Influence of Oil–Pressboard Mass Ratio on the Equilibrium Characteristics of Furfural under Oil Replacement Conditions

Abstract

:1. Introduction

2. Sample Preparation and Experiments

2.1. Sample Pretreatment and Accelerated Thermal Aging Experiment

- First, the insulating pressboard was cut into rectangular pieces (6.0 cm × 3.6 cm) and put on a bracket. Then, the bracket with insulation pressboard and the steel tank containing insulating oil were dried for at least 48 h in the vacuum immersion device at 105 °C for 48 h;

- Second, the insulation pressboard was immersed in a steel tank containing dry oil in vacuum at 60 °C for 48 h. This ensured that the initial moisture content of the insulating pressboard was less than 0.8%, and that of insulating oil was less than 35 mg/kg;

- Thirdly, insulating pressboard and oil were placed into ten ground glass bottles, according to different oil–pressboard mass ratios. An appropriate number of copper sheets was put into each bottle to make the thermal aging experiment condition close to the actual operation state of the transformer. Furthermore, each bottle was filled with high-purity nitrogen and strictly sealed. This process was repeated after the oil replacement operation and sampling operation to eliminate the effect of oxygen;

2.2. Oil Replacement Experiment

2.3. Sampling and Parameter Measurement

3. Experimental Results

3.1. Relationship Between Aging Time and Furfural Concentration

3.2. Furfural Concentration in the Oil and Pressboard

3.3. The DP of Pressboard and Furfural Concentration in Oil

4. Data Analysis and Model Building

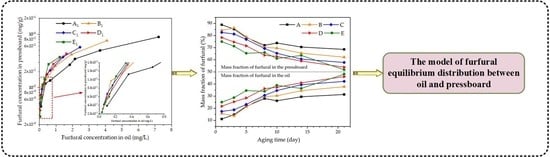

4.1. Equilibrium Distribution Ratio of Furfural

4.2. The Establishment of the Equilibrium Distribution Model

4.3. The Influence of Oil Replacement on the Equilibrium Distribution Ratio of Furfural and Correction

5. Conclusions

- Furfural partitioning between oil and pressboard was influenced by the oil–pressboard mass ratio. The mass fraction of the furfural in oil increased with the decrease of the oil–pressboard mass ratio. In addition, the experiment shows that the aging degree of pressboard is an important factor that determines the distribution behavior of furfural between oil and pressboard, while the aging degree of oil has little effect on the distribution behavior of furfural;

- The equilibrium distribution model of furfural was then established. The results show that the proportion of furfural in oil is also affected by the aging degree of insulating pressboard: the deeper the age of the insulating pressboard, the greater the distribution ratio of furfural in the oil;

- The modified model of furfural distribution ratios in oil after oil replacement was established. The lower the oil–pressboard mass ratio is, the less oil replacement operations influence the furfural distribution in oil. This paper provides a new reference for the equilibrium distribution of furfural in insulation systems, which is expected to improve the accuracy of transformer aging state assessment based on furfural analysis in oil.

Author Contributions

Funding

Conflicts of Interest

References

- Kachler, A.J.; Hohlein, I. Aging of cellulose at transformer service temperatures. Part 1: Influence of type of oil and air on the degree of polymerization of pressboard, dissolved gases, and furanic compounds in oil. IEEE Electr. Insul. Mag. 2005, 21, 15–21. [Google Scholar] [CrossRef]

- Wang, M.; Vandermaar, A.J.; Srivastava, K.D. Review of condition assessment of power transformers in service. IEEE Electr. Insul. Mag. 2003, 18, 12–25. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Zhang, Y.; Li, S. Frequency domain spectroscopy prediction of transformer oil-Immersed cellulose insulation under diverse temperature and moisture. IEEE Trans. Dielectr. Electr. Insul. 2020. [Google Scholar] [CrossRef]

- Rodríguez-Serna, J.M.; Albarracín-Sánchez, R.; Dong, M.; Ren, M. Computer simulation of partial discharges in voids inside epoxy resins using three-capacitance and analytical models. Polymers 2020, 12, 77. [Google Scholar] [CrossRef] [Green Version]

- Du, Y.; Zahn, M.; Lesieutre, B.C.; Mamishev, A.V.; Lindgren, S.R. Moisture equilibrium in transformer paper-oil systems. IEEE Electr. Insul. Mag. 2002, 15, 11–20. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Hansen, W.; Linhjell, D.; Painter, T.J. Aging of oil-impregnated paper in power transformers. IEEE Trans. Power Deliv. 2004, 19, 230–239. [Google Scholar] [CrossRef]

- Liu, J.; Yang, S.; Zhang, Y.; Zheng, H.; Shi, Z.; Zhang, C. A modified X-model of the oil-impregnated bushing including non-uniform thermal aging of cellulose insulation. Cellulose 2020, 27, 4525–4538. [Google Scholar] [CrossRef]

- Pradhan, M.K. Assessment of the status of insulation during thermal stress accelerated experiments on transformer prototypes. IEEE Trans. Dielectr. Electr. Insul. 2006, 13, 227–237. [Google Scholar] [CrossRef]

- Leibfried, T.; Jaya, M.; Majer, N.; Schafer, M.; Stach, M.; Voss, S. Postmortem investigation of power transformers-profile of degree of polymerization and correlation with furan concentration in the oil. IEEE Trans. Power Deliv. 2013, 28, 886–893. [Google Scholar] [CrossRef]

- Liu, C.; Hao, J.; Li, Y.; Liao, R. Fabrication of ZnO-Al2O3-PTFE multilayer nano-structured functional film on cellulose insulation polymer surface and its effect on moisture inhibition and dielectric properties. Polymers 2019, 11, 1367. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.; Fan, X.; Zhang, Y.; Zhang, C.; Wang, Z. Aging evaluation and moisture prediction of oil-immersed cellulose insulation in field transformer using frequency domain spectroscopy and aging kinetics model. Cellulose 2020, 27, 7175–7189. [Google Scholar] [CrossRef]

- Feng, D.; Hao, J.; Liao, R.; Chen, X.; Cheng, L.; Liu, M. Comparative study on the thermal-aging characteristics of cellulose insulation polymer immersed in new three-element mixed oil and mineral oil. Polymers 2019, 11, 1292. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saha, T. Review of modern diagnostic techniques for assessing insulation condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef] [Green Version]

- Oommen, T.V.; Prevost, T.A. Cellulose insulation in oil-filled power transformers: Part II maintaining insulation integrity and life. IEEE Electr. Insul. Mag. 2006, 22, 5–14. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Zhang, Y.; Zheng, H.; Jiao, J. Temperature correction to dielectric modulus and activation energy prediction of oil-immersed cellulose insulation. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 956–963. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Zhang, Y.; Zheng, H.; Zhang, C. Condition prediction for oil-immersed cellulose insulation in field transformer using fitting fingerprint database. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 279–287. [Google Scholar] [CrossRef]

- Ali, M.; Eley, C.; Emsley, A.M.; Heywood, R. Measuring and understanding the ageing of kraft insulating paper in power transformers. IEEE Electr. Insul. Mag. 1996, 12, 28–34. [Google Scholar] [CrossRef]

- Kelly, J.J. Transformer fault diagnosis by dissolved-gas analysis. IEEE Trans. Ind. Appl. 1980, 16, 777–782. [Google Scholar] [CrossRef]

- Feng, D.; Wang, Z.; Jarman, P. Transmission power transformer assessment using furan measurement with the aid of thermal model. In Proceedings of the IEEE International Conference on Condition Monitoring and Diagnosis, Bali, Indonesia, 23–27 September 2012; pp. 521–524. [Google Scholar]

- Abu-Siada, A.; Lai, S.P.; Islam, S.M. A novel fuzzy-logic approach for furan estimation in transformer oil. IEEE Trans. Power. Deliv. 2012, 27, 469–474. [Google Scholar] [CrossRef]

- Scheirs, J.; Camino, G.; Avidano, M.; Tumiatti, W. Origin of furanic compounds in thermal degradation of cellulosic insulating paper. J. Appl. Polym. Sci. 1998, 69, 2541–2547. [Google Scholar] [CrossRef]

- Emsley, A.M.; Xiao, X.; Heywood, R.J.; Ali, M. Degradation of cellulosic insulation in power transformers. Part 2: Formation of furan products in insulating oil. IEE P-sci. Meas. Technol. 2000, 147, 110–114. [Google Scholar] [CrossRef]

- Unsworth, J.; Mitchell, F. Degradation of electrical insulating paper monitored with high performance liquid chromatography. IEEE Trans. Electr. Insul. 1990, 25, 737–746. [Google Scholar] [CrossRef]

- Jalbert, J.; Lessard, M.C.; Ryadi, M. Cellulose chemical markers in transformer oil insulation part 1: Temperature correction factors. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 2287–2291. [Google Scholar] [CrossRef]

- Kan, H.; Miyamoto, T.; Makino, Y.; Namba, S.; Hara, T. Absorption of CO2 and CO gases and furfural in insulating oil into paper insulation in oil-immersed transformers. In Proceedings of the 1994 IEEE International Symposium on Electrical Insulation, Pittsburgh, PA, USA, 5–8 June 1994; pp. 41–44. [Google Scholar]

- Feng, D.; Yang, L.; Liao, R.; Zhou, L. Effect of moisture content on the production and partitioning of furfural in oil–paper insulation. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 2389–2397. [Google Scholar] [CrossRef]

- Yang, L.; Lin, Y.; Liao, R.; Zhao, X.; Sun, W.; Zhang, Y. Effects of temperature and aging on furfural partitioning in the oil-paper system of power transformers. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1393–1401. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, L.; Liao, R.; Sun, W.; Zhang, Y. Effect of oil replacement on furfural analysis and aging assessment of power transformers. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 2611–2619. [Google Scholar] [CrossRef]

- Shang, Y.; Yang, L.; Guo, Z.J.; Yan, Z. Assessing aging of large transformers by furfural investigation. In Proceedings of the IEEE International Conference on Solid Dielectrics, Eindhoven, The Netherlands, 25–29 June 2001. [Google Scholar]

- Lelekakis, N.; Guo, W.; Martin, D.; Wijaya, J.; Susa, D. A field study of aging in paper-oil insulation systems. IEEE Electr. Insul. Mag. 2012, 28, 12–19. [Google Scholar] [CrossRef]

- Abdi, S.; Boubakeur, A.; Haddad, A.; Harid, N. Influence of artificial thermal aging on transformer oil properties. Electr. Power Compon. Syst. 2011, 39, 1701–1711. [Google Scholar] [CrossRef]

- Tang, C.; Li, X.; Li, Z.; Tian, W.; Zhou, Q. Molecular simulation on the thermal stability of meta-aramid insulation paper fiber at transformer operating temperature. Polymers 2018, 10, 1348. [Google Scholar] [CrossRef] [Green Version]

- Pablo, A.; Pahlavanpour, B. Furanic compounds analysis: A tool for predictive maintenance of oil filled electrical equipment. Electra 1997, 175, 9–18. [Google Scholar]

- Pablo, D. Furfural and ageing: How are they related. In Proceedings of the IEE Colloquium Insulating Liquidss, Leatherhead, UK, 27 May 1999; p. 5. [Google Scholar]

- Lundgaard, L.E.; Hansen, W.; Ingebrigtsen, S. Ageing of mineral oil impregnated cellulose by acid catalysis. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 540–546. [Google Scholar] [CrossRef]

| Cellulose Pressboard | Insulation Oil | Methanol | |||

|---|---|---|---|---|---|

| Brand | Weidmann T4 pressboard | Brand | Karamay no. 25 naphthenic mineral oil | Brand | Fisher |

| Provider | Taizhou Weidmann high voltage insulation Co. LTD, Taizhou, China | Provider | China National Petroleum Corporation. Beijing, China | Provider | Thermo Fisher Scientific. Ottawa, Canada |

| Diameter | 160 mm | Pourpoint | −45 °C | Purity | 99.9% |

| Thickness | 1 mm | Flashpoint | 135 °C | ||

| Tensile strength | MD a 105 MPa CMD b 80 MPa | Dielectric loss | 4 × 10−4 | Density | 0.791 g/ml |

| Group | Oil Replacement Ratio | Oil–Pressboard Mass Ratio |

|---|---|---|

| A1 | 0% | 5:1 |

| A2 | 100% | 5:1 |

| B1 | 0% | 10:1 |

| B2 | 100% | 10:1 |

| C1 | 0% | 15:1 |

| C2 | 100% | 15:1 |

| D1 | 0% | 20:1 |

| D2 | 100% | 20:1 |

| E1 | 0% | 25:1 |

| E2 | 100% | 25:1 |

| Group | Oil–Pressboard Mass Ratio | Oil Replacement Ratio | Furfural Residual Ratio | Furfural Recovery Ratio |

|---|---|---|---|---|

| A2 | 5:1 | 100% | 14.2% | 89.4% |

| B2 | 10:1 | 100% | 14.8% | 71.3% |

| C2 | 15:1 | 100% | 20.1% | 62.2% |

| D2 | 20:1 | 100% | 23.1% | 65.6% |

| E2 | 25:1 | 100% | 35.7% | 51.7% |

| Sample Group | Sample Detail | Oil–Pressboard Mass Ratio |

|---|---|---|

| R1 | Pressboard aged for 5 days + new oil | 10:1 |

| R2 | Pressboard aged for 10 days + new oil | 10:1 |

| R3 | Pressboard aged for 14 days + new oil | 10:1 |

| R4 | Pressboard aged for 21 days + new oil | 10:1 |

| R5 | Pressboard aged for 14 days + oil aged for 5 days | 10:1 |

| R6 | Pressboard aged for 14 days + oil aged for 10 days | 10:1 |

| R7 | Pressboard aged for 14 days + oil aged for 14 days | 10:1 |

| R8 | Pressboard aged for 14 days + oil aged for 21 days | 10:1 |

| Parameters | Standard Error | t-Value | Significance Level |

|---|---|---|---|

| MR | 6.86 × 10−4 | 10.59 | <0.05 |

| DP | 3.23 × 10−5 | −16.06 | <0.05 |

| Group | MR | DP | Woil (%) | Predicted Value (%) | Accuracy (%) |

|---|---|---|---|---|---|

| S31 | 5 | 324 | 29.5 | 31.8 | 92.23 |

| S32 | 10 | 270 | 37.8 | 38.2 | 98.94 |

| S33 | 15 | 514 | 30.7 | 29.2 | 95.08 |

| S34 | 20 | 433 | 37.3 | 37.0 | 99.26 |

| S35 | 25 | 662 | 28.8 | 28.8 | 99.99 |

| Group | m | n | k | R2 |

|---|---|---|---|---|

| A2 | 1.000 | −0.809 | 0.26 | 0.985 |

| B2 | 0.931 | −0.690 | 0.287 | 0.999 |

| C2 | 0.836 | −0.506 | 0.396 | 0.975 |

| D2 | 0.777 | −0.364 | 0.598 | 0.922 |

| E2 | 0.722 | −0.179 | 0.868 | 0.899 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Cao, Z.; Fan, X.; Zhang, H.; Geng, C.; Zhang, Y. Influence of Oil–Pressboard Mass Ratio on the Equilibrium Characteristics of Furfural under Oil Replacement Conditions. Polymers 2020, 12, 2760. https://doi.org/10.3390/polym12112760

Liu J, Cao Z, Fan X, Zhang H, Geng C, Zhang Y. Influence of Oil–Pressboard Mass Ratio on the Equilibrium Characteristics of Furfural under Oil Replacement Conditions. Polymers. 2020; 12(11):2760. https://doi.org/10.3390/polym12112760

Chicago/Turabian StyleLiu, Jiefeng, Zhanwei Cao, Xianhao Fan, Heng Zhang, Chuhan Geng, and Yiyi Zhang. 2020. "Influence of Oil–Pressboard Mass Ratio on the Equilibrium Characteristics of Furfural under Oil Replacement Conditions" Polymers 12, no. 11: 2760. https://doi.org/10.3390/polym12112760

APA StyleLiu, J., Cao, Z., Fan, X., Zhang, H., Geng, C., & Zhang, Y. (2020). Influence of Oil–Pressboard Mass Ratio on the Equilibrium Characteristics of Furfural under Oil Replacement Conditions. Polymers, 12(11), 2760. https://doi.org/10.3390/polym12112760