multiple applications. Springerplus 2016, 5, 250. [Google Scholar] [CrossRef]

- Dhami, N.K.; Reddy, M.S.; Mukherjee, M.S. Biomineralization of calcium carbonates and their engineered applications: A review. Front. Microbiol. 2013, 4, 314. [Google Scholar] [CrossRef]

- Mokhtar, N.; Ilias, Z.S.M.; Tajarudin, H.A.; Johari, M.A.M. Optimization of HCO3-production reflect to CaCO3 precipitation for self-healing by Bacillus Sphaericus. Appl. Mech. Mater. 2015, 802, 549. [Google Scholar] [CrossRef]

- Seligra, P.G.; Jaramillo, C.M.; Famá, L.; Goyanes, S. Biodegradable and non-retrogradable eco-films based on starch–glycerol with citric acid as crosslinking agent. Carbohydr. Polym. 2016, 138, 66–74. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Johnston, M.B.; Snaith, H.J. Efficient planar heterojunction perovskite solar cells by vapour deposition. Nature 2013, 501, 395. [Google Scholar] [CrossRef]

- Arham, R.; Mulyati, M.T.; Metusalach, M.; Salengke, S. Physical and mechanical properties of agar based edible film with glycerol plasticizer. Int. Food Res. J. 2016, 23, 1669. [Google Scholar] [CrossRef]

- Monjazeb Marvdashti, L.; Koocheki, A.; Yavarmanesh, M. Alyssum homolocarpum seed gum-polyvinyl alcohol biodegradable composite film: Physicochemical, mechanical, thermal and barrier properties. Carbohydr. Polym. 2017, 155, 280–293. [Google Scholar] [CrossRef] [PubMed]

- Slavutsky, A.M.; Bertuzzi, M.A.; Armada, M. Water barrier properties of starch-clay nanocomposite films. Braz. J. Food Technol. 2012, 15, 208–218. [Google Scholar] [CrossRef] [Green Version]

- Yu, H.J.; Wang, L.; Shi, Q.; Jiang, G.H.; Zhao, Z.R.; Dong, X.C. Study on nano-CaCO3 modified epoxy powder coatings. Prog. Org. Coat. 2006, 55, 296–300. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Ariffin, F.; Mahmud, S.; Alias, A.K.; Najafi, A.; Ahmad, M. Characterization of semolina biopolymer films enriched with zinc oxide nano rods. Ital. J. Food Sci. 2017, 29, 1120–1770. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Alias, A.K.; Ariffin, F.; Mahmud, S. Physico-mechanical and microstructural properties of semolina flour films as influenced by different sorbitol/glycerol concentrations. Int. J. Food Prop. 2018, 21, 983–995. [Google Scholar] [CrossRef]

- Rhim, J.W. Effect of PLA lamination on performance characteristics of agar/κ-carrageenan/clay bio-nanocomposite film. Food Res. Int. 2013, 51, 714–722. [Google Scholar] [CrossRef]

- Tan, Z.; Yi, Y.; Wang, H.; Zhou, W.; Yang, Y.; Wang, C. Physical and degradable properties of mulching films prepared from natural fibers and biodegradable polymers. Appl. Sci. 2016, 6, 147. [Google Scholar] [CrossRef]

- Bilck, A.P.; Grossmann, M.V.E.; Yamashita, F. Biodegradable mulch films for strawberry production. Polym. Test. 2010, 29, 471–476. [Google Scholar] [CrossRef]

- Lamont, W.J. Plastics: Modifying the microclimate for the production of vegetable crops. Horttechnology 2005, 15, 477–481. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Lai, T.K.; Tye, Y.Y.; Paridah, M.T.; Fazita, M.R.N.; Azniwati, A.A.; Dungani, R.; Rizal, S. Preparation and Characterization of Microcrystalline Cellulose from Sacred Bali Bamboo as Reinforcing Filler in Seaweed-based Composite Film. Fibers Polym. 2018, 19, 423–434. [Google Scholar] [CrossRef]

- Khalil, A.P.S.A.; Yap, S.W.; Tye, Y.Y.; Tahir, P.M.; Rizal, S.; Nurul Fazit, M.R. Effects of corn starch and Kappaphycus alvarezii seaweed blend concentration on the optical, mechanical, and water vapor barrier properties of composite films. BioResources 2018, 13, 1157–1173. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Tye, Y.Y.; Ismail, Z.; Leong, J.Y.; Saurabh, C.K.; Lai, T.K.; Ni Chong, E.W.; Aditiawati, P.; Tahir, P.M.; Dungani, R. Oil palm shell nanofiller in seaweed-based composite film: Mechanical, physical, and morphological properties. BioResources 2017, 12, 5996–6010. [Google Scholar] [CrossRef]

- Uthayakumar, U.S.; Paridah, M.T.; Owolabi, F.A.T.; Gopakumar, D.A.; Rizal, S.; Amirul, A.A.; Rahman, A.A.; Alfatah, T.; Mistar, E.M.; Sri Aprilla, N.A.; et al. Neem Leaves Extract Based Seaweed Bio-degradable Composite Films with Excellent Antimicrobial Activity for Sustainable Packaging Material. BioResources 2018, 14, 700–713. [Google Scholar]

- Johnson, M.S.; Fennimore, S.A. Weed and crop response to colored plastic mulches in strawberry production. HortScience 2005, 40, 1371–1375. [Google Scholar]

- da Gois, G.S.; de Andrade, M.F.; Garcia, S.M.S.; Vinhas, G.M.; Santos, A.S.F.; Medeiros, E.S.; Oliveira, J.E.; de Almeida, Y.M.B. Soil Biodegradation of PLA/CNW Nanocomposites Modified with Ethylene Oxide Derivatives. Mater. Res. 2017, 20, 899–904. [Google Scholar] [CrossRef]

- Chung, T.-J.; Park, J.-W.; Lee, H.-J.; Kwon, H.-J.; Kim, H.-J.; Lee, Y.-K.; Tai Yin Tze, W. The Improvement of Mechanical Properties, Thermal Stability, and Water Absorption Resistance of an Eco-Friendly PLA/Kenaf Biocomposite Using Acetylation. Appl. Sci. 2018, 8, 376. [Google Scholar] [CrossRef]

- Hoidy, W.H.; Ahmad, M.B.; Al-Mulla, E.A.J.; Ibrahim, N.A.B. Preparation and characterization of polylactic acid/polycaprolactone clay nanocomposites. J. Appl. Sci. 2010, 10, 97–106. [Google Scholar] [CrossRef]

- Yuniarto, K.; Purwanto, Y.A.; Purwanto, S.; Welt, B.A.; Purwadaria, H.K.; Sunarti, T.C. Infrared and Raman studies on polylactide acid and polyethylene glycol-400 blend. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2016; Volume 1725, p. 20101. [Google Scholar] [CrossRef] [Green Version]

- Swain, S.K.; Pradhan, G.C.; Dash, S.; Mohanty, F.; Behera, L. Preparation and characterization of bionanocomposites based on soluble starch/nano CaCO3. Polym. Compos. 2018, 39, E82–E89. [Google Scholar] [CrossRef]

- Sun, Q.; Xi, T.; Li, Y.; Xiong, L. Characterization of corn starch films reinforced with CaCO3 nanoparticles. PLoS ONE 2014, 9, e106727. [Google Scholar] [CrossRef] [PubMed]

- Kisku, S.K.; Sarkar, N.; Dash, S.; Swain, S.K. Preparation of starch/PVA/CaCO3 nanobiocomposite films: Study of fire retardant, thermal resistant, gas barrier and biodegradable properties. Polym. Plast. Technol. Eng. 2014, 53, 1664–1670. [Google Scholar] [CrossRef]

- Prusty, K.; Swain, S.K. Nano CaCO3 imprinted starch hybrid polyethylhexylacrylate\polyvinylalcohol nanocomposite thin films. Carbohydr. Polym. 2016, 139, 90–98. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-W.; Han, H.-S.; Han, K.-J.; Park, J.; Jeon, H.; Ok, M.-R.; Seok, H.-K.; Ahn, J.-P.; Lee, K.E.; Lee, D.-H. Long-term clinical study and multiscale analysis of in vivo biodegradation mechanism of Mg alloy. Proc. Natl. Acad. Sci. USA 2016, 113, 716–721. [Google Scholar] [CrossRef] [PubMed]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of poly (lactide). Appl. Microbiol. Biotechnol. 2006, 72, 244–251. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Madbouly, S.A.; Schrader, J.A.; Srinivasan, G.; Grewell, D.; McCabe, K.G.; Kessler, M.R.; Graves, W.R. Characterization and biodegradation behavior of bio-based poly (lactic acid) and soy protein blends for sustainable horticultural applications. Green Chem. 2015, 17, 380–393. [Google Scholar] [CrossRef]

- Ali, N.A.; Noori, F.T.M. Gas barrier properties of biodegradable polymer nanocomposites films. Chem. Mater. Res. 2014, 6, 44–51. [Google Scholar]

| Samples | Thickness (µm) | WVP (×10−10 g·m/m2·s·Pa) | Tensile strength (N/mm2) | Young Modulus (MPa) | Elongation at break (%) |

|---|---|---|---|---|---|

| Control (no filler) | 58.20 ± 25.03 b | 3.87 ± 0.05 c | 38.32 ± 2.99 b | 182.87 ± 35.88 a | 23.26 ± 2.77 b |

| MB–CaCO3 0.15% | 60.00 ± 24.37 c | 2.05 ± 1.06 a | 58.50 ± 5.95 c | 286.79 ± 39.92 b | 29.1 ± 1.88 c |

| C–CaCO3 0.10% | 61.20 ± 24.63 d | 2.45 ± 0.05 b | 69.31 ± 0.74 d | 351.89 ± 12.71 c | 25.22 ± 1.08 bc |

| Conventional mulch | 13.4 ± 1.14 a | 2.68 ± 0.35 c | 10.45 ± 1.49 a | 159.30 ± 17.86 a | 15.66 ± 3.72 a |

| Types of Matrices | Fillers/Additives | Thickness (µm) | Water vapor permeability (WVP) (×10−10 g·m/m2·s·Pa) | Tensile Strength (N/mm2) | Young Modulus (MPa) | Elongation at Break (%) | References |

|---|---|---|---|---|---|---|---|

| Seaweed | Cellulosic pulp fiber | 74–171 | ND | 45–81 | ND | 2.5–5.4 | [13] |

| Seaweed | Microcrystalline Cellulose (MCC) | 80–15 | ND | 20.21–29.76 | ND | 13.57–19.17 | [33] |

| Seaweed/starch | none | 58.7–145.1 | 1.73–4.27 | 41.37–65.73 | 1.64–6.43 | 6.17–18.4 | [34] |

| Seaweed | Oil palm shell nanofiller | 79.1–89.0 | ND | 31.4–44.8 | 2150–3000 | 2.08–3.30 | [35] |

| Seaweed | Neem leaves | 93–112 | 4.42–9.37 | 34.55–39.95 | ND | 17.64–20.73 | [36] |

| Seaweed | MB–CaCO3 0.15% | 60.00 ± 24.37 c | 2.05 ± 1.06 a | 58.50 ± 5.95 c | 286.79 ± 39.92 b | 29.1 ± 1.88 c | This work |

| Seaweed | C–CaCO3 0.10% | 61.20 ± 24.63 d | 2.45 ± 0.05 b | 69.31 ± 0.74 d | 351.89 ± 12.71 c | 25.22 ± 1.08 bc | This work |

| Types of Films | L* | a* | b* | C* | Opacity |

|---|---|---|---|---|---|

| Control | 87.04 ± 0.04 a | −0.18 ± 0.02 d | 17.51 ± 0.07 c | 17.51 ± 0.07 c | 15.31 ± 0.01 a |

| MB–CaCO3 | 89.79 ± 0.08 c | −0.63 ± 0.07 b | 14.29 ± 1.12 b | 14.3 ± 1.12 b | 16.21 ± 0.02 b |

| C–CaCO3 | 88.34 ± 0.21 b | −0.42 ± 0.05 c | 16.80 ± 0.39 c | 16.80 ± 0.39 c | 16.84 ± 0.13 b |

| Conventional mulch | 92.79 ± 0.10 d | −0.82 ± 0.02 a | 5.48 ± 0.05 a | 5.54 ± 0.05 a | 6.34 ± 0.76 c |

| Types of filler | Ton (°C) | Tmax (°C) | Weight Loss due to Degradation (%) |

|---|---|---|---|

| Control | 210 | 226 | 85 |

| MB–CaCO3 0.15% | 226 | 249 | 80 |

| C–CaCO3 0.1% | 236 | 257 | 83 |

| Conventional mulch | 260 | 352 | 95 |

| Wave Numbers (cm−1) | Functional Groups/Bonds/Vibrations | ||

|---|---|---|---|

| Types of Films | Before Burial | After Burial | |

| Control | 3329 | 3325 | O–H stretching vibration |

| 2924 | 2908 | Stretching of aliphatic C–H | |

| 1647 | 1647 | Stretching vibration of C=O | |

| 1219 | 1219 | Sulphate ester group/ stretching vibration of S=O | |

| 1034 | 1033 | Stretching of C–O–C glycosidic bond | |

| 922 | 922 | 3, 6-anhydro-d-galactose | |

| 845 | 845 | d-galactose-4-sulphate | |

| MB–CaCO3 | 3325 | 3320 | O–H stretching vibration |

| 1646 | 1616 | Stretching vibration of C=O | |

| 1219 | 1201 | Sulphate ester group/ stretching vibration of S=O | |

| 1034 | 1026 | Stretching of C–O–C glycosidic bond | |

| 922 | 902 | 3, 6-anhydro-d-galactose | |

| 845 | 823 | d-galactose-4-sulphate | |

| C–CaCO3 | 3320 | 3302 | O-H stretching vibration |

| 2889 | 2873 | stretching of aliphatic C–H | |

| 1643 | 1639 | Stretching vibration of C=O | |

| 1219 | 1253 | Sulphate ester group/ stretching vibration of S=O | |

| 1034 | 1014 | Stretching of C–O–C glycosidic bond | |

| 922 | 925 | 3, 6-anhydro-d-galactose | |

| 845 | 848 | d-galactose-4-sulphate | |

| Conventional mulch | 2959 | 2927 | stretching of aliphatic C–H |

| 1712 | 1710 | Stretching vibration of C=O | |

| 1386 | 1386 | CH deformation and asymmetric | |

| 1361 | 1361 | CH deformation and asymmetric | |

| 1016 | 1012 | C–O–C asymmetric | |

| 699 to 729 | 679 to 723 | Stretching vibration of C=O | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

M, H.; Chong, E.W.N.; Jafarzadeh, S.; Paridah, M.T.; Gopakumar, D.A.; Tajarudin, H.A.; Thomas, S.; Abdul Khalil, H.P.S. Enhancement in the Physico-Mechanical Functions of Seaweed Biopolymer Film via Embedding Fillers for Plasticulture Application—A Comparison with Conventional Biodegradable Mulch Film. Polymers 2019, 11, 210. https://doi.org/10.3390/polym11020210

M H, Chong EWN, Jafarzadeh S, Paridah MT, Gopakumar DA, Tajarudin HA, Thomas S, Abdul Khalil HPS. Enhancement in the Physico-Mechanical Functions of Seaweed Biopolymer Film via Embedding Fillers for Plasticulture Application—A Comparison with Conventional Biodegradable Mulch Film. Polymers. 2019; 11(2):210. https://doi.org/10.3390/polym11020210

Chicago/Turabian StyleM, Hasan, E.W.N. Chong, Shima Jafarzadeh, M.T. Paridah, Deepu A. Gopakumar, H.A. Tajarudin, Sabu Thomas, and H.P.S. Abdul Khalil. 2019. "Enhancement in the Physico-Mechanical Functions of Seaweed Biopolymer Film via Embedding Fillers for Plasticulture Application—A Comparison with Conventional Biodegradable Mulch Film" Polymers 11, no. 2: 210. https://doi.org/10.3390/polym11020210

APA StyleM, H., Chong, E. W. N., Jafarzadeh, S., Paridah, M. T., Gopakumar, D. A., Tajarudin, H. A., Thomas, S., & Abdul Khalil, H. P. S. (2019). Enhancement in the Physico-Mechanical Functions of Seaweed Biopolymer Film via Embedding Fillers for Plasticulture Application—A Comparison with Conventional Biodegradable Mulch Film. Polymers, 11(2), 210. https://doi.org/10.3390/polym11020210