Flax, Basalt, E-Glass FRP and Their Hybrid FRP Strengthened Wood Beams: An Experimental Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacture of FRP and FRP–Wood Specimens

2.3. Test Matrix

2.4. Test Instrumentation

| rate of crosshead motion, mm/min | |

| rate of straining of the outer fibric, 0.01%/min | |

| support span, mm | |

| thickness of the specimen, mm. |

| flexural elastic modulus, GPa | |

| support span, mm | |

| width of the tested beam, mm | |

| depth of the tested beam, mm | |

| difference of force between 20% to 40% of the maximum bending loading, kN | |

| difference of mid-span displacement at the corresponding bending loading, mm |

2.5. Data Analysis Method

3. Results and Discussion

3.1. Tensile and Bending Tests for FRP Laminates

3.2. Bending Tests for FRP Strengthened Wood Beams

3.2.1. Effect of FRP Thicknesses on the Bending Behavior of FRP Strengthened Wood Beams

3.2.2. Effect of FRP Materials on the Bending Behavior of FRP Strengthened Wood Beams

3.3. Failure Modes and Microstructure of FRP–Wood Beam System

3.3.1. Failure Modes

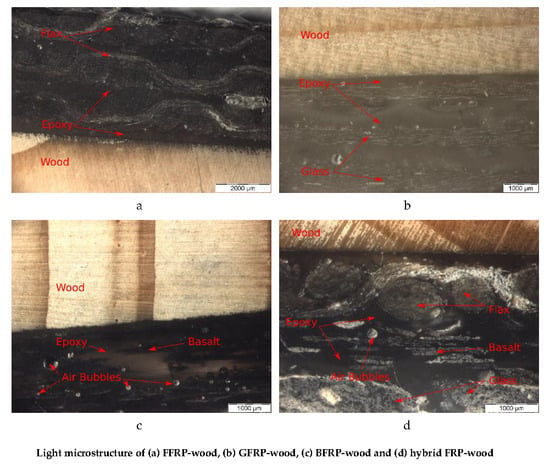

3.3.2. Microstructure

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Walberg, D. Massiv-und Holzbau bei Wohngebäuden: Vergleich von Massiven Bauweisen mit Holzfertigbauten aus Kostenseitiger, Bautechnischer und Nachhaltiger Sicht; Arbeitsgemeinschaft für Zeitgemäßes Bauen: Kaunas, Lithuania, 2015. [Google Scholar]

- Rowell, R.M.; Barbour, R.J. Archaelogical Wood Properties, Chemistry, and Preservation; ACS: Washington, DC, USA, 1990. [Google Scholar]

- Johns, K.C.; Lacroix, S. Composite reinforcement of timber in bending. Can. J. Civ. Eng. 2000, 27, 899–906. [Google Scholar] [CrossRef]

- Plevris, N.; Triantafillou, T.C. FRP-Reinforced Wood as Structural Material. J. Mater. Civ. Eng. 1992, 4, 300–317. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Deskovic, N. Prestressed FRP Sheets as External Reinforcement of Wood Members. J. Struct. Eng. 1992, 118, 1270–1284. [Google Scholar] [CrossRef]

- Yan, L.B.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Yan, L.B.; Chouw, N. Compressive and flexural behaviour and theoretical analysis of flax fibre reinforced polymer tube encased coir fibre reinforced concrete composite. Mater. Des. (1980–2015) 2013, 52, 801–811. [Google Scholar] [CrossRef]

- Yan, L.B.; Chouw, N. Natural FRP tube confined fibre reinforced concrete under pure axial compression. Thin-Walled Struct. 2014, 82, 159–169. [Google Scholar] [CrossRef]

- Lopez-Anido, R.; Michael, A.P.; Sandford, T.C. Experimental characterization of FRP composite-wood pile structural response by bending tests. Mar. Struct. 2003, 16, 257–274. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M.; Grazini, A. A method for flexural reinforcement of old wood beams with CFRP materials. Compos. Part B Eng. 2005, 36, 143–153. [Google Scholar] [CrossRef]

- Borri, A.; Corradi, M.; Grazini, A. FRP reinforcement of wood elements under bending loads. In Proceedings of the 10th International Conference on Structural Faults and Repair, London, UK, 1–3 July 2003. [Google Scholar]

- Tingley, D.A. The Stress-Strain Relationships in Wood and Fiber-Reinforced Plastic Laminae of Reinforced Glued-Laminated Wood Beams. Ph.D. Thesis, Oregon State University, Corvallis, OR, USA, 1996. [Google Scholar]

- Van de Velde, K.; Kiekens, P.; van Langenhove, L. Basalt fibres as reinforcement for composites. In Proceedings of the 10th International Conference on Composites/nano Engineering, New Orleans, LA, USA, 1 January 2003. [Google Scholar]

- Zoghi, M. The International Handbook of FRP Composites in Civil Engineering; CRC Press: Florida, FL, USA, 2013. [Google Scholar]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Huang, L.; Yan, B.; Yan, L.B.; Xu, Q.; Tan, H.Z.; Kasal, B. Reinforced concrete beams strengthened with externally bonded natural flax FRP plates. Compos. Part B Eng. 2016, 91, 569–578. [Google Scholar] [CrossRef]

- Yan, L.B.; Su, S.; Chouw, N. Microstructure, flexural properties and durability of coir fibre reinforced concrete beams externally strengthened with flax FRP composites. Compos. Part B Eng. 2015, 80, 343–354. [Google Scholar] [CrossRef]

- Yan, L.B. Plain concrete cylinders and beams externally strengthened with natural flax fabric reinforced epoxy composites. Mater. Struct. 2016, 49, 2083–2095. [Google Scholar] [CrossRef]

- Yan, B.; Huang, L.; Yan, L.B.; Gao, C.; Kasal, B. Behavior of flax FRP tube encased recycled aggregate concrete with clay brick aggregate. Constr. Build. Mater. 2017, 136, 265–276. [Google Scholar] [CrossRef]

- Yan, L.B.; Chouw, N. Experimental study of flax FRP tube encased coir fibre reinforced concrete composite column. Constr. Build. Mater. 2013, 40, 1118–1127. [Google Scholar] [CrossRef]

- Yan, L.B.; Chouw, N.; Jayaraman, K. Effect of column parameters on flax FRP confined coir fibre reinforced concrete. Constr. Build. Mater. 2014, 55, 299–312. [Google Scholar] [CrossRef]

- Speranzini, E.; Tralascia, S. Engineered lumber: LVL and solid wood reinforced with natural fibres. In Proceedings of the WCTE, Trentino, Italy, 20–24 June 2010; pp. 1685–1690. [Google Scholar]

- Borri, A.; Corradi, M.; Speranzini, E. Reinforcement of wood with natural fibers. Compos. Part B Eng. 2013, 53, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Borri, A.; Corradi, M.; Speranzini, E. Bending Tests on Natural Fiber Reinforced Fir Wooden Elements. Adv. Mater. Res. 2013, 778, 537–544. [Google Scholar] [CrossRef]

- André, A.; Johnsson, H. Flax Fiber-Reinforced Glued-Laminated Timber in Tension Perpendicular to the Grain: Experimental Study and Probabilistic Analysis. J. Mater. Civ. Eng. 2010, 22, 827–835. [Google Scholar] [CrossRef]

- Kim, H.S.; Shin, Y.S. Flexural behavior of reinforced concrete (RC) beams retrofitted with hybrid fiber reinforced polymers (FRPs) under sustaining loads. Compos. Struct. 2011, 93, 802–811. [Google Scholar] [CrossRef]

- Yan, L.B.; Wang, B.; Kasal, B. Can Plant-Based Natural Flax Replace Basalt and E-Glass for Fiber-Reinforced Polymer Tubular Energy Absorbers? A Comparative Study on Quasi-Static Axial Crushing. Front. Mater. 2017, 4, 635. [Google Scholar] [CrossRef]

- Huang, L.; Gao, C.; Yan, L.; Kasal, B. Reliability assessment of confinement models of carbon fiber reinforced polymer-confined concrete. J. Reinf. Plast. Compos. 2016, 12, 996–1026. [Google Scholar] [CrossRef]

- Gupta, M.K.; Srivastava, R.K. Mechanical Properties of Hybrid Fibers-Reinforced Polymer Composite: A Review. Polym. Plast. Technol. Eng. 2016, 55, 626–642. [Google Scholar] [CrossRef]

- Yang, Y.L.; Liu, J.W.; Xiong, G.J. Flexural behavior of wood beams strengthened with HFRP. Constr. Build. Mater. 2013, 43, 118–124. [Google Scholar] [CrossRef]

- Fiorelli, J.; Dias, A.A. Fiberglass-reinforced glulam beams: Mechanical properties and theoretical model. Mater. Res. 2006, 9, 263–269. [Google Scholar] [CrossRef]

- Fiorelli, J.; Dias, A.A. Glulam beams reinforced with FRP externally-bonded: Theoretical and experimental evaluation. Mater. Struct. 2011, 44, 1431–1440. [Google Scholar] [CrossRef]

- Marinella, F.; Giovanni, M.; Maurizio, P. Flexural behaviour of glulam timber beams reinforced with FRP cords. Constr. Build. Mater. 2015, 95, 54–64. [Google Scholar]

- Barkoula, N.M.; Garkhail, S.K.; Peijs, T. Biodegradable composites based on flax/polyhydroxybutyrate and its copolymer with hydroxyvalerate. Ind. Crop. Prod. 2010, 31, 34–42. [Google Scholar] [CrossRef]

- Testing of Wood, Bending Test: DIN 52186; Deutsches Institue für Normung: Berlin, Germany, 1978.

- Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials: ASTM D 3039; ASTM International: West Conshohocken, PA, USA, 2000.

- Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials: ASTM. D 790; ASTM International: West Conshohocken, PA, USA, 2007.

- Reyes-Araiza, J.L.; Manzano-Ramírez, A.; Rubio-Avalos, J.C.; González-Sosa, E.; Pérez-Robles, J.F.; Arroyo-Contreras, M.; Signoret, C.; Castillo-Castañeda, E.; Vorobiev, Y.V. Comparative study on tensile behavior of inorganic fibers embedded in unsaturated polyester bisphenol “A”-styrene copolymer. Inorg. Mater. 2008, 44, 549–554. [Google Scholar] [CrossRef]

- Quagliarini, E.; Monni, F.; Lenci, S.; Bondioli, F. Tensile characterization of basalt fiber rods and ropes: A first contribution. Constr. Build. Mater. 2012, 34, 372–380. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Li, Y.; Ma, H.; Yu, T. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

| Specimen | Name 1 | Number of the FRP Laminates | Number of Replications |

|---|---|---|---|

| Wood | W | 0 | 3 |

| FFRP–wood | W_1L-F | 1 | 3 |

| W_2L-F | 2 | 3 | |

| W_3L-F | 3 | 3 | |

| BFRP–wood | W_1L-B | 1 | 3 |

| W_2L-B | 2 | 3 | |

| W_3L-B | 3 | 3 | |

| GFRP–wood | W_1L-G | 1 | 3 |

| W_2L-G | 2 | 3 | |

| W_3L-G | 3 | 3 | |

| Hybrid–wood | W_3L-GBF | 3 | 3 |

| W_3L-BFG | 3 | 3 | |

| W_3L-BGF | 3 | 3 |

| Name 1 | Number of Replications | Nominal Fiber Thickness 2 | Thickness | Elastic Modulus | Strength | Strain at Peak Load |

|---|---|---|---|---|---|---|

| mm | mm | GPa | MPa | % | ||

| Tensile span of extensometer = 140 mm, testing speed = 2.5 mm/min | ||||||

| 1L_B_Te | 10 | 0.7 | 1.11 | 6.2 (± 0.8) | 49.6 (± 8.2) | 0.92 (± 0.22) |

| 2L_B_Te | 9 | 1.4 | 3.11 | 6.1 (± 0.7) | 61.1 (± 9.4) | 1.15 (± 0.15) |

| 3L_B_Te | 10 | 2.1 | 3.41 | 6.0 (± 0.4) | 56.3 (± 6.1) | 1.03 (± 0.12) |

| 1L_F_Te | 10 | 1.2 | 1.81 | 4.8 (± 0.3) | 41.7 (± 5.5) | 1.29 (± 0.31) |

| 2L_F_Te | 8 | 2.4 | 3.07 | 5.4 (± 0.2) | 48.2 (± 1.7) | 1.30 (± 0.07) |

| 3L_F_Te | 6 | 3.6 | 4.33 | 5.6 (± 0.1) | 76.8 (± 2.1) | 1.69 (± 0.12) |

| 1L_G_Te | 10 | 0.9 | 1.06 | 19.3 (± 1.5) | 377.1 (± 55.7) | 2.12 (± 0.68) |

| 2L_G_Te | 5 | 1.7 | 1.71 | 23.3 (± 0.7) | 493.6 (± 46.0) | 2.18 (± 0.29) |

| 3L_G_Te | 10 | 2.6 | 2.72 | 22.4 (± 1.0) | 449.1 (± 38.8) | 2.09 (± 0.47) |

| Bending span = 100 mm; testing speed = 1%/min, maximum strain before stop = 5% | ||||||

| 1L_B_Be | 10 | 0.7 | 1.11 | 5.8 (± 0.5) | 79.6 (± 7.2) | 2.07 (± 0.24) |

| 2L_B_Be | 10 | 1.4 | 3.11 | 6.3 (± 0.5) | 156.8 (± 11.5) | 2.74 (± 0.15) |

| 3L_B_Be | 10 | 2.1 | 3.41 | 5.8 (± 0.5) | 139.9 (± 11.8) | 2.65 (± 0.18) |

| 1L_F_Be | 9 | 1.2 | 1.81 | 3.7 (± 0.7) | 60.3 (± 10.0) | 2.26 (± 0.36) |

| 2L_F_Be | 10 | 2.4 | 3.07 | 5.1 (± 0.2) | 94.6 (± 7.1) | 3.37 (± 0.25) |

| 3L_F_Be | 10 | 3.6 | 4.33 | 4.8 (± 0.2) | 90.3 (± 3.0) | 3.23 (± 0.23) |

| 1L_G_Be | 10 | 0.9 | 1.06 | 8.0 (± 0.6) | 90.4 (± 6.8) | 1.90 (± 0.20) |

| 2L_G_Be | 10 | 1.7 | 1.71 | 18.1 (± 2.6) | 331.0 (± 31.3) | 2.80 (± 0.15) |

| 3L_G_Be | 10 | 2.6 | 2.72 | 16.9 (± 2.1) | 525.0 (± 50.9) | 4.18 (± 0.36) |

| FRP Type | Layer | Name | Maximum Load Capacity | Load Capacity Improvement | Elastic Modulus | Elastic Modulus Improvement | Maximum Mid-Span Deflection | Deflection Improvement |

|---|---|---|---|---|---|---|---|---|

| Fmax | DF | E | DE | D | Dd | |||

| kN | % | GPa | % | Mm | % | |||

| None | 0 | W | 2.8 (± 0.8) | ------ | 9.0 | ------ | 12.7 (± 1.0) | ------ |

| Flax | 1 | W_1L-F | 4.5 (± 0.6) | 60.7 | 12.7 | 40.5 | 16.4 (± 2.6) | 29.1 |

| 2 | W_2L-F | 5.5 (± 0.3) | 96.4 | 12.6 | 39.8 | 18.8 (± 6.0) | 48.0 | |

| 3 | W_3L-F1 | 6.2 (± 0.0) | 121.4 | 12.9 | 42.4 | 21.2 (± 3.2) | 66.9 | |

| Basalt | 1 | W_1L-B1 | 3.2 (± 0.3) | 14.3 | 10.1 | 12.0 | 21.8 (± 8.6) | 71.7 |

| 2 | W_2L-B | 4.2 (± 0.7) | 50.0 | 10.0 | 10.5 | 21.5 (± 7.3) | 69.3 | |

| 3 | W_3L-B | 5.8 (± 0.3) | 107.1 | 11.0 | 21.7 | 20.7 (± 3.1) | 63.0 | |

| Glass | 1 | W_1L-G | 4.8 (± 0.8) | 71.4 | 9.2 | 1.8 | 34.2 (± 3.7) | 169.3 |

| 2 | W_2L-G | 6.1(± 0.1) | 117.9 | 13.3 | 46.9 | 31.1 (± 6.9) | 144.9 | |

| 3 | W_3L-G | 6.5 (± 0.4) | 132.1 | 15.1 | 66.6 | 26.8 (± 5.1) | 111.0 | |

| Hybrid | 3 | W_3L-BFG | 5.6 (± 0.5) | 100.0 | 13.9 | 53.3 | 28.1 (± 4.0) | 121.3 |

| 3 | W_3L-BGF | 5.8 (± 0.3) | 107.1 | 14.6 | 61.8 | 30.8 (± 5.8) | 142.5 | |

| 3 | W_3L-GBF | 5.9 (± 0.4) | 110.7 | 11.4 | 26.6 | 29.8 (± 1.9) | 134.6 |

| FRP Type | Number of FRP Layers | ||||

|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | ||

| without FRP | Tensile failure | --- | --- | --- | |

| FFRP | --- | Tensile failure | Tensile failure | Debonding at mid-span | |

| BFRP | --- | Tensile failure | Tensile failure | Tensile failure | |

| GFRP | --- | Debonding at edge | Debonding at edge | Debonding at edge | |

| HFRP | W_3L-BFG | --- | --- | --- | Debonding at edge |

| W_3L-BGF | --- | --- | --- | Debonding at edge | |

| W_3L-GBF | --- | --- | --- | Tensile failure | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Bachtiar, E.V.; Yan, L.; Kasal, B.; Fiore, V. Flax, Basalt, E-Glass FRP and Their Hybrid FRP Strengthened Wood Beams: An Experimental Study. Polymers 2019, 11, 1255. https://doi.org/10.3390/polym11081255

Wang B, Bachtiar EV, Yan L, Kasal B, Fiore V. Flax, Basalt, E-Glass FRP and Their Hybrid FRP Strengthened Wood Beams: An Experimental Study. Polymers. 2019; 11(8):1255. https://doi.org/10.3390/polym11081255

Chicago/Turabian StyleWang, Bo, Erik Valentine Bachtiar, Libo Yan, Bohumil Kasal, and Vincenzo Fiore. 2019. "Flax, Basalt, E-Glass FRP and Their Hybrid FRP Strengthened Wood Beams: An Experimental Study" Polymers 11, no. 8: 1255. https://doi.org/10.3390/polym11081255

APA StyleWang, B., Bachtiar, E. V., Yan, L., Kasal, B., & Fiore, V. (2019). Flax, Basalt, E-Glass FRP and Their Hybrid FRP Strengthened Wood Beams: An Experimental Study. Polymers, 11(8), 1255. https://doi.org/10.3390/polym11081255