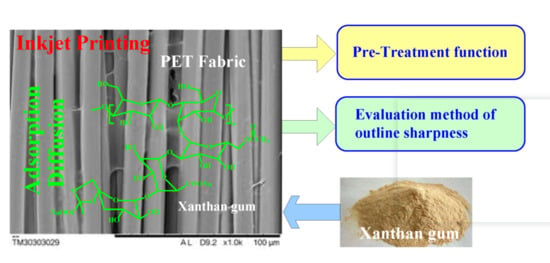

Application of Xanthan Gum as a Pre-Treatment and Sharpness Evaluation for Inkjet Printing on Polyester

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Salt-Containing Xanthan Gum

2.3. Printing of Polyester Fabric

2.4. Ink Drop Experiment and New Methods for the Definition of Inkjet Printing

- La was the long axis of the inkblot ellipse (it was typically in the weft direction of the fabric), cm.

- Lb was the short axis of the inkblot ellipse (it was typically in the warp direction of the fabric), cm.

3. Results and Discussion

3.1. Effect of Salt Concentration on the K/S Value of Inkjet Printing

3.2. Effect of Salt Concentration on the Outline Sharpness of Inkjet Printing

3.3. New Evaluation Method of Outline Sharpness for Inkjet Printing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhan, Z.Y.; An, J.N.; Wei, Y.F.; Tran, V.T.; Du, H.J. Inkjet-printed optoelectronics. Nanoscale 2017, 9, 965–993. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Parrillo-Chapman, L.; Freeman, H.S. A study of the effects of fabric pretreatment on color gamut from inkjet printing on polyester. J. Text. Inst. 2017, 109, 1143–1151. [Google Scholar] [CrossRef]

- Ding, Y.; Shamey, R.; Chapman, L.P.; Freeman, H.S. Pretreatment effects on pigment-based textile inkjet printing -colour gamut and crockfastness properties. Coloration Technol. 2019, 135, 77–86. [Google Scholar] [CrossRef]

- Zhang, C.M.; Zhao, M.H.; Wang, L.B.; Yu, M. Effect of atmospheric-pressure air/He plasma on the surface properties related to ink-jet printing polyester fabric. Vacuum 2017, 137, 42–48. [Google Scholar] [CrossRef]

- Kumar, A.; Rao, K.M.; Han, S.S. Application of xanthan gum as polysaccharide in tissue engineering: A review. Carbohydr. Polym. 2018, 180, 128–144. [Google Scholar] [CrossRef] [PubMed]

- Noppakundilograt, S.; Buranagul, P.; Graisuwan, W.; Koopipat, C.; Kiatkamjornwong, S. Modified chitosan pretreatment of polyester fabric for printing by ink jet ink. Carbohydr. Polym. 2010, 82, 1124–1135. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, C.; Chen, K.; Yin, Y. Improvement of ink-jet printing performances using β-cyclodextrin forming inclusion complex on cotton fabric. Fiber. Polym. 2017, 18, 619–624. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, M.; Zhang, L.P.; Tian, A.L.; Zhang, Y.; Fu, S.H. Influence of diffusion behavior of disperse dye ink on printing accuracy for warp-knitted polyester fabrics. Text. Res. J. 2019, 89, 162–171. [Google Scholar] [CrossRef]

- Li, M.; Zhang, L.P.; Wang, D.T.; Agbo, C.; Fu, S.H. Influence of nano-coated pigment ink formulation on ink-jet printability and printing accuracy. Coloration Technol. 2017, 133, 476–484. [Google Scholar] [CrossRef]

- Li, M.; Zhang, L.; An, Y.; Ma, W.; Fu, S. Relationship between silk fabric pretreatment, droplet spreading, and ink-jet printing accuracy of reactive dye inks. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Sriviriyakul, T.; Bogren, S.; Schaller, V.; Jonasson, C.; Blomgren, J.; Ahrentorp, F.; Lopez-Sanchez, P.; Berta, M.; Grüttner, C.; Zeng, L.; et al. Nanorheological studies of xanthan/water solutions using magnetic nanoparticles. J. Magn. Magn. Mater. 2019, 473, 268–271. [Google Scholar] [CrossRef]

- Vilgis, T.A. Gels: Model systems for soft matter food physics. Curr. Opin. Food Sci. 2015, 3, 71–84. [Google Scholar] [CrossRef]

- Morris, E.R. Ordered conformation of xanthan in solutions and "weak gels": Single helix, double helix - or both? Food Hydrocoll. 2017, 86, 18–25. [Google Scholar] [CrossRef]

- Owens, C.; Griffin, K.; Khouryieh, H.; Williams, K. Creaming and oxidative stability of fish oil-in-water emulsions stabilized by whey protein-xanthan-locust bean complexes: Impact of pH. Food Chem. 2018, 239, 314–322. [Google Scholar] [CrossRef]

- Karimi, K.; Taherzadeh, M.J. A critical review of analytical methods in pretreatment of lignocelluloses: Composition, imaging, and crystallinity. Bioresour. Technol. 2016, 200, 1008–1018. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martin-Alfonso, J.E.; Cuadri, A.A.; Berta, M.; Stading, M. Relation between concentration and shear-extensional rheology properties of xanthan and guar gum solutions. Carbohydr. Polym. 2018, 181, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Chaudhary, S.; Sharma, J.; Kaith, B.S.; yadav, S.; Sharma, A.K.; Goel, A. Gum xanthan-psyllium-cl-poly(acrylic acid-co-itaconic acid) based adsorbent for effective removal of cationic and anionic dyes: Adsorption isotherms, kinetics and thermodynamic studies. Ecotoxicol. Environ. Saf. 2018, 149, 150–158. [Google Scholar] [CrossRef] [PubMed]

- Thakur, S.; Pandey, S.; Arotiba, O.A. Sol-gel derived xanthan gum/silica nanocomposite-a highly efficient cationic dyes adsorbent in aqueous system. Int. J. Biol. Macromol. 2017, 103, 596–604. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhu, F.; Yang, Q.; Lu, D. Rheological properties of modified xanthan and their influence on printing performances on cotton with reactive dyes in screen printing. Cellulose 2013, 20, 2125–2135. [Google Scholar] [CrossRef]

- Krstonošić, V.; Milanović, M.; Dokić, L. Application of different techniques in the determination of xanthan gum-SDS and xanthan gum-Tween 80 interaction. Food Hydrocoll. 2019, 87, 108–118. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, B.; Lu, Y.; Qiu, X.; Jin, H.; Liu, Y.; Wang, L.; Tian, M.; Li, K. Rheological properties of water-soluble cross-linked xanthan gum. J. Dispers. Sci. Technol. 2016, 38, 361–366. [Google Scholar] [CrossRef]

- Mierczynska, J.; Cybulska, J.; Solowiej, B.; Zdunek, A. Effect of Ca(2+), Fe(2+) and Mg(2+) on rheological properties of new food matrix made of modified cell wall polysaccharides from apple. Carbohydr. Polym. 2015, 133, 547–555. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Liu, B.; Yang, Q.; Lu, D. Rheological studies of mixed printing pastes from sodium alginate and modified xanthan and their application in the reactive printing of cotton. Coloration Technol. 2014, 130, 273–279. [Google Scholar] [CrossRef]

- Chen, L.; Wang, C.X.; Tian, A.L.; Wu, M. An attempt of improving polyester inkjet printing performance by surface modification using ss-cyclodextrin. Surf. Interface Anal. 2012, 44, 1324–1330. [Google Scholar] [CrossRef]

- Bu, G.J.; Wang, C.X.; Fu, S.H.; Tian, A.L. Water-soluble cationic chitosan derivative to improve pigment-based inkjet printing and antibacterial properties for cellulose substrates. J. Appl. Polym. Sci. 2012, 125, 1674–1680. [Google Scholar] [CrossRef]

- Reinoso, D.; Martin-Alfonso, M.J.; Luckham, P.F.; Martinez-Boza, F.J. Rheological characterisation of xanthan gum in brine solutions at high temperature. Carbohydr. Polym. 2019, 203, 103–109. [Google Scholar] [CrossRef]

- Xu, L.; Dong, M.; Gong, H.; Sun, M.; Li, Y. Effects of inorganic cations on the rheology of aqueous welan, xanthan, gellan solutions and their mixtures. Carbohydr. Polym. 2015, 121, 147–154. [Google Scholar] [CrossRef]

- Sotiropoulos, K.; Papagiannopoulos, A. Modification of xanthan solution properties by the cationic surfactant DTMAB. Int. J. Biol. Macromol. 2017, 105, 1213–1219. [Google Scholar] [CrossRef]

- Galván, Z.R.N.; Soares, L.d.S.; Medeiros, E.A.A.; Soares, N.d.F.F.; Ramos, A.M.; Coimbra, J.S.d.R.; de Oliveira, E.B. Rheological Properties of Aqueous Dispersions of Xanthan Gum Containing Different Chloride Salts Are Impacted by both Sizes and Net Electric Charges of the Cations. Food Biophys. 2018, 13, 186–197. [Google Scholar] [CrossRef]

- Papagiannopoulos, A.; Sotiropoulos, K.; Pispas, S. Particle tracking microrheology of the power-law viscoelasticity of xanthan solutions. Food Hydrocoll. 2016, 61, 201–210. [Google Scholar] [CrossRef]

- Lutfi, Z.; Alam, F.; Nawab, A.; Haq, A.; Hasnain, A. Effect of NaCl on physicochemical properties of xanthan gum – Water chestnut starch complexes. Int. J. Biol. Macromol. 2019, 131, 557–563. [Google Scholar] [CrossRef] [PubMed]

- Karanikas, E.; Nikolaidis, N.; Tsatsaroni, E. Disperse Inkjet Inks with a New Antibacterial Agent as Additive: Properties and Application to Polyester and Polyamide Fibres. Fibers Polym. 2016, 17, 248–256. [Google Scholar] [CrossRef]

- Hajipour, A.; Shams-Nateri, A. The effect of fabric density on the quality of digital printing on polyester. Fibers Polym. 2017, 18, 2462–2468. [Google Scholar] [CrossRef]

- Zhu, L.M.; Schuster, P.; Klinge, U. Mesh implants: An overview of crucial mesh parameters. World J. Gastrointest. Surg. 2015, 7, 226–236. [Google Scholar] [CrossRef] [PubMed]

| Salt | Mathematical Mode | Variance Test | ||

|---|---|---|---|---|

| R2 | F-value | p-value | ||

| NaCl | y = x/(0.030486 + 0.662404x) + 9.2098 | 0.9896 | 238.6056 | 0.0000 |

| KCl | y = x/(0.021555 + 0.859289x) + 9.1859 | 0.9909 | 271.7458 | 0.0000 |

| CaCl2 | y = x/(0.000925 + 0.386375x) + 9.2005 | 0.9943 | 432.5051 | 0.0000 |

| MgCl2 | y = x/(0.001341 + 0.478476x) + 9.2032 | 0.9633 | 65.6802 | 0.0003 |

| Definition of Grades | Ink Drop Experiment | Line Width of Actual Printing | |||||

|---|---|---|---|---|---|---|---|

| La (cm) | Lb (cm) | T | S (cm2) | Warp (μm) | Weft (μm) | Observe | |

| Grade 1 | 2.5 | 1.5 | 0.60 | 2.94 | 551.3 | 1353.3 | ○ |

| Grade 2 | 2.3 | 1.3 | 0.57 | 2.35 | 546.4 | 1178.5 | ◎ |

| 2.4 | 1.4 | 0.58 | 2.64 | 549.3 | 1202.5 | ◎ | |

| 2.4 | 1.4 | 0.58 | 2.64 | 539.3 | 1054.6 | ◎ | |

| 2.2 | 1.3 | 0.59 | 2.25 | 522.6 | 1063.1 | ◎ | |

| 2.2 | 1.3 | 0.59 | 2.25 | 516.3 | 1033.2 | ◎ | |

| 2.1 | 1.3 | 0.62 | 2.14 | 521.6 | 974.2 | ◎ | |

| 1.9 | 1.2 | 0.63 | 1.79 | 502.3 | 972.1 | ◎ | |

| 2.2 | 1.4 | 0.64 | 2.42 | 537.6 | 1032.0 | ◎ | |

| 2.3 | 1.5 | 0.65 | 2.71 | 541.4 | 1040.0 | ◎ | |

| 2.0 | 1.3 | 0.65 | 2.04 | 524.8 | 964.2 | ◎ | |

| 2.2 | 1.5 | 0.68 | 2.59 | 528.5 | 1008.2 | ◎ | |

| 2.0 | 1.4 | 0.70 | 2.20 | 515.5 | 1014.6 | ◎ | |

| Grade 3 | 1.8 | 1.3 | 0.72 | 1.84 | 509.6 | 1012.0 | ● |

| 1.7 | 1.3 | 0.76 | 1.73 | 502.4 | 989.2 | ● | |

| 1.8 | 1.4 | 0.78 | 1.98 | 520.4 | 997.4 | ● | |

| Grade 4 | 1.3 | 1.2 | 0.92 | 1.22 | 507.0 | 807.6 | ☆ |

| 1.3 | 1.2 | 0.92 | 1.22 | 497.2 | 865.7 | ☆ | |

| 1.5 | 1.4 | 0.93 | 1.65 | 510.3 | 992.5 | ☆ | |

| Grade 5 | 1.2 | 1.2 | 1.00 | 1.13 | 490.0 | 758.3 | ★ |

| 1.1 | 1.1 | 1.00 | 0.95 | 497.1 | 693.2 | ★ | |

| 0.8 | 0.8 | 1.00 | 0.50 | 482.1 | 673.6 | ★ | |

| 0.4 | 0.4 | 1.00 | 0.13 | 492.0 | 681.3 | ★ | |

| 0.4 | 0.4 | 1.00 | 0.13 | 492.2 | 677.1 | ★ | |

| 0.4 | 0.4 | 1.00 | 0.13 | 491.8 | 632.4 | ★ | |

| 0.4 | 0.4 | 1.00 | 0.13 | 481.2 | 642.3 | ★ | |

| 0.4 | 0.4 | 1.00 | 0.13 | 479.3 | 688.3 | ★ | |

| 0.4 | 0.4 | 1.00 | 0.13 | 480.1 | 647.4 | ★ | |

| 0.4 | 0.4 | 1.00 | 0.13 | 472.6 | 663.8 | ★ | |

| Definition of Grades | T | Pattern I | Pattern II | Definition of Marginal | Definition of Internal |

|---|---|---|---|---|---|

| Grade 1 | 0.60 |  |  | ○ | ○ |

| Grade 2 | 0.57 |  |  | ◎ | ◎ |

| Grade 2 | 0.61 |  |  | ◎ | ◎ |

| Grade 3 | 0.72 |  |  | ● | ● |

| Grade 3 | 0.78 |  |  | ● | ● |

| Grade 4 | 0.92 |  |  | ☆ | ☆ |

| Grade 4 | 0.93 |  |  | ☆ | ☆ |

| Grade 5 | 1.00 |  |  | ★ | ★ |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, H.; Ai, L.; Yang, Z.; Zhu, Y. Application of Xanthan Gum as a Pre-Treatment and Sharpness Evaluation for Inkjet Printing on Polyester. Polymers 2019, 11, 1504. https://doi.org/10.3390/polym11091504

Cao H, Ai L, Yang Z, Zhu Y. Application of Xanthan Gum as a Pre-Treatment and Sharpness Evaluation for Inkjet Printing on Polyester. Polymers. 2019; 11(9):1504. https://doi.org/10.3390/polym11091504

Chicago/Turabian StyleCao, Hongmei, Li Ai, Zhenming Yang, and Yawei Zhu. 2019. "Application of Xanthan Gum as a Pre-Treatment and Sharpness Evaluation for Inkjet Printing on Polyester" Polymers 11, no. 9: 1504. https://doi.org/10.3390/polym11091504

APA StyleCao, H., Ai, L., Yang, Z., & Zhu, Y. (2019). Application of Xanthan Gum as a Pre-Treatment and Sharpness Evaluation for Inkjet Printing on Polyester. Polymers, 11(9), 1504. https://doi.org/10.3390/polym11091504