Biosourced Disposable Trays Made of Brewer’s Spent Grain and Potato Starch

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Brewers’ Spent Grain Drying

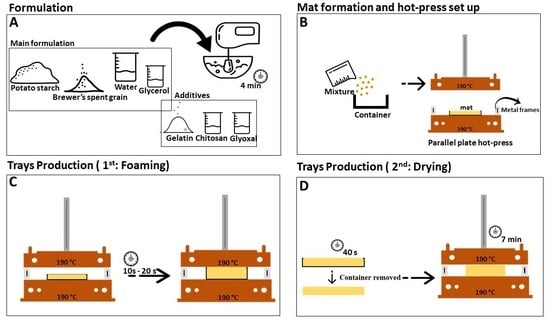

2.2.2. Trays Production

2.2.3. Coating with Beeswax

2.2.4. Trays Characterization

Scanning Electron Microscopic (SEM) Analysis

Density and Moisture Content

Mechanical Properties

Water Resistance

3. Results and Discussion

3.1. Brewer’s Spent Grain Content

3.2. Trays Morphology

3.3. Effect of Gelatin, Chitosan, Glyoxal and Beeswax on the Properties of BSG/Starch Trays

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- European Union Changing the Way We Use Plastics. Luxembourg, 2018. Available online: https://publications.europa.eu/en/publication-detail/-/publication/e6f102e3-0bb9-11e8-966a-01aa75ed71a1/language-en (accessed on 21 January 2019).

- Cruz-Tirado, J.P.; Siche, R.; Cabanillas, A.; Díaz-Sánchez, L.; Vejarano, R.; Tapia-Blácido, D.R. Properties of baked foams from oca (Oxalis tuberosa) starch reinforced with sugarcane bagasse and asparagus peel fiber. Procedia Eng. 2017, 200, 178–185. [Google Scholar] [CrossRef]

- Lawton, J.W.; Shogren, R.L.; Tiefenbacher, K.F. Aspen fiber addition improves the mechanical properties of baked cornstarch foams. Ind. Crops Prod. 2004, 19, 41–48. [Google Scholar] [CrossRef]

- Soykeabkaew, N.; Supaphol, P.; Rujiravanit, R. Preparation and characterization of jute-and flax-reinforced starch-based composite foams. Carbohydr. Polym. 2004, 58, 53–63. [Google Scholar] [CrossRef]

- Soykeabkaew, N.; Thanomsilp, C.; Suwantong, O. A review: Starch-based composite foams. Compos. Part A Appl. Sci. Manuf. 2015, 78, 246–263. [Google Scholar] [CrossRef]

- Chiellini, E.; Cinelli, P.; Ilieva, V.I.; Imam, S.H.; Lawton, J.W. Environmentally compatible foamed articles based on potato starch, corn fiber, and poly(vinyl alcohol). J. Cell. Plast. 2009, 45, 17–32. [Google Scholar] [CrossRef]

- Kaisangsri, N.; Kerdchoechuen, O.; Laohakunjit, N. Biodegradable foam tray from cassava starch blended with natural fiber and chitosan. Ind. Crops Prod. 2012, 37, 542–546. [Google Scholar] [CrossRef]

- De Carvalho, F.A.; Bilck, A.P.; Yamashita, F.; Mali, S. Baked Foams Based on Cassava Starch Coated with Polyvinyl Alcohol with a Higher Degree of Hydrolysis. J. Polym. Environ. 2018, 26, 1445–1452. [Google Scholar] [CrossRef]

- Cruz-Tirado, J.P.; Vejarano, R.; Tapia-Blácido, D.R.; Barraza-Jáuregui, G.; Siche, R. Biodegradable foam tray based on starches isolated from different Peruvian species. Int. J. Biol. Macromol. 2018, 125, 800–807. [Google Scholar] [CrossRef] [PubMed]

- Matsuda, D.K.M.; Verceheze, A.E.S.; Carvalho, G.M.; Yamashita, F.; Mali, S. Baked foams of cassava starch and organically modified nanoclays. Ind. Crops Prod. 2013, 44, 705–711. [Google Scholar] [CrossRef]

- Kaisangsri, N.; Kerdchoechuen, O.; Laohakunjit, N. Characterization of cassava starch based foam blended with plant proteins, kraft fiber, and palm oil. Carbohydr. Polym. 2014, 110, 70–77. [Google Scholar] [CrossRef]

- Chiarathanakrit, C.; Mayakun, J.; Prathep, A.; Kaewtatip, K. Comparison of the effects of calcified green macroalga (Halimeda macroloba Decaisne) and commercial CaCO3 on the properties of composite starch foam trays. Int. J. Biol. Macromol. 2019, 121, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Uslu, M.K.; Polat, S. Effects of glyoxal cross-linking on baked starch foam. Carbohydr. Polym. 2012, 87, 1994–1999. [Google Scholar] [CrossRef]

- Patel, A.K.; Mathias, J.-D.; Michaud, P. Polysaccharides as Adhesives: A Critical Review. Rev. Adhes. Adhes. 2013, 1, 312–345. [Google Scholar] [CrossRef]

- Paiva, D.; Pereira, A.M.; Pires, A.L.; Martins, J.; Carvalho, L.H.; Magalhães, F.D. Reinforcement of thermoplastic corn starch with crosslinked starch/chitosan microparticles. Polymers (Basel) 2018, 10, 985. [Google Scholar] [CrossRef]

- Monteiro, S.; Martins, J.; Magalhães, F.D.; Carvalho, L. Low density wood-based particleboards bonded with foamable sour cassava starch: Preliminary studies. Polymers (Basel) 2016, 8, 354. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, A.; Pereira, J.; Almeida, M.; Ferra, J.; Paiva, N.; Martins, J.; Magalhães, F.; Carvalho, L. Biosourced Binder for Wood Particleboards Based on Spent Sulfite Liquor and Wheat Flour. Polymers (Basel) 2018, 10, 1070. [Google Scholar] [CrossRef]

- Waterschoot, J.; Gomand, S.V.; Fierens, E.; Delcour, J.A. Production, structure, physicochemical and functional properties of maize, cassava, wheat, potato and rice starches. Starch/Staerke 2015, 67, 14–29. [Google Scholar] [CrossRef]

- Wang, W.; Chen, W.; Yang, H.; Cui, M. Textural and rheological properties of potato starch as affected by amino acids. Int. J. Food Prop. 2018, 20, S3123–S3134. [Google Scholar] [CrossRef]

- European Starch Industry Association EU Starch Market Data. Available online: https://www.starch.eu/the-european-starch-industry/#data (accessed on 23 January 2019).

- Łaba, W.; Piegza, M.; Kawa-Rygielska, J. Evaluation of brewer’s spent grain as a substrate for production of hydrolytic enzymes by keratinolytic bacteria. J. Chem. Technol. Biotechnol. 2017, 92, 1389–1396. [Google Scholar] [CrossRef]

- Ivanova, K.; Denkova, R.; Kostov, G.; Petrova, T.; Bakalov, I.; Ruscova, M.; Penov, N. Extrusion of brewers’ spent grains and application in the production of functional food. Characteristics of spent grains and optimization of extrusion. J. Inst. Brew. 2017, 123, 544–552. [Google Scholar] [CrossRef]

- Ikram, S.; Huang, L.Y.; Zhang, H.; Wang, J.; Yin, M. Composition and Nutrient Value Proposition of Brewers Spent Grain. J. Food Sci. 2017, 82, 2232–2242. [Google Scholar] [CrossRef] [Green Version]

- Mullen, A.; Álvarez, C.; Pojic, M.; Hadnadev, T.; Papageorgiou, M. Food Waste Recovery: Processing Technologies and Industrial Techniques; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2015; p. 28. ISBN 9780128004197. [Google Scholar]

- Fratini, F.; Cilia, G.; Turchi, B.; Felicioli, A. Beeswax: A minireview of its antimicrobial activity and its application in medicine. Asian Pac. J. Trop. Med. 2016, 9, 839–843. [Google Scholar] [CrossRef]

- FAO Beeswax—Useful and Valuable Product. Available online: http://www.fao.org/docrep/006/y5110e/y5110e07.htm (accessed on 30 January 2019).

- Gomez-Guillen, M.C.; Gimenez, B.; Lopez-Caballero, M.E.; Montero, M.P. Functional and bioactive properties of collagen and gelatin from alternative sources: A review. Food Hydrocoll. 2011, 25, 1813–1827. [Google Scholar] [CrossRef] [Green Version]

- Duconseille, A.; Astruc, T.; Quintana, N.; Meersman, F.; Sante-Lhoutellier, V. Gelatin structure and composition linked to hard capsule dissolution: A review. Food Hydrocoll. 2015, 43, 360–376. [Google Scholar] [CrossRef]

- Kumar, M.N.V.R. A review of chitin and chitosan applications. React. Funct. Polym. 2000, 46, 1–27. [Google Scholar] [CrossRef]

- Radusch, H.-J.; Osswald, F.; Anton, W.; Kolesov, I.; Glomb, M.A.; Spanneberg, R. Model Studies on Chemical and Textural Modifications in Gelatin Films by Reaction with Glyoxal and Glycolaldehyde. J. Agric. Food Chem. 2010, 58, 3580–3585. [Google Scholar]

- International Organization for Standardization. Plastics—Determination of Flexural Properties; EN ISO 178: 2003; International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

| BSG (g/100 g Solids) | Potato Starch (g/100 g Solids) | Glycerol (g/100 g Solids) | Deionized Water (g/100 g Formulation) | Gelatin (g/100 g Solids) | Chitosan (g/100 g Solids) | Glyoxal (g/100 g Solids) |

|---|---|---|---|---|---|---|

| 20.0 | 76.7 | 3.3 | 50 | - | - | - |

| 40.0 | 56.7 | 3.3 | 50 | - | - | - |

| 60.0 | 36.7 | 3.3 | 50 | - | - | - |

| 80.0 | 16.7 | 3.3 | 50 | - | - | - |

| 60.0 | 35.7 | 3.3 | 50 | 1 | - | - |

| 60.0 | 35.7 | 3.3 | 50 | 1 | - | 0.02 |

| 60.9 | 32.7 | 3.3 | 49.6 | - | 3.0 | - |

| 60.0 | 32.1 | 3.3 | 50 | - | 3.0 | 1.6 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferreira, A.M.; Martins, J.; Carvalho, L.H.; Magalhães, F.D. Biosourced Disposable Trays Made of Brewer’s Spent Grain and Potato Starch. Polymers 2019, 11, 923. https://doi.org/10.3390/polym11050923

Ferreira AM, Martins J, Carvalho LH, Magalhães FD. Biosourced Disposable Trays Made of Brewer’s Spent Grain and Potato Starch. Polymers. 2019; 11(5):923. https://doi.org/10.3390/polym11050923

Chicago/Turabian StyleFerreira, Ana M., Jorge Martins, Luísa H. Carvalho, and Fernão D. Magalhães. 2019. "Biosourced Disposable Trays Made of Brewer’s Spent Grain and Potato Starch" Polymers 11, no. 5: 923. https://doi.org/10.3390/polym11050923

APA StyleFerreira, A. M., Martins, J., Carvalho, L. H., & Magalhães, F. D. (2019). Biosourced Disposable Trays Made of Brewer’s Spent Grain and Potato Starch. Polymers, 11(5), 923. https://doi.org/10.3390/polym11050923