Effect of Fibre Orientation and Hostile Solutions on Stress Relaxation of Glass/Polyamide Composites

Abstract

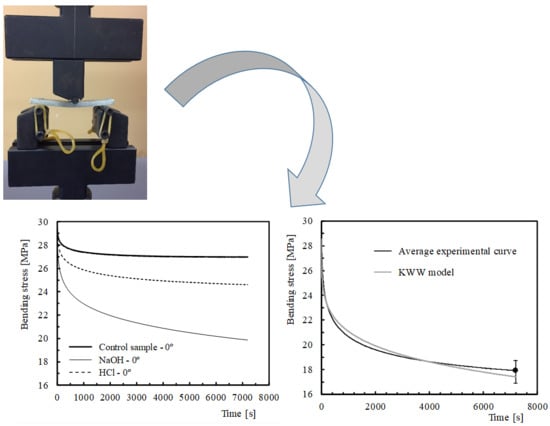

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| b | Width of the specimen (mm) |

| h | Thickness of the specimen (mm) |

| I | Moment of inertia of the cross-section (mm4) |

| L | Spam length (mm) |

| P | Load (N) |

| t | Time (seconds) |

| β | Fractional power exponent (known as non-exponential factor) |

| ΔP | Load range in the middle span for an interval in the linear region (N) |

| Δu | Flexural displacement range in the middle span for an interval in the linear region (mm) |

| Δσ | Difference between initial and final stress divided by the initial stress |

| σ0 | Stress at t = 0; initial bending stress |

| σ(t) | Stress at time t |

| σ | Bending stress at any given moment of the test |

| τ | KWW relaxation time |

| ∅ | Relaxation function |

Abbreviations

| ASTM | American Society for Testing and Materials |

| GFRP | Glass fibre-reinforced polymer |

| GRP | Glass-reinforced pipes |

| H+ | Hydrogen ions |

| H2O | Water molecule |

| HCl | Hydrochloric acid |

| HNO3 | Nitric acid |

| H3PO4 | Phosphoric acid |

| H2SO4 | Sulfuric acid |

| NaCl | Sodium chloride |

| NaOH | Sodium hydroxide |

| PA6 | Polyamide 6 |

| KWW | Kohlrausch–Williams–Watts function |

| SR | Stress relaxation |

| Std Dev | Standard deviation |

| 3PB | Three-point bending static tests |

References

- Machado, M.; Cakmak, U.D.; Kallai, I.; Major, Z. Thermomechanical viscoelastic analysis of woven-reinforced thermoplastic-matrix composites. Compos. Struct. 2016, 157, 256–264. [Google Scholar] [CrossRef]

- Zheng, X.; Lin, Q.; Jiang, P.; Li, Y.; Li, J. Ionic liquids incorporating polyamide 6: Miscibility and physical properties. Polymers 2018, 10, 562. [Google Scholar] [CrossRef] [Green Version]

- Arhant, M.; Briançon, C.; Burtin, C.; Davies, P. Carbon/polyamide 6 thermoplastic composite cylinders for deep sea applications. Compos. Struct. 2019, 212, 535–546. [Google Scholar] [CrossRef] [Green Version]

- Han, M.-H.; Nairn, J.A. Hygrothermal aging of polyimide matrix composite laminates. Compos. Part A Appl. Sci. Manuf. 2003, 34, 979–986. [Google Scholar] [CrossRef] [Green Version]

- Bergeret, A.; Ienny, L.F.P. Influence of the fibre/matrix interface on ageing mechanisms of glass fibre reinforced thermoplastic composites (PA-6,6, PET, PBT) in a hygrothermal environment. Polym. Degrad. Stab. 2009, 94, 1315–1324. [Google Scholar] [CrossRef]

- Haddar, N.; Ksouri, I.; Kallel, T.; Mnif, N. Effect of Hygrothermal Ageing on the Monotonic and Cyclic Loading of Glass Fiber Reinforced Polyamide. Polym. Compos. 2014, 35, 501–508. [Google Scholar]

- Karger-Kocsis, J. Environmental stress corrosion behavior of polyamides and their composites with short glass fiber and glass swirl mat. Polym. Bull. 1991, 26, 123–130. [Google Scholar] [CrossRef]

- Kawaia, M.; Takeuchia, H.; Taketa, I.; Tsuchiya, A. Effects of temperature and stress ratio on fatigue life of injection molded short carbon fiber-reinforced polyamide composite. Compos. Part A Appl. Sci. Manuf. 2017, 98, 9–24. [Google Scholar] [CrossRef]

- Barbouchi, S.; Bellenger, V.; Tcharkhtchi, A.; Castaing, P.; Jollivet, T. Effect of water on the fatigue behaviour of a pa66/glass fibers composite material. J. Mater. Sci. 2007, 42, 2181–2188. [Google Scholar] [CrossRef]

- Ksouri, I.; Guermazi, N.; Haddar, N.; Ayedi, H.F. Effects of processing steps and hygrothermal ageing on mechanical performance of PA6GF30 composite: Interfacial shear strength. Polym. Compos. 2018, 39, 504–512. [Google Scholar] [CrossRef]

- Stamenovic, M.; Putic, S.; Rakin, M.; Medjo, B.; Čikara, D. Effect of alkaline and acid solutions on the tensile properties of glass-polyester pipes. Mater. Des. 2011, 3, 2456–2461. [Google Scholar] [CrossRef]

- Feng, P.; Wang, J.; Wang, Y.; Loughery, D.; Niu, D. Effect of corrosive environments on properties of pultruded GFRP plates. Compos. Part B Eng. 2014, 67, 427–433. [Google Scholar] [CrossRef]

- Amaro, A.M.; Reis, P.N.B.; Neto, M.A.; Louro, C. Effects of alkaline and acid solutions on glass/epoxy composites. Polym. Degrad. Stab. 2013, 98, 853–862. [Google Scholar] [CrossRef]

- Amaro, A.M.; Reis, P.N.B.; Neto, M.A.; Louro, C. Effect of different acid solutions on glass/epoxy composites. J. Reinf. Plast. Comp. 2013, 32, 1018–1029. [Google Scholar] [CrossRef]

- Kamal, H.M.; Kadhim, M.J. Effect of chemical solutions on the mechanical properties of nano-silica reinforced (glass/Kevlar) fabrics polyester hybrid composite materials. Int. J. Energy Environ. 2018, 9, 187–194. [Google Scholar]

- Mahmoud, M.K.; Tantawi, S.H. Effect of strong acids on mechanical properties of glass/polyester GRP pipe at normal and high temperatures. Polym. Plast. Technol. Eng. 2003, 42, 677–688. [Google Scholar] [CrossRef]

- Barbosa, A.P.C.; Fulco, A.P.P.; Guerra, E.S.S.; Arakaki, F.K.; Tosatto, M.; Costa, M.C.B.; Melo, J.D.D. Accelerated aging effects on carbon fiber/epoxy composites. Compos. Part B Eng. 2017, 110, 298–306. [Google Scholar] [CrossRef]

- Benmokrane, B.; Ali, A.H.; Mohamed, H.M.; ElSafty, A.; Manalo, A. Laboratory assessment and durability performance of vinyl-ester, polyester, and epoxy glass-FRP bars for concrete structures. Compos. Part B Eng. 2017, 114, 163–174. [Google Scholar] [CrossRef] [Green Version]

- Bazli, M.; Ashrafi, H.; Oskouei, A.V. Effect of harsh environments on mechanical properties of GFRP pultruded profiles. Compos. Part B Eng. 2016, 99, 203–215. [Google Scholar] [CrossRef]

- Tanks, J.D.; Arao, Y.; Kubouchi, M. Diffusion kinetics, swelling, and degradation of corrosion-resistant C-glass/epoxy woven composites in harsh environments. Compos. Struct. 2018, 202, 686–694. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, L.; Shen, H.; Wu, Z. Long-term performance of pultruded basalt fiber reinforced polymer profiles under acidic conditions. J. Mater. Civ. Eng. 2018, 30, 04018096. [Google Scholar] [CrossRef]

- Kusano, M.; Kanai, T.; Arao, Y.; Kubouchi, M. Degradation behavior and lifetime estimation of fiber reinforced plastics tanks for hydrochloric acid storage. Eng. Fail. Anal. 2017, 79, 971–979. [Google Scholar] [CrossRef]

- Haghara, H.; Watanabe, R.; Shimada, T.; Funabashi, M.; Kumioka, M.; Sato, H. Degradation behavior and lifetime estimation of fiber reinforced plastics tanks for hydrochloric acid storage. Compos. Part A Appl. Sci. Manuf. 2018, 112, 126–133. [Google Scholar]

- Obaid, N.; Kortschot, M.T.; Sain, M. Understanding the stress relaxation behavior of polymers reinforced with short elastic fibers. Materials 2017, 10, 472. [Google Scholar] [CrossRef] [Green Version]

- Tang, T.; Felicelli, S.D. Computational evaluation of effective stress relaxation behavior of polymer composites. Int. J. Eng. Sci. 2015, 90, 76–85. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Silva, M.P.; Santos, P. Stress relaxation in delaminated carbon/epoxy composites. Fiber Polym. 2019, 20, 1284–1289. [Google Scholar] [CrossRef]

- Wang, J.; GangaRao, H.; Lian, R.; Liu, W. Durability and prediction models of fiber-reinforced polymer composites under various environmental conditions: A critical review. J. Reinf. Plast. Compos. 2016, 35, 179–211. [Google Scholar] [CrossRef]

- Papanicolaou, G.C.; Zaoutsos, S.P.; Kontou, E.A. Fiber orientation dependence of continuous carbon/epoxy composites nonlinear viscoelastic behavior. Compos. Sci. Technol. 2004, 64, 2535–2545. [Google Scholar] [CrossRef]

- Goertzen, W.K.; Kessler, M.R. Creep behavior of carbon fiber/epoxy matrix composite. Mater. Sci. Eng. A Struct. Mater. 2006, 421, 217–225. [Google Scholar] [CrossRef]

- Kontou, E. Tensile creep behavior of unidirectional glass-fiber polymer composites. Polym. Compos. 2005, 26, 287–292. [Google Scholar] [CrossRef]

- Galloa, S.C.; Li, X.; Zhang, Z.; Charitidis, C.; Dong, H. Viscoelastic response of carbon fibre reinforced polymer during push-out tests. Compos. Part A Appl. Sci. Manuf. 2018, 112, 178–185. [Google Scholar] [CrossRef]

- Kim, H.; Takemura, K. Influence of water absorption on creep behavior of carbon/epoxy laminates. Procedia Eng. 2011, 10, 2731–2736. [Google Scholar] [CrossRef] [Green Version]

- Arao, Y.; Koyanagi, J.; Utsunomiya, S.; Kawada, H. Time-dependent out-of-plane deformation of UD-CFRP in humid environment. Compos. Sci. Technol. 2009, 69, 1720–1725. [Google Scholar] [CrossRef]

- Arao, Y.; Koyanagi, J.; Utsunomiya, S.; Takeda, S.; Kawada, H. Analysis of time-dependent deformation of a CFRP mirror under hot and humid conditions. Mech. Time Depend Mater. 2009, 13, 183–197. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G.; Rashid, K. Creep behavior of resin matrix and basalt fiber reinforced polymer (BFRP) plate at elevated temperatures. J. Compos. Sci. 2017, 1, 3. [Google Scholar] [CrossRef] [Green Version]

- Kontou, E. Viscoplastic Deformation of an epoxy resin at elevated temperatures. J. Appl. Polym. Sci. 2006, 101, 2027–2033. [Google Scholar] [CrossRef]

- Kutty, S.K.N.; Nando, G.B. Stress relaxation behavior of short Kevlar fiber-reinforced thermoplastic polyurethane. J. Appl. Polym. Sci. 1991, 42, 1835–1844. [Google Scholar] [CrossRef]

- Kawai, M.; Masuko, Y.; Kazama, T. Stress relaxation behavior of angle-ply CFRP laminate at elevated temperature. Trans. Jpn. Soc. Mech. Eng. A 2003, 69, 1678–1685. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.H.; Ilisch, S.; Radusch, H.J. Characterization of the effect of the filler dispersion on the stress relaxation behavior of carbon black filled rubber composites. Polymer 2009, 50, 2294–2303. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Gorbatikh, L.; Ivens, J.; Lomov, S.V. Strain-rate sensitivity and stress relaxation of hybrid self-reinforced polypropylene composites under bending loads. Compos. Struct. 2019, 209, 802–810. [Google Scholar] [CrossRef]

- Bhagawan, S.S.; Tripathy, D.K.; De, S.K. Stress relaxation in short jute fiber-reinforced nitrile rubber composites. J. Appl. Polym. Sci. 1987, 33, 1623–1639. [Google Scholar] [CrossRef]

- Varghese, S.; Kuriakose, B.; Thomas, S. Stress relaxation in short sisal-fiber-reinforced natural rubber composites. J. Appl. Polym. Sci. 1994, 53, 1051–1060. [Google Scholar] [CrossRef]

- Obaid, N.; Kortschot, M.T.; Sain, M. Predicting the stress relaxation behavior of glass-fiber reinforced polypropylene composites. Compos. Sci. Technol. 2018, 161, 85–91. [Google Scholar] [CrossRef]

- Masuko, Y.; Kawai, M. Application of a phenomenological viscoplasticity model to the stress relaxation behavior of unidirectional and angle-ply CFRP laminates at high temperature. Compos. Part A Appl. Sci. Manuf. 2004, 35, 817–826. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Neto, M.A.; Amaro, A.M. Effect of hostile solutions on stress relaxation of carbon/epoxy composites. Polym. Degrad. Stab. 2019, 165, 60–67. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Silva, M.P.; Santos, P.; Parente, J.M.; Bezazi, A. Viscoelastic behaviour of composites with epoxy matrix filled by cork powder. Compos. Struct. 2019. [Google Scholar] [CrossRef]

- Banna, M.H.; Shirokoff, J.; Molgaard, J. Effects of two aqueous acid solutions on polyester and bisphenol a epoxy vinyl ester resins. Mater. Sci. Eng. A Struct. 2011, 528, 2137–2142. [Google Scholar] [CrossRef]

- Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials; ASTM D 7264/D 7264M-07; American Society for Testing and Materials: West Conshohocken, PA, USA, 2007.

- Ferreira, J.A.M.; Reis, P.N.B.; Costa, J.D.M.; Richardson, M.O.W. Fatigue behavior of Kevlar composites with nanoclay filled epoxy resin. J. Compos. Mater. 2013, 45, 1885–1895. [Google Scholar] [CrossRef]

- Standard Test Methods for Stress Relaxation for Materials and Structures; E 328-02; American Society for Testing and Materials: West Conshohocken, PA, USA, 2002.

- Koc, M.; Sonmez, F.O.; Ersoy, N.; Cinar, K. Failure behavior of composite laminates under four-point bending. J. Compos. Mater. 2016, 50, 3679–3697. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Ferreira, J.A.M.; Antunes, F.V.; Costa, J.D.M. Flexural behaviour of hybrid laminated composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1612–1620. [Google Scholar] [CrossRef] [Green Version]

- Griffiths, R.; Ball, A. An assessment of the properties and degradation behaviour of glass-fibre-reinforced polyester polymer concrete. Compos. Sci. Technol. 2000, 60, 2747–2753. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Joseph, R.; Thomas, S. Stress-relaxation behaviour in composites based on short oil-palm fibres and phenol formaldehyde resin. Compos. Sci. Technol. 2001, 61, 1175–1188. [Google Scholar] [CrossRef]

- Ferreira, J.A.M.; Costa, J.D.M.; Reis, P.N.B. Static and fatigue behaviour of glass-fibre-reinforced polypropylene composites. Theor. Appl. Fract. Mech. 1999, 31, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Hirai, T.; Fukumori, K.; Ikawa, T.; Oda, T. Polyamide 6 and high molecular weight phenol novolac blend having excellent mechanical properties in humid conditions. J. Thermoplast. Compos. Mater. 2019, 32, 778–794. [Google Scholar] [CrossRef]

- Palmer, R.G.; Stein, D.L.; Abrahams, E.; Anderson, P.W. Models of Hierarchically Constrained Dynamics for Glassy Relaxation. Phys. Rev. Lett. 1984, 53, 958–961. [Google Scholar] [CrossRef]

- Alvarez, F.; Alegria, A.; Colmenero, J. Relationship between the time-domain Kohlrausch-Williams-Watts and frequency-domain Havriliak-Negami relaxation functions. Phys. Rev. B 1991, 44, 7306–7312. [Google Scholar] [CrossRef]

- Hutchinson, J.M.; Smith, S.; Horne, B.; Gourlay, G.M. Physical Aging of Polycarbonate: Enthalpy Relaxation, Creep Response, and Yielding Behavior. Macromolecules 1999, 32, 5046–5061. [Google Scholar] [CrossRef]

- Fancey, K.S. A mechanical model for creep, recovery and stress relaxation in polymeric materials. J. Mater. Sci. 2005, 40, 4827–4831. [Google Scholar] [CrossRef]

- Razavi-Nouri, M. Creep and Stress Relaxation Behavior of Polypropylene, Metallocene-Prepared Polyethylene and their Blends. Iran. J. Chem. Eng. 2012, 9, 60–69. [Google Scholar]

- Vaidyanathan, T.K.; Vaidyanathan, J. Validity of predictive models of stress relaxation in selected dental polymers. Dent. Mater. 2015, 31, 799–806. [Google Scholar] [CrossRef]

| Solutions | pH Level | Fibre Orientation | Immersion Time (Days) |

|---|---|---|---|

| Control sample (CS) | - | 0° | - |

| 30° | |||

| 45° | |||

| HCl | 0.6 | 0° | 30 |

| 30° | |||

| 45° | |||

| NaOH | 13.7 | 0° | 30 |

| 30° | |||

| 45° |

| Samples | Flexural Strength/MPa | Flexural Modulus/GPa | |||

|---|---|---|---|---|---|

| Average Value | Std Dev | Average Value | Std Dev | ||

| CS | 0° | 152.2 | 12.1 | 10.7 | 0.7 |

| 30° | 102.1 | 10.4 | 4.9 | 0.3 | |

| 45° | 76.5 | 2.8 | 3.4 | 0.2 | |

| HCl | 0° | 114.9 | 13.3 | 9.5 | 0.8 |

| 30° | 95.9 | 3.9 | 3.6 | 0.3 | |

| 45° | 66.2 | 5.0 | 3.1 | 0.2 | |

| NaOH | 0° | 107.1 | 12.2 | 8.7 | 0.3 |

| 30° | 92.9 | 7.1 | 3.1 | 0.4 | |

| 45° | 62.1 | 2.9 | 2.8 | 0.7 | |

| Samples | Initial Stress/MPa | Final Stress/MPa | Δσ/% | ||

|---|---|---|---|---|---|

| Average Value | Std Dev | ||||

| CS | 0° | 30 | 26.9 | 0.46 | 10.3 |

| 30° | 20.9 | 0.81 | 30.3 | ||

| 45° | 19.3 | 0.45 | 35.7 | ||

| HCl | 0° | 30 | 24.6 | 1.12 | 18.0 |

| 30° | 19.8 | 1.44 | 34.0 | ||

| 45° | 17.9 | 1.46 | 40.3 | ||

| NaOH | 0° | 30 | 19.9 | 1.31 | 33.7 |

| 30° | 18.9 | 1.13 | 37.0 | ||

| 45° | 17.4 | 1.10 | 42.0 | ||

| Fibre Orientation | Solution | β | τ | Bending Stress after 3 h (MPa) | ||

|---|---|---|---|---|---|---|

| Exp. Value | KWW Value | Error (%) | ||||

| 0° | Control | 0.173419 | 5,451,440,860 | 26.98 | 26.79 | 0.71 |

| HCl | 0.210335 | 17,397,543 | 24.61 | 24.38 | 0.94 | |

| NaOH | 0.245194 | 254,842 | 19.87 | 19.71 | 0.81 | |

| 30° | Control | 0.214439 | 891,560 | 20.98 | 20,7 | 1.35 |

| HCl | 0.221025 | 381,474 | 19.76 | 19.37 | 2.01 | |

| NaOH | 0.22324 | 245,827 | 18.92 | 18.58 | 1.83 | |

| 45° | Control | 0.224938 | 304,551 | 19.30 | 18.88 | 2.22 |

| HCl | 0.247563 | 124,048 | 17.92 | 17.41 | 2.93 | |

| NaOH | 0.252633 | 116,068 | 17.58 | 17.24 | 1.97 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, P.N.B.d.; Amaro, A.M.; Neto, M.A. Effect of Fibre Orientation and Hostile Solutions on Stress Relaxation of Glass/Polyamide Composites. Polymers 2020, 12, 20. https://doi.org/10.3390/polym12010020

Reis PNBd, Amaro AM, Neto MA. Effect of Fibre Orientation and Hostile Solutions on Stress Relaxation of Glass/Polyamide Composites. Polymers. 2020; 12(1):20. https://doi.org/10.3390/polym12010020

Chicago/Turabian StyleReis, Paulo Nobre Balbis dos, Ana Martins Amaro, and Maria Augusta Neto. 2020. "Effect of Fibre Orientation and Hostile Solutions on Stress Relaxation of Glass/Polyamide Composites" Polymers 12, no. 1: 20. https://doi.org/10.3390/polym12010020

APA StyleReis, P. N. B. d., Amaro, A. M., & Neto, M. A. (2020). Effect of Fibre Orientation and Hostile Solutions on Stress Relaxation of Glass/Polyamide Composites. Polymers, 12(1), 20. https://doi.org/10.3390/polym12010020