Internal Residual Strain Measurements in Carbon Fiber-Reinforced Polymer Laminates Curing Process Using Embedded Tilted Fiber Bragg Grating Sensor

Abstract

:1. Introduction

2. Working Principle of TFBG Sensors

3. Experimental Method

3.1. The Manufacturing of the TFBG Sensor

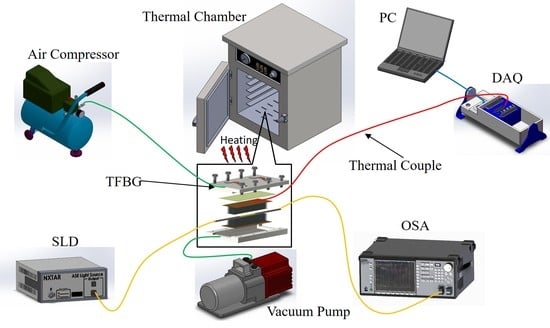

3.2. The Curing Monitoring Experimental Setup for Carbon Fiber-Reinforced Polymer Materials.

4. Results and Discussion

4.1. DSC Analysis of CFRP Materials

4.2. The Result of CFRP Curing Monitoring with TFBG Sensor

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Okabe, Y.; Yashiro, S.; Tsuji, R.; Mizutani, T.; Takeda, N. Effect of thermal residual stress on the reflection spectrum from fiber Bragg grating sensors embedded in CFRP laminates. Compos. Part A Appl. Sci. Manuf. 2002, 33, 991–999. [Google Scholar] [CrossRef]

- Bagherpour, S. Fibre Reinforced Polyester Composites; InTech.: London, UK, 2012; pp. 135–166. [Google Scholar]

- Lisantono, A.; Pinang, P. Axial and Flexural Strength of Square RC Columns with No-rounded Corners Wrapped with CFRP under Eccentric Loading. Int. J. Eng. Technol. Innov. 2018, 8, 38. [Google Scholar]

- Rudolph, M.; Naumann, C.; Stockmann, M. Degree of cure definition for an epoxy resin based on thermal diffusivity measurements. Mater. Today 2016, 3, 1144–1149. [Google Scholar] [CrossRef]

- Erdmann, M.; Trappe, V.; Sturm, H.; Braun, U.; Duemichen, E. Cure conversion of structural epoxies by cure state analysis and in situ cure kinetics using nondestructive NIR spectroscopy. Thermochim. Acta 2017, 650, 8–17. [Google Scholar] [CrossRef]

- Drake, D.A.; Sullivan, R.W.; Spowart, J. Cure Monitoring of CFRP Composites using Embedded Optical Fibers. In Proceedings of the 2018 AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 8–12 January 2018; p. 1373. [Google Scholar]

- Qi, Y.; Jiang, D.; Ju, S.; Zhang, J. Investigation of strain history in fast and conventional curing epoxy matrix composites by FBGs. Compos. Sci. Technol. 2018, 159, 18–24. [Google Scholar] [CrossRef]

- Aludin, M.S.; Akmal, S.S.; Rosiyah, Y. Preparation and characterization of form-stabilized paraffin/polycaprolactone (PCL) composites as phase change materials. Proc. Mechan. Eng. Res. Day 2016, 2016, 177–178. [Google Scholar]

- Kobayashi, D.; Hsieh, Y.T.; Takahara, A. Interphase structure of carbon fiber reinforced polyamide 6 revealed by microbeam X-ray diffraction with synchrotron radiation. Polymer 2016, 89, 154–158. [Google Scholar] [CrossRef]

- Pattanaik, A.; Bhuyan, S.K.; Samal, S.K.; Behera, A.; Mishra, S.C. Dielectric properties of epoxy resin fly ash composite. In Proceedings of the 5th National Conference on Processing and Characterization of Materials Publishing, Rourkela, India, 12–13 December 2015; p. 012003. [Google Scholar]

- Stark, W.; Jaunich, M.; McHugh, J. Dynamic Mechanical Analysis (DMA) of epoxy carbon-fibre prepregs partially cured in a discontinued autoclave analogue process. Polym. Test. 2015, 41, 140–148. [Google Scholar] [CrossRef]

- Khan, L.A.; Nesbitt, A.; Day, R.J. Hygrothermal degradation of 977-2A carbon/epoxy composite laminates cured in autoclave and Quickstep. Compos. Part A Appl. Sci. Manuf. 2010, 41, 942–953. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Gendy, A.; Kamel, S. Evaluation of corn husk fibers reinforced recycled low density polyethylene composites. Mater. Chem. Phys. 2015, 152, 26–33. [Google Scholar] [CrossRef]

- Kister, G.; Dossi, E. Cure monitoring of CFRP composites by dynamic mechanical analyser. Polym. Test. 2015, 47, 71–78. [Google Scholar] [CrossRef] [Green Version]

- Dong, X.; Zhang, H.; Liu, B.; Miao, Y. Tilted fiber Bragg gratings: Principle and sensing applications. Photonic Sens. 2001, 1, 6–30. [Google Scholar] [CrossRef] [Green Version]

- Albert, J.; Shao, L.Y.; Caucheteur, C. Tilted fiber Bragg grating sensors. Laser Photonics Rev. 2013, 7, 83–108. [Google Scholar] [CrossRef]

- Osuch, T.; Jurek, T.; Markowski, K.; Jedrzejewski, K. Simultaneous measurement of liquid level and temperature using tilted fiber Bragg grating. IEEE Sens. J. 2016, 16, 1205–1209. [Google Scholar] [CrossRef]

- Sun, T.T.; Pei, S.X.; Li, J.H.; Zhao, L.L. Transverse strain sensor based on tilted fiber Bragg grating. J. Optoelectron. Laser 2015, 26, 1854–1859. [Google Scholar]

- Guo, T.; Liu, F.; Guan, B.O.; Albert, J. Tilted fiber grating mechanical and biochemical sensors. Opt. Laser Technol. 2016, 78, 19–33. [Google Scholar] [CrossRef] [Green Version]

- Buggy, S.J.; Chehura, E.; James, S.W.; Tatam, R.P. Optical fibre grating refractometers for resin cure monitoring. J. Opt. A Pure Appl. Opt. 2007, 9, S60. [Google Scholar] [CrossRef]

- Takeda, S.I.; Koyanagi, J.; Utsunomiya, S.; Kinoshita, Y.; Arao, Y.; Kawada, H. Monitoring of internal residual strain changes in CFRP using FBG sensors. In Proceedings of the 4th International Conference on Experimental Mechanics, International Society for Optics and Photonics, Singapore, 18–20 November 2009; Volume 7522, p. 75223N. [Google Scholar]

- Shen, X.Y. Cure monitoring of composites based on embedded fiber Bragg gratings. Adv. Mat. Res. 2010, 211, 585–589. [Google Scholar] [CrossRef]

- Kinet, D.; Caucheteur, C.; Wuilpart, M.; Garray, D.; Narbonneau, F.; Mégret, P. Effect of epoxy curing on tilted fiber Bragg gratings transmission spectrum. In Proceedings of the 18th International Conference on Composite Materials (ICCM), Jeju Island, Korea, 21–26 August 2011; pp. 1–5. [Google Scholar]

- Laffont, G.; Ferdinand, P. Tilted short-period fibre-Bragg-grating-induced coupling to cladding modes for accurate refractometry. Meas. Sci. Technol. 2001, 12, 765. [Google Scholar] [CrossRef]

- Majumder, M.; Gangopadhyay, T.K.; Chakraborty, A.K.; Dasgupta, K.; Bhattacharya, D.K. Fibre Bragg gratings in structural health monitoring—Present status and applications. Sens. Actuators A 2008, 147, 150–164. [Google Scholar] [CrossRef]

- Guemes, J.A.; Menendez, J.M. Response of Bragg grating fiber-optic sensors when embedded in composite laminates. Compos. Sci. Technol. 2002, 62, 959–966. [Google Scholar] [CrossRef]

- Luyckx, G.; Voet, E.; Lammens, N.; Degrieck, J. Strain Measurements of Composite Laminates with Embedded Fibre Bragg Gratings: Criticism and Opportunities for Research. Sensors 2011, 11, 384–408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| TFBG Sensor | ||

|---|---|---|

| −22.25 | −10.70 | −5.27 |

| −281.351 | −89.91 | 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, K.-P.; Wu, C.-W.; Tsai, Y.-T.; Hsu, Y.-C.; Chiang, C.-C. Internal Residual Strain Measurements in Carbon Fiber-Reinforced Polymer Laminates Curing Process Using Embedded Tilted Fiber Bragg Grating Sensor. Polymers 2020, 12, 1479. https://doi.org/10.3390/polym12071479

Ma K-P, Wu C-W, Tsai Y-T, Hsu Y-C, Chiang C-C. Internal Residual Strain Measurements in Carbon Fiber-Reinforced Polymer Laminates Curing Process Using Embedded Tilted Fiber Bragg Grating Sensor. Polymers. 2020; 12(7):1479. https://doi.org/10.3390/polym12071479

Chicago/Turabian StyleMa, Ke-Ping, Chao-Wei Wu, Yao-Tung Tsai, Ya-Chun Hsu, and Chia-Chin Chiang. 2020. "Internal Residual Strain Measurements in Carbon Fiber-Reinforced Polymer Laminates Curing Process Using Embedded Tilted Fiber Bragg Grating Sensor" Polymers 12, no. 7: 1479. https://doi.org/10.3390/polym12071479

APA StyleMa, K. -P., Wu, C. -W., Tsai, Y. -T., Hsu, Y. -C., & Chiang, C. -C. (2020). Internal Residual Strain Measurements in Carbon Fiber-Reinforced Polymer Laminates Curing Process Using Embedded Tilted Fiber Bragg Grating Sensor. Polymers, 12(7), 1479. https://doi.org/10.3390/polym12071479