Micro and Nano Smart Composite Films Based on Copper-Iodine Coordination Polymer as Thermochromic Biocompatible Sensors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cell Culture and Viability Studies

2.2. AlamarBlue Viability Assay

2.3. Synthesis of [Cu2I2(Apyz)]n@PLA Films

2.4. Synthesis of [Cu2I2(Apyz)]n@PLA Ultra-thin Films

3. Results and Discussion

3.1. Synthesis and Characterization

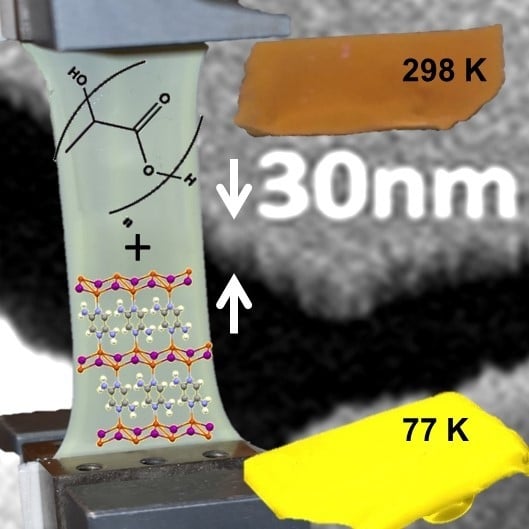

3.2. Control of Composite Film Thickness

3.3. Tunable Luminescent Properties of [Cu2I2(Apyz)]n@PLA Films

3.4. Thermal Analysis

3.5. Mechanical Stress Measurements of [Cu2I2(Apyz)]n@PLA Films

3.6. Toxicity Tests of [Cu2I2(Apyz)]n@PLA 4% in MCF7 and MDA-MB-231 Tumoral Cells

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kwon, E.; Kim, J.; Lee, K.Y.; Kim, T.H. Non-phase-transition luminescence mechanochromism of a copper(I) coordination polymer. Inorg. Chem. 2017, 56, 943–949. [Google Scholar] [CrossRef] [PubMed]

- Yan, Y.; Chen, J.; Zhang, N.-N.; Wang, M.-S.; Sun, C.; Xing, X.-S.; Li, R.; Xu, J.-G.; Zheng, F.-K.; Guo, G.-C. Grinding size-dependent mechanoresponsive luminescent Cd(II) coordination polymer. Dalton Trans. 2016, 45, 18074–18078. [Google Scholar] [CrossRef] [PubMed]

- Troyano, J.; Perles, J.; Amo-Ochoa, P.; Martínez, J.I.; Gimeno, M.C.; Fernández-Moreira, V.; Zamora, F.; Delgado, S. Luminescent thermochromism of 2D coordination polymers based on copper(I) halides with 4-hydroxythiophenol. Chem. Eur. J. 2016, 22, 18027–18035. [Google Scholar] [CrossRef] [PubMed]

- Vegas, V.G.; Lorca, R.; Latorre, A.; Hassanein, K.; Gómez-García, C.J.; Castillo, O.; Somoza, A.; Zamora, F.; Amo-Ochoa, P. Copper(II)-thymine coordination polymer nanoribbons as potential oligonucleotide nanocarriers. Angew. Chem. Int. Ed. 2017, 56, 987–991. [Google Scholar] [CrossRef] [PubMed]

- Rodenas, T.; Luz, I.; Prieto, G.; Seoane, B.; Miro, H.; Corma, A.; Kapteijn, F.; Llabrés i Xamena, F.X.; Gascon, J. Metal-organic framework nanosheets in polymer composite materials for gas separation. Nat. Mater. 2015, 14, 48–55. [Google Scholar] [CrossRef] [PubMed]

- Cariati, E.; Lucenti, E.; Botta, C.; Giovanella, U.; Marinotto, D.; Righetto, S. Cu(I) hybrid inorganic-organic materials with intriguing stimuli responsive and optoelectronic properties. Coord. Chem. Rev. 2016, 306, 566–614. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, J.H.; Wang, N.Y.; Steinbach, F.; Liu, X.L.; Caro, J. Remarkably enhanced gas separation by partial self-conversion of a laminated membrane to metal-organic frameworks. Angew. Chem. Int. Ed. 2015, 54, 3028–3032. [Google Scholar] [CrossRef]

- Xue, J.-Y.; Li, J.-C.; Li, H.-X.; Li, H.-Y.; Lang, J.-P. Chan-Lam cross-coupling reactions promoted by anionic copper(I)/iodide species with cationic methyl-((pyridinyl)-pyrazolyl)pyridin-1-ium. Tetrahedron 2016, 72, 7014–7020. [Google Scholar] [CrossRef]

- Li, J.-C.; Li, H.-X.; Li, H.-Y.; Gong, W.-J.; Lang, J.-P. Ligand coordination site-directed assembly of copper(I) iodide complexes of ((pyridyl)-1-pyrazolyl)pyridine. Cryst. Growth Des. 2016, 16, 1617–1625. [Google Scholar] [CrossRef]

- Conesa-Egea, J.; Zamora, F.; Amo-Ochoa, P. Perspectives of the smart Cu-Iodine coordination polymers: A portage to the world of new nanomaterials and composites. Coord. Chem. Rev. 2019, 381, 65–78. [Google Scholar] [CrossRef]

- Dou, A.N.; Du, Y.C.; Chen, Q.L.; Luo, K.L.; Zhang, C.; Zhu, A.X.; Li, Q.X. 3D Luminescent copper(I) iodide coordination polymer based on Cu4I4 clusters and an ethyl-bridging bis(triazole) ligand. Zeitschrift für Anorganische und Allgemeine Chemie 2016, 642, 731–735. [Google Scholar] [CrossRef]

- Demir, S.; Cepni, H.M.; Bilgin, N.; Holynska, M.; Yilmaz, F. Metal-organic frameworks based on copper(I) iodide and pyridine-3,5-dicarboxylic acid: Synthesis, crystal structures and luminescent properties. Polyhedron 2016, 115, 236–241. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, Y.-N.; Dong, W.-W.; Wu, Y.-P.; Li, D.-S.; Zhang, Q.-C. A robust luminescent Tb(III)-MOF with Lewis basic pyridyl sites for the highly sensitive detection of metal ions and small molecules. Inorg. Chem. 2016, 55, 3265–3271. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Fan, R.Q.; Wang, P.; Wang, X.M.; Gao, S.; Du, X.; Yang, Y.L.; Luan, T.Z. Copper(I)-iodide based coordination polymers: Bifunctional properties related to thermochromism and PMMA-doped polymer film materials. J. Mater. Chem. C 2015, 3, 6249–6259. [Google Scholar] [CrossRef]

- Benito, Q.; Le Goff, X.-F.; Nocton, G.; Fargues, A.; Garcia, A.; Berhault, A.; Kahlal, S.; Saillard, J.Y.; Martineau, C.; Trebosc, J.; et al. Geometry flexibility of copper iodide clusters: Variability in luminescence thermochromism. Inorg. Chem. 2015, 54, 4483–4494. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.-W.; Ma, J.-P.; Liu, Q.-K.; Wang, X.-R.; Liu, Y.; Yang, J.; Yang, J.-S.; Dong, Y.-B. An in situ self-assembled Cu4I4-MOF-based mixed matrix membrane: A highly sensitive and selective naked-eye sensor for gaseous HCl. Chem. Commun. 2016, 52, 5238–5241. [Google Scholar] [CrossRef] [PubMed]

- Hassanein, K.; Conesa-Egea, J.; Delgado, S.; Castillo, O.; Benmansour, S.; Martinez, J.I.; Abellan, G.; Gomez-Garcia, C.J.; Zamora, F.; Amo-Ochoa, P. Electrical conductivity and strong luminescence in copper iodide double chains with isonicotinato derivatives. Chem. Eur. J. 2015, 21, 17282–17292. [Google Scholar] [CrossRef]

- Yan, Y.; Zhang, N.-N.; Li, R.; Xu, J.-G.; Lu, J.; Zheng, F.-K.; Guo, G.-C. Coordination polymers with grinding-size-dependent mechanoresponsive luminescence induced by π···π stacking interactions. Eur. J. Inorg. Chem. 2017, 2017, 3811–3814. [Google Scholar] [CrossRef]

- Conesa-Egea, J.; Gallardo-Martínez, J.; Delgado, S.; Martínez, J.I.; Gonzalez-Platas, J.; Fernández-Moreira, V.; Rodríguez-Mendoza, U.R.; Ocón, P.; Zamora, F.; Amo-Ochoa, P. Multistimuli response micro- and nanolayers of a coordination polymer based on cu2i2 chains linked by 2-aminopyrazine. Small 2017, 13, 1700965. [Google Scholar] [CrossRef]

- Amo-Ochoa, P.; Hassanein, K.; Gomez-Garcia, C.J.; Benmansour, S.; Perles, J.; Castillo, O.; Martinez, J.I.; Ocon, P.; Zamora, F. Reversible stimulus-responsive Cu(I) iodide pyridine coordination polymer. Chem. Commun. 2015, 51, 14306–14309. [Google Scholar] [CrossRef]

- Rodriguez-San-Miguel, D.; Amo-Ochoa, P.; Zamora, F. MasterChem: Cooking 2D-polymers. Chem. Commun. 2016, 52, 4113–4127. [Google Scholar] [CrossRef]

- Conesa-Egea, J.; Nogal, N.; Martínez, J.I.; Fernández-Moreira, V.; Rodríguez-Mendoza, U.R.; González-Platas, J.; Gómez-García, C.J.; Delgado, S.; Zamora, F.; Amo-Ochoa, P. Smart composite films of nanometric thickness based on copper-iodine coordination polymers. Toward sensors. Chem. Sci. 2018, 9, 8000–8010. [Google Scholar] [CrossRef] [PubMed]

- Chuayjuljit, S.; Wongwaiwattanakul, C.; Chaiwutthinan, P.; Prasassarakich, P. Biodegradable poly(lactic acid)/poly(butylene succinate)/wood flour composites: Physical and morphological properties. Polym. Compos. 2017, 38, 2841–2851. [Google Scholar] [CrossRef]

- Liu, W.; Fang, Y.; Wei, G.Z.; Teat, S.J.; Xiong, K.; Hu, Z.; Lustig, W.P.; Li, J. A family of highly efficient CuI-based lighting phosphors prepared by a systematic, bottom-up synthetic approach. J. Am. Chem. Soc. 2015, 137, 9400–9408. [Google Scholar] [CrossRef] [PubMed]

- Horcas, I.; Fernández, R.; Gómez-Rodríguez, J.M.; Colchero, J.; Gómez-Herrero, J.; Baro, A.M. WSXM: A software for scanning probe microscopy and a tool for nanotechnology. Rev. Sci. Instr. 2007, 78, 013705. [Google Scholar] [CrossRef] [PubMed]

- Troyano, J.; Castillo, O.; Martínez, J.I.; Fernández-Moreira, V.; Ballesteros, Y.; Maspoch, D.; Zamora, F.; Delgado, S. Reversible thermochromic polymeric thin films made of ultrathin 2D crystals of coordination polymers based on copper(I)-thiophenolates. Adv. Funct. Mater. 2018, 28, 1704040. [Google Scholar] [CrossRef]

- Denny, M.S., Jr.; Cohen, S.M. In situ modification of metal-organic frameworks in mixed-matrix membranes. Angew. Chem. Int. Ed. 2015, 54, 9029–9032. [Google Scholar] [CrossRef] [PubMed]

- Monzón-Hierro, T.; Sanchiz, J.; González-Pérez, S.; González-Díaz, B.; Holinski, S.; Borchert, D.; Hernández-Rodríguez, C.; Guerrero-Lemus, R. A new cost-effective polymeric film containing an Eu(III) complex acting as UV protector and down-converter for Si-based solar cells and modules. Sol. Energy Mater. Sol. Cells 2015, 136, 187–192. [Google Scholar] [CrossRef]

- González-Pérez, S.; Sanchiz, J.; González-Díaz, B.; Holinski, S.; Borchert, D.; Hernández-Rodríguez, C.; Guerrero-Lemus, R. Luminescent polymeric film containing an Eu(III) complex acting as UV protector and down-converter for Si-based solar cells and modules. Surf. Coat. Technol. 2015, 271, 106–111. [Google Scholar] [CrossRef]

- Kräuter, G.; Schumacher, A.; Gösele, U. Low temperature silicon direct bonding for application in micromechanics: Bonding energies for different combinations of oxides. Sens. Act. A Phys. 1998, 70, 271–275. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Conesa-Egea, J.; Moreno-Vázquez, A.; Fernández-Moreira, V.; Ballesteros, Y.; Castellanos, M.; Zamora, F.; Amo-Ochoa, P. Micro and Nano Smart Composite Films Based on Copper-Iodine Coordination Polymer as Thermochromic Biocompatible Sensors. Polymers 2019, 11, 1047. https://doi.org/10.3390/polym11061047

Conesa-Egea J, Moreno-Vázquez A, Fernández-Moreira V, Ballesteros Y, Castellanos M, Zamora F, Amo-Ochoa P. Micro and Nano Smart Composite Films Based on Copper-Iodine Coordination Polymer as Thermochromic Biocompatible Sensors. Polymers. 2019; 11(6):1047. https://doi.org/10.3390/polym11061047

Chicago/Turabian StyleConesa-Egea, Javier, Alberto Moreno-Vázquez, Vanesa Fernández-Moreira, Yolanda Ballesteros, Milagros Castellanos, Félix Zamora, and Pilar Amo-Ochoa. 2019. "Micro and Nano Smart Composite Films Based on Copper-Iodine Coordination Polymer as Thermochromic Biocompatible Sensors" Polymers 11, no. 6: 1047. https://doi.org/10.3390/polym11061047

APA StyleConesa-Egea, J., Moreno-Vázquez, A., Fernández-Moreira, V., Ballesteros, Y., Castellanos, M., Zamora, F., & Amo-Ochoa, P. (2019). Micro and Nano Smart Composite Films Based on Copper-Iodine Coordination Polymer as Thermochromic Biocompatible Sensors. Polymers, 11(6), 1047. https://doi.org/10.3390/polym11061047