In Situ WAXD and SAXS during Tensile Deformation Of Moulded and Sintered Polyamide 12

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Sample Preparation

2.2. Mechanical Test

2.3. X-ray Analysis

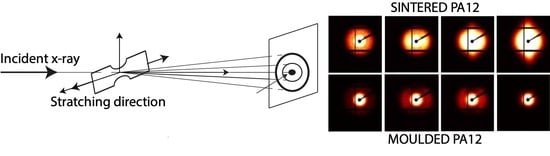

- simultaneous SAXS and 1D WAXD patterns were recorded with a Pilatus 1M detector and a Pilatus 3K respectively, with a pixel size of 172 × 172 m. The sample to detector distance was 2410 mm for SAXS measurements, resulting in a maximum detectable dimension of 30 nm, and 275 mm for the 1D WAXD measurements.

- 2D WAXD patters were collected with a FReLon 2000 with a pixel size of 46.3 m and placed at 147 mm from the sample.

2.3.1. Data Reduction

2.3.2. WAXD Analysis

2.3.3. SAXS Analysis

3. Results and Discussion

3.1. Tensile Test Results

3.2. 2D WAXD Results

3.2.1. 2D WAXD Results: Compression Moulded PA12

- at very low macroscopic strain, the increases linearly, following the elastic macroscopic deformation. Just before the yield point, starts to increase faster as depicted by the change in slope. Immediately after yielding, the slope becomes steeper: this can be rationalized by considering that the sample starts to neck and the cross section reduces resulting in an increase of the local stress. Eventually, a plateau value is reached when the growth of the neck slows down and becomes stable. The first change in slope can be identified as the onset of plastic crystal deformation.

- The increase of shows a clear temperature dependence: at 10 C, the increase of the is always faster (and larger) than the case at 24 C indicating that the transmitted stress to the crystals determines a faster crystal plane deformation. At 120 C, the remains almost constant: at such high temperature, the resulting stress on crystals is much lower and it does not result in a significant change in d-spacing.

- In contrast to the , shows an opposite trend: in the linear-elastic regime, it remains constant until, in correspondence with the change in the slope of , it starts to rapidly decrease and it reaches a plateau level after the yield point. Once again, this can be explained considering that the material is necking and high strain localizations are present in the sample. This sudden change of slope just before the yield point marks the onset of crystal plasticity.

- Remarkably, the final plateau value of both and is reached in correspondence with the same macroscopic strain. At 120 C, a different trend can be seen: in contrast with to the , the slowly decreases with increasing stress.

3.2.2. 2D WAXD Results: Laser Sintered PA12

3.3. SAXS Results

3.3.1. SAXS Results: Compression Moulded PA12

3.3.2. SAXS Results: Laser Sintered PA12

- at 10 C, for moulded PA12, voids start to appear before yielding and the fraction decreases during softening. A similar trend is found at 24 C but, in these cases, the void fraction remains nearly constant with increasing strain. Two possible explanations can be given for this behaviour: the cavities grow to larger dimensions and they are too big to be detected or, due to high voids’ elongation, the negative hydrostatic stress, responsible for the void formation, reduces causing voids to collapse [28].

- for sintered PA12, the void fractions at 10 C and 24 C rapidly increase in correspondence with the beginning of plastic deformation, i.e., right before yielding of the sample. As expected, this fast increase is more pronounced at low temperature.

- At 120 C, the void fractions are much lower than those obtained at low temperature. Both moulded and sintered PA12 show the same trend: the void fraction slightly increases after the macroscopic yield. This increase in is higher for sintered material than moulded where the fraction of void is almost zero.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pinkerton, A.J. Lasers in additive manufacturing. Opt. Laser Technol. 2016, 78, 25–32. [Google Scholar] [CrossRef]

- Goodridge, R.; Tuck, C.; Hague, R. Laser sintering of polyamides and other polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Zarringhalam, H.; Hopkinson, N.; Kamperman, N.; De Vlieger, J. Effects of processing on microstructure and properties of SLS Nylon 12. Mater. Sci. Eng. A 2006, 435, 172–180. [Google Scholar] [CrossRef]

- Ameen, W.; Ghaleb, A.M.; Alatefi, M.; Alkhalefah, H.; Alahmari, A. An overview of selective laser sintering and melting research using bibliometric indicators. Virtual Phys. Prototyp. 2018, 13, 282–291. [Google Scholar] [CrossRef]

- Van Hooreweder, B.; De Coninck, F.; Moens, D.; Boonen, R.; Sas, P. Microstructural characterization of SLS-PA12 specimens under dynamic tension/compression excitation. Polym. Test. 2010, 29, 319–326. [Google Scholar] [CrossRef]

- Salazar, A.; Rico, A.; Rodríguez, J.; Escudero, J.S.; Seltzer, R.; de la Escalera Cutillas, F.M. Fatigue crack growth of SLS polyamide 12: Effect of reinforcement and temperature. Compos. Part B Eng. 2014, 59, 285–292. [Google Scholar] [CrossRef]

- Van Hooreweder, B.; Moens, D.; Boonen, R.; Kruth, J.P.; Sas, P. On the difference in material structure and fatigue properties of nylon specimens produced by injection molding and selective laser sintering. Polym. Test. 2013, 32, 972–981. [Google Scholar] [CrossRef]

- Wu, J.; Xu, X.; Zhao, Z.; Wang, M.; Zhang, J. Study in performance and morphology of polyamide 12 produced by selective laser sintering technology. Rapid Prototyp. J. 2018, 24, 813–820. [Google Scholar] [CrossRef]

- Sutton, A.T.; Kriewall, C.S.; Leu, M.C.; Newkirk, J.W. Powder characterisation techniques and effects of powder characteristics on part properties in powder-bed fusion processes. Virtual Phys. Prototyp. 2017, 12, 3–29. [Google Scholar] [CrossRef]

- Strondl, A.; Lyckfeldt, O.; Brodin, H.; Ackelid, U. Characterization and control of powder properties for additive manufacturing. JOM 2015, 67, 549–554. [Google Scholar] [CrossRef]

- Manshoori Yeganeh, A.; Movahhedy, M.; Khodaygan, S. An efficient scanning algorithm for improving accuracy based on minimising part warping in selected laser sintering process. Virtual Phys. Prototyp. 2019, 14, 59–78. [Google Scholar] [CrossRef]

- Butler, M.F.; Donald, A.M.; Ryan, A.J. Time resolved simultaneous small-and wide-angle X-ray scattering during polyethylene deformation—II. Cold drawing of linear polyethylene. Polymer 1998, 39, 39–52. [Google Scholar] [CrossRef]

- Bowden, P.; Young, R. Deformation mechanisms in crystalline polymers. J. Mater. Sci. 1974, 9, 2034–2051. [Google Scholar] [CrossRef]

- Xiong, B.; Lame, O.; Chenal, J.M.; Rochas, C.; Seguela, R.; Vigier, G. In-situ SAXS study of the mesoscale deformation of polyethylene in the pre-yield strain domain: Influence of microstructure and temperature. Polymer 2014, 55, 1223–1227. [Google Scholar] [CrossRef]

- Xiong, B.; Lame, O.; Chenal, J.M.; Rochas, C.; Seguela, R.; Vigier, G. Temperature-microstructure mapping of the initiation of the plastic deformation processes in polyethylene via in situ WAXS and SAXS. Macromolecules 2015, 48, 5267–5275. [Google Scholar] [CrossRef]

- Humbert, S.; Lame, O.; Vigier, G. Polyethylene yielding behaviour: What is behind the correlation between yield stress and crystallinity? Polymer 2009, 50, 3755–3761. [Google Scholar] [CrossRef]

- Aboulfaraj, M.; G’sell, C.; Ulrich, B.; Dahoun, A. In situ observation of the plastic deformation of polypropylene spherulites under uniaxial tension and simple shear in the scanning electron microscope. Polymer 1995, 36, 731–742. [Google Scholar] [CrossRef]

- Galeski, A. Strength and toughness of crystalline polymer systems. Prog. Polym. Sci. 2003, 28, 1643–1699. [Google Scholar] [CrossRef]

- Paolucci, F. Characterisation of Crystallisation Kinetics and Mechanical Properties of Polyamide 12. Ph.D. Thesis, Technical University of Eindhoven, Eindhoven, The Netherlands, 2019. [Google Scholar]

- Bras, W.; Dolbnya, I.; Detollenaere, D.; Tol, R.V.; Malfois, M.; Greaves, G.; Ryan, A.; Heeley, E. Recent experiments on a small-angle/wide-angle X-ray scattering beam line at the ESRF. J. Appl. Crystallogr. 2003, 36, 791–794. [Google Scholar] [CrossRef] [Green Version]

- Paolucci, F.; Baeten, D.; Roozemond, P.; Goderis, B.; Peters, G. Quantification of isothermal crystallization of polyamide 12: Modelling of crystallization kinetics and phase composition. Polymer 2018, 155, 187–198. [Google Scholar] [CrossRef] [Green Version]

- Porod, G. Die Röntgenkleinwinkelstreuung von dichtgepackten kolloiden Systemen. Colloid Polym. Sci. 1951, 124, 83–114. [Google Scholar] [CrossRef]

- Debye, P.; Bueche, A. Scattering by an inhomogeneous solid. J. Appl. Phys. 1949, 20, 518–525. [Google Scholar] [CrossRef]

- Zhang, H.; Scholz, A.K.; De Crevoisier, J.; Vion-Loisel, F.; Besnard, G.; Hexemer, A.; Brown, H.R.; Kramer, E.J.; Creton, C. Nanocavitation in carbon black filled styrene–butadiene rubber under tension detected by real time small angle X-ray scattering. Macromolecules 2012, 45, 1529–1543. [Google Scholar] [CrossRef]

- Li, L.; Koch, M.; De Jeu, W. Crystalline structure and morphology in nylon-12: A small- and wide-angle X-ray scattering study. Macromolecules 2003, 36, 1626–1632. [Google Scholar] [CrossRef]

- Wang, D.; Shao, C.; Zhao, B.; Bai, L.; Wang, X.; Yan, T.; Li, J.; Pan, G.; Li, L. Deformation-induced phase transitions of polyamide 12 at different temperatures: an in situ wide-angle X-ray scattering study. Macromolecules 2010, 43, 2406–2412. [Google Scholar] [CrossRef]

- Dencheva, N.; Nunes, T.G.; Oliveira, M.J.; Denchev, Z. Crystalline structure of polyamide 12 as revealed by solid-state 13C NMR and synchrotron WAXS and SAXS. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 3720–3733. [Google Scholar] [CrossRef]

- Caelers, H.; Troisi, E.; Govaert, L.; Peters, G. Deformation-induced phase transitions in iPP polymorphs. Polymers 2017, 9, 547. [Google Scholar] [CrossRef]

- Humbert, S.; Lame, O.; Chenal, J.; Rochas, C.; Vigier, G. New insight on initiation of cavitation in semicrystalline polymers: in situ SAXS measurements. Macromolecules 2010, 43, 7212–7221. [Google Scholar] [CrossRef]

- Castagnet, S.; Deburck, Y. Relative influence of microstructure and macroscopic triaxiality on cavitation damage in a semi-crystalline polymer. Mater. Sci. Eng. A 2007, 448, 56–66. [Google Scholar] [CrossRef]

- Capaccio, G.; Ward, I. Effect of molecular weight on the morphology and drawing behaviour of melt crystallized linear polyethylene. Polymer 1975, 16, 239–243. [Google Scholar] [CrossRef]

- Hubert, L.; David, L.; Séguéla, R.; Vigier, G. Small-angle X-ray scattering investigation of the deformation processes in the amorphous phase of high density polyethylene. Polym. Int. 2004, 53, 582–585. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, Z.; Fu, L.; Lu, Y.; Men, Y. Lamellar thickness and stretching temperature dependency of cavitation in semicrystalline polymers. PLoS ONE 2014, 9, e97234. [Google Scholar] [CrossRef]

- Pawlak, A. Cavitation during tensile deformation of high-density polyethylene. Polymer 2007, 48, 1397–1409. [Google Scholar] [CrossRef]

- Pawlak, A.; Galeski, A. Plastic deformation of crystalline polymers: The role of cavitation and crystal plasticity. Macromolecules 2005, 38, 9688–9697. [Google Scholar] [CrossRef]

- Huang, Y.L.; Brown, N. Dependence of slow crack growth in polyethylene on butyl branch density: Morphology and theory. J. Polym. Sci. Part B Polym. Phys. 1991, 29, 129–137. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paolucci, F.; Govaert, L.; Peters, G. In Situ WAXD and SAXS during Tensile Deformation Of Moulded and Sintered Polyamide 12. Polymers 2019, 11, 1001. https://doi.org/10.3390/polym11061001

Paolucci F, Govaert L, Peters G. In Situ WAXD and SAXS during Tensile Deformation Of Moulded and Sintered Polyamide 12. Polymers. 2019; 11(6):1001. https://doi.org/10.3390/polym11061001

Chicago/Turabian StylePaolucci, Fabio, Leon Govaert, and Gerrit Peters. 2019. "In Situ WAXD and SAXS during Tensile Deformation Of Moulded and Sintered Polyamide 12" Polymers 11, no. 6: 1001. https://doi.org/10.3390/polym11061001

APA StylePaolucci, F., Govaert, L., & Peters, G. (2019). In Situ WAXD and SAXS during Tensile Deformation Of Moulded and Sintered Polyamide 12. Polymers, 11(6), 1001. https://doi.org/10.3390/polym11061001