Characterisation of Polyamide (PA)12 Nanocomposites with Montmorillonite (MMT) Filler Clay Used for the Incremental Forming of Sheets

Abstract

:1. Introduction

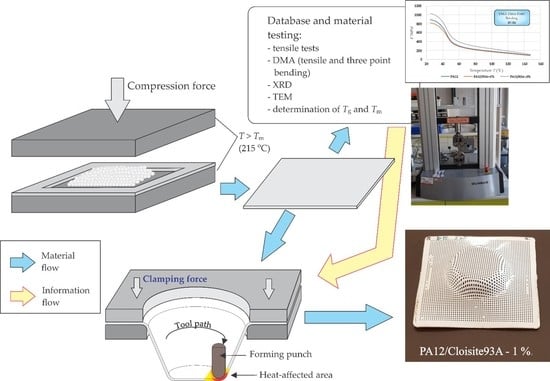

2. Materials and Methods

2.1. Materials

2.2. Preparation

2.3. Morphological and Structural Characterisation

2.4. Mechanical Characterisation

3. Results and Discussion

3.1. Structure and Morphology

3.2. Mechanical Properties

3.2.1. Tensile Test

3.2.2. Three-Point Bending Test

- Stretchability: Both nanocomposites expressed significantly better elongation at break in comparison to the neat PA12 material; however, their values were similar. More specifically, the PA12/Cloisite 93A–3% had 3% higher elongation at break and could be favoured regarding this parameter.

- Glass transition temperature Tg: To obtain the formability of the polymer during the SPIF process at the lowest possible temperatures is desirable; therefore, the determination of the glass transition temperature is indispensable. Among all three analysed materials, the PA12/Cloisite 93A–1% had the lowest Tg at 57 °C and could be, according to this parameter, favoured for selection of SPIF technology.

- Storage modulus E’: Due to the local bending and unbending process, this parameter is of importance during the SPIF process. Its determination through DMA three-point bending showed that in the range applicable for SPIF (above the Tg) it was distinguished at the conditions at lower and higher bending frequencies. At lower frequencies of 1 Hz and 5 Hz, all materials expressed similar values of E’. However, at the highest analysed frequency of 10 Hz, the PA12/Cloisite 93A–3% expresser noticeably higher values of E’ than the other two materials. Since, due to the shortening of production times at SPIF, the higher feed rates, also causing higher bending frequencies, are preferred, and the PA12/Cloisite 93A–3% material was not favourable in this case.

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Chavarria, F.; Paul, D.R. Comparison of nanocomposites based on nylon 6 and nylon 66. Polymer 2004, 45, 8501–8515. [Google Scholar] [CrossRef]

- Willkie, C.A.; Morgan, A.B. Nanocomposites I: Current developments in nanocomposites as novel flame retardants. In Advances in Fire Retardant Materials, 1st ed.; Horrocks, A.R., Price, D., Eds.; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2008; pp. 95–123. [Google Scholar]

- Ray, S.S.; Okamoto, M. Polymer/layered silicate nanocomposites: A review from preparation to processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar]

- Okamoto, M. Polymer/Layered Silicate Nano-composites. Adv. Polym. Mater. Eng. 2006, 5, 487–496. [Google Scholar] [CrossRef]

- Liu, L.; Qi, Z.; Zhu, X. Studies on Nylon 6/Clay Nanocomposites by Melt-Intercalation Process. J. Appl. Polym. Sci. 1999, 71, 1133–1138. [Google Scholar] [CrossRef]

- Wang, Z.; Pinnavaia, T.J. Nanolayer Reinforcement of Elastomeric Polyurethane. Chem. Mater. 1998, 10, 3769–3771. [Google Scholar] [CrossRef]

- González, I.; Eguiazábal, J.I.; Nazábal, J. Exfoliated PA6,6 nanocomposites by modification with PA6. Polymer 2005, 46, 2978–2985. [Google Scholar] [CrossRef]

- Liang, Y.; Xia, X.; Lou, Y.; Jia, Z. Synthesis and performances of Fe2O3/PA-6 nanocomposite fiber. Mater. Lett. 2007, 61, 3269–3272. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, S.; Ling, Z.; Zhuang, Y.; Chen, Z.; Fan, W. Preparation and Combustion Properties of Flame Retardant Nylon 6/Montmorillonite Nanocomposite. Macromol. Mater. Eng. 2003, 288, 272–276. [Google Scholar] [CrossRef]

- Schmidt, D.; Shah, D.; Giannelis, E.P. New advances in polymer/layered silicate nanocomposites. Curr. Opin. Solid State Mater. Sci. 2002, 6, 205–212. [Google Scholar] [CrossRef]

- Gilman, J.W. Flammability and thermal stability studies of polymer layered-silicate (clay) nanocomposites. Appl. Clay Sci. 1999, 15, 31–49. [Google Scholar] [CrossRef]

- Bourbigot, S.; Bras, M.; Dabrowski, F.; Gilman, J.W.; Kashiwagi, T. PA-6 Clay Nanocomposite Hybrid as Char Forming Agent in Intumescent Formulations. Fire Mater. 2000, 208, 201–208. [Google Scholar] [CrossRef]

- Horrocks, R.; Sitpalan, A.; Zhou, C.; Kandola, B.K. Flame Retardant Polyamide Fibres: The Challenge of Minimising Flame Retardant Additive Contents with Added Nanoclays. Polymers 2016, 8, 288. [Google Scholar] [CrossRef] [PubMed]

- Majka, T.M.; Leszczyńska, A.; Kandola, B.K.; Pornwannachai, W.; Pielichowsk, K. Modification of organo-montmorillonite with disodium H-phosphonate to develop flame retarded polyamide 6 nanocomposites. Appl. Clay Sci. 2017, 139, 28–39. [Google Scholar] [CrossRef]

- He, W.; Zhu, H.; Xiang, Y.; Long, L.; Qin, S.; Yu, J. Enhancement of flame retardancy and mechanical properties of polyamide 6 by incorporating an aluminum salt of diisobutylphosphinic combined with organoclay. Polym. Degrad. Stab. 2017, 144, 442–453. [Google Scholar] [CrossRef]

- Yano, K.; Armitsu, U.; Okada, A.; Kurauchi, T.; Kamigaito, O. Synthesis and Properties of Polyimide-Clay Hybrid. J. Polym. Sci. Part A Polym. Chem. 1993, 31, 2493–2498. [Google Scholar] [CrossRef]

- Messersmith, P.B.; Emmanuel, G.P. Synthesis and Barrier Properties of Poly(ε-Caprolactone)-Layered Silicate Nanocomposites. J. Polym. Sci. Part A Polym. Chem. 1995, 33, 1047–1057. [Google Scholar] [CrossRef]

- Xu, R.; Manias, E.; Snyder, A.J.; Runt, J. New Biomedical Poly(urethane urea)-Layered Silicate Nanocomposites. Macromolecules 2001, 34, 337–339. [Google Scholar] [CrossRef]

- Bharadwaj, R.K. Modeling the Barrier Properties of Polymer-Layered Silicate Nanocomposites. Macromolecules 2001, 34, 9189–9192. [Google Scholar] [CrossRef]

- Yoshitsugu, K.; Usuki, A.; Kawasumi, M.; Okada, A.; Fukushima, Y.; Kurauchi, T.; Kamigaito, O. Mechanical properties of nylon 6-clay hybrid. J. Mater. Res. 1993, 8, 1185–1189. [Google Scholar]

- Alix, S.; Follain, N.; Tenn, N.; Alexandre, B.; Bourbigot, S.; Soulestin, J.; Marais, S. Effect of Highly Exfoliated and Oriented Organoclays on the Barrier Properties of Polyamide 6 Based Nanocomposites. J. Phys. Chem. C 2012, 116, 4937–4947. [Google Scholar] [CrossRef]

- Sabard, M.; Gouanvé, F.; Espuche, E.; Fulchiron, R.; Fillot, L.-A.; Trouillet-Fonti, L. Erasure of the processing effects in polyamide 6 based cast films by the introduction of montmorillonite: Effect on water and oxygen transport properties. J. Memb. Sci. 2014, 456, 11–20. [Google Scholar] [CrossRef]

- Follain, N.; Alexandre, B.; Chappey, C.; Colasse, L.; Médéric, P.; Marais, S. Barrier properties of polyamide 12/montmorillonite nanocomposites: Effect of clay structure and mixing conditions. Compos. Sci. Technol. 2016, 136, 18–28. [Google Scholar] [CrossRef]

- Medeiros, K.M.; Arujo, E.M.; Lucena Lira, H.; Farias Lima, D.; Lima, C.A.P. Hybrid Membranes of Polyamide Applied in Treatment of Waste Water. Mater. Res. 2017, 20, 308–316. [Google Scholar] [CrossRef] [Green Version]

- Zhisheng Chen, C.; Cooper, S.L. Recent Advances in Antimicrobial Dendrimers. Adv. Mater. 2000, 12, 843–846. [Google Scholar] [CrossRef]

- Chen, G.; Wu, D.; Weng, W.; Yan, W. Preparation of Polymer/Graphite Conducting Nanocomposite by Intercalation Polymerization. J. Appl. Polym. Sci. 2001, 82, 2506–2513. [Google Scholar] [CrossRef]

- Yoon, P.J.; Fornes, T.D.; Paul, D.R. Thermal expansion behavior of nylon 6 nanocomposites. Polymer 2002, 43, 6727–6741. [Google Scholar] [CrossRef]

- Dahiya, J.B.; Muller-Hagedorn, M.; Bockhorn, H.; Kandola, B.K. Synthesis and thermal behaviour of polyamide 6/bentonite/ammonium polyphosphate composites. Polym. Degrad. Stab. 2008, 93, 2038–2041. [Google Scholar] [CrossRef]

- Ray, S.S.; Yamada, K.; Okamoto, M.; Ueda, K. Polylactide-Layered Silicate Nanocomposite: A Novel Biodegradable Material. Nano Lett. 2002, 2, 1093–1096. [Google Scholar]

- Fukushima, Y.; Inagaki, S. Synthesis of an Intercalated Compound of Montmorillonite and 6-Polyamide. J. Incl. Phenom. 1987, 5, 473–482. [Google Scholar] [CrossRef]

- Usuki, A.; Kojima, Y.; Kawasumi, M.; Okada, A. Synthesis of nylon 6-clay hybrid. J. Mater. Res. 1993, 8, 1179–1184. [Google Scholar] [CrossRef]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O. One-Pot Synthesis of Nylon 6-Clay Hybrid. J. Polym. Sci. Part A Polym. Chem. 1993, 31, 1755–1758. [Google Scholar] [CrossRef]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O. Synthesis of Nylon 6-Clay Hybrid by Montmorillonite Intercalated with ɛ-Caprolactam. J. Polym. Sci. Part A Polym. Chem. 1993, 31, 983–986. [Google Scholar] [CrossRef]

- Usuki, A.; Kawasumi, M.; Kojima, Y.; Okada, A.; Kurauchi, T.; Kamigaito, O. Swelling behavior of montmorillonite cation exchanged for Ω-amino acids by ε-caprolactam. J. Mater. Res. 1993, 8, 1174–1178. [Google Scholar] [CrossRef]

- Kojima, Y.; Usuki, A.; Kawasumi, M.; Okada, A.; Kurauchi, T.; Kamigaito, O. Sorption of Water in Nylon 6-Clay Hybrid. J. Appl. Polym. Sci. 1993, 49, 1259–1264. [Google Scholar] [CrossRef]

- Cho, J.W.; Paul, D.R. Nylon 6 nanocomposites by melt compounding. Polymer 2001, 42, 1083–1094. [Google Scholar] [CrossRef]

- Vannini, M.; Marchese, P.; Celli, A.; Marega, C.; Lorenzetti, C. Strategy to improve PA6 performances by melt compounding. Polym. Test. 2018, 67, 84–91. [Google Scholar] [CrossRef]

- Dennis, H.R.; Hunter, D.L.; Chang, D.; Kim, S.; White, J.L.; Cho, J.W.; Paul, D.R. Effect of melt processing conditions on the extent of exfoliation in organoclay-based nanocomposites. Polymer 2001, 42, 9513–9522. [Google Scholar] [CrossRef]

- Hoffmann, B.; Kressler, J.; Stöppelmann, G.; Friedrich, C.; Kim, G. Rheology of nanocomposites based on layered silicates and polyamide-12. Colloid Polym. Sci. 2000, 636, 629–636. [Google Scholar] [CrossRef]

- Kim, G.-M.; Lee, D.-H.; Hoffmann, B.; Kressler, J.; Stöppelmann, G. Influence of nanofillers on the deformation process in layered silicate/polyamide-12 nanocomposites. Polymer 2001, 42, 1095–1100. [Google Scholar] [CrossRef]

- Reichert, P.; Kressler, J.; Thomann, R.; Mülhaupt, R.; Stöppelmann, G. Nanocomposites based on a synthetic layer silicate and polyamide-12. Acta Polym. 1998, 49, 116–123. [Google Scholar] [CrossRef]

- McNally, T.; Murphy, W.R.; Lew, C.Y.; Turner, R.J.; Brennan, G.P. Polyamide-12 layered silicate nanocomposites by melt blending. Polymer 2003, 44, 2761–2772. [Google Scholar] [CrossRef]

- Stojšić, J.; Raos, P.; Kalendová, A. A Study of Structure and Tensile Properties of Polyamide 12/Clay Nanocomposites. Polym. Compos. 2014, 37, 684–691. [Google Scholar] [CrossRef]

- Mošková, D.J.; Janigová, I.; Nógellová, Z.; Sedničková, M.; Jankovič, L.; Komadel, P.; Šlouf, M.; Chodák, I. Prediction of compatibility of organomodified clay with various polymers using rheological measurements. Polym. Test. 2018, 69, 359–365. [Google Scholar] [CrossRef]

- Zhu, B.; Xiuwei, W.; Zeng, Q.; Wang, P.; Wang, Y.; Liu, C.; Shen, C. Enhanced mechanical properties of biodegradable poly (ε-caprolactone)/cellulose acetate butyrate nanocomposites filled with organoclay. Compos. Commun. 2019, 13, 70–74. [Google Scholar] [CrossRef]

- Liu, X.; Li, C.; Pan, Y.; Schubert, D.W.; Liu, C. Shear-induced rheological and electrical properties of molten poly (methyl methacrylate)/carbon black nanocomposites. Compos. Part B 2018, 164, 37–44. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, X.; Kaschta, J.; Hao, X.; Liu, C.; Schubert, D.W. Viscoelastic and electrical behavior of poly (methyl methacrylate)/carbon black composites prior to and after annealing. Polymer 2017, 113, 34–38. [Google Scholar] [CrossRef]

- Bek, M.; Betjes, J.; Bernstorff, B.-S.; Emri, I. Viscoelasticity of new generation thermoplastic polyurethane vibration isolators Viscoelasticity of new generation thermoplastic polyurethane vibration isolators. Phys. Fluids 2017, 29, 1–18. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Polymers, 2nd ed.; ChemTec Publishing: Toronto, ON, Canada, 2016; pp. 1–712. [Google Scholar]

- Duleba, B.; Spišák, E.; Greškovič, F. Mechanical properties of PA6/MMT polymer nanocomposites and prediction based on content of nanofiller. Procedia Eng. 2014, 96, 75–80. [Google Scholar] [CrossRef]

- Yu, S.; Yek, W.M.; Ho, S.Y.; Rannou, S.A.D.; Lim, S.H. Microstructure and impact strength of polyamide 6 composites. Mater. Today Commun. 2015, 4, 199–203. [Google Scholar] [CrossRef]

- Rohlmann, C.O.; Horst, M.F.; Quinzani, L.M.; Failla, M.D. Comparative analysis of nanocomposites based on polypropylene and different montmorillonites. Eur. Polym. J. 2008, 44, 2749–2760. [Google Scholar] [CrossRef]

- Gelineau, P.; Weigand, S.; Cauvin, L.; Bédoui, F. Compatibility effects of modified montmorillonite on elastic and visco-elastic properties of nano-reinforced Poly (lactic acid): Experimental and modeling study. Polym. Test. 2018, 70, 441–448. [Google Scholar] [CrossRef]

- Sharmila, T.K.B.; Ayswarya, E.P.; Abraham, B.T.; Begum, P.M.S.; Thacil, E.T. Fabrication of partially exfoliated and disordered intercalated cloisite epoxy nanocomposites via in situ polymerization: Mechanical, dynamic mechanical, thermal and barrier properties. Appl. Clay Sci. 2014, 102, 220–230. [Google Scholar] [CrossRef]

- Ianchis, R.; Rosca, I.D.; Ghiurea, M.; Spataru, C.I.; Nicolae, C.A.; Gabor, R.; Raditoiu, V.; Preda, S.; Fierascu, R.C.; Donescu, D. Synthesis and properties of new epoxy-organolayered silicate nanocomposites. Appl. Clay Sci. 2015, 103, 28–33. [Google Scholar] [CrossRef]

- Mohomane, S.M.; Djokovic, V.; Thomas, S.; Luyt, A.S. Polychloroprene nanocomposites filled with different organically modified clays: Morphology, thermal degradation and stress relaxation behavior. Polym. Test. 2011, 30, 585–593. [Google Scholar] [CrossRef]

- Martins, P.A.F.; Kwiatkowski, L.; Franzen, V.; Tekkaya, A.E.; Kleiner, M. Single point incremental forming of polymers. CIRP Ann. Manuf. Technol. 2009, 58, 229–232. [Google Scholar] [CrossRef] [Green Version]

- Marques, T.A.; Silva, M.B.; Martins, P.A.F. On the potential of single point incremental forming of sheet polymer parts. Int. J. Adv. Manuf. Technol. 2012, 60, 75–86. [Google Scholar] [CrossRef]

- Iseki, H.; Kato, K.; Sakamoto, S. Flexible and incremental sheet metal forming with spherical and cylindrical rollers. In Proceedings of the 40th JJCTP, Japan, 9–10 June 1989; pp. 41–44. [Google Scholar]

- Iseki, H.; Kato, K.; Sakamoto, S. Flexible and incremental sheet metal bulging using a path-controlled spherical roller. Trans. Jpn. Soc. Mech. Eng. Ser. C 1992, 554, 3147–3155. [Google Scholar] [CrossRef]

- Franzen, V.; Kwiatkowski, L.; Martins, P.A.F.; Tekkaya, A.E. Single point incremental forming of PVC. J. Mater. Process. Technol. 2009, 209, 462–469. [Google Scholar] [CrossRef]

- Le, V.S.; Ghiotti, A.; Lucchetta, G. Preliminary studies on Single Point Incremental Forming for Thermoplastic Materials. Int. J. Mater. Form. 2008, 1, 1179–1182. [Google Scholar] [CrossRef]

- Lozano-Sánchez, L.M.; Bagudanch, I.; Sustaita, A.O.; Iturbe-Ek, J.; Elizalde, L.E.; Garcia-Romeu, M.L.; Elías-Zúñiga, A. Single-Point Incremental Forming of Two Biocompatible Polymers: An Insight into Their Thermal and Structural Properties. Polymers 2018, 10, 391. [Google Scholar] [CrossRef]

- PA 2200 PA 12 Data Sheet; EOS GmbH (Electro Optical Systems): Krailling, Germany, 2010; pp. 1–12.

- Pilipović, A.; Brajlih, T.; Drstvenšek, I. Influence of Processing Parameters on Tensile Properties of SLS Polymer Product. Polymers 2018, 10, 1208. [Google Scholar] [CrossRef] [PubMed]

- Čatić, I.; Čaloska, J.; Godec, D.; Kovačić, M.; Pilipović, A.; Skala, K. Fluid-deposition of rocks is natural model for additive production. Interdiscip. Descr. Complex Syst. 2017, 15, 180–189. [Google Scholar] [CrossRef]

- Paolucci, F.; Govaert, L.; Peters, G. In Situ WAXD and SAXS during Tensile Deformation of Moulded and Sintered Polyamide 12. Polymers 2019, 11, 1001. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Wang, Y.; Wei, Q. PA12 Powder Recycled from SLS for FDM. Polymers 2019, 11, 727. [Google Scholar] [CrossRef] [PubMed]

- Material Data Sheet PA 2200; EOS GmbH (Electro Optical Systems): Krailling, Germany, 2008; pp. 1–2.

- Rahim, T.N.A.T.; Abdullah, A.M.; Akil, H.M.; Mohamad, D. Comparison of mechanical properties for polyamide 12 composite-based biomaterials fabricated by fused filament fabrication and injection molding. In Proceedings of the AIP Conference, Pinang, Malaysia, 9–11 August 2016. [Google Scholar]

- Dotchev, K.; Yusoff, W. Recycling of polyamide 12 based powders in the laser sintering process. Rapid Prototyp. J. 2009, 15, 192–203. [Google Scholar] [CrossRef]

- MatWeb-Material Property Data–BYK Closite 93A Nanoclay. Available online: http://www.matweb.com/search/datasheet.aspx?MatGUID=3181d0899a0b46a592eb37c47f0f841b (accessed on 20 May 2019).

- Stojšić, J. Utjecaj Parametara Smješavanja na Svojstva Nanokompozita od Poliamida 12 Ojačanog Slojevitim Glinama. Ph.D. Thesis, Josip Juraj Strossmayer University of Osijek, Osijek, Croatia, 2013. (In Croatian). [Google Scholar]

- Plastics-Determination of Tensile Properties-Part 2: Test Conditions for Moulding and Extrusion Plastics; EN ISO 527-2:2012; ISO: Geneva, Switzerland, 2012.

- Plastics-Determination of Tensile Properties-Part 3: Test Conditions for Films and Sheets; EN ISO 527-3:2018; ISO: Geneva, Switzerland, 2018.

- Ebnesajjad, S.; Ebnesajjad, C. Surface and Material Characterization Techniques. In Surface Treatment of Materials for Adhesive Bonding, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 39–75. [Google Scholar]

- Dynamic Mechanical Analysis Comprehensive Materials Characterization; Mettler Toledo: Columbus, OH, USA, 2016; pp. 1–14.

- Menard, K.; Menard, N. Dynamic mechanical analysis in the analysis. In Encyclopedia of Polymer Science and Technology, 4th ed.; Mark, F., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2015; Volume 1, pp. 1–33. [Google Scholar]

- Petek, A. The Definition of Stable Technological Window by Incremental Sheet Metal Forming. Ph.D. Thesis, University of Ljubljana, Ljubljana, Slovenia, 2008. [Google Scholar]

- Ivanković, M. Polimerni nanokompoziti. Polimeri 2007, 28, 156–167. [Google Scholar]

- Chin, I.-J.; Thurn-Albrecht, T.; Kim, H.-C.; Russell, T.P.; Wang, J. On exfoliation of montmorillonite in epoxy. Polymer 2001, 42, 5947–5952. [Google Scholar] [CrossRef]

- Jose, S.; Thomas, S.; Biju, P.K.; Koshy, P.; Karger-Kocis, J. Thermal degradation and crystallisation studies of reactively compatibilised polymer blends. Polym. Degrad. Stab. 2008, 93, 1176–1187. [Google Scholar] [CrossRef]

- Atuanya, C.U.; Aigbodion, V.S.; Agbo, C.O.A.; Anene, F.A. Thermo-mechanical behavior of functional polymer nanocomposites. Int. J. Adv. Manuf. Technol. 2019, 102, 1–5. [Google Scholar]

- Elmer, P. Dynamic Mechanical Analysis (DMA) A Beginner’s Guide; PerkinElmer Ltd.: Waltham, MA, USA, 2013; pp. 1–23. [Google Scholar]

- Ramkumar, A.; Gnanamoorthy, R. Effect of nanoclay addition on the displacement-controlled flexural fatigue behavior of a polymer. J. Mater. Sci. 2010, 45, 4180–4187. [Google Scholar] [CrossRef]

- Shen, L.; Tjiu, W.C.; Liu, T. Nanoindentation and morphological studies on injection-molded nylon-6 nanocomposites. Polymer 2005, 46, 11969–11977. [Google Scholar] [CrossRef]

- Kashani Rahimi, S.; Otaigbe, J.U. Polyamide 6 nanocomposites incorporating cellulose nanocrystals prepared by in situ ring-opening polymerization: Viscoelasticity, creep behavior, and melt rheological properties. Polym. Eng. Sci. 2016, 56, 1045–1060. [Google Scholar] [CrossRef]

| D | 42 mm |

| L | 252 mm |

| L/D | 6 |

| Max. Temperature | 350 °C |

| Index | “11” Δz1 = 0.25 mm RRT1 = 3 mm | “12” Δz2 = 0.25 mm RRT1 = 3 mm | “13” Δz3 = 0.25 mm RRT1 = 3 mm | “21” Δz1 = 0.25 mm RRT2 = 4 mm | “22” Δz2 = 0.25 mm RRT2 = 4 mm | “23” Δz3 = 0.25 mm RRT2 = 4 mm |

| β (rad) | 0.411 | 0.586 | 0.723 | 0.355 | 0.505 | 0.622 |

| b (mm) | 1.233 | 1.757 | 2.168 | 1.422 | 2.021 | 2.489 |

| Technological Parameters | vf1 = 1000 mm/min = 16.67 mm/s A | vf2 = 1500 mm/min = 25 mm/s B | vf3 = 2000 mm/min = 33.33 mm/s C |

|---|---|---|---|

| t11 | 0.222 | 0.148 | 0.111 |

| t12 | 0.316 | 0.211 | 0.158 |

| t13 | 0.390 | 0.260 | 0.195 |

| t21 | 0.256 | 0.171 | 0.128 |

| t22 | 0.364 | 0.243 | 0.182 |

| t23 | 0.448 | 0.299 | 0.224 |

| Condition | A [Hz] | B [Hz] | C [Hz] |

|---|---|---|---|

| f11 | 4.50 | 6.76 | 9.01 |

| f12 | 3.16 | 4.74 | 6.32 |

| f13 | 2.56 | 3.84 | 5.12 |

| f21 | 3.91 | 5.86 | 7.82 |

| f22 | 2.75 | 4.12 | 5.50 |

| f23 | 2.23 | 3.35 | 4.46 |

| PA12 | PA12/Cloisite 93A–1% | PA12/Cloisite 93A –3% | |

|---|---|---|---|

| Tg (°C) | 60 | 57 | 58 |

| Tm (°C) | 179 | 179 | 183 |

| Tcc (°C) | 150 | 150 | 150 |

| X (%) | 69 | 64 | 57 |

| Tα tensile (°C) | 54 | 51 | 53 |

| Tα bending 1 Hz (°C) | 48 | 52 | 50 |

| Tα bending 5 Hz (°C) | 51 | 51 | 51 |

| Tα bending 10 Hz (°C) | 51 | 51 | 50 |

| PA12 | PA12/Cloisite 93A–1% | PA12/Cloisite 93A–3% | |

|---|---|---|---|

| E [MPa] | 875 (± 35) | 771 (± 63) | 913 (± 62) |

| σm [MPa] | 52 (± 3) | 54 (± 1) | 55 (± 3) |

| ε [%] | 45 (± 11) | 65 (± 12) | 67 (± 7) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borić, A.; Kalendová, A.; Urbanek, M.; Pepelnjak, T. Characterisation of Polyamide (PA)12 Nanocomposites with Montmorillonite (MMT) Filler Clay Used for the Incremental Forming of Sheets. Polymers 2019, 11, 1248. https://doi.org/10.3390/polym11081248

Borić A, Kalendová A, Urbanek M, Pepelnjak T. Characterisation of Polyamide (PA)12 Nanocomposites with Montmorillonite (MMT) Filler Clay Used for the Incremental Forming of Sheets. Polymers. 2019; 11(8):1248. https://doi.org/10.3390/polym11081248

Chicago/Turabian StyleBorić, Andrej, Alena Kalendová, Michal Urbanek, and Tomaž Pepelnjak. 2019. "Characterisation of Polyamide (PA)12 Nanocomposites with Montmorillonite (MMT) Filler Clay Used for the Incremental Forming of Sheets" Polymers 11, no. 8: 1248. https://doi.org/10.3390/polym11081248

APA StyleBorić, A., Kalendová, A., Urbanek, M., & Pepelnjak, T. (2019). Characterisation of Polyamide (PA)12 Nanocomposites with Montmorillonite (MMT) Filler Clay Used for the Incremental Forming of Sheets. Polymers, 11(8), 1248. https://doi.org/10.3390/polym11081248