Valorization of Alkaline Peroxide Mechanical Pulp by Metal Chloride-Assisted Hydrotropic Pretreatment for Enzymatic Saccharification and Cellulose Nanofibrillation

Abstract

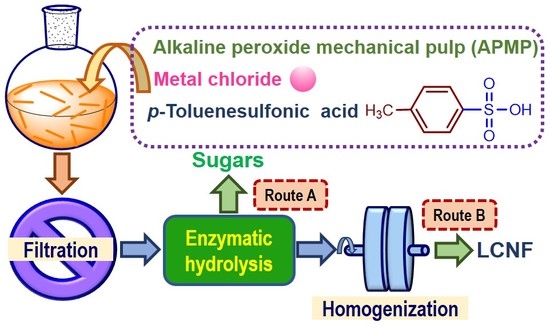

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Metal Chloride-Assisted Hydrotropic Pretreatment

2.3. Enzymatic Saccharification

2.4. Lignocellulosic Nanofibrils Production

2.5. Characterization

3. Results

3.1. Component Change of the Fibers after Pretreatments

3.2. Effect of Treatments on Fiber Morphology and Microstructure

3.3. Enzymatic Digestibility of Acid-Hydrolyzed Fraction

3.4. Properties of LCNF

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Huang, C.; Lai, C.; Wu, X.; Huang, Y.; He, J.; Huang, C.; Li, X.; Yong, Q. An integrated process to produce bio-ethanol and xylooligosaccharides rich in xylobiose and xylotriose from high ash content waste wheat straw. Bioresour. Technol. 2017, 241, 228–235. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Ma, J.; Liang, C.; Li, X.; Yong, Q. Influence of sulfur dioxide-ethanol-water pretreatment on the physicochemical properties and enzymatic digestibility of bamboo residues. Bioresour. Technol. 2018, 263, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Kamireddy, S.R.; Li, J.; Tucker, M.; Degenstein, J.; Ji, Y. Effects and mechanism of metal chloride salts on pretreatment and enzymatic digestibility of corn stover. Ind. Eng. Chem. Res. 2013, 52, 1775–1782. [Google Scholar] [CrossRef]

- Long, L.-Y.; Weng, Y.-X.; Wang, Y.-Z. Cellulose aerogels: Synthesis, applications, and prospects. Polymers 2018, 10, 623. [Google Scholar] [CrossRef]

- Chen, W.; Yu, H.; Lee, S.Y.; Wei, T.; Li, J.; Fan, Z. Nanocellulose: A promising nanomaterial for advanced electrochemical energy storage. Chem. Soc. Rev. 2018, 47, 2837–2872. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.; Hu, X.; You, X.; Sun, Y.; Wen, Y.; Yang, W.; Zhang, X.; Li, Y.; Chen, H. Hydrophobic modification of nanocellulose via a two-step silanation method. Polymers 2018, 10, 1035. [Google Scholar] [CrossRef]

- Ji, H.; Song, Y.; Zhang, X.; Tan, T. Using a combined hydrolysis factor to balance enzymatic saccharification and the structural characteristics of lignin during pretreatment of Hybrid poplar with a fully recyclable solid acid. Bioresour. Technol. 2017, 238, 575–581. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Zhou, X.; Liu, G.; Xu, Y.; Balan, V. Integrated production of gluconic acid and xylonic acid using dilute acid pretreated corn stover by two-stage fermentation. Biochem. Eng. J. 2018, 137, 18–22. [Google Scholar] [CrossRef]

- Wu, H.; Dai, X.; Zhou, S.L.; Gan, Y.Y.; Xiong, Z.Y.; Qin, Y.H.; Ma, J.; Yang, L.; Wu, Z.K.; Wang, T.L.; et al. Ultrasound-assisted alkaline pretreatment for enhancing the enzymatic hydrolysis of rice straw by using the heat energy dissipated from ultrasonication. Bioresour. Technol. 2017, 241, 70–74. [Google Scholar] [CrossRef]

- Mohtar, S.S.; Tengku Malim Busu, T.N.Z.; Md Noor, A.M.; Shaari, N.; Mat, H. An ionic liquid treatment and fractionation of cellulose, hemicellulose and lignin from oil palm empty fruit bunch. Carbohydr. Polym. 2017, 166, 291–299. [Google Scholar] [CrossRef]

- Romani, A.; Garrote, G.; Lopez, F.; Parajo, J.C. Eucalyptus globulus wood fractionation by autohydrolysis and organosolv delignification. Bioresour. Technol. 2011, 102, 5896–5904. [Google Scholar] [CrossRef] [Green Version]

- Bian, H.; Chen, L.; Dai, H.; Zhu, J.Y. Integrated production of lignin containing cellulose nanocrystals (LCNC) and nanofibrils (LCNF) using an easily recyclable di-carboxylic acid. Carbohydr. Polym. 2017, 167, 167–176. [Google Scholar] [CrossRef]

- Ferrer, A.; Quintana, E.; Filpponen, I.; Solala, I.; Vidal, T.; Rodríguez, A.; Laine, J.; Rojas, O.J. Effect of residual lignin and heteropolysaccharides in nanofibrillar cellulose and nanopaper from wood fibers. Cellulose 2012, 19, 2179–2193. [Google Scholar] [CrossRef]

- Mou, H.; Li, B.; Fardim, P. Pretreatment of corn stover with the modified hydrotropic method to enhance enzymatic hydrolysis. Energy Fuels 2014, 28, 4288–4293. [Google Scholar] [CrossRef]

- Luo, X.; Liu, J.; Wang, H.; Huang, L.; Chen, L. Comparison of hot-water extraction and steam treatment for production of high purity-grade dissolving pulp from green bamboo. Cellulose 2014, 21, 1445–1457. [Google Scholar] [CrossRef] [Green Version]

- Huang, C.; Chu, Q.; Xie, Y.; Li, X.; Jin, Y.; Min, D.; Yong, Q. Effect of kraft pulping pretreatment on the chemical composition, enzymatic digestibility, and sugar release of moso bamboo residues. Bioresources 2014, 10, 240–255. [Google Scholar] [CrossRef]

- Gabov, K.; Gosselink, R.J.; Smeds, A.I.; Fardim, P. Characterization of lignin extracted from birch wood by a modified hydrotropic process. J. Agric. Food Chem. 2014, 62, 10759–10767. [Google Scholar] [CrossRef]

- Chen, L.; Dou, J.; Ma, Q.; Li, N.; Wu, R.; Bian, H.; Yelle, D.J.; Vuorinen, T.; Fu, S.; Pan, X.; et al. Rapid and near-complete dissolution of wood lignin at ≤80 °C by a recyclable acid hydrotrope. Sci. Adv. 2017, 3, e1701735. [Google Scholar] [CrossRef]

- Dou, J.; Bian, H.; Yelle, D.J.; Ago, M.; Vajanto, K.; Vuorinen, T.; Zhu, J. Lignin containing cellulose nanofibril production from willow bark at 80 °C using a highly recyclable acid hydrotrope. Ind. Crops Prod. 2019, 129, 15–23. [Google Scholar] [CrossRef]

- Bian, H.; Gao, Y.; Yang, Y.; Fang, G.; Dai, H. Improving cellulose nanofibrillation of waste wheat straw using the combined methods of prewashing, p-toluenesulfonic acid hydrolysis, disk grinding, and endoglucanase post-treatment. Bioresour. Technol. 2018, 256, 321–327. [Google Scholar] [CrossRef]

- Bian, H.; Chen, L.; Gleisner, R.; Dai, H.; Zhu, J.Y. Producing wood-based nanomaterials by rapid fractionation of wood at 80 °C using a recyclable acid hydrotrope. Green Chem. 2017, 19, 3370–3379. [Google Scholar] [CrossRef]

- Ji, H.; Chen, L.; Zhu, J.Y.; Gleisner, R.; Zhang, X. Reaction kinetics based optimization of furfural production from corncob using a fully recyclable solid acid. Ind. Eng. Chem. Res. 2016, 55, 11253–11259. [Google Scholar] [CrossRef]

- Cheng, M.; Qin, Z.; Chen, Y.; Hu, S.; Ren, Z.; Zhu, M. Efficient extraction of cellulose nanocrystals through hydrochloric acid hydrolysis catalyzed by inorganic chlorides under hydrothermal conditions. ACS Sustain. Chem. Eng. 2017, 5, 4656–4664. [Google Scholar] [CrossRef]

- Chen, L.; Chen, R.; Fu, S. FeCl3 pretreatment of three lignocellulosic biomass for ethanol production. ACS Sustain. Chem. Eng. 2015, 3, 1794–1800. [Google Scholar] [CrossRef]

- Du, H.; Liu, C.; Mu, X.; Gong, W.; Lv, D.; Hong, Y.; Si, C.; Li, B. Preparation and characterization of thermally stable cellulose nanocrystals via a sustainable approach of FeCl3-catalyzed formic acid hydrolysis. Cellulose 2016, 23, 2389–2407. [Google Scholar] [CrossRef]

- Wu, X.; Huang, C.; Tang, W.; Huang, C.; Lai, C.; Yong, Q. Use of metal chlorides during waste wheat straw autohydrolysis to overcome the self-buffering effect. Bioresour. Technol. 2018, 268, 259–265. [Google Scholar] [CrossRef]

- Li, J.; Qiang, D.; Zhang, M.; Xiu, H.; Zhang, X. Joint action of ultrasonic and Fe3+ to improve selectivity of acid hydrolysis for microcrystalline cellulose. Carbohydr. Polym. 2015, 129, 44–49. [Google Scholar] [CrossRef]

- Mao, L.; Zhang, L.; Gao, N.; Li, A. Seawater-based furfural production via corncob hydrolysis catalyzed by FeCl3 in acetic acid steam. Green Chem. 2013, 15, 727–737. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Structural Carbohydrates and Lignin in Biomass; NREL Chemical Analysis and Testing Laboratory Analytical Procedures; NREL/TP-510-42618; NREL: Golden, CO, USA, 2008. [Google Scholar]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Vom Stein, T.; Grande, P.; Sibilla, F.; Commandeur, U.; Fischer, R.; Leitner, W.; de María, P.D. Salt-assisted organic-acid-catalyzed depolymerization of cellulose. Green Chem. 2010, 12, 1844–1849. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, X.; Shi, Y.; Gao, B.; Wu, J.; Kirk, T.B.; Xu, J.; Xue, W. Green synthesis of lignin nanoparticle in aqueous hydrotropic solution toward broadening the window for its processing and application. Chem. Eng. J. 2018, 346, 217–225. [Google Scholar] [CrossRef]

- Tripathi, A.; Ferrer, A.; Khan, S.A.; Rojas, O.J. Morphological and thermochemical changes upon autohydrolysis and microemulsion treatments of coir and empty fruit bunch residual biomass to isolate lignin-rich micro- and nanofibrillar cellulose. ACS Sustain. Chem. Eng. 2017, 5, 2483–2492. [Google Scholar] [CrossRef]

- Hu, J.; Arantes, V.; Saddler, J.N. The enhancement of enzymatic hydrolysis of lignocellulosic substrates by the addition of accessory enzymes such as xylanase: Is it an additive or synergistic effect? Biotechnol. Biofuels 2011, 4, 36. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhu, J.Y.; Fu, S.Y. Effects of lignin-metal complexation on enzymatic hydrolysis of cellulose. J. Agric. Food Chem. 2010, 58, 7233–7238. [Google Scholar] [CrossRef] [PubMed]

- Rojo, E.; Peresin, M.S.; Sampson, W.W.; Hoeger, I.C.; Vartiainen, J.; Laine, J.; Rojas, O.J. Comprehensive elucidation of the effect of residual lignin on the physical, barrier, mechanical and surface properties of nanocellulose films. Green Chem. 2015, 17, 1853–1866. [Google Scholar] [CrossRef] [Green Version]

- Jia, C.; Chen, L.; Shao, Z.; Agarwal, U.P.; Hu, L.; Zhu, J.Y. Using a fully recyclable dicarboxylic acid for producing dispersible and thermally stable cellulose nanomaterials from different cellulosic sources. Cellulose 2017, 24, 2483–2498. [Google Scholar] [CrossRef]

- Nair, S.S.; Yan, N. Effect of high residual lignin on the thermal stability of nanofibrils and its enhanced mechanical performance in aqueous environments. Cellulose 2015, 22, 3137–3150. [Google Scholar] [CrossRef]

| Sample Abbreviation 1 | Solid | Spent Liquor | |||||

|---|---|---|---|---|---|---|---|

| Glucan (%) | Xylan (%) | Acid Soluble Lignin (%) | Klason Lignin (%) | Solid Yield (%) | Glucose (g/L) | Xylose (g/L) | |

| APMP | 46.07 | 16.03 | 2.92 | 17.73 | 100 | – | – |

| P | 51.18 | 14.70 | 1.07 | 12.13 | 80.18 | ND | 1.1 |

| P–FeCl3 | 53.31 | 13.02 | 0.67 | 10.80 | 65.94 | 0.2 | 1.6 |

| P–AlCl3 | 58.59 | 13.22 | 0.83 | 9.17 | 63.32 | 0.1 | 1.6 |

| P–CuCl2 | 61.64 | 13.02 | 0.74 | 9.03 | 64.47 | 0.2 | 1.7 |

| Sample Abbreviation | Average Height (nm) | CrI (%) | Zeta Potential (mV) | TmaxⅠ (°C) | TmaxⅡ (°C) |

|---|---|---|---|---|---|

| APMP | – | 53.8 | – | 368.7 | |

| P–LCNF | 25.2 | 44.3 | –31.4 ± 1.7 | 197.0 | 282.0 |

| P–FeCl3–LCNF | 15.1 | 44.7 | –30.7 ± 1.7 | 197.2 | 282.2 |

| P–AlCl3–LCNF | 11.5 | 47.8 | –33.7 ± 2.7 | 195.5 | 280.5 |

| P–CuCl2–LCNF | 9.0 | 51.9 | –35.4 ± 1.8 | 197.6 | 282.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bian, H.; Wu, X.; Luo, J.; Qiao, Y.; Fang, G.; Dai, H. Valorization of Alkaline Peroxide Mechanical Pulp by Metal Chloride-Assisted Hydrotropic Pretreatment for Enzymatic Saccharification and Cellulose Nanofibrillation. Polymers 2019, 11, 331. https://doi.org/10.3390/polym11020331

Bian H, Wu X, Luo J, Qiao Y, Fang G, Dai H. Valorization of Alkaline Peroxide Mechanical Pulp by Metal Chloride-Assisted Hydrotropic Pretreatment for Enzymatic Saccharification and Cellulose Nanofibrillation. Polymers. 2019; 11(2):331. https://doi.org/10.3390/polym11020331

Chicago/Turabian StyleBian, Huiyang, Xinxing Wu, Jing Luo, Yongzhen Qiao, Guigan Fang, and Hongqi Dai. 2019. "Valorization of Alkaline Peroxide Mechanical Pulp by Metal Chloride-Assisted Hydrotropic Pretreatment for Enzymatic Saccharification and Cellulose Nanofibrillation" Polymers 11, no. 2: 331. https://doi.org/10.3390/polym11020331

APA StyleBian, H., Wu, X., Luo, J., Qiao, Y., Fang, G., & Dai, H. (2019). Valorization of Alkaline Peroxide Mechanical Pulp by Metal Chloride-Assisted Hydrotropic Pretreatment for Enzymatic Saccharification and Cellulose Nanofibrillation. Polymers, 11(2), 331. https://doi.org/10.3390/polym11020331