Studying a Flexible Polyurethane Elastomer with Improved Impact-Resistant Performance

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material Preparation and Molecular Structure

2.2. Quasi-Static Compression Tests and Properties

2.3. Dynamic Compression Tests at Various Strain Rates

3. Dynamic Experimental Results and Discussions

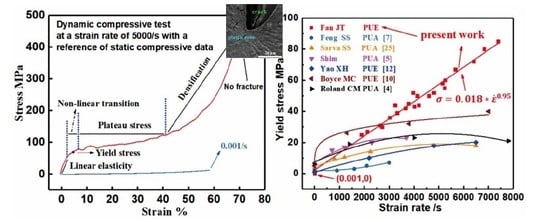

3.1. Dynamic Stress–Strain Characteristics

3.2. Strain Rate Dependency and the Improved Impact-Resistant Performance

3.3. Mechanisms of Dynamic Yielding and Straining

3.4. Mechanisms of Strain Energy Absorption and Impact Resistance

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Rocco, J.A.F.F.; Lima, J.E.S.; Lourenço, V.L.; Batista, N.L.; Botelho, E.C.; Iha, K. Dynamic mechanical properties for polyurethane elastomers applied in elastomeric mortar. J. Appl. Polym. Sci. 2012, 126, 1461–1467. [Google Scholar] [CrossRef]

- Nwosu, S.N.; Hui, D.; Dutta, P.K. Dynamic mode II delamination fracture of unidirectional graphite/epoxy composites. Compos. Part B 2003, 34, 303–316. [Google Scholar] [CrossRef]

- Qi, H.J.; Boyce, M.C. Stress-strain behavior of thermoplastic polyurethanes. Mech. Mater. 2005, 37, 817–839. [Google Scholar] [CrossRef]

- Roland, C.M.; Twigg, J.N.; Vu, Y.; Mott, P.H. High strain rate mechanical behavior of polyuria. Polymer 2007, 2, 574–578. [Google Scholar] [CrossRef]

- Shim, J.; Mohr, D. Using split Hopkinson pressure bars to perform large strain compression tests on polyurea at low, intermediate and high strain rates. Int. J. Impact Eng. 2009, 36, 1116–1127. [Google Scholar] [CrossRef]

- Li, Z.; Lambros, J. Strain rate effects on the thermomechanical behavior of polymers. Int. J. Solids Struct. 2001, 38, 3549–3562. [Google Scholar] [CrossRef]

- Bai, Y.; Liu, C.M.; Huang, G.Y.; Li, W.; Feng, S.S. A hyper-viscoelastic constitutive model for polyurea under uniaxial compressive loading. Polymers 2016, 8, 133. [Google Scholar] [CrossRef]

- Raman, S.N.; Ngo, T.; Mendis, P.; Pham, T. Elastomeric polymers for retrofitting of reinforced concrete structures against the explosive effects of blast. Adv. Mater. Sci. Eng. 2012, 754142. [Google Scholar] [CrossRef]

- Ackland, K.; Anderson, C.; Ngo, T.D. Deformation of polyurea-coated steel plates under localised blast loading. Int. J. Impact Eng. 2013, 51, 13–22. [Google Scholar] [CrossRef]

- Yi, J.; Boyce, M.C.; Lee, G.F.; Balizer, E. Large deformation rate-dependent stress-strain behavior of polyurea and polyurethanes. Polymer 2006, 47, 319–329. [Google Scholar] [CrossRef]

- Schneider, N.S.; Desper, C.R.; Illinger, J.L.; King, A.O.; Barr, D. Structural studies of crystalline MDI-based polyurethanes. J. Macromol. Sci. B 1975, 11, 527–552. [Google Scholar] [CrossRef]

- Zhang, L.H.; Yao, X.H.; Zang, S.G.; Gu, Y.B. Temperature- and strain rate-dependent constitutive modeling of the large deformation behavior of a transparent polyurethane interlayer. Polym. Eng. Sci. 2015, 55, 1864–1872. [Google Scholar] [CrossRef]

- Sonnenschein, M.F.; Rondan, N.; Wendt, B.L.; Cox, J.M. Synthesis of transparent thermoplastic polyurethane elastomers. J. Polym. Sci. Pol. Chem. 2004, 42, 271–278. [Google Scholar] [CrossRef]

- Fan, J.T.; Weerheijm, J.; Sluys, L.J. High-strain-rate tensile mechanical response of a polyurethane elastomeric material. Polymer 2015, 65, 72–80. [Google Scholar] [CrossRef]

- Kendall, M.J.; Siviour, C.R. Rate dependence of poly (vinyl chloride), the effects of plasticizer and time-temperature superposition. Phys. R. Soc. A 2014, 470, 20140012. [Google Scholar] [CrossRef]

- Fan, J.T.; Weerheijm, J.; Sluys, L.J. Dynamic compressive mechanical response of a soft polymer material. Mater. Des. 2015, 79, 73–85. [Google Scholar] [CrossRef]

- Pavlicevic, J.; Bera, O.; Jovicic, M.; Spirkova, M.; Pilic, B.; Balos, S.; Budinski-Simendic, J. The influence of ZnO nanoparticles on thermal and mechanical behavior of polycarbonate-based polyurethane composites. Compos. Part B 2014, 60, 673–679. [Google Scholar] [CrossRef]

- Levchik, S.V.; Weil, E.D. Thermal decomposition, combustion and fire-retardancy of polyurethanes—A review of the recent literature. Polym. Int. 2004, 53, 1585–1610. [Google Scholar] [CrossRef]

- Cornille, A.; Auvergne, R.; Figovsky, O.; Boutevin, B.; Caillol, S. A perspective approach to sustainable routes for non-isocyanate polyurethanes. Eur. Polym. J. 2017, 87, 535–552. [Google Scholar] [CrossRef]

- Zia, K.M.; Barikani, M.; Bhatti, I.A.; Zuber, M.; Bhatti, H.N. Synthesis and thermomechanical characterization of polyurethane elastomers extended with α, ω-alkane diols. J. Appl. Polym. Sci. 2008, 109, 1840–1849. [Google Scholar] [CrossRef]

- Matejka, L.; Spirkova, M.; Dybal, J. Structure evolution during order-disorder transitions in aliphatic polycarbonate based polyurethanes. Self-healing polymer. Chem. Eng. J. 2019, 357, 611–624. [Google Scholar] [CrossRef]

- Yilgör, I.; Yilgör, E.; Wilkes, G.L. Critical parameters in designing segmented polyurethanes and their effect on morphology and properties: A comprehensive review. Polymer 2015, 45, A1–A36. [Google Scholar] [CrossRef]

- Seidler, K.; Ehrmann, K.; Steinbauer, P. A structural reconsideration: Linear aliphatic or alicyclic hard segments for biodegradable thermoplastic polyurethanes. J. Polym. Sci. Part A 2018, 56, 2214–2224. [Google Scholar] [CrossRef]

- Mishra, A.; Maiti, P. Morphology of polyurethanes at various length scale: The influence of chain structure. J. Appl. Polym. Sci. 2015, 120, 3546–3555. [Google Scholar] [CrossRef]

- Lin, L.L.; Ma, J.Q.; Mei, Q.J. Elastomeric polyurethane foams incorporated with nanosized hydroxyapatite fillers for plastic reconstruction. Nanomaterials 2018, 8, 972. [Google Scholar] [CrossRef]

- Hoseini, Z.; Nikje, M.M.A. Synthesis and characterization of a novel thermally stable water dispersible polyurethane and its magnetic nanocomposites. Iran. Polym. J. 2018, 27, 733–743. [Google Scholar] [CrossRef]

- Liu, M.L.; Liu, T.F.; Chen, X.W. Nano-silver-incorporated biomimetic polydopamine coating on a thermoplastic polyurethane porous nanocomposite as an efficient antibacterial wound dressing. J. Nanobiotechnol. 2018, 16, 89. [Google Scholar] [CrossRef]

- Javaid, M.A.; Rizwan, M.; Khera, R.A. Thermal degradation behavior and X-ray diffraction studies of chitosan based polyurethane bio-nanocomposites using different diisocyanates. Int. J. Biol. Macromol. 2018, 117, 762–772. [Google Scholar] [CrossRef]

- Fan, J.T.; Weerheijm, J.; Sluys, L.J. Compressive response of multiple-particles-polymer systems at various strain rates. Polymer 2016, 91, 62–73. [Google Scholar] [CrossRef]

- Fan, J.T.; Weerheijm, J.; Sluys, L.J. Compressive response of a glass-polymer system at various strain rates. Mech. Mater. 2016, 95, 49–59. [Google Scholar] [CrossRef]

- Guo, H.; Guo, W.G.; Amirkhizi, A.V.; Zou, R.L.; Yuan, K.B. Experimental investigation and modeling of mechanical behaviors of polyurea over wide ranges of strain rates and temperatures. Polym. Test. 2016, 53, 234–244. [Google Scholar] [CrossRef] [Green Version]

- Sarva, S.S.; Deschanel, S.; Boyce, M.C.; Chen, W.N. Stress-strain behavior of a polyurea and a polyurethane from low to high strain rates. Polymer 2007, 48, 2208–2213. [Google Scholar] [CrossRef]

- Johnson, T.P.M.; Sarva, S.S.; Socrate, S. Comparison of low impedance split Hopkinson pressure bar techniques in the characterization of polyuria. Exp. Mech. 2010, 50, 931–940. [Google Scholar] [CrossRef]

- Davies, E.D.H.; Hunter, S.C. The dynamic compression testing of solids by the method of the split Hopkinson pressure bar. J. Mech. Phys. Solids 1963, 11, 155–179. [Google Scholar] [CrossRef]

- Mousavi, S.; Welch, K.; Valdek, U.; Lundberg, B. Non-equilibrium split Hopkinson pressure bar procedure for non-parametric identification of complex modulus. Int. J. Impact Eng. 2005, 31, 1133–1151. [Google Scholar] [CrossRef]

- Lee, O.S.; Kim, K.J. Dynamic compressive deformation behavior of rubber materials. J. Mater. Sci. 2003, 22, 1157–1160. [Google Scholar]

- Frew, D.J.; Forrestal, M.J.; Chen, W. Pulse shaping techniques for testing brittle materials with a split Hopkinson pressure bar. Exp. Mech. 2002, 42, 93–106. [Google Scholar] [CrossRef]

- Zhao, H.; Gary, G.; Klepaczko, J.R. On the use of a viscoelastic split Hopkinson pressure bar. Int. J. Impact Eng. 1997, 19, 319–330. [Google Scholar] [CrossRef]

- Field, J.E.; Walley, S.M.; Proud, W.G.; Goldrein, H.T.; Siviour, C.R. Review of experimental techniques for high rate deformation and shock studies. Int. J. Impact Eng. 2004, 30, 725–775. [Google Scholar] [CrossRef]

- Kariem, M.A.; Beynon, J.H.; Ruan, D. Misalignment effect in the split Hopkinson pressure bar technique. Int. J. Impact Eng. 2012, 47, 60–70. [Google Scholar] [CrossRef]

- Lifshitz, J.M.; Leber, H. Data-procession in the split Hopkinson pressure bar tests. Int. J. Impact Eng. 1994, 15, 723–733. [Google Scholar] [CrossRef]

- Asija, N.; Chouhan, H.; Gebremeskel, S.A.; Bhatnagar, N. High strain rate characterization of shear thickening fluids using split Hopkinson pressure bar technique. Int. J. Impact Eng. 2017, 110, 365–370. [Google Scholar] [CrossRef]

- Song, B.; Chen, W.N.; Frew, D.J. Dynamic compressive response and failure behavior of an epoxy syntactic foam. J. Compos. Mater. 2004, 38, 915–936. [Google Scholar] [CrossRef]

- Fan, J.T.; Weerheijm, J.; Sluys, L.J. Glass interface effect on high-strain-rate tensile response of a soft polyurethane elastomeric polymer material. Compos. Sci. Technol. 2015, 118, 55–62. [Google Scholar] [CrossRef]

- Richeton, J.; Ahzi, S.; Vecchio, K.S.; Jiang, F.C.; Adharapurapu, R.R. Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: Characterization and modeling of the compressive yield stress. Int. J. Solids Struct. 2006, 43, 2318–2335. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Lu, L.; Rabczuk, T. The tensile and shear failure behavior dependence on chain length and temperature in amorphous polymers. Comput. Mater. Sci. 2015, 96, 567–572. [Google Scholar] [CrossRef] [Green Version]

- Rault, J. Yielding in amorphous and semi-crystalline polymers: The compensation law. J. Non-Cryst. Solids 1998, 235, 737–741. [Google Scholar] [CrossRef]

- Song, B.; Chen, W.N.; Liu, Z.S.; Erhan, S.Z. Compressive properties of soybean oil-based polymers at quasi-static and dynamic strain rates. J. Appl. Polym. Sci. 2006, 99, 2759–2770. [Google Scholar] [CrossRef]

- Mulliken, A.D.; Boyce, M.C. Mechanics of the rate-dependent elastic-plastic deformation of glassy polymers from low to high strain rates. Int. J. Solids Struct. 2006, 43, 1331–1356. [Google Scholar] [CrossRef]

- Stachurski, Z.H. Deformation mechanisms and yield strength in amorphous polymers. Prog. Polym. Sci. 1997, 22, 407–474. [Google Scholar] [CrossRef]

- Gibbs, J.H.; Dimarzio, E.A. Nature of the glass transition and the glassy state. J. Chem. Phys. 1958, 28, 373–383. [Google Scholar] [CrossRef]

- Wosu, S.N.; Hui, D.; Daniel, L. Hygrothermal effects on the dynamic compressive properties of graphite/epoxy composite material. Compos. Part B 2012, 43, 841–855. [Google Scholar] [CrossRef]

- Goble, D.L.; Wolff, E.G. Strain-rate sensitivity index of thermoplastics. J. Mater. Sci. 1993, 28, 5986–5994. [Google Scholar] [CrossRef]

- Dasari, A.; Sarang, S.; Misra, R.D.K. Strain rate sensitivity of homopolymer polypropylenes and micrometric wollastonite-filled polypropylene composites. Mater. Sci. Eng. A 2004, 368, 191–204. [Google Scholar] [CrossRef]

- Fan, J.T. Strain rate dependent mechanical properties of a high-strength poly (methyl methacrylate). J. Appl. Polym. Sci. 2018, 135, 46189. [Google Scholar] [CrossRef]

- Fan, J.T.; Weerheijm, J.; Sluys, L.J. Deformation to fracture evolution of a flexible polymer under split Hopkinson pressure bar loading. Polym. Test. 2018, 70, 192–196. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Chen, A. Studying a Flexible Polyurethane Elastomer with Improved Impact-Resistant Performance. Polymers 2019, 11, 467. https://doi.org/10.3390/polym11030467

Fan J, Chen A. Studying a Flexible Polyurethane Elastomer with Improved Impact-Resistant Performance. Polymers. 2019; 11(3):467. https://doi.org/10.3390/polym11030467

Chicago/Turabian StyleFan, Jitang, and Ang Chen. 2019. "Studying a Flexible Polyurethane Elastomer with Improved Impact-Resistant Performance" Polymers 11, no. 3: 467. https://doi.org/10.3390/polym11030467

APA StyleFan, J., & Chen, A. (2019). Studying a Flexible Polyurethane Elastomer with Improved Impact-Resistant Performance. Polymers, 11(3), 467. https://doi.org/10.3390/polym11030467