Systematic Investigation on the Structure-Property Relationship in Isotactic Polypropylene Films Processed via Cast Film Extrusion

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

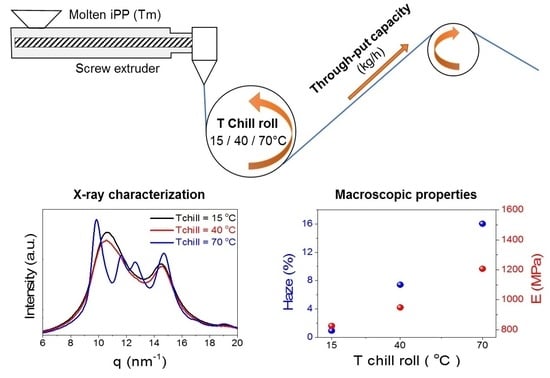

3.1. Processing to Nanostructure

3.2. Nano-Structure to Macro-Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gahleitner, M.; Mileva, D.; Androsch, R.; Gloger, D.; Tranchida, D.; Sandholzer, M.; Doshev, P. Crystallinity-based product design: Utilizing the polymorphism of isotactic pp homoand copolymers. Int. Polym. Process. 2016, 31, 618–627. [Google Scholar] [CrossRef]

- Mileva, D.; Tranchida, D.; Gahleitner, M. Designing polymer crystallinity: An industrial perspective. Polym. Cryst. 2018, 1, e10009. [Google Scholar] [CrossRef]

- De Rosa, C.; Auriemma, F.; Di Girolamo, R.; De Ballesteros, O.R. Crystallization of the mesomorphic form and control of the molecular structure for tailoring the mechanical properties of isotactic polypropylene. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 677–699. [Google Scholar] [CrossRef]

- Van Lierde, S. Latest medical applications of polypropylene. Med. Device Technol. 2004, 15, 33–34. [Google Scholar] [PubMed]

- Gahleitner, M.; Paulik, C. Polypropylene and Other Polyolefins. In Brydson’s Plastics Materials, 8th ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 279–309. ISBN 9780323358248. [Google Scholar]

- Schöbel, A.; Herdtweck, E.; Parkinson, M.; Rieger, B. Ultra-rigid metallocenes for highly iso- and regiospecific polymerization of propene: The search for the perfect polypropylene helix. Chem. A Eur. J. 2012, 18, 4174–4178. [Google Scholar] [CrossRef] [PubMed]

- Pantani, R.; Balzano, L.; Peters, G.W.M. Flow-induced morphology of iPP solidified in a shear device. Macromol. Mater. Eng. 2012, 297, 60–67. [Google Scholar] [CrossRef]

- Gahleitner, M.; Bachner, C.; Ratajski, E.; Rohaczek, G.; Neißl, W. Effects of the catalyst system on the crystallization of polypropylene. J. Appl. Polym. Sci. 1999, 73, 2507–2516. [Google Scholar] [CrossRef]

- Gahleitner, M.; Mileva, D.; Gloger, D.; Androsch, R.; Tranchida, D. Polymer structure effects on crystallization and properties in polypropylene film casting Polymer Structure Effects on Crystallization and Properties in Polypropylene Film Casting. AIP Conf. Proc. 2017, 1914, 130001. [Google Scholar]

- Gahleitner, M.; Jääskeläinen, P.; Ratajski, E.; Paulik, C.; Reussner, J.; Wolfschwenger, J.; Neißl, W. Propylene-ethylene random copolymers: Comonomer effects on crystallinity and application properties. J. Appl. Polym. Sci. 2005. [Google Scholar] [CrossRef]

- Cavallo, D.; Gardella, L.; Alfonso, G.C.; Mileva, D.; Androsch, R. Effect of comonomer partitioning on the kinetics of mesophase formation in random copolymers of propene and higher α-olefins. Polymer (Guildf) 2012, 53, 4429–4437. [Google Scholar] [CrossRef]

- Wallner, G.M.; Resch, K.; Teichert, C.; Gahleitner, M.; Binder, W. Effect of material structure and additives on the optical properties of PP cast films. Mon. Fur Chem. 2006, 137, 887–897. [Google Scholar] [CrossRef]

- Resch, K.; Wallner, G.M.; Teichert, C.; Nther Maier, G.; Gahleitner, M. Optical Properties of Highly Transparent Polypropylene Cast Films: Influence of Material Structure, Additives, and Processing Conditions. Polym. Eng. Sci. 2006. [Google Scholar] [CrossRef]

- Baeten, D.; Cavallo, D.; Portale, G.; Androsch, R.; Mathot, V.; Goderis, B. Combining fast scanning chip calorimetry with structural and morphological characterization techniques. In Fast Scanning Calorimetry; Springer: Berlin/Heidelberg, Germany, 2016; pp. 327–359. ISBN 9783319313290. [Google Scholar]

- Lotz, B.; Wittmann, J.C.; Lovinger, A.J. Structure and morphology of poly(propylenes): A molecular analysis. Polymer (Guildf) 1996, 37, 4979–4992. [Google Scholar] [CrossRef]

- Natta, G.; Corradini, P. Structure and properties of isotactic polypropylene. Nuovo Cim. Ser. 10 1960, 15, 40–51. [Google Scholar] [CrossRef]

- Zia, Q.; Androsch, R.; Radusch, H.J.; Piccarolo, S. Morphology, reorganization and stability of mesomorphic nanocrystals in isotactic polypropylene. Polymer (Guildf) 2006, 47, 8163–8172. [Google Scholar] [CrossRef]

- Zia, Q.; Mileva, D.; Androsch, R. Rigid amorphous fraction in isotactic polypropylene. Macromolecules 2008, 41, 8095–8102. [Google Scholar] [CrossRef]

- Lamberti, G.; Brucato, V. Real-time orientation and crystallinity measurements during the isotactic polypropylene film-casting process. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 998–1008. [Google Scholar] [CrossRef]

- Resch, K.; Wallner, G.M.; Teichert, C.; Gahleitner, M. Highly transparent polypropylene cast films: Relationships between optical properties, additives, and surface structure. Polym. Eng. Sci. 2007, 47, 1021–1032. [Google Scholar] [CrossRef]

- Zhou, Y.-G.; Wu, W.-B.; Zou, J.; Turng, L.-S. Dual-scale modeling and simulation of film casting of isotactic polypropylene. J. Plast. Film Sheeting 2016, 32, 239–271. [Google Scholar] [CrossRef]

- Liu, J.J.; Xu, M.; Zhang, S.; Liang, J.; Quan, H.; Liu, J.J.; Shi, H.; Gao, D. Influences of processing on the phase transition and crystallization of polypropylene cast films. J. Appl. Polym. Sci. 2014. [Google Scholar] [CrossRef]

- Ma, Z.; Fernandez-Ballester, L.; Cavallo, D.; Gough, T.; Peters, G.W.M. High-stress shear-induced crystallization in isotactic polypropylene and propylene/ethylene random copolymers. Macromolecules 2013, 46, 2671–2680. [Google Scholar] [CrossRef] [Green Version]

- Roozemond, P.C.; Steenbakkers, R.J.A.; Peters, G.W.M. A model for flow-enhanced nucleation based on fibrillar dormant precursors. Macromol. Theory Simul. 2011. [Google Scholar] [CrossRef]

- Hammersley, A. The FIT2D Home Page. Available online: http://www.esrf.eu/computing/scientific/FIT2D/ (accessed on 14 April 2020).

- Ryanf, A.J.; Brass, W.; Mant, G.R.; Derbyshire, G.E. A direct method to determine the degree of crystallinity and lamellar thickness of polymers: Application to polyethylene*. Polymer (Guildf) 1994, 35, 4537–4544. [Google Scholar] [CrossRef]

- Li, X.; Ding, J.; Liu, Y.; Tian, X. A new model for mesomorphic-monoclinic phase transition of isotactic polypropylene. Polymer (Guildf) 2017, 108, 242–250. [Google Scholar] [CrossRef]

- Tighe, B.J. Optical Properties of Polymers. Met. Mater. Technol. 1978, 10, 483–487. [Google Scholar] [CrossRef]

- Mileva, D.; Gahleitner, M.; Gloger, D. Structure and properties of polypropylene cast films: Polymer type and processing effects. AIP Conf. Proc. 2016, 1736, 020069. [Google Scholar] [CrossRef]

- Konishi, T.; Nishida, K.; Kanaya, T.; Kaji, K. Effect of isotacticity on formation of mesomorphic phase of isotactic polypropylene. Macromolecules 2005, 38, 8749–8754. [Google Scholar] [CrossRef]

- Pukánszky, B.; Mudra, I.; Staniek, P. Relation of Crystalline Structure and Mechanical Properties of Nucleated Polypropylene. J. Vinyl Addit. Technol. 1997, 3, 53–57. [Google Scholar] [CrossRef]

- Zia, Q.; Androsch, R.; Radusch, H.J. Effect of the structure at the micrometer and nanometer scales on the light transmission of isotactic polypropylene. J. Appl. Polym. Sci. 2010, 117, 1013–1020. [Google Scholar] [CrossRef]

- Johnson, M.B.; Wilkes, G.L.; Sukhadia, A.M.; Rohlfing, D.C. Optical properties of blown and cast polyethylene films: Surface versus bulk structural considerations. J. Appl. Polym. Sci. 2000, 77, 2845–2864. [Google Scholar] [CrossRef]

| Polymer | Tmelt (°C) | Isotacticity <mm> (%) | 2,1 Regiodefects (%) | Mw/Mn | C2 (wt %) |

|---|---|---|---|---|---|

| SSC–low-iso | 154 | 99.2 | 0.70 | 3.5 | 0 |

| SSC–high-iso | 160 | 99.8 | 0.23 | 3.5 | 0 |

| ZNC–high-iso | 165 | 98.9 | 0.0 | 5.4 | 0 |

| ZNC–RACO | 153 | 96.5 | 0.0 | 3.4 | 2.2 |

| Processing Parameters | |||

|---|---|---|---|

| Chill-roll temperature (Tchill—°C) | 15 | 40 | 70 |

| Melt temperature (Tmelt—°C) | 230 | 260 | |

| Throughput capacity (TPC—kg\h) | 6 | 12 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Sacco, F.; Gahleitner, M.; Wang, J.; Portale, G. Systematic Investigation on the Structure-Property Relationship in Isotactic Polypropylene Films Processed via Cast Film Extrusion. Polymers 2020, 12, 1636. https://doi.org/10.3390/polym12081636

Di Sacco F, Gahleitner M, Wang J, Portale G. Systematic Investigation on the Structure-Property Relationship in Isotactic Polypropylene Films Processed via Cast Film Extrusion. Polymers. 2020; 12(8):1636. https://doi.org/10.3390/polym12081636

Chicago/Turabian StyleDi Sacco, Federico, Markus Gahleitner, Jingbo Wang, and Giuseppe Portale. 2020. "Systematic Investigation on the Structure-Property Relationship in Isotactic Polypropylene Films Processed via Cast Film Extrusion" Polymers 12, no. 8: 1636. https://doi.org/10.3390/polym12081636

APA StyleDi Sacco, F., Gahleitner, M., Wang, J., & Portale, G. (2020). Systematic Investigation on the Structure-Property Relationship in Isotactic Polypropylene Films Processed via Cast Film Extrusion. Polymers, 12(8), 1636. https://doi.org/10.3390/polym12081636