Physical Foaming and Crosslinking of Polyethylene with Modified Talcum

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

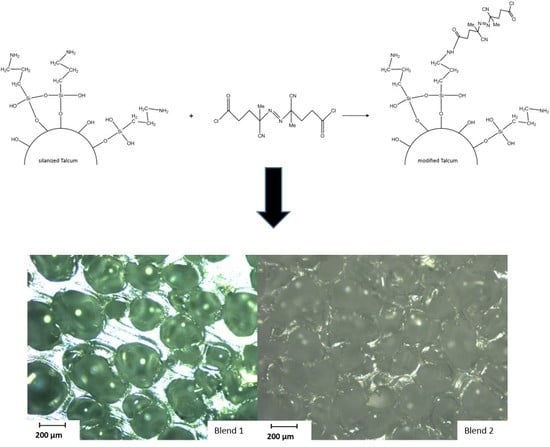

2.2. Modification of Talcum

2.3. Crosslinking Experiments

Characterization of the Degree of Crosslinking of the Swelling Tests

2.4. Foaming Experiments

Characterization of the Foamed Samples

3. Results and Discussion

3.1. Modification of Talcum

3.2. Crosslinking Experiments

3.3. Foaming Experiments

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tamboli, S.M.; Mhaske, S.T.; Kale, D.D. Crosslinked polyethylene. Indian J. Chem. Technol. 2004, 11, 853–864. [Google Scholar]

- Berger, K.; Keimel, C.; Helfer, E.; Haar, B.; Mattausch, H.; Riess, G.; Kern, W. The effects of e-beam crosslinking of LDPE on the permeation of hydrocarbons. J. Appl. Polym. Sci. 2017, 134, 853. [Google Scholar] [CrossRef]

- Morshedian, J.; Hoseinpour, P. Polyethylene crosslinking by two-step silane method: A review. Iran. Polym. J. 2009, 18, 103–128. [Google Scholar]

- Berger, K.; Keimel, C.; Helfer, E.; Haar, B.; Eder, A.; Mattausch, H.; Riess, G. Permeation of hydrocarbons through organosilane crosslinked LDPE. J. Appl. Polym. Sci. 2017, 134, 45374. [Google Scholar] [CrossRef]

- Zhang, X.M.; Elkoun, S.; Ajji, A.; Huneault, M.A. Oriented structure and anisotropy properties of polymer blown films: HDPE, LLDPE and LDPE. Polymer 2004, 45, 217–229. [Google Scholar] [CrossRef]

- Baur, E.; Brinkmann, S.; Osswald, T.A.; Schmachtenberg, E. Saechtling Kunststoff Taschenbuch, 30th ed.; Carl Hanser: München, Germany, 2007. [Google Scholar]

- Rocha, M.C.G.; Leyva, M.E.; Oliveira, M.G. Thermoplastic elastomers blends based on linear low density polyethylene, ethylene-1-octene copolymers and ground rubber tire. Polímeros 2014, 24, 23–29. [Google Scholar] [CrossRef] [Green Version]

- Yussuf, A.A.; Kosior, E.; Alban, L. Silane Grafting and Crosslinking of Metallocene-catalysed LLDPE and LDPE. Malaysian Polym. J. 2007, 2, 58–71. [Google Scholar]

- Shieh, Y.-T.; Liu, C.-M. Silane grafting reactions of LDPE, HDPE, and LLDPE. J. Appl. Polym. Sci. 1999, 74, 3404. [Google Scholar] [CrossRef]

- Morshedian, J.; Mohammad, H.P.; Azizi, H.; Parvizzad, R. Effect of polymer structure and additives on silane grafting of polyethylene. Express Polym. Lett. 2009, 3, 105–115. [Google Scholar] [CrossRef]

- Wong, A.; Park, C.B. The effects of extensional stresses on the foamability of polystyrene–talc composites blown with carbon dioxide. Chem. Eng. Sci. 2012, 75, 49–62. [Google Scholar] [CrossRef]

- Park, C.B.; Baldwin, D.F.; Suh, N.P. Effect of the pressure drop rate on cell nucleation in continuous processing of microcellular polymers. Polym. Eng. Sci. 1995, 35, 432–440. [Google Scholar] [CrossRef]

- Yang, H.-H.; Han, C.D. The effect of nucleating agents on the foam extrusion characteristics. J. Appl. Polym. Sci. 1984, 29, 4465–4470. [Google Scholar] [CrossRef]

- Chen, L.; Blizard, K.; Straff, R.; Wang, X. Effect of Filler Size on Cell Nucleation during Foaming Process. J. Cellul. Plas. 2002, 38, 139–148. [Google Scholar] [CrossRef]

- Lee, S.H.; Zhang, Y.; Kontopoulou, M.; Park, C.B.; Wong, A.; Zhai, W. Optimization of Dispersion of Nanosilica Particles in a PP Matrix and Their Effect on Foaming. Int. Polym. Process. 2011, 26, 388–398. [Google Scholar] [CrossRef]

- Fiorentino, B.; Fulchiron, R.; Bounor-Legaré, V.; Majesté, J.-C.; Leblond, J.C.; Duchet-Rumeau, J. Chemical modification routes of synthetic talc: Influence on its nucleating power and on its dispersion state. Appl. Clay Sci. 2015, 109–110, 107–118. [Google Scholar] [CrossRef]

- Leong, Y.W.; Bakar, M.B.A.; Mohd, I.Z.A.; Ariffin, A. Effects of filler treatments on the mechanical, flow, thermal, and morphological properties of talc and calcium carbonate filled polypropylene hybrid composites. J. Appl. Polym. Sci. 2005, 98, 413–426. [Google Scholar] [CrossRef]

- Velasco, J.I.; Saja, J.A.; de Martinez, A.B. Crystallization behavior of polypropylene filled with surface-modified talc. J. Appl. Polym. Sci. 1996, 61, 125–132. [Google Scholar] [CrossRef]

- Wang, T.; Liu, D.; Keddie, J.L. An alternative approach to the modification of talc for the fabrication of polypropylene/talc composites. J. Appl. Polym. Sci. 2007, 106, 386–393. [Google Scholar] [CrossRef]

- Müller, T.K.H.; Cao, P.; Ewert, S.; Wohlgemuth, J.; Liu, H.; Willett, T.C.; Theodosiou, E.; Thomas, O.R.T.; Franzreb, M. Integrated system for temperature-controlled fast protein liquid chromatography comprising improved copolymer modified beaded agarose adsorbents and a travelling cooling zone reactor arrangement. J. Chromatogr. A 2013, 1285, 97–109. [Google Scholar] [CrossRef] [Green Version]

- Zimmermann, J. Polyol- und Azlacton-Makromonomere für Netzwerksysteme, neue Werkstoffe und biomedizinische Anwendungen. Ph.D. Thesis, Fakultät für Chemie und Pharmazie der Albert-Ludwigs-Universität Freiburg i. Br., Freiburg in Breisgau, Germany, 2001. [Google Scholar]

- Golze, S. Oberflächengebundene Polymermonolagen für die Herstellung von DNA-Chips. Ph.D. Thesis, Fachbereich Chemie und Pharmazie der Johannes Gutenberg-Universität Mainz, Mainz, Germany, 2001. [Google Scholar]

- Boven, G.; Oosterling, M.L.C.M.; Challa, G.; Schouten, A.J. Grafting kinetics of poly(methyl methacrylate) on microparticulate silica. Polymer 1990, 31, 2377–2383. [Google Scholar] [CrossRef] [Green Version]

- Murray, K.A.; Kennedy, J.E.; McEvoy, B.; Vrain, O.; Ryan, D.; Cowman, R.; Higginbotham, C.L. The effects of high energy electron beam irradiation in air on accelerated aging and on the structure property relationships of low density polyethylene. Nucl. Instrum. Method. Phys. Res. Sect. B Beam Interact. Mater. Atoms 2013, 297, 64–74. [Google Scholar] [CrossRef]

- ASTM D 2765-01 Standard Test Methods for Determination of Gel Content and Swell Ratio of Crosslinked Ethylene Plastics. Available online: https://www.astm.org/ (accessed on 6 September 2019).

- Sirisinha, K.; Meksawat, D. Comparison in processability mechanical thermal properties of ethylene-octene copolymer crosslinked by different techniques. J. Appl. Polym. Sci. 2004, 93, 1179–1185. [Google Scholar] [CrossRef]

- Elliott, J.E.; Macdonald, M.; Nie, J.; Bowman, C.N. Structure and swelling of poly(acrylic acid) hydrogels: Effect of pH, ionic strength, and dilution on the crosslinked polymer structure. Polymer 2004, 45, 1503–1510. [Google Scholar] [CrossRef]

- Gu, Y.; Wu, J. Volumetric properties of binary mixtures of, (N, N-diethylformamide + xylenes) at temperatures between T=293.15 K and T=353.15K at p=0.1 MPa. J. Mol. Liq. 2008, 137, 163–173. [Google Scholar] [CrossRef]

- Zhang, Y.; Rodrigue, D.; Ait-Kadi, A. High-density polyethylene foams. I. Polymer and foam characterization. J. Appl. Polym. Sci. 2003, 90, 2111–2119. [Google Scholar] [CrossRef]

- Shameli, K.; Ahmad, M.B.; Yunus, W.Z.W.; Ibrahim, N.A.; Darroudi, M. Synthesis and characterization of silver/talc nanocomposites using the wet chemical reduction method. Int. J. Nanomed. 2001, 5, 743–751. [Google Scholar] [CrossRef]

- Bini, R.A.; Marques, R.F.C.; Santos, F.J.; Chaker, J.A.; Jafelicci, M. Synthesis and functionalization of magnetite nanoparticles with different amino-functional alkoxysilanes. J. Magn. Magn. Mater. 2012, 324, 534–539. [Google Scholar] [CrossRef] [Green Version]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies, 3rd ed.; John Wiley & Sons LTD: West Sussex, UK, 2001. [Google Scholar]

- Khoee, S.; Bagheri, Y.; Hashemi, A. Composition controlled synthesis of PCL-PEG Janus nanoparticles: Magnetite nanoparticles prepared from one-pot photo-click reaction. Nanoscale 2015, 7, 4134–4148. [Google Scholar] [CrossRef] [PubMed]

- Shen, W.; He, H.; Zhu, J.; Yuan, P.; Ma, Y.; Liang, X. Preparation and characterization of 3-aminopropyltriethoxysilane grafted montmorillonite and acid-activated montmorillonite. Sci. Bull. 2009, 54, 265–271. [Google Scholar] [CrossRef]

- He, H.; Duchet, J.; Galy, J.; Gerard, J.F. Grafting of swelling clay materials with 3-aminopropyltriethoxysilane. J. Colloid Interface Sci. 2005, 288, 171–176. [Google Scholar] [CrossRef] [Green Version]

- Sharif-Pakdaman, A.; Morshedian, J.; Jahani, Y. Influence of the silane grafting of polyethylene on the morphology barrier, thermal rheological properties of high-density polyethylene/organoclay nanocomposites. J. Appl. Polym. Sci. 2012, 125, E305–E313. [Google Scholar] [CrossRef]

- Mezger, T.G. The Rheology Handbook: For Users of Rotational and Oscillatory Rheometers; Vincentz Network GmbH & Co KG: Hannover, Germany, 2006. [Google Scholar]

- Liu, H.; Fang, Z.; Peng, M.; Shen, L.; Wang, Y. The effects of irradiation cross-linking on the thermal degradation and flame-retardant properties of the HDPE/EVA/magnesium hydroxide composites. Radiat. Phys. Chem. 2009, 78, 922–926. [Google Scholar] [CrossRef]

| Is Equal to 100 phr | Additives | |||

|---|---|---|---|---|

| Sample | LDPE/EOC (Ratio) | 1.6 wt% | Silane (phr) | Dicumyl Peroxide (phr) |

| Sample 1 | 80/20 | - | - | - |

| Sample 2 | 80/20 | - | 4 | 0.5 |

| Sample 3 | 80/20 | pure talcum | 4 | 0.5 |

| Sample 4 | 80/20 | talcum modified with chlorinated azoinitiator | 4 | 0.5 |

| LDPE/EOC (Ratio) | Pure Talcum (wt%) | Modified Talcum (wt%) | N2 (wt%) | |

|---|---|---|---|---|

| Blend 1 | 80/20 | 2 | - | 0.05 |

| Blend 2 | 80/20 | - | 2 | 0.05 |

| Blend 3 | 80/20 | - | - | - |

| Sample | η0 (kPa s) | G’ (kPa) |

|---|---|---|

| Sample 4 | 303.6 | 29.2 |

| Sample 2 | 151.8 | 13.4 |

| Sample 3 | 65.2 | 4.4 |

| Sample 1 | 21.4 | 0.8 |

| Sample | Molar Mass Mc (g/mol) |

|---|---|

| Sample 2 | 2.1 × 105 |

| Sample 4 | 1.1 × 105 |

| Sample | Density (kg/m³) |

|---|---|

| Blend 3 | 902 |

| Blend 1 | 323 |

| Blend 2 | 274 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaltenegger-Uray, A.; Rieß, G.; Lucyshyn, T.; Holzer, C.; Kern, W. Physical Foaming and Crosslinking of Polyethylene with Modified Talcum. Polymers 2019, 11, 1472. https://doi.org/10.3390/polym11091472

Kaltenegger-Uray A, Rieß G, Lucyshyn T, Holzer C, Kern W. Physical Foaming and Crosslinking of Polyethylene with Modified Talcum. Polymers. 2019; 11(9):1472. https://doi.org/10.3390/polym11091472

Chicago/Turabian StyleKaltenegger-Uray, Anna, Gisbert Rieß, Thomas Lucyshyn, Clemens Holzer, and Wolfgang Kern. 2019. "Physical Foaming and Crosslinking of Polyethylene with Modified Talcum" Polymers 11, no. 9: 1472. https://doi.org/10.3390/polym11091472

APA StyleKaltenegger-Uray, A., Rieß, G., Lucyshyn, T., Holzer, C., & Kern, W. (2019). Physical Foaming and Crosslinking of Polyethylene with Modified Talcum. Polymers, 11(9), 1472. https://doi.org/10.3390/polym11091472