Synthesis, Characterization, and Analysis of Hybrid Carbon Nanotubes by Chemical Vapor Deposition: Application for Aluminum Removal

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Reagents

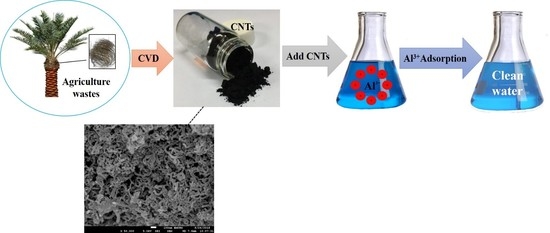

2.2. Synthesis of Hybrid CNTs

2.2.1. Catalyst Impregnation

2.2.2. CVD Growth

2.3. Characterizations

2.4. Adsorption Study

2.4.1. Experimental Design for Optimization of Al3+ Adsorption

2.4.2. Kinetic and Isotherm Adsorption

3. Results and Discussion

3.1. Characterization and Analysis

3.1.1. FESEM, EDX, and TEM of Hybrid CNTs

3.1.2. X-ray Diffraction

3.1.3. Fourier-Transform Infrared (FTIR) Analysis

3.1.4. Thermogravimetric Analysis (TGA)

3.1.5. Brunauer–Emmett–Teller (BET)

3.1.6. Zeta Potential

3.2. Application Studies

3.2.1. Optimization Study

3.2.2. Effect of Factors on Optimization of Adsorption of Al3+ by Hybrid CNTs

3.2.3. Adsorption Studies

Kinetics Studies

Isotherm Studies

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Basheer, A.; M Hanafiah, M.; Abdulhakim Alsaadi, M.; Al-Douri, Y.; Malek, M.A.; Mohammed Aljumaily, M.; Saadi Fiyadh, S. Synthesis and characterization of natural extracted precursor date palm fibre-based activated carbon for aluminum removal by RSM optimization. Processes 2019, 7, 249. [Google Scholar] [CrossRef] [Green Version]

- Mishra, M.; Chauhan, M. Biosorption as a Novel Approach for Removing Aluminium from Water Treatment Plant Residual—A Review. In Water Quality Management; Springer: Berlin, Germany, 2018; pp. 93–99. [Google Scholar]

- Mohd-Salleh, S.N.A.; Mohd-Zin, N.S.; Othman, N. A Review of Wastewater Treatment using Natural Material and Its Potential as Aid and Composite Coagulant. Sains Malays. 2019, 48, 155–164. [Google Scholar] [CrossRef]

- Al-Muhtaseb, S.A.; El-Naas, M.H.; Abdallah, S. Removal of aluminum from aqueous solutions by adsorption on date-pit and BDH activated carbons. J. Hazard. Mater. 2008, 158, 300–307. [Google Scholar] [CrossRef] [PubMed]

- Al-Raad, A.A.; Hanafiah, M.M.; Naje, A.S.; Ajeel, M.A.; O Basheer, A.; Ali Aljayashi, T.; Ekhwan Toriman, M. Treatment of Saline Water Using Electrocoagulation with Combined Electrical Connection of Electrodes. Processes 2019, 7, 242. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Zeng, X.; Guo, L.; Lan, J.; Zhang, L.; Cao, D. Heavy metal ion removal of wastewater by zeolite-imidazolate frameworks. Sep. Purif. Technol. 2018, 194, 462–469. [Google Scholar] [CrossRef]

- Fang, L.; Li, L.; Qu, Z.; Xu, H.; Xu, J.; Yan, N. A novel method for the sequential removal and separation of multiple heavy metals from wastewater. J. Hazard. Mater. 2018, 342, 617–624. [Google Scholar] [CrossRef]

- Ang, W.L.; Mohammad, A.W.; Johnson, D.; Hilal, N. Forward osmosis research trends in desalination and wastewater treatment: A review of research trends over the past decade. J. Water Process Eng. 2019, 31, 100886. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, L.; Liu, J.; Logan, B.E. Electrochemical technologies for wastewater treatment and resource reclamation. Environ. Sci. Water Res. Technol. 2016, 2, 800–831. [Google Scholar] [CrossRef]

- Thue, P.S.; dos Reis, G.S.; Lima, E.C.; Sieliechi, J.M.; Dotto, G.; Wamba, A.G.; Dias, S.L.; Pavan, F.A. Activated carbon obtained from sapelli wood sawdust by microwave heating for o-cresol adsorption. Res. Chem. Intermed. 2017, 43, 1063–1087. [Google Scholar] [CrossRef]

- Kizito, S.; Wu, S.; Kirui, W.K.; Lei, M.; Lu, Q.; Bah, H.; Dong, R. Evaluation of slow pyrolyzed wood and rice husks biochar for adsorption of ammonium nitrogen from piggery manure anaerobic digestate slurry. Sci. Total Environ. 2015, 505, 102–112. [Google Scholar] [CrossRef]

- Intani, K.; Latif, S.; Kabir, A.R.; Müller, J. Effect of self-purging pyrolysis on yield of biochar from maize cobs, husks and leaves. Bioresour. Technol. 2016, 218, 541–551. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. The properties of the self-compacting concrete with fly ash and ground granulated blast furnace slag mineral admixtures. J. Clean. Prod. 2015, 95, 66–74. [Google Scholar] [CrossRef]

- Fiyadh, S.S.; AlSaadi, M.A.; Jaafar, W.Z.B.; AlOmar, M.K.; Fayaed, S.S.; Mohd, N.S.B.; Hin, L.S.; El-Shafie, A. Review on heavy metal adsorption processes by carbon nanotubes. J. Clean. Prod. 2019, 230, 783–793. [Google Scholar] [CrossRef]

- Chen, G.; Liu, X.; Brookes, P.C.; Xu, J. Opportunities for phytoremediation and bioindication of arsenic contaminated water using a submerged aquatic plant: Vallisneria natans (Lour.) Hara. Int. J. Phytorem. 2015, 17, 249–255. [Google Scholar] [CrossRef]

- Murray, C.C.; Vatankhah, H.; McDonough, C.A.; Nickerson, A.; Hedtke, T.T.; Cath, T.Y.; Higgins, C.P.; Bellona, C.L. Removal of per-and polyfluoroalkyl substances using super-fine powder activated carbon and ceramic membrane filtration. J. Hazard. Mater. 2019, 366, 160–168. [Google Scholar] [CrossRef]

- Lee, S.; Ko, K.; Youk, J.; Lim, D.; Jeong, W. Preparation and Properties of Carbon Fiber/Carbon Nanotube Wet-Laid Composites. Polymers 2019, 11, 1597. [Google Scholar] [CrossRef] [Green Version]

- Puglisi, R.A.; Bongiorno, C.; Caccamo, S.; Fazio, E.; Mannino, G.; Neri, F.; Scalese, S.; Spucches, D.; La Magna, A. Chemical Vapor Deposition Growth of Silicon Nanowires with Diameter Smaller Than 5 nm. ACS Omega 2019, 4, 17967–17971. [Google Scholar] [CrossRef]

- Xiang, X.; Zhang, L.; Hima, H.I.; Li, F.; Evans, D.G. Co-based catalysts from Co/Fe/Al layered double hydroxides for preparation of carbon nanotubes. Appl. Clay Sci. 2009, 42, 405–409. [Google Scholar] [CrossRef]

- Aljumaily, M.M.; Alsaadi, M.A.; Hashim, N.A.; Alsalhy, Q.F.; Mjalli, F.S.; Atieh, M.A.; Al-Harrasi, A. PVDF-co-HFP/superhydrophobic acetylene-based nanocarbon hybrid membrane for seawater desalination via DCMD. Chem. Eng. Res. Des. 2018, 138, 248–259. [Google Scholar] [CrossRef]

- Alayan, H.M.; Alsaadi, M.A.; AlOmar, M.K.; Hashim, M.A. Growth and optimization of carbon nanotubes in powder activated carbon for an efficient removal of methylene blue from aqueous solution. Environ. Technol. 2019, 40, 2400–2415. [Google Scholar] [CrossRef]

- Yahyazadeh, A.; Khoshandam, B. Carbon nanotube synthesis via the catalytic chemical vapor deposition of methane in the presence of iron, molybdenum, and iron–molybdenum alloy thin layer catalysts. Results Phys. 2017, 7, 3826–3837. [Google Scholar] [CrossRef]

- Zhao, Y.; Choi, J.; Kim, P.; Fei, W.; Lee, C.J. Large-scale synthesis and characterization of super-bundle single-walled carbon nanotubes by water-assisted chemical vapor deposition. RSC Adv. 2015, 5, 30564–30569. [Google Scholar] [CrossRef]

- Chen, G.; Davis, R.C.; Kimura, H.; Sakurai, S.; Yumura, M.; Futaba, D.N.; Hata, K. The relationship between the growth rate and the lifetime in carbon nanotube synthesis. Nanoscale 2015, 7, 8873–8878. [Google Scholar] [CrossRef]

- Mamtm, A.; Ma’an, F.; Zahirah, A.; Yehya, M.; Mohammed, A. Optimisation of arsenic adsorption from water by carbon nanofibres grown on powdered activated carbon impregnated with nickel. J. Appl. Sci. 2009, 9, 3180–3183. [Google Scholar]

- Aljumaily, M.M.; Alsaadi, M.A.; Hashim, N.A.; Alsalhy, Q.F.; Das, R.; Mjalli, F. Embedded high-hydrophobic CNMs prepared by CVD technique with PVDF-co-HFP membrane for application in water desalination by DCMD. Desalin. Water Treat. 2019, 142, 37–48. [Google Scholar] [CrossRef]

- AlOmar, M.K.; Alsaadi, M.A.; Hayyan, M.; Akib, S.; Ibrahim, R.K.; Hashim, M.A. Lead removal from water by choline chloride based deep eutectic solvents functionalized carbon nanotubes. J. Mol. Liq. 2016, 222, 883–894. [Google Scholar] [CrossRef]

- Fiyadh, S.S.; AlOmar, M.K.; Binti Jaafar, W.Z.; AlSaadi, M.A.; Fayaed, S.S.; Binti Koting, S.; Lai, S.H.; Chow, M.F.; Ahmed, A.N.; El-Shafie, A. Artificial Neural Network Approach for Modelling of Mercury Ions Removal from Water Using Functionalized CNTs with Deep Eutectic Solvent. Int. J. Mol. Sci. 2019, 20, 4206. [Google Scholar] [CrossRef] [Green Version]

- Pakade, V.E.; Tavengwa, N.T.; Madikizela, L.M. Recent advances in hexavalent chromium removal from aqueous solutions by adsorptive methods. RSC Adv. 2019, 9, 26142–26164. [Google Scholar] [CrossRef] [Green Version]

- Boscarino, S.; Filice, S.; Sciuto, A.; Libertino, S.; Scuderi, M.; Galati, C.; Scalese, S. Investigation of ZnO-decorated CNTs for UV Light Detection Applications. Nanomaterials 2019, 9, 1099. [Google Scholar] [CrossRef] [Green Version]

- Ionescu, M.I. Direct synthesis of carbon nanotubes on metallic foams as a cathode material with high mass load for lithium–air batteries. RSC Adv. 2017, 7, 30365–30369. [Google Scholar] [CrossRef] [Green Version]

- Minakshi, M.; Mitchell, D.R.; Baur, C.; Chable, J.; Barlow, A.J.; Fichtner, M.; Banerjee, A.; Chakraborty, S.; Ahuja, R. Phase evolution in calcium molybdate nanoparticles as a function of synthesis temperature and its electrochemical effect on energy storage. Nanoscale Adv. 2019, 1, 565–580. [Google Scholar] [CrossRef] [Green Version]

- Roe, D.P.; Xu, R.; Roberts, C.B. Influence of a carbon nanotube support and supercritical fluid reaction medium on Fe-catalyzed Fischer-Tropsch synthesis. Appl. Catal. A Gen. 2017, 543, 141–149. [Google Scholar] [CrossRef]

- Shen, D.; Liu, J.; Gan, L.; Huang, N.; Long, M. Green synthesis of Fe 3 O 4/cellulose/polyvinyl alcohol hybride aerogel and its application for dye removal. J. Polym. Environ. 2018, 26, 2234–2242. [Google Scholar] [CrossRef]

- Syafiuddin, A.; Salmiati, S.; Hadibarata, T.; Kueh, A.B.H.; Salim, M.R.; Zaini, M.A.A. Silver Nanoparticles in the Water Environment in Malaysia: Inspection, characterization, removal, modeling, and future perspective. Sci. Rep. 2018, 8, 986. [Google Scholar] [CrossRef]

- Aljumaily, M.M.; Alsaadi, M.A.; Das, R.; Hamid, S.B.A.; Hashim, N.A.; AlOmar, M.K.; Alayan, H.M.; Novikov, M.; Alsalhy, Q.F.; Hashim, M.A. Optimization of the synthesis of superhydrophobic carbon nanomaterials by chemical vapor deposition. Sci. Rep. 2018, 8, 2778. [Google Scholar] [CrossRef]

- Minakshi, M.; Barmi, M.J.; Jones, R.T. Rescaling metal molybdate nanostructures with biopolymer for energy storage having high capacitance with robust cycle stability. Dalton Trans. 2017, 46, 3588–3600. [Google Scholar] [CrossRef]

- Ţucureanu, V.; Matei, A.; Avram, A.M. FTIR spectroscopy for carbon family study. Crit. Rev. Anal. Chem. 2016, 46, 502–520. [Google Scholar] [CrossRef]

- ROSNAN, N.A.; Haan, T.Y.; Mohammad, A.W. The Effect of ZnO Loading for the Enhancement of PSF/ZnO-GO Mixed Matrix Membrane Performance. Sains Malays. 2018, 47, 2035–2045. [Google Scholar] [CrossRef]

- Gupta, V.K.; Agarwal, S.; Saleh, T.A. Synthesis and characterization of alumina-coated carbon nanotubes and their application for lead removal. J. Hazard. Mater. 2011, 185, 17–23. [Google Scholar] [CrossRef]

- Rodiles, X.; Reguero, V.; Vila, M.; Alemán, B.; Arévalo, L.; Fresno, F.; de la Peña O’Shea, V.; Vilatela, J. Carbon nanotube synthesis and spinning as macroscopic fibers assisted by the ceramic reactor tube. Sci. Rep. 2019, 9, 9239. [Google Scholar] [CrossRef] [Green Version]

- Misra, A.; Tyagi, P.K.; Rai, P.; Misra, D. FTIR Spectroscopy of multiwalled carbon nanotubes: A Simple approachto study the nitrogen doping. J. Nanosci. Nanotechnol. 2007, 7, 1820–1823. [Google Scholar] [CrossRef]

- Quan, C.; Li, A.; Gao, N. Synthesis of carbon nanotubes and porous carbons from printed circuit board waste pyrolysis oil. J. Hazard. Mater. 2010, 179, 911–917. [Google Scholar] [CrossRef]

- Bellanger, H.; Darmanin, T.; Taffin de Givenchy, E.; Guittard, F. Chemical and physical pathways for the preparation of superoleophobic surfaces and related wetting theories. Chem. Rev. 2014, 114, 2694–2716. [Google Scholar] [CrossRef]

- Hildago-Oporto, P.; Navia, R.; Hunter, R.; Coronado, G.; Gonzalez, M. Synthesis of carbon nanotubes using biochar as precursor material under microwave irradiation. J. Environ. Manag. 2019, 244, 83–91. [Google Scholar]

- Lawal, I.A.; Dolla, T.H.; Pruessner, K.; Ndungu, P. Synthesis and characterization of deep eutectic solvent functionalized CNT/ZnCo2O4 nanostructure: Kinetics, isotherm and regenerative studies on Eosin Y adsorption. J. Environ. Chem. Eng. 2019, 7, 102877. [Google Scholar] [CrossRef]

- Alayan, H.M.; Alsaadi, M.A.; Abo-Hamad, A.; AlOmar, M.K.; Aljumaily, M.M.; Das, R.; Hashim, M.A. Hybridizing carbon nanomaterial with powder activated carbon for an efficient removal of Bisphenol A from water: The optimum growth and adsorption conditions. Desalin. Water Treat. 2017, 95, 128–143. [Google Scholar]

- Lee, W.J.; Lee, J.M.; Kochuveedu, S.T.; Han, T.H.; Jeong, H.Y.; Park, M.; Yun, J.M.; Kwon, J.; No, K.; Kim, D.H. Biomineralized N-doped CNT/TiO2 core/shell nanowires for visible light photocatalysis. ACS Nano 2011, 6, 935–943. [Google Scholar] [CrossRef]

- Fraczek-Szczypta, A.; Dlugon, E.; Weselucha-Birczynska, A.; Nocun, M.; Blazewicz, M. Multi walled carbon nanotubes deposited on metal substrate using EPD technique. A spectroscopic study. J. Mol. Struct. 2013, 1040, 238–245. [Google Scholar] [CrossRef]

- Ngulube, T.; Gumbo, J.; Masindi, V.; Maity, A. Preparation and characterisation of high performing magnesite-halloysite nanocomposite and its application in the removal of methylene blue dye. J. Mol. Struct. 2019, 1184, 389–399. [Google Scholar] [CrossRef]

- Gatabi, M.P.; Moghaddam, H.M.; Ghorbani, M. Point of zero charge of maghemite decorated multiwalled carbon nanotubes fabricated by chemical precipitation method. J. Mol. Liq. 2016, 216, 117–125. [Google Scholar] [CrossRef]

- Halder, G.; Sinha, K.; Dhawane, S. Defluoridation of wastewater using powdered activated carbon developed from Eichhornia crassipes stem: Optimization by response surface methodology. Desalin. Water Treat. 2015, 56, 953–966. [Google Scholar] [CrossRef]

- AlOmar, M.K.; Alsaadi, M.A.; Hayyan, M.; Akib, S.; Ibrahim, M.; Hashim, M.A. Allyl triphenyl phosphonium bromide based DES-functionalized carbon nanotubes for the removal of mercury from water. Chemosphere 2017, 167, 44–52. [Google Scholar] [CrossRef]

- Ahmad, N.S.; Radiman, S.; Yaacob, W.Z.W. Aggregation and Stability of Iron Oxide and Alumina Nanoparticles: Influences of pH and Humic Acid Concentration. Sains Malays. 2019, 48, 435–442. [Google Scholar] [CrossRef]

- Bradl, H.B. Adsorption of heavy metal ions on soils and soils constituents. J. Colloid Interface Sci. 2004, 277, 1–18. [Google Scholar] [CrossRef]

- Kumar, A.S.K.; Jiang, S.-J. Chitosan-functionalized graphene oxide: A novel adsorbent an efficient adsorption of arsenic from aqueous solution. J. Environ. Chem. Eng. 2016, 4, 1698–1713. [Google Scholar] [CrossRef]

- Ashrafi, A.; Rahbar-Kelishami, A.; Shayesteh, H. Highly efficient simultaneous ultrasonic assisted adsorption of Pb (II) by Fe3O4@ MnO2 core-shell magnetic nanoparticles: Synthesis and characterization, kinetic, equilibrium, and thermodynamic studies. J. Mol. Struct. 2017, 1147, 40–47. [Google Scholar] [CrossRef]

- Alvarez-Torrellas, S.; Boutahala, M.; Boukhalfa, N.; Munoz, M. Effective Adsorption of Methylene Blue dye onto Magnetic Nanocomposites. Modeling and Reuse Studies. Appl. Sci. 2019, 9, 4563. [Google Scholar] [CrossRef] [Green Version]

- Lakkaboyana, S.K.; Khantong, S.; Asmel, N.K.; Yuzir, A.; Yaacob, W.Z.W. Synthesis of Copper Oxide Nanowires-Activated Carbon (AC@ CuO-NWs) and Applied for Removal Methylene Blue from Aqueous Solution: Kinetics, Isotherms, and Thermodynamics. J. Inorg. Organomet. Polym. Mater. 2019, 29, 1–11. [Google Scholar] [CrossRef]

- Rong, J.; Rong, X.; Qiu, F.; Zhu, X.; Pan, J.; Zhang, T.; Yang, D. Facile preparation of glucose functionalized multi-wall carbon nanotubes and its application for the removal of cationic pollutants. Mater. Lett. 2016, 183, 9–13. [Google Scholar] [CrossRef]

- Lin, Y.-F.; Chang, C.-Y. Magnetic mesoporous iron oxide/carbon aerogel photocatalysts with adsorption ability for organic dye removal. RSC Adv. 2014, 4, 28628–28631. [Google Scholar] [CrossRef]

- Ibrahim, R.K.; El-Shafie, A.; Hin, L.S.; Mohd, N.S.B.; Aljumaily, M.M.; Ibraim, S.; AlSaadi, M.A. A clean approach for functionalized carbon nanotubes by deep eutectic solvents and their performance in the adsorption of methyl orange from aqueous solution. J. Environ. Manag. 2019, 235, 521–534. [Google Scholar] [CrossRef]

- Madrakian, T.; Afkhami, A.; Ahmadi, M.; Bagheri, H. Removal of some cationic dyes from aqueous solutions using magnetic-modified multi-walled carbon nanotubes. J. Hazard. Mater. 2011, 196, 109–114. [Google Scholar] [CrossRef]

| Run | Dosage (mg/g) | pH | Time (min) | Response Removal (%) | Response Capacity (mg/g) |

|---|---|---|---|---|---|

| 1 | 5 | 11 | 10 | 93.62 | 93.62 |

| 2 | 20 | 3 | 120 | 96.74 | 24.185 |

| 3 | 12.50 | 7 | 65 | 84.68 | 33.872 |

| 4 | 12.50 | 7 | 65 | 84.68 | 33.872 |

| 5 | 12.50 | 7 | 10 | 87.86 | 35.144 |

| 6 | 5 | 7 | 65 | 99.26 | 99.26 |

| 7 | 20 | 11 | 120 | 7.08 | 1.77 |

| 8 | 12.50 | 7 | 120 | 77.52 | 31.008 |

| 9 | 12.50 | 3 | 65 | 9.08 | 3.632 |

| 10 | 20 | 3 | 10 | 3.16 | 0.79 |

| 11 | 12.50 | 7 | 65 | 84.68 | 33.872 |

| 12 | 20 | 7 | 65 | 87.14 | 21.785 |

| 13 | 12.50 | 11 | 65 | 96.84 | 38.736 |

| 14 | 5 | 3 | 10 | 6.54 | 6.54 |

| 15 | 5 | 3 | 120 | 14.54 | 14.54 |

| 16 | 20 | 11 | 10 | 90.58 | 22.645 |

| 17 | 5 | 11 | 120 | 97.52 | 97.52 |

| Materials | BET Surface Area (m2/g) | Pore-Volume (m3/g) | Pore Size (nm) | References |

|---|---|---|---|---|

| Hybrid CNTs | 71.24 | 0.230 | 12 | This work |

| Synthesized CNTs | 57.35 | 0.01 | 10 | [45] |

| CNT/ZnCo2O4 | 67.60 | 1.103 | - | [46] |

| CNMH | 164.60 | 0.29 | 9 | [47] |

| CNT/TiO2 | 51.44 | 0.67 | 9.33 | [48] |

| Sample | pH | Zeta Potential (MV) |

|---|---|---|

| 1 | 3 | 0.111 |

| 2 | 5 | −5.255 |

| 3 | 7 | −7.602 |

| 4 | 9 | −10.558 |

| 5 | 11 | −23 |

| Source | Sum of Squares | df | Mean Square | F Value | P−Value Prob > F |

|---|---|---|---|---|---|

| Model | 0.27 | 9 | 0.030 | 3.99 | 0.0409 |

| A-Dose | 8.642 × 10−3 | 1 | 8.642 × 10−3 | 1.14 | 0.3209 |

| B-pH | 0.074 | 1 | 0.074 | 9.81 | 0.0165 |

| C-Contact Time | 9.866 × 10−3 | 1 | 9.866 × 10−3 | 1.30 | 0.2913 |

| AB | 8.801 × 10−3 | 1 | 8.801 × 10−3 | 1.16 | 0.3168 |

| AC | 4.389 × 10−4 | 1 | 4.389 × 10−4 | 0.058 | 0.8167 |

| BC | 0.092 | 1 | 0.092 | 12.16 | 0.0102 |

| A2 | 2.525 × 10−4 | 1 | 2.525 × 10−4 | 0.033 | 0.8603 |

| B2 | 0.040 | 1 | 0.040 | 5.32 | 0.0544 |

| C2 | 6.937 × 10−4 | 1 | 6.937E × 10−4 | 0.092 | 0.7710 |

| Source | Sum of Squares | df | Mean Square | F Value | P − Value Prob > F |

|---|---|---|---|---|---|

| Model | 15582.14 | 9 | 1731.35 | 14.14 | 0.0010 |

| A-Dose | 5774.65 | 1 | 5774.65 | 47.17 | 0.0002 |

| B-pH | 4186.28 | 1 | 4186.28 | 34.19 | 0.0006 |

| C-Contact Time | 10.58 | 1 | 10.58 | 0.086 | 0.7774 |

| AB | 3638.90 | 1 | 3638.90 | 29.72 | 0.0010 |

| AC | 11 | 1 | 11 | 0.090 | 0.7731 |

| BC | 292.46 | 1 | 292.46 | 2.39 | 0.1661 |

| A2 | 1181.14 | 1 | 1181.14 | 9.65 | 0.0172 |

| B2 | 901.39 | 1 | 901.39 | 7.36 | 0.0301 |

| C2 | 111.47 | 1 | 111.47 | 0.91 | 0.3718 |

| Pseudo-First-Order ln(qc − qt) vs time (t) | Pseudo-Second-Order (t/qc vs t) | Intraparticle (qc vs t0.5) | |||

|---|---|---|---|---|---|

| Dose mg | pH | C0 mg/L | R2 | R2 | R2 |

| 13.5 | 7 | 3 | 0.9091 | 0.9583 | 0.8769 |

| 13.5 | 7 | 5 | 0.7084 | 0.999 | 0.522 |

| 13.5 | 7 | 10 | 0.8275 | 0.8736 | 0.874 |

| Absorbent | Pollutant | Capacity (mg/g) | References |

|---|---|---|---|

| Hybrid CNTs | Al3+ | 347.88 | This study |

| MWCNT | RhB | 568.181 | [60] |

| mesoporous composite γ-Fe2O3/α-Fe2O3/CA | RhB | 165 | [61] |

| Pn,n-CNTs | MO | 263.14 | [62] |

| magnetic-modified multi-walled carbon nanotubes | MB | 48.1 | [63] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basheer, A.O.; Hanafiah, M.M.; Alsaadi, M.A.; Wan Yaacob, W.Z.; Al-Douri, Y. Synthesis, Characterization, and Analysis of Hybrid Carbon Nanotubes by Chemical Vapor Deposition: Application for Aluminum Removal. Polymers 2020, 12, 1305. https://doi.org/10.3390/polym12061305

Basheer AO, Hanafiah MM, Alsaadi MA, Wan Yaacob WZ, Al-Douri Y. Synthesis, Characterization, and Analysis of Hybrid Carbon Nanotubes by Chemical Vapor Deposition: Application for Aluminum Removal. Polymers. 2020; 12(6):1305. https://doi.org/10.3390/polym12061305

Chicago/Turabian StyleBasheer, Alfarooq O., Marlia M. Hanafiah, Mohammed Abdulhakim Alsaadi, Wan Zuhairi Wan Yaacob, and Y. Al-Douri. 2020. "Synthesis, Characterization, and Analysis of Hybrid Carbon Nanotubes by Chemical Vapor Deposition: Application for Aluminum Removal" Polymers 12, no. 6: 1305. https://doi.org/10.3390/polym12061305

APA StyleBasheer, A. O., Hanafiah, M. M., Alsaadi, M. A., Wan Yaacob, W. Z., & Al-Douri, Y. (2020). Synthesis, Characterization, and Analysis of Hybrid Carbon Nanotubes by Chemical Vapor Deposition: Application for Aluminum Removal. Polymers, 12(6), 1305. https://doi.org/10.3390/polym12061305