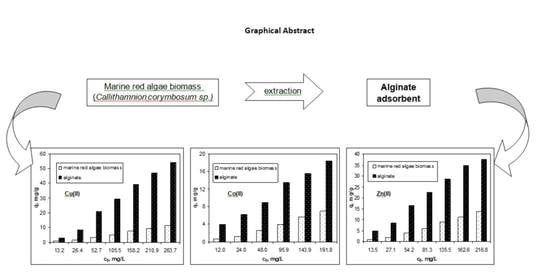

Equilibrium and Kinetics Studies of Metal Ions Biosorption on Alginate Extracted from Marine Red Algae Biomass (Callithamnion corymbosum sp.)

Abstract

:1. Introduction

2. Experimental

2.1. Reagents and Chemicals

2.2. Biosorbent Preparation and Characterization

2.3. Biosorption Experiments

3. Results and Discussion

3.1. Optimization of Experimental Parameters

3.2. Effect of Contact Time and Kinetic Modelling

3.3. Effect of Initial Metal Ions Concentration and Isotherm Modelling

3.4. Desorption of Metal Ions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Akpor, O.B.; Muchie, M. Environmental and public health implications of wastewater quality. Afr. J. Biotechnol. 2011, 10, 2379–2387. [Google Scholar]

- De Gisi, S.; Lofrano, G.; Grassi, M.; Notarnicola, M. Characteristics and adsorption capacities of low-cost sorbents for wastewater treatment: A review. Sust. Mater. Technol. 2016, 9, 10–40. [Google Scholar] [CrossRef] [Green Version]

- Fu, F.; Wang, Q. Removal of Heavy Metal Ions from Wastewaters: A Review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef] [PubMed]

- Crini, G.; Lichtfouse, E.; Wilson, L.D.; Morin-Crini, N. Conventional and non-conventional adsorbents for wastewater treatment. Environ. Chem. Lett. 2019, 17, 195–213. [Google Scholar] [CrossRef]

- Aji, B.A.; Yavuz, Y.; Koparal, A.S. Electrocoagulation of heavy metals containing model wastewater using monopolar ion electronedes. Sep. Purif. Technol. 2012, 86, 248–254. [Google Scholar] [CrossRef]

- Edebali, S.; Pehlivan, E. Evalution of chelate and cation exchange resins to remove copper ions. Powder Tehnol. 2016, 301, 520–525. [Google Scholar] [CrossRef]

- Abdel-Aziz, M.H.; Nirdosh, I.; Sedahmed, G.H. Ion-exchange-assisted electrochemical removal of heavy metals from dilute solutions in a stirred-tank electrochemical reactor: A mass-transfer study. Ind. Eng. Chem. Res. 2013, 52, 11655–11662. [Google Scholar] [CrossRef]

- Rivas, B.L.; Palencia, M. Removal-concentration of pollutant metal-ions by water-soluble polymers in conjunction with double emulsion systems: A new hybrid method of membrane-based separation. Sep. Purif. Technol. 2011, 81, 435–443. [Google Scholar] [CrossRef]

- Orooji, Y.; Ghasali, E.; Emami, N.; Noorisafa, F.; Razmjou, A. ANOVA design for the optimization of TiO2 coating on polyether sulfone membranes. Molecules 2019, 24, 2924. [Google Scholar] [CrossRef] [Green Version]

- Park, D.; Yun, Y.S.; Park, J.M. The past, present, and future trends of biosorption. Biotechnol. Bioproc. Eng. 2010, 15, 86–102. [Google Scholar] [CrossRef]

- Vijayaraghavan, K.; Balasubramanian, R. Is biosorption suitable for decontamination of metal-bearing wastewaters? A critical review on the state-of-the-art of biosorption processes and future directions. J. Environ. Manag. 2015, 160, 283–296. [Google Scholar] [CrossRef] [PubMed]

- Anastopoulos, I.; Kyzas, G.Z. Progress in batch biosorption of heavy metals onto algae. J. Molec. Liq. 2015, 209, 77–86. [Google Scholar] [CrossRef]

- Farooq, U.; Kozinski, J.A.; Khan, M.A.; Athat, M. Biosorption of heavy metal ions using wheat based biosorbents—A review of the recent literature. Biores. Technol. 2010, 101, 5043–5053. [Google Scholar] [CrossRef] [PubMed]

- Deniz, F.; Karabulut, A. Biosorption of heavy metal ions by chemically modified biomass of coastal seaweed community: Studies on phycoremediation system modelling and design. Ecol. Eng. 2017, 106, 101–108. [Google Scholar] [CrossRef]

- Jayakumar, V.; Govindaradjane, S. Biosorption of Cadmium by Green Algae—A Review. J. Adv. Chem. Sci. 2017, 3, 480–484. [Google Scholar]

- El Gamal, A.A. Biological importance of marine algae. Saudi Pharm. J. 2010, 18, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Febrianto, J.; Kosasih, A.N.; Sunarso, J.; Ju, Y.H.; Indrawati, N.; Ismadji, S. Equilibrium and kinetic studies in adsorption of heavy metals using biosorbent: A summary of recent studies. J. Hazard. Mater. 2009, 162, 616–645. [Google Scholar] [CrossRef]

- Khan, M.A.; Jung, W.; Kwon, O.H.; Jung, Y.M.; Paeng, K.J.; Cho, S.Y.; Jeon, B.H. Sorption studies of manganese and cobalt from aqueous phase onto alginate beads and nano-graphite encapsulated alginate beads. J. Ind. Eng. Chem. 2014, 20, 4353–4362. [Google Scholar] [CrossRef]

- Barquilha, C.E.R.; Cossich, E.S.; Tavares, C.R.G.; Silva, E.A. Biosorption of nickel(II) and copper(II) ions by Sargassum sp. in nature and alginate extraction products. Biores. Technol. Rep. 2019, 5, 43–50. [Google Scholar] [CrossRef]

- Cheng, S.Y.; Show, P.L.; Lau, B.F.; Chang, J.S.; Ling, T.C. New prospects for modified algae in heavy metal adsorption. Trends Biotechnol. 2019, 37, 1255–1268. [Google Scholar] [CrossRef]

- El Atouani, S.; Bentiss, F.; Reani, A.; Zrid, R.; Belattmania, Z.; Pereira, L.; Mortadi, A.; Cherkaoui, O.; Sabour, B. The invasive brown seaweed Sargassum muticum as new resource for alginate in morocco: Spectroscopic and rheological characterization. Phycol. Res. 2016, 64, 185–193. [Google Scholar] [CrossRef]

- Attar, K.; Demey, H.; Bouazza, D.; Sastr, A.M. Sorption and desorption studies of Pb(II) and Ni(II) from aqueous solutions by a new composite based on alginate and magadiite materials. Polymers 2019, 11, 340. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fawzy, M.A.; Gomaa, M.; Hifney, A.F.; Abdel-Gawad, K.M. Optimization of alginate alkaline extraction technology from Sargassum latifolium and its potential antioxidant and emulsifying properties. Carbohydr. Polym. 2017, 157, 1903–1912. [Google Scholar] [CrossRef] [PubMed]

- Lucaci, A.R.; Bulgariu, L. Comparative study of alginate extraction methods from red marine algae Callithamnion Corymbosum sp. Bull. Polytech. Inst. Jassy 2018, 64, 51–60. [Google Scholar]

- Romera, E.; González, F.; Ballester, A.; Blázquez, M.L.; Muñoz, J.A. Biosorption with algae: A statistical review. Crit. Rev. Biotechnol. 2006, 26, 223–235. [Google Scholar] [CrossRef]

- Kumar, D.; Pandey, L.K.; Gaur, J.P. Metal sorption by algal biomass: From batch to continuous system. Algal Res. 2016, 18, 95–109. [Google Scholar] [CrossRef]

- Cardoso, S.L.; Costa, C.S.D.; Nishikawa, E.; da Silva, M.G.C.; Vieira, M.G.A. Biosorption of toxic metals using the alginate extraction residue from the brown algae Sargassum filipendula as a natural ion-exchanger. J. Clean. Prod. 2017, 165, 491–499. [Google Scholar] [CrossRef]

- Ahmad, A.; Bhat, A.H.; Buang, A. Biosorption of transition metals by freely suspended and Ca-alginate immobilised with Chlorella vulgaris: Kinetic and equilibrium modeling. J. Clean. Prod. 2018, 171, 1361–1375. [Google Scholar] [CrossRef]

- Chen, J.P.; Hong, L.; Wu, S.; Wang, L. Elucidation of interactions between metal ions and ca alginate-based ion-exchange resin by spectroscopic analysis and modeling simulation. Langmuir 2002, 18, 9413–9421. [Google Scholar] [CrossRef]

- Wang, F.; Lu, X.; Li, X.Y. Selective removals of heavy metals (Pb2+, Cu2+, and Cd2+) fromwastewater by gelation with alginate for effective metal recovery. J. Hazard. Mater. 2016, 308, 75–83. [Google Scholar] [CrossRef]

- Ho, Y.S.; McKay, G. Pseudo-second-order model for sorption processes. Process Biochem. 1999, 34, 451–465. [Google Scholar] [CrossRef]

- Gerente, C.; Lee, V.K.C.; Lee, P.; McKay, G. Application of chitosan for the removal of metals from wastewaters by adsorption-mechanisms and models review. Crit. Rev. Environ. Sci. Technol. 2007, 37, 41–127. [Google Scholar] [CrossRef]

- Cheung, W.H.; Szeto, Y.S.; McKay, G. Intra-particle diffusion processes during acid dye adsorption onto chitosan. Biores. Technol. 2007, 98, 2897–2904. [Google Scholar] [CrossRef] [PubMed]

- Michalak, I.; Chojnacka, K.; Witek-Krowiak, A. State of the Art for the Biosorption Process—A Review. Appl. Biochem. Biotechnol. 2013, 170, 1389–1416. [Google Scholar] [CrossRef] [Green Version]

- Rangabhashiyam, S.; Anu, N.; Nandagopal Giri, M.S.; Selvaraju, N. Relevance of isotherm models in biosorption of pollutants by agricultural by-products. J. Environ. Chem. Eng. 2014, 2, 398–414. [Google Scholar] [CrossRef]

- Yousef, N.S.; Farouq, R.; Hazza, R. Adsorption kinetics and isotherms for the removal of nickel ions from aqueous solutions by an ion-exchange resin: Application of two and three parameter isotherm models. Desalin. Water Treat. 2016, 57, 21925–21938. [Google Scholar] [CrossRef]

- Dada, A.O.; Alalekan, A.P.; Dada, A.M. Langmuir, freundlich, temkin and dubinin–radushkevich isotherms studies of equilibrium sorption of Zn2+ unto phosphoric acid modified rice husk. IOSR J. Appl. Chem. 2012, 3, 38–45. [Google Scholar]

- Kumar, Y.P.; King, P.; Prasad, V.S.R.K. Removal of copper from aqueous solution using Ulva fasciata sp.—A marine green algae. J. Hazard. Mater. 2006, B137, 367–373. [Google Scholar] [CrossRef]

- Liu, Y.; Cao, Q.; Luo, F.; Chen, J. Biosorption of Cd2+, Cu2+, Ni2+ and Zn2+ ions from aqueous solutions by pretreated biomass of brown algae. J. Hazard. Mater. 2009, 163, 931–938. [Google Scholar] [CrossRef]

- Foroutan, R.; Esmaeili, H.; Abbasi, M.; Rezakazemi, M.; Mesbah, M. Adsorption behavior of Cu(II) and Co(II) using chemically modified marine algae. Environ. Technol. 2018, 39, 2792–2800. [Google Scholar] [CrossRef]

- Romera, E.; Gonzalez, F.; Ballester, A.; Blazquez, M.L.; Munoz, J.A. Comparative study of biosorption of heavy metals using different types of algae. Bioresour. Technol. 2007, 98, 3344–3353. [Google Scholar] [CrossRef] [PubMed]

- Zeraatkar, A.K.; Ahmadzadeh, H.; Talebi, A.F.; Moheimani, N.R.; McHenry, M.P. Potential use of algae for heavy metal bioremediation, a critical review. J. Environ. Manag. 2016, 181, 817–831. [Google Scholar] [CrossRef] [PubMed]

| Kinetic Model | Mathematical Equation | Parameters | Cu(II) | Co(II) | Zn(II) |

|---|---|---|---|---|---|

| Pseudo-first order model | qeexp, mg/g | 13.62 | 6.46 | 10.24 | |

| R2 | 0.8901 | 0.9399 | 0.8375 | ||

| qecalc, mg/g | 0.71 | 2.91 | 1.01 | ||

| k1, 1/min | 0.0086 | 0.0176 | 0.0028 | ||

| Pseudo-second order model | R2 | 0.9999 | 0.9999 | 0.9999 | |

| qecalc, mg/g | 13.64 | 6.67 | 10.19 | ||

| k2, g/mg min | 0.0107 | 0.0291 | 0.0488 | ||

| Intra-particle diffusion model | R2I | 0.9208 | 0.8695 | 0.9135 | |

| cI, mg/L | 12.06 | 2.97 | 8.84 | ||

| kdiff, I, mg/g min1/2 | 0.2939 | 0.4853 | 0.1318 | ||

| R2II | 0.9074 | 0.9391 | 0.9510 | ||

| cII, mg/L | 12.93 | 5.85 | 8.47 | ||

| kdiff, II, mg/g min1/2 | 0.0533 | 0.0475 | 0.1281 |

| Isotherm Model | Mathematical Equation | Parameters | Cu(II) | Co(II) | Zn(II) |

|---|---|---|---|---|---|

| Langmuir model | R2 | 0.9858 | 0.9895 | 0.9837 | |

| qmax, mg/g | 64.52 | 18.79 | 37.04 | ||

| KL, L/g | 0.0409 | 0.0410 | 0.0424 | ||

| Freundlich model | R2 | 0.7893 | 0.8955 | 0.9187 | |

| n | 2.34 | 3.23 | 2.59 | ||

| KF, (mg/g)/(L/mg)1/n | 2.9194 | 2.8132 | 2.2977 | ||

| Temkin model | R2 | 0.9531 | 0.9479 | 0.9497 | |

| AT, L/g | 0.2099 | 0.4519 | 0.3252 | ||

| B, J/mol | 21.75 | 14.13 | 20.24 |

| Marine Algae Biomass | pH/Biosorbent Dosage | Cu(II) | Co(II) | Zn(II) | Reference |

|---|---|---|---|---|---|

| Ulva fasciata sp. | 5.0/3.3 g/L | 26.88 | - | 13.50 | [38] |

| Laminaria sp. | 4.3/3.0 g/L | 61.59 | - | 54.26 | [39] |

| Padina sanctae crucis sp. | 6.0/4.0 g/L | 13.99 | 13.73 | - | [40] |

| Codium vermilara sp. | 5.0/0.5 g/L | 16.90 | - | 23.80 | [41] |

| Callithamnion corymbosum sp. | 4.4/2.0 g/L | 24.25 | 9.89 | 19.12 | This study |

| Alginate | 4.4/2.0 g/L | 64.52 | 18.79 | 37.04 | This study |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lucaci, A.R.; Bulgariu, D.; Ahmad, I.; Bulgariu, L. Equilibrium and Kinetics Studies of Metal Ions Biosorption on Alginate Extracted from Marine Red Algae Biomass (Callithamnion corymbosum sp.). Polymers 2020, 12, 1888. https://doi.org/10.3390/polym12091888

Lucaci AR, Bulgariu D, Ahmad I, Bulgariu L. Equilibrium and Kinetics Studies of Metal Ions Biosorption on Alginate Extracted from Marine Red Algae Biomass (Callithamnion corymbosum sp.). Polymers. 2020; 12(9):1888. https://doi.org/10.3390/polym12091888

Chicago/Turabian StyleLucaci, Alina Roxana, Dumitru Bulgariu, Iftikhar Ahmad, and Laura Bulgariu. 2020. "Equilibrium and Kinetics Studies of Metal Ions Biosorption on Alginate Extracted from Marine Red Algae Biomass (Callithamnion corymbosum sp.)" Polymers 12, no. 9: 1888. https://doi.org/10.3390/polym12091888

APA StyleLucaci, A. R., Bulgariu, D., Ahmad, I., & Bulgariu, L. (2020). Equilibrium and Kinetics Studies of Metal Ions Biosorption on Alginate Extracted from Marine Red Algae Biomass (Callithamnion corymbosum sp.). Polymers, 12(9), 1888. https://doi.org/10.3390/polym12091888