Effect of NaOH Treatment on the Flexural Modulus of Hemp Core Reinforced Composites and on the Intrinsic Flexural Moduli of the Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Hemp Core Fibers Treatment

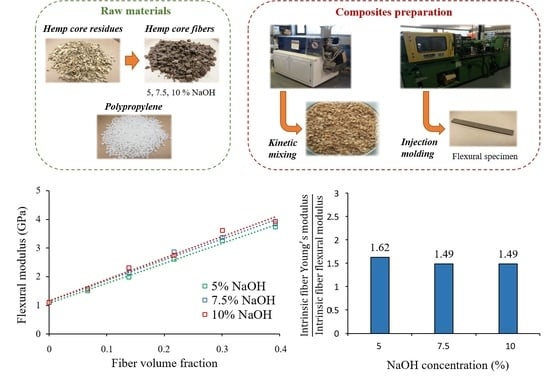

2.2.2. Composite Preparation and Sample Obtaining

2.2.3. Characterization of the Fibers

2.3. Modeling the Flexural Modulus

3. Results

3.1. Effect of Sodium Hydroxyde (NaOH) Treatment on Hemp Core Fibers

3.2. Macro-Mechanics of the Flexural Modulus

3.3. Contribution of the Fibers to the Flexural Modulus

3.4. Micromechanics of the Flexural Modulus

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, Z. Progress in the research and applications of natural fiber-reinforced polymer matrix composites. Sci. Eng. Compos. Mater. 2018, 25, 835–846. [Google Scholar] [CrossRef]

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Väisänen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Price, J.L.; Joseph, J.B. Demand management—A basis for waste policy: A critical review of the applicability of the waste hierarchy in terms of achieving sustainable waste management. Sustain. Dev. 2000, 8, 96–105. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Tarrés, Q.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Vilaseca, F. Biobased Composites from Biobased-Polyethylene and Barley Thermomechanical Fibers: Micromechanics of Composites. Materials 2019, 12, 4182. [Google Scholar] [CrossRef] [Green Version]

- Serra-Parareda, F.; Tarrés, Q.; Espinach, F.X.; Vilaseca, F.; Mutjé, P.; Delgado-Aguilar, M. Influence of lignin content on the intrinsic modulus of natural fibers and on the stiffness of composite materials. Int. J. Biol. Macromol. 2020. [Google Scholar] [CrossRef]

- Reixach, R.; Franco-Marquès, E.; El Mansouri, N.-E.; Ramirez de Cartagena, F.; Arbat, G.; Espinach, F.X.; Mutje, P. Micromechanics of Mechanical, Thermomechanical, and Chemi-Thermomechanical Pulp from Orange Tree Pruning as Polypropylene Reinforcement: A Comparative Study. BioResources 2013, 8, 3231–3246. [Google Scholar] [CrossRef] [Green Version]

- Haque, A.; Mondal, D.; Khan, I.; Usmani, M.A.; Bhat, A.H.; Gazal, U. Fabrication of composites reinforced with lignocellulosic materials from agricultural biomass. Lignocellul. Fibre Biomass-Based Compos. Mater. Process. Prop. Appl. 2017, 179–191. [Google Scholar] [CrossRef]

- Heitzmann, M.T.; Ali, A.M.; Legras, A.; Vandi, L.J.; Milne, J. Hemp hurd flour as an alternative low cost filler in wood plastic composites. In Proceedings of the International Conference on Performance-Based and Life-Cycle Structural Engineering, Brisbane, Australia, 9–11 December 2015; pp. 109–115. [Google Scholar]

- Li, X.; Xiao, R.; Morrell, J.J.; Zhou, X.; Du, G. Improving the performance of hemp hurd/polypropylene composites using pectinase pre-treatments. Ind. Crops Prod. 2017, 97, 465–468. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Julián, F.; Pèlach, M.À.; Espinach, F.X.; Méndez, J.A.; Mutjé, P. Fast and simple method for prediction of the micromechanical parameters and macromechanical properties of composite materials. Cellul. Chem. Technol. 2016, 50, 423–428. [Google Scholar]

- Lopez, J.P.; Vilaseca, F.; Barberà, L.; Bayer, R.J.; Pèlach, M.A.; Mutjé, P. Processing and properties of biodegradable composites based on Mater-Bi ® and hemp core fibres. Resour. Conserv. Recycl. 2012, 59, 38–42. [Google Scholar] [CrossRef]

- Balčiunas, G.; Vejelis, S.; Vaitkus, S.; Kairyte, A. Physical properties and structure of composite made by using hemp hurds and different binding materials. Procedia Eng. 2013, 57, 159–166. [Google Scholar] [CrossRef] [Green Version]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt J. Pet. 2018, 27, 775–873. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Keener, T.J.; Stuart, R.K.; Brown, T.K. Maleated coupling agents for natural fibre composites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Araújo, J.R.; Waldman, W.R.; De Paoli, M.A. Thermal properties of high density polyethylene composites with natural fibres: Coupling agent effect. Polym. Degrad. Stab. 2008, 93, 1770–1775. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Reixach, R.; Espinach, F.X.; Franco-Marquès, E.; Ramirez de Cartagena, F.; Pellicer, N.; Tresserras, J.; Mutje, P. Modeling of the tensile moduli of mechanical, thermomechanical, and chemi-thermomechanical pulps from orange tree pruning. Polym. Compos. 2013, 34, 1840–1846. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of various chemical treatments on the fibre structure and tensile properties of industrial hemp fibres. Compos. Part A Appl. Sci. Manuf. 2011, 42, 888–895. [Google Scholar] [CrossRef] [Green Version]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F.; Aravinthan, T. Mechanical properties of chemically-treated hemp fibre reinforced sandwich composites. Compos. Part B Eng. 2012, 43, 159–169. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Anastas, P.T.; Warner, J.C. Principles of green chemistry. Green Chem. Theory Pract. 1998, 39, 29–56. [Google Scholar]

- Granda, L.A.; Espinach, F.X.; Tarrés, Q.; Méndez, J.A.; Delgado-Aguilar, M.; Mutjé, P. Towards a good interphase between bleached kraft softwood fibers and poly(lactic) acid. Compos. Part B Eng. 2016, 99, 514–520. [Google Scholar] [CrossRef]

- Sunny, T.; Pickering, K.L.; Lim, S.H. Alkali treatment of hemp fibres for the production of aligned hemp fibre mats for composite reinforcement. Cellulose 2020, 27, 2569–2582. [Google Scholar] [CrossRef]

- Zabihzadeh, S.M.; Ebrahimi, G.; Enayati, A.A. Effect of Compatibilizer on Mechanical, Morphological, and Thermal Properties of Chemimechanical Pulp-reinforced PP Composites. J. Thermoplast. Compos. Mater. 2011, 24, 221–231. [Google Scholar] [CrossRef]

- Pimenta, M.T.B.; Carvalho, A.J.F.; Vilaseca, F.; Girones, J.; López, J.P.; Mutjé, P.; Curvelo, A.A.S. Soda-treated sisal/polypropylene composites. J. Polym. Environ. 2008, 16, 35–39. [Google Scholar] [CrossRef]

- Vilaseca, F.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Pèlach, M.À.; López, J.P.; Mutjé, P. Biocomposites from abaca strands and polypropylene. Part I: Evaluation of the tensile properties. Bioresour. Technol. 2010, 101, 387–395. [Google Scholar] [CrossRef] [PubMed]

- Neagu, R.C.; Gamstedt, E.K.; Berthold, F. Stiffness Contribution of Various Wood Fibers to Composite Materials. J. Compos. Mater. 2006, 40, 663–969. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Julian, F.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Research on the use of lignocellulosic fibers reinforced bio-polyamide 11 with composites for automotive parts: Car door handle case study. J. Clean. Prod. 2019, 226, 64–73. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.X.; Tresserras, J.; Pellicer, N.; Alcala, M.; Mutje, P. Study on the technical feasibility of replacing glass fibers by old newspaper recycled fibers as polypropylene reinforcement. J. Clean. Prod. 2014, 65, 489–496. [Google Scholar] [CrossRef]

- Ngaowthong, C.; Rungsardthong, V.; Siengchin, S. Polypropylene/hemp woody core fiber composites: Morphology, mechanical, thermal properties, and water absorption behaviors. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef] [Green Version]

- Thomason, J.L.; Vlug, M.A. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 1. Tensile and flexural modulus. Compos. Part A Appl. Sci. Manuf. 1996, 27, 477–484. [Google Scholar] [CrossRef]

- Tarrés, Q.; Soler, J.; Rojas-Sola, J.I.; Oliver-Ortega, H.; Julián, F.; Espinach, F.X.; Mutje, P.; Delgado-Aguilar, M. Flexural Properties and Mean Intrinsic Flexural Strength of Old Newspaper Reinforced Polypropylene Composites. Polymers 2019, 11, 1244. [Google Scholar] [CrossRef] [Green Version]

- Oliver-Ortega, H.; Llop, M.F.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Study of the flexural modulus of lignocellulosic fibers reinforced bio-based polyamide11 green composites. Compos. Part B Eng. 2018, 152, 126–132. [Google Scholar] [CrossRef]

- Hirsch, T.J. Modulus of elasticity of concrete affected by elastic moduli of cement paste matrix and aggregate. J. Am. Concr. Inst. 1962, 59, 427–452. [Google Scholar]

- Halpin, J.C.; Pagano, N.J. The Laminate Approximation for Randomly Oriented Fibrous Composites. J. Compos. Mater. 1969, 3, 720–724. [Google Scholar] [CrossRef]

- Halpin, J.C. Effects of Environmental Factors on Composite Materials; Tehnical Report AMFL-TR-67-423; Air Force Material Laboratory: Wright-Patterson Air Force Base, OH, USA, 1969. [Google Scholar]

- Tarrés, Q.; Vilaseca, F.; Herrera-Franco, P.J.; Espinach, F.X.; Delgado-Aguilar, M.; Mutjé, P. Interface and micromechanical characterization of tensile strength of bio-based composites from polypropylene and henequen strands. Ind. Crops Prod. 2019, 132, 319–326. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72. [Google Scholar] [CrossRef]

- Krenchel, H. Fibre Reinforcement; Theoretical and Practical Investigations of the Elasticity and Strength of Fibre-Reinforced Materials; Akademisk Forlag: Coppenhagen, Denmark, 1964. [Google Scholar]

- Sanomura, Y.; Kawamura, M. Fiber orientation control of short-fiber reinforced thermoplastics by ram extrusion. Polym. Compos. 2003, 24, 587–596. [Google Scholar] [CrossRef]

- Jiménez, A.M.; Delgado-Aguilar, M.; Tarrés Farres, Q.; Quintana, G.; Fullana-i-Palmer, P.; Mutjé, P.; Orus, E.X. Sugarcane Bagasse Reinforced Composites: Studies on the Young’s Modulus and Macro and Micro-Mechanics. BioResources 2017, 12, 3618–3629. [Google Scholar] [CrossRef] [Green Version]

- López, J.P.; Mutjé, P.; Angels Pèlach, M.; El Mansouri, N.E.; Boufi, S.; Vilaseca, F. Analysis of the tensile modulus of polypropylene composites reinforced with stone groundwood fibers. BioResources 2012, 7, 1310–1323. [Google Scholar] [CrossRef]

- Mittal, R.K.; Gupta, V.B.; Sharma, P. The effect of fibre orientation on the interfacial shear stress in short fibre-reinforced polypropylene. J. Mater. Sci. 1987, 22, 1949–1955. [Google Scholar] [CrossRef]

- López, J.P.; Boufi, S.; El Mansouri, N.E.; Mutjé, P.; Vilaseca, F. PP composites based on mechanical pulp, deinked newspaper and jute strands: A comparative study. Compos. Part B Eng. 2012, 43, 3453–3461. [Google Scholar] [CrossRef]

- Fukuda, H.; Kawata, K. On Young’s modulus of short fibre composites. Fibre Sci. Technol. 1974, 7, 207–222. [Google Scholar] [CrossRef]

- Culebras, M.; Sanchis, M.J.; Beaucamp, A.; Carsí, M.; Kandola, B.K.; Horrocks, A.R.; Panzetti, G.; Birkinshaw, C.; Collins, M.N. Understanding the thermal and dielectric response of organosolv and modified kraft lignin as a carbon fibre precursor. Green Chem. 2018, 20, 4461–4472. [Google Scholar] [CrossRef]

- Culebras, M.; Beaucamp, A.; Wang, Y.; Clauss, M.M.; Frank, E.; Collins, M.N. Biobased Structurally Compatible Polymer Blends Based on Lignin and Thermoplastic Elastomer Polyurethane as Carbon Fiber Precursors. ACS Sustain. Chem. Eng. 2018, 6, 8816–8825. [Google Scholar] [CrossRef]

- Beaucamp, A.; Wang, Y.; Culebras, M.; Collins, M.N. Carbon fibres from renewable resources: The role of the lignin molecular structure in its blendability with biobased poly(ethylene terephthalate). Green Chem. 2019, 21, 5063–5072. [Google Scholar] [CrossRef]

- Chatterjee, S.; Saito, T. Lignin-Derived Advanced Carbon Materials. ChemSusChem 2015, 8, 3941–3958. [Google Scholar] [CrossRef] [PubMed]

- Saito, T.; Brown, R.H.; Hunt, M.A.; Pickel, D.L.; Pickel, J.M.; Messman, J.M.; Baker, F.S.; Keller, M.; Naskaret, A.K. Turning renewable resources into value-added polymer: Development of lignin-based thermoplastic. Green Chem. 2012, 14, 3295–3303. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Méndez, J.A.; Tresserras, J.; Delgado-Aguilar, M.; Mutjé, P. Semichemical fibres of Leucaena collinsii reinforced polypropylene composites: Young’s modulus analysis and fibre diameter effect on the stiffness. Compos. Part B Eng. 2016, 92, 332–337. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; López, F.; García, J.C.; Delgado-Aguilar, M.; Mutjé, P. Semichemical fibres of Leucaena collinsii reinforced polypropylene: Macromechanical and micromechanical analysis. Compos. Part B Eng. 2016, 91, 384–391. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Granda, L.A.; Espinach, F.X.; Delgado-Aguilar, M.; Duran, J.; Mutjé, P. Stiffness of bio-based polyamide 11 reinforced with softwood stone ground-wood fibres as an alternative to polypropylene-glass fibre composites. Eur. Polym. J. 2016, 84, 481–489. [Google Scholar] [CrossRef]

- Thomason, J.L. The Influence of Fibre Properties on the Properties of Glass-Fibre-Reinforced Polyamide 6,6. J. Compos. Mater. 2000, 34, 158–172. [Google Scholar] [CrossRef]

- López, J.P.; Gironès, J.; Mendez, J.A.; Pèlach, M.A.; Vilaseca, F.; Mutjé, P. Impact and flexural properties of stone-ground wood pulp-reinforced polypropylene composites. Polym. Compos. 2013, 34, 842–848. [Google Scholar] [CrossRef]

- Vilaseca, F.; Del Rey, R.; Serrat, R.; Alba, J.; Mutje, P.; Espinach, F.X. Macro and micro-mechanics behavior of stifness in alkaline treated hemp core fibres polypropylene-based composites. Compos. Part B Eng. 2018, 144, 118–125. [Google Scholar] [CrossRef]

- Del Rey, R.; Serrat, R.; Alba, J.; Perez, I.; Mutje, P.; Espinach, F. Effect of Sodium Hydroxide Treatments on the Tensile Strength and the Interphase Quality of Hemp Core Fiber-Reinforced Polypropylene Composites. Polymers 2017, 9, 377. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shah, N.; Fehrenbach, J.; Ulven, C.A. Hybridization of Hemp Fiber and Recycled-Carbon Fiber in Polypropylene Composites. Sustainability 2019, 11, 3163. [Google Scholar] [CrossRef] [Green Version]

- Joseph, P.V.; Joseph, K.; Thomas, S. Effect of processing variables on the mechanical properties of sisal-fiber-reinforced polypropylene composites. Compos. Sci. Technol. 1999, 59, 1625–1640. [Google Scholar] [CrossRef]

- Puglia, D.; Biagiotti, J.; Kenny, J.M. A review on natural fibre-based composites—Part II: Application of natural reinforcements in composite materials for automotive industry. J. Nat. Fibers 2004, 1, 23–65. [Google Scholar] [CrossRef]

- Thomason, J.L. Interfacial strength in thermoplastic composites—At last an industry friendly measurement method? Compos. Part A Appl. Sci. Manuf. 2002, 33, 1283–1288. [Google Scholar] [CrossRef] [Green Version]

- Shibata, S.; Cao, Y.; Fukumoto, I. Flexural modulus of the unidirectional and random composites made from biodegradable resin and bamboo and kenaf fibres. Compos. Part A Appl. Sci. Manuf. 2008, 39, 640–646. [Google Scholar] [CrossRef]

- O’Brien, T.K.; Chawan, A.D.; DeMarco, K.; Paris, I. Influence of specimen configuration and size on composite transverse tensile strength and scatter measured through flexure testing. J. Compos. Technol. Res. 2003, 25, 3–21. [Google Scholar] [CrossRef]

- Adams, D.F.; King, T.R.; Blackketter, D.M. Evaluation of the transverse flexure test method for composite materials. Compos. Sci. Technol. 1990, 39, 341–353. [Google Scholar] [CrossRef]

- Ruan, F.; Bao, L. Effect of covering filaments on the compression performance and failure mechanism of unidirectional fiber-reinforced plastic. Polym. Compos. 2018, 39, 247–253. [Google Scholar] [CrossRef]

- Fajrin, J. Compressive Properties of Tropical Natural Fibers Reinforced Epoxy Polymer Composites. J. Ilmu Dan Teknol. Kayu Trop. 2018, 14, 127–135. [Google Scholar]

- Espinach, F.X.; Méndez, J.A.; Granda, L.A.; Pelach, M.A.; Delgado-Aguilar, M.; Mutjé, P. Bleached kraft softwood fibers reinforced polylactic acid composites, tensile and flexural strengths. Nat. Fiber Reinf. Biodegrad. Bioresorbable Polym. Compos. 2017, 73–90. [Google Scholar] [CrossRef]

- Sanadi, A.R.; Young, R.A.; Clemons, C.; Rowell, R.M. Recycled Newspaper Fibers as Reinforcing Fillers in Thermoplastics: Part I-Analysis of Tensile and Impact Properties in Polypropylene. J. Reinf. Plast. Compos. 1994, 13, 54–67. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.X.; Julian, F.; del Rey, R.; Mendez, J.A.; Mutje, P. Estimation of the interfacial shears strength, orientation factor and mean equivalent intrinsic tensile strength in old newspaper fiber/polypropylene composites. Compos. Part B Eng. 2013, 50, 232–238. [Google Scholar] [CrossRef]

- Espinach, F.X.; Julian, F.; Verdaguer, N.; Torres, L.; Pelach, M.A.; Vilaseca, F.; Mutjé, P. Analysis of tensile and flexural modulus in hemp strands/polypropylene composites. Compos. Part B Eng. 2013, 47, 339–343. [Google Scholar] [CrossRef]

| NaOH (wt %) | Process Yield (wt %) | Kappa Number | lwwF (µm) | dF (µm) | lwwF/dF |

|---|---|---|---|---|---|

| 5 | 78.6 | 73.2 ± 0.3 | 655 ± 9 | 23.7 ± 0.4 | 16.0 |

| 7.5 | 76.4 | 68.1 ± 0.3 | 665 ± 12 | 24.5 ± 0.6 | 15.8 |

| 10 | 66.9 | 57.0 ± 0.4 | 684 ± 6 | 24.6 ± 0.6 | 16.1 |

| 0 wt % MAPP | 6 wt % MAPP | |||||

|---|---|---|---|---|---|---|

| NaOH (wt %) | Hemp Core (wt %) | VF | Efc (GPa) | Ɛfc (%) | Efc (GPa) | Ɛfc (%) |

| PP | - | - | 1.10 ± 0.05 | 9.60 ± 0.12 | 1.10 ± 0.05 | 9.60 ± 0.12 |

| 5 | 10 | 0.067 | 1.57 ± 0.06 | 7.01 ± 0.13 | 1.51 ± 0.03 | 7.89 ± 0.12 |

| 20 | 0.139 | 2.12 ± 0.09 | 5.52 ± 0.09 | 1.98 ± 0.04 | 6.89 ± 0.11 | |

| 30 | 0.217 | 2.67 ± 0.03 | 4.21 ± 0.14 | 2.61 ± 0.06 | 5.78 ± 0.11 | |

| 40 | 0.301 | 3.30 ± 0.04 | 2.89 ± 0.08 | 3.26 ± 0.04 | 4.90 ± 0.07 | |

| 50 | 0.393 | 3.72 ± 0.09 | 2.09 ± 0.09 | 3.73 ± 0.03 | 4.11 ± 0.09 | |

| 7.5 | 10 | 0.067 | 1.59 ± 0.10 | 7.24 ± 0.06 | 1.57 ± 0.05 | 8.14 ± 0.12 |

| 20 | 0.139 | 2.21 ± 0.04 | 5.64 ± 0.14 | 2.15 ± 0.06 | 7.26 ± 0.13 | |

| 30 | 0.217 | 2.70 ± 0.06 | 4.32 ± 0.15 | 2.87 ± 0.04 | 6.21 ± 0.06 | |

| 40 | 0.301 | 3.41 ± 0.04 | 3.35 ± 0.10 | 3.37 ± 0.03 | 5.41 ± 0.12 | |

| 50 | 0.393 | 3.90 ± 0.05 | 2.50 ± 0.11 | 3.85 ± 0.02 | 4.86 ± 0.06 | |

| 10 | 10 | 0.067 | 1.58 ± 0.03 | 7.11 ± 0.08 | 1.58 ± 0.04 | 7.92 ± 0.11 |

| 20 | 0.139 | 2.18 ± 0.02 | 5.54 ± 0.09 | 2.31 ± 0.04 | 7.12 ± 0.12 | |

| 30 | 0.217 | 2.71 ± 0.07 | 4.41 ± 0.13 | 2.74 ± 0.02 | 6.14 ± 0.14 | |

| 40 | 0.301 | 3.51 ± 0.02 | 3.41 ± 0.11 | 3.61 ± 0.04 | 5.35 ± 0.09 | |

| 50 | 0.393 | 3.93 ± 0.05 | 2.48 ± 0.13 | 3.92 ± 0.03 | 4.82 ± 0.11 | |

| NaOH (wt %) | Hemp Core (wt %) | EfF—Hirsch (GPa) | EfF—TP&HT (GPa) |

|---|---|---|---|

| 5 | 10 | 14.8 | 15.2 |

| 20 | 15.2 | 15.3 | |

| 30 | 16.6 | 16.7 | |

| 40 | 16.9 | 16.5 | |

| 50 | 15.4 | 14.0 | |

| 7.5 | 10 | 17.0 | 18.7 |

| 20 | 18.2 | 19.9 | |

| 30 | 19.5 | 21.2 | |

| 40 | 17.8 | 17.5 | |

| 50 | 16.2 | 14.9 | |

| 10 | 10 | 17.4 | 19.2 |

| 20 | 21.1 | 24.6 | |

| 30 | 18.0 | 18.8 | |

| 40 | 19.8 | 20.5 | |

| 50 | 19.6 | 15.4 |

| NaOH (wt %) | ηe | ηl | ηo | αo | α |

|---|---|---|---|---|---|

| 5 | 0.492 | 0.910 | 0.540 | 53.39 | 29.49 |

| 7.5 | 0.483 | 0.902 | 0.535 | 53.53 | 29.55 |

| 10 | 0.479 | 0.902 | 0.531 | 54.10 | 29.83 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serra-Parareda, F.; Espinach, F.X.; Pelach, M.À.; Méndez, J.A.; Vilaseca, F.; Tarrés, Q. Effect of NaOH Treatment on the Flexural Modulus of Hemp Core Reinforced Composites and on the Intrinsic Flexural Moduli of the Fibers. Polymers 2020, 12, 1428. https://doi.org/10.3390/polym12061428

Serra-Parareda F, Espinach FX, Pelach MÀ, Méndez JA, Vilaseca F, Tarrés Q. Effect of NaOH Treatment on the Flexural Modulus of Hemp Core Reinforced Composites and on the Intrinsic Flexural Moduli of the Fibers. Polymers. 2020; 12(6):1428. https://doi.org/10.3390/polym12061428

Chicago/Turabian StyleSerra-Parareda, Ferran, Francesc Xavier Espinach, Maria Àngels Pelach, José Alberto Méndez, Fabiola Vilaseca, and Quim Tarrés. 2020. "Effect of NaOH Treatment on the Flexural Modulus of Hemp Core Reinforced Composites and on the Intrinsic Flexural Moduli of the Fibers" Polymers 12, no. 6: 1428. https://doi.org/10.3390/polym12061428

APA StyleSerra-Parareda, F., Espinach, F. X., Pelach, M. À., Méndez, J. A., Vilaseca, F., & Tarrés, Q. (2020). Effect of NaOH Treatment on the Flexural Modulus of Hemp Core Reinforced Composites and on the Intrinsic Flexural Moduli of the Fibers. Polymers, 12(6), 1428. https://doi.org/10.3390/polym12061428