Wastewater Treatment by a Polymeric Bioflocculant and Iron Nanoparticles Synthesized from a Bioflocculant

Abstract

:1. Introduction

2. Materials and Methods

2.1. Production Medium Chemicals

2.2. Extraction and Purification of the Bioflocculant

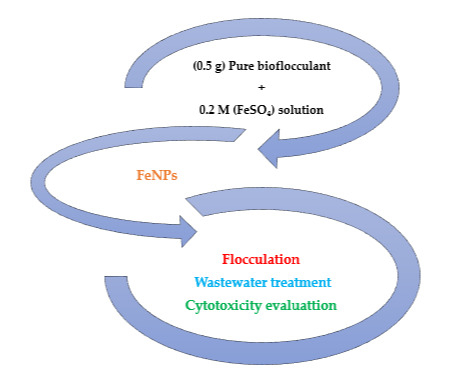

2.3. Synthesis of the Iron Nanoparticles (FeNPs)

2.4. Characterization of the Bioflocculant and Iron Nanoparticles

2.4.1. Morphology and Element Analysis

2.4.2. Functional Groups Analysis

2.5. Determination of Flocculation Activity

2.6. Optimization of the Flocculation Efficiency of the Bioflocculant and FeNPs

2.6.1. Evaluation of Flocculation Activity of the Bioflocculant and FeNPs

2.6.2. Effect of Cations on Flocculating Activity

2.6.3. Effect of pH and Temperature on Flocculating Activity

2.7. Wastewater Treatment

2.8. Cytotoxicity of the Bioflocculant and Iron Nanoparticles

2.9. Experimental, Software, and Statistical Analysis

3. Results

3.1. FT-IT Spectra of the Bioflocculant and Iron Nanoparticles

3.2. The SEM Morphology of the Bioflocculant and Iron Nanoparticles

3.3. Elemental Composition of the Bioflocculant and Iron Nanoparticles

3.4. Dosage Concentration Effect on Flocculation

3.5. Temperature Effect on Flocculation Activity

3.6. Effect of pH on Flocculation Activity

3.7. Effect of Metal Ions on Flocculation Activity

3.8. The Removal of COD and BOD

3.9. Evaluation of Cytotoxicity of the FeNPs and Bioflocculant

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Corcoran, E.; Nellemann, C.; Baker, E.; Bos, R.; Osborn, D.; Savelli, H. (Eds.) Sick Water? The Central Role of Wastewater Management in Sustainable Development: A Rapid Response Assessment; United Nations Environment Programme: Birkeland Trykkeri AS, Norway, 2010. [Google Scholar]

- Yang, Z.; Liu, S.; Zhang, W.; Wen, Q.; Guo, Y. Enhancement of coal waste slurry flocculation by CTAB combined with bioflocculant produced by Azotobacter chroococcum. Sep. Purif. Technol. 2019, 211, 587–593. [Google Scholar] [CrossRef]

- Santschi, P.H. Marine colloids, agents of the self-cleansing capacity of aquatic systems: Historical perspective and new discoveries. Mar. Chem. 2018, 207, 124–135. [Google Scholar] [CrossRef]

- Ali, I.; Asim, M.; Khan, T.A. Low cost adsorbents for the removal of organic pollutants from wastewater. J. Environ. Manag. 2012, 113, 170–183. [Google Scholar] [CrossRef] [PubMed]

- Qu, X.; Alvarez, P.J.; Li, Q. Applications of nanotechnology in water and wastewater treatment. Water Res. 2013, 47, 3931–3946. [Google Scholar] [CrossRef] [PubMed]

- Verma, Y. Acute toxicity assessment of textile dyes and textile and dye industrial effluents using Daphnia magna bioassay. Toxicol. Ind. Health 2008, 24, 491–500. [Google Scholar] [CrossRef]

- Samanta, A.K.; Agarwal, P. Application of natural dyes on textiles. Indian J. Fibre Text. Res. 2009, 34, 384–399. [Google Scholar]

- Merzouk, B.; Madani, K.; Sekki, A. Using electrocoagulation–electroflotation technology to treat synthetic solution and textile wastewater, two case studies. Desalination 2010, 250, 573–577. [Google Scholar] [CrossRef]

- Verma, A.K.; Dash, R.R.; Bhunia, P. A review on chemical coagulation/flocculation technologies for removal of colour from textile wastewaters. J. Environ. Manag. 2012, 93, 154–168. [Google Scholar] [CrossRef]

- Tiwari, D.K.; Behari, J.; Sen, P. Application of nanoparticles in waste water treatment 1. World Appl. Sci. J. 2008, 3, 417–433. [Google Scholar]

- Maliehe, T.S.; Basson, A.K.; Dlamini, N.G. Removal of Pollutants in Mine Wastewater by a Non-Cytotoxic Polymeric Bioflocculant from Alcaligenes faecalis HCB2. Int. J. Environ. Res. Public Health 2019, 16, 4001. [Google Scholar] [CrossRef] [Green Version]

- Lu, H.; Wang, J.; Wang, T.; Wang, N.; Bao, Y.; Hao, H. Crystallization techniques in wastewater treatment: An overview of applications. Chemosphere 2017, 173, 474–484. [Google Scholar] [CrossRef]

- Agunbiade, M.O.; Pohl, C.; Van Heerden, E.; Oyekola, O.; Ashafa, A. Evaluation of FreshWater Actinomycete Bioflocculant and Its Biotechnological Applications in Wastewaters Treatment and Removal of Heavy Metals. Int. J. Environ. Res. Public Health 2019, 16, 3337. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ugbenyen, A.; Okoh, A. Characteristics of a bioflocculant produced by a consortium of Cobetia and Bacillus species and its application in the treatment of wastewaters. Water SA 2014, 40, 140–144. [Google Scholar] [CrossRef] [Green Version]

- Guo, H.; Hong, C.; Zhang, C.; Zheng, B.; Jiang, D.; Qin, W. Bioflocculants’ production from a cellulase-free xylanase-producing Pseudomonas boreopolis G22 by degrading biomass and its application in cost-effective harvest of microalgae. Bioresour. Technol. 2018, 255, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Karthiga devi, K.; Natarajan, K.A. Production and characterization of bioflocculants for mineral processing applications. Int. J. Miner. Process. 2015, 137, 15–25. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, X.; Miao, X.; Zhou, J. Preparation and characteristics of bioflocculants from excess biological sludge. Bioresour. Technol. 2012, 126, 362–366. [Google Scholar] [CrossRef] [PubMed]

- Abu Tawila, Z.; Ismail, S.; Dadrasnia, A.; Usman, M. Production and characterization of a bioflocculant produced by Bacillus salmalaya 139SI-7 and its applications in wastewater treatment. Molecules 2018, 23, 2689. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Bao, H.-Y.; Xin, M.-X.; Liu, Y.-X.; Li, Q.; Zhang, Y.-F. Characterization of a bioflocculant from a newly isolated Vagococcus sp. W31. J. Zhejiang Univ. Sci. B 2006, 7, 186–192. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, Z.-Q.; Bo, L.; XIA, S.-Q.; Wang, X.-J.; Yang, A.-M. Production and application of a novel bioflocculant by multiple-microorganism consortia using brewery wastewater as carbon source. J. Environ. Sci. 2007, 19, 667–673. [Google Scholar] [CrossRef]

- Dlamini, N.G.; Basson, A.K.; Pullabhotla, V.S.R. Optimization and Application of Bioflocculant Passivated Copper Nanoparticles in the Wastewater Treatment. Int. J. Environ. Res. Public Health 2019, 16, 2185. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dlamini, N.G.; Basson, A.K.; Shandu, J.S.E.; Mavuso, S.S.; Pullabhotla, V.S.R. Biosynthesis, Characterization, and Application of Iron Nanoparticles: In Dye Removal and as Antimicrobial Agent. Water Air Soil Pollut. 2020, 231, 1–10. [Google Scholar] [CrossRef]

- Xia, X.; Lan, S.; Li, X.; Xie, Y.; Liang, Y.; Yan, P.; Chen, Z.; Xing, Y. Characterization and coagulation-flocculation performance of a composite flocculant in high-turbidity drinking water treatment. Chemosphere 2018, 206, 701–708. [Google Scholar] [CrossRef] [PubMed]

- Daniels, A.N.; Singh, M. Sterically stabilized siRNA: Gold nanocomplexes enhance c-MYC silencing in a breast cancer cell model. Nanomedicine 2019, 14, 1387–1401. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.; Wang, Y.; Yu, Y.; Li, Q.; Wang, H.; Chen, R.; He, N. Production and characterization of a novel bioflocculant from Bacillus licheniformis. Appl. Environ. Microbiol. 2010, 76, 2778–2782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mata, Y.; Torres, E.; Blazquez, M.; Ballester, A.; González, F.; Munoz, J. Gold (III) biosorption and bioreduction with the brown alga Fucus vesiculosus. J. Hazard. Mater. 2009, 166, 612–618. [Google Scholar] [CrossRef] [PubMed]

- Li, X.-M.; Yang, Q.; Huang, K.; Zeng, G.-M.; Liao, D.-X.; Liu, J.-J.; Long, W.-F. Screening and characterization of a bioflocculant produced by Aeromonas sp. Biomed. Environ. Sci. BES 2007, 20, 274–278. [Google Scholar]

- Wang, L.; Ma, F.; Qu, Y.; Sun, D.; Li, A.; Guo, J.; Yu, B. Characterization of a compound bioflocculant produced by mixed culture of Rhizobium radiobacter F2 and Bacillus sphaeicus F6. World J. Microbiol. Biotechnol. 2011, 27, 2559–2565. [Google Scholar] [CrossRef]

- Gong, W.-X.; Wang, S.-G.; Sun, X.-F.; Liu, X.-W.; Yue, Q.-Y.; Gao, B.-Y. Bioflocculant production by culture of Serratia ficaria and its application in wastewater treatment. Bioresour. Technol. 2008, 99, 4668–4674. [Google Scholar] [CrossRef]

- Sekelwa, C.; Anthony, U.M.; Vuyani, M.L.; Anthony, O.I. Characterization of a thermostable polysaccharide bioflocculant produced by Virgibacillus species isolated from Algoa bay. Afr. J. Microbiol. Res. 2013, 7, 2925–2938. [Google Scholar]

- Manivasagan, P.; Kang, K.-H.; Kim, D.G.; Kim, S.-K. Production of polysaccharide-based bioflocculant for the synthesis of silver nanoparticles by Streptomyces sp. Int. J. Biol. Macromol. 2015, 77, 159–167. [Google Scholar] [CrossRef]

- Wu, J.-Y.; Ye, H.-F. Characterization and flocculating properties of an extracellular biopolymer produced from a Bacillus subtilis DYU1 isolate. Process. Biochem. 2007, 42, 1114–1123. [Google Scholar] [CrossRef]

- Pathak, M.; Devi, A.; Bhattacharyya, K.; Sarma, H.; Subudhi, S.; Lal, B. Production of a non-cytotoxic bioflocculant by a bacterium utilizing a petroleum hydrocarbon source and its application in heavy metal removal. RSC Adv. 2015, 5, 66037–66046. [Google Scholar] [CrossRef]

| Elements | Sample | |

|---|---|---|

| Bioflocculant (wt.%) | FeNPs (wt.%) | |

| C | 13.21 | 12.39 |

| O | 55.25 | 47.94 |

| Mg | 13.35 | 1.12 |

| P | 16.00 | 13.43 |

| K | 0.14 | 0.24 |

| Ca | 2.04 | 7.33 |

| Fe | - | 17.31 |

| Cu | - | 0.30 |

| Total | 100.00 | 100.00 |

| Cations | Flocculation Activity (%) | |

|---|---|---|

| Bioflocculant | FeNPs | |

| Control | 49 ± 3.35 | 46 ± 2.03 b |

| Fe3+ | 31 ± 3.15 | 85 ± 2.72 a |

| Mg2+ | 63 ± 6.78 | 82 ± 1.53 a |

| Ca2+ | 71 ± 5.42 | 82 ± 3.64 a |

| Li+ | 75 ± 2.31 | 72 ± 1.15 a |

| Na+ | 62 ± 7.28 | 72 ± 1.15 a |

| Flocculant | Types of Waste Water | Types of Pollutants in Water | Water Quality before Treatment (mg/L) | Water Quality after Treatment (mg/L) | Removal Efficiency (%) |

|---|---|---|---|---|---|

| FeNPs | Coal mine water | COD BOD | 842 123.2 | 204 23 | 76 81 |

| Mzingazi river water | COD BOD | 3.300 136 | 1.700 24 | 48 82 | |

| Bioflocculant | Coal mine water | COD BOD | 842 123.2 | 208 77.88 | 72 59 |

| Mzingazi river water | COD BOD | 3.300 136 | 1.68 72.08 | 51 53 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dlamini, N.G.; Basson, A.K.; Pullabhotla, R.V. Wastewater Treatment by a Polymeric Bioflocculant and Iron Nanoparticles Synthesized from a Bioflocculant. Polymers 2020, 12, 1618. https://doi.org/10.3390/polym12071618

Dlamini NG, Basson AK, Pullabhotla RV. Wastewater Treatment by a Polymeric Bioflocculant and Iron Nanoparticles Synthesized from a Bioflocculant. Polymers. 2020; 12(7):1618. https://doi.org/10.3390/polym12071618

Chicago/Turabian StyleDlamini, Nkosinathi Goodman, Albertus Kotze Basson, and Rajasekhar VSR Pullabhotla. 2020. "Wastewater Treatment by a Polymeric Bioflocculant and Iron Nanoparticles Synthesized from a Bioflocculant" Polymers 12, no. 7: 1618. https://doi.org/10.3390/polym12071618

APA StyleDlamini, N. G., Basson, A. K., & Pullabhotla, R. V. (2020). Wastewater Treatment by a Polymeric Bioflocculant and Iron Nanoparticles Synthesized from a Bioflocculant. Polymers, 12(7), 1618. https://doi.org/10.3390/polym12071618