3.1. Hydrolytic and Enzymatic Degradation of P4HB Sutures

Hydrolytic degradation of commercial P4HB sutures was evaluated through weight loss and molecular weight measurements using media of three different pH values (i.e., acidic, neutral, and basic) and two temperatures (i.e., 37 and 55 °C that are associated to physiological conditions and the higher available temperature before starting fusion, respectively).

Weight loss (

Wl) of the specimens was determined through Equation 1 where

Wd is the sample weight after degradation and

W0 is the initial sample weight:

Figure 1a clearly reveals that scarce soluble fragments were produced during degradation since a loss of only 2.1–1.8% was achieved after 27 days of exposure to the media at 55 °C.

A slightly higher loss was detected for experiments performed at the pH 10 basic medium since fragments having the neutralized carboxylate terminal groups coming from P4HB degradation should have a higher water solubility than those ending with carboxylic acid groups. Exposure to the 37 °C medium caused a minimum weight loss (0.6–0.4%), mainly associated to the first days and which probably corresponded to the solubilization of minor additives as typical colorant molecules.

Therefore, evidences of degradation were only found through GPC measurements.

Mn and

Mw data after 27 days of exposure to the indicated media and temperature are depicted in

Figure 1b for the studied sutures and a representative film was exposed to pH 3. Three points merit attention: (a) Degradation is highly significant at 55 °C, decreasing, for example,

Mw from 235,000 g/mol to a minimum value of 83,000 g/mol. On the contrary, a scarce variation was found for samples degraded at 37 °C. (b) The pH of the medium has a moderate influence on degradability, which specifically becomes slightly enhanced in the acidic condition. This feature confirms the above indicated association between weight loss and solubility. Note that the reaction may also be base-catalyzed, although the given results pointed out to an apparent acid-catalysis. (c) Degradability is highly dependent on the crystallinity and morphology of exposed samples. Note the high variation between

Mw values of annealed sutures and melt pressed films after exposure to pH 3 media at 55 °C (i.e., 83,000 g/mol with respect to 25,000 g/mol). Even a remarkable difference is found at 37 °C (i.e., 200,000 g/mol with respect to 180,000 g/mol).

Degradation in the presence of two different lipases which are able to promote hydrolysis of the ester bonds of P4HB has been evaluated. Results are quite different from those attained with the hydrolytic degradation due to high efficacy of the enzymatic attack and also to its characteristic erosion mechanism that contrasts with the bulk process associated to the hydrolytic process.

Figure 2a, shows the evolution of weight loss during exposure to both enzymatic media and to an aqueous medium at 37 °C and pH 7 used as a control.

Rhizopus oryzae seems more effective that

Pseudomonas cepacia enzyme, but both lead to a significant weight loss (i.e., 9–10%) that is clearly higher than observed for the control. It is clear that the enzymatic attack should produce small fragments probably as a consequence of a stepwise chain scission from the terminal groups that contrasts with the random bond cleavage expected from the bulk degradation.

Figure 2a also displays the results attained for a melt pressed film, which reveals again the decisive influence of crystallinity and the annealed morphology on degradability.

Figure 2b shows the impact of enzymatic degradation on the molecular weight, which is summarized as follows: (a) A progressive decrease of molecular weight with the exposure time is observed for both enzymatic media. (b) Hydrolytic degradation seems negligible under the low temperature conditions. (c) The enzymatic attack is more effective than hydrolysis at high temperature (e.g.,

Mn values of 64,000 and 28,000 g/mol were determined after 21 days of exposure to the

Rhizopus oryzae medium and to the aqueous pH 3 medium at 55 °C after 27 days, respectively). (d) Enzymatic attack is less effective on the annealed and highly crystalline sutures than on the melt pressed films, demonstrating again the difficulty of enzymes to erode the constitutive crystals and a limited activity towards amorphous regions, including folding lamellar surfaces.

3.2. Influence of Degradation on Thermal Properties

Sutures are submitted to a set of thermal and stretching treatment processes in order to improve their mechanical performance. This treatment has a significant influence on crystallinity but also on morphological features, such as the thickness of the constitutive lamellae. As described in the preceding section, crystallinity plays a determinant role on the degradability of samples, but it is also evident that thermal properties will be affected, as well as the variation of crystalline morphological parameters during degradation processes.

Figure 3a shows the significant difference on the melting behavior between conventional melt pressed films and annealed sutures. Note that fusion is characterized by a predominant peak and a shoulder at a lower temperature (e.g., 49.7 and 58.2 °C for the film and 61.9 and 72.0 °C for the suture, heating rate of 10 °C/min), which reflects the existence of two populations of lamellar crystals with different thicknesses. The shoulder temperature strongly depends on crystallization and annealing processes since it is related to the less perfect formed crystals that are susceptible to reorganization processes. Therefore, molecular folds in these thinner lamellae underwent a slight reordering that led to an increase of the lamellar crystalline thickness. Basically, a simple melt crystallization leads to lamellae that are worse (i.e., lower thickness and more irregular folding surface) than those attained after annealing. Both shoulder and main melting peak logically appear at lower temperatures for the melt crystallized samples. It merits also attention the low value of the main melting peak, which indicates a limited reordering process of folds that precludes to get the highly organized lamellae derived from annealing (i.e., 58.2 °C with respect to 72 °C). Note also that the expected maximum melting temperature is reported to be 79.9 °C [

20] as estimated from the Hoffman-Weeks extrapolation [

25] for an infinite dimension of P4HB crystals.

Figure 3a also depicts the melting behavior of samples exposed to aggressive hydrolytic conditions (i.e., pH 10, temperature of 55 °C, and 27 days of exposure). Both types of samples, film and suture, shows the disappearance of the shoulder and a clear increase of the melting peak temperature. Degradation affects the folding surface, facilitates the reordering process, and leads to improved lamellae with a higher melting point. Note the difference around 7 °C that indicates the greater facility of annealed samples to render practically perfect crystals and that in this case a maximum melting temperature (79.0 °C) close to the equilibrium temperature was attained. Note also that molecular weight measurements showed only a moderate decrease during degradation, which means that thermal behavior is still associated to polymeric samples. Moreover, crystalline phases are those less susceptible to degradation and therefore should show lower changes on their associated properties (i.e., melting point).

The influence of the degradation time on the melting point is displayed in

Figure 3b for the high temperature and the less pH aggressive conditions. A progressive increase of the melting point with the exposure time is clearly detected (i.e., from 74.1 to 79.0 °C for three and 27 days, respectively), as well as an increase of the melting enthalpy (i.e., from 57.8 to 63.3 J/g). The observation demonstrates that the crystalline lamellar thickness increases during degradation probably because of some chain breakages in the amorphous lamellar folding surfaces.

The increased chain mobility in the lamellar surface may favor the molecular reordering that leads to an increased crystalline lamellar thickness. In addition, an annealing effect caused, by the exposure to a degradation medium at 55 °C, may be discarded since the observed dependence with long exposure times is not well justified. A highlight also the fact that any stress that could favor annealing was not applied during degradation. Obviously, chain mobility is increased at 55 °C and the reordering process that took place after the chain breakage should be enhanced. In fact, degradation performed at 37 °C showed reasonably a less significant change.

Figure 3c compares the DSC curves of sutures exposed at pH 10 for 27 days at 37 and 55 °C. The sample exposed to the low temperature showed minor changes with respect to the initial suture that mainly affected the low temperature shoulder related to crystals more susceptible to reorganization (i.e., the temperature increased from 61.9 to 63.7 °C). In this case, the molecular weight decrease was low and the observed impact on thermal properties was limited to the preliminary phase concerning the less perfect crystals.

The impact of the pH of the medium on thermal properties was relatively scarce and the same kind of crystals seems to be attained at 55 °C after 27 days of exposure (

Figure 3d). These correspond to the best reorganization that could be obtained from the initial commercial suture.

Figure 3d confirms that temperature has a great influence on the degradation of the less perfect crystals since the peak shoulder completely disappeared.

Table 1 summarizes the calorimetric data attained with representative samples.

Thermal properties were scarcely affected by the enzymatic degradation. Thus, DSC curves for the control (hydrolytic medium without enzyme) and the two selected enzymatic media were practically identical (

Figure 4,

Table 2). The result agrees with an enzymatic surface erosion of the suture with significant loss of material that contrasts with the indicated bulk hydrolytic degradation mechanism.

Figure 5 shows SEM micrographs that revealed an enzymatic attack that only affected the monofilament surface in a time dependent manner. Therefore, the DSC traces only reflect the impact of the hydrolytic degradation that as discussed before, mainly concerns the peak shoulder that decreased on intensity and moved from 61.9 to 64.3 °C.

3.3. Changes on Lamellar Microstructure during Degradation

The degradation behavior of highly annealed sutures is significantly different than observed for melt pressed films as a consequence of the different internal morphology. Stacking of oriented microfibrils with a lamellar organization and disordered spherulitic growth up to collision, are the specific morphologic trends of sutures and films, respectively. The impact of such morphologies led to a lower degradability of annealed samples due to their higher crystallinity. Furthermore, during degradation both crystallinity and melting temperature increased, although the effect was less significant for the annealed sample due to its scarce marge of improvement.

All studied P4HB samples displayed clear SAXS reflections that were analyzed to improve the comprehension of differences related to the supramolecular order since specific data concerning the geometrical parameters of constitutive lamellar structures could be easily derived.

Specifically, the study was performed from an isotropic integration of the oriented suture patterns or analyzing directly the disordered rings of film samples. In both cases, the normalized one-dimensional correlation function [

26] was employed:

where

I (

q) is the intensity of the SAXS peak at each value of the scattering vector (

q = [4π sin

θ/λ] = 2π/

d, with

θ and

d being the Bragg angle and the Bragg spacing, respectively). Basically, it is assumed that the lamellar stack is constituted by a high number of lamellae that had an infinite lateral size so the stack can be reduced to a one-dimensional two-phase structure that satisfies the Bragg condition.

Limited experimental collection of SAXS data was solved by extrapolation for low and high

q values through the Vonk model [

27] and the Porod’s law, respectively.

Analysis of the correlation function allows determining: (1) The long period, Lγ; (2) the crystallinity within the lamellar stacks, XcSAXS; (3) the crystalline lamellar thickness, lc, and the amorphous layer thickness, la. In this way, Lγ corresponds to the r value of the first maximum of the correlation function; la has been assigned to the r value for the intersection of the LRAT (linear regression in the autocorrelation triangle) with the ordinate equal to the first minimum of the correlation function; lc corresponds to Lγ, la; and XcSAXS is calculated as lc/Lγ. The lower thickness of the two-phase lamellar model has been assigned to the amorphous layer thickness although the correlation function cannot distinguish the thickness associated with each phase.

Figure 6 illustrates representative correlation functions that allows comparing and inferring a distinct evolution of films and sutures during the hydrolytic degradation. Thus, the progression of film degradation led to a shift of the correlation function to higher distances and also to more pronounced peaks. Therefore,

Lγ increased from 8.60 to 9.80 nm when the temperature of the hydrolytic medium increased from 37 to 55 °C, a change that was a consequence of the increase of the lamellar crystalline thickness (i.e.,

lc increased from 6.91 to 7.32 nm). Moreover, an increase was also observed for the amorphous layer thickness (i.e., from 1.69 to 2.48 nm) leading to a practically constant crystallinity of the lamellar stack (i.e., 80 ± 1%). The amorphous phase seems to be less dense due to the increasing thickness probably caused by the chain breakage. The increase on the electronic contrast between crystalline and amorphous phases is observed through the more pronounced profile of the correlation function.

Figure 6b displays by contrast that the correlation profile becomes smoother when degradation increases, a feature that cannot be well explained at this stage and a more accurate evaluation of the microstructure of the biphasic systems is required. Nevertheless, a slight shift of the correlation function to the increasing distances is clear. Specifically,

Lγ and

lc increased from 10.30 and 8.31 nm to 10.90 and 8.80 nm, respectively when the temperature of the degradation medium increased from 37 to 55 °C. Underlined here that changes are moderate due to the high initial thickness of the annealed lamellae as previously deduced from the closeness between the experimental melting temperature and the theoretical value deduced from the equilibrium melting temperature. Furthermore, the crystallinity of the lamellar stack remained equal to 80.7%.

In addition to the

Lγ value, which is associated with the most probable distance between the centers of gravity of two adjacent crystals, a long period determined from twice the value of the first minimum of the correlation function,

, is also useful. This is interpreted as the most probable distance between the centers of gravity of a crystal and its adjacent amorphous layer. A discrepancy between both values indicates a broad distribution of the layer widths of the major component [

28], which in this case corresponds to the crystal phase.

Table 3 summarizes the morphological parameters determined for representative degraded film and suture samples. The following trends can be indicated: (a) Discrepancy between

Lγ and 2 ×

Lγm is decreasing as the degradation process becomes more significant. This feature can be explained considering the lamellar reordering process that, for example, lead to a decrease of the population of thinner crystals in film samples, and consequently to a narrow distribution. Note, for example, that differences around ~1 and ~0.6 nm are determined for degradations performed at 37 and 55 °C. (b) Annealed samples showed a greater discrepancy than films (e.g., ~1 and ~2.1 nm for films and sutures, respectively). This feature seems strange since a narrow distribution is expected for the thicker annealed lamellae of sutures.

The SAXS pattern displayed in

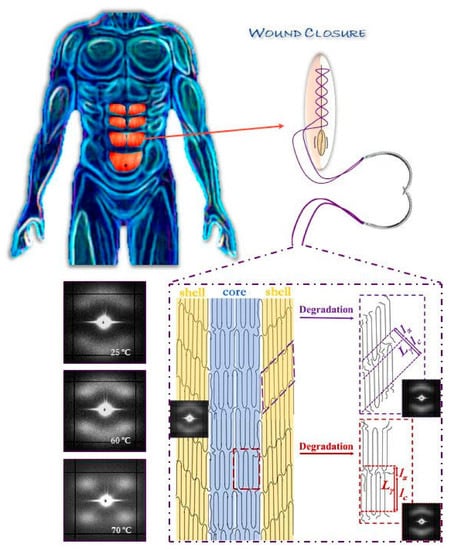

Figure 7a for a sample exposed to a very little aggressive degradation condition (therefore similar to that observed with the initial suture) reveals that the thermal annealing process at which the commercial sutures were submitted lead to a peculiar morphology where two different types of lamellar stacks exists. These differences come up from the distinct lamellar organization in the skin and the core of sutures. Obviously, this phenomenon is of a different nature than that caused by a simple crystallization process, where usually populations of lamellae with different thicknesses and organizations of folding surfaces are derived. The observations justify the above indicated broad lamellar distribution found in sutures.

The SAXS pattern is characterized by four off meridional spots and two meridional arches (

Figure 7a). The first ones are indicative of the stacking of breadth lamellar crystals tilted with respect to the fiber direction and logically arranged with a cylindrical symmetry. The characteristic spacing of these stacks is 14.0 nm. The second ones have a higher spacing (i.e., 14.1 nm) and corresponds to lamellar crystals with lower lateral extension (longer and diffuse reflection) and perpendicularly oriented to the fiber axis. The nanostructure of the core material as compared to the shell material appears rougher and more imperfect. The external part of sutures is submitted to a higher temperature than the core and suffers a higher shear stress. In this way, a shift between molecular chains along the annealing direction of lamellae, as well as an increase of the lamellar thickness is produced. Therefore, tilted lamellar surfaces, which moreover appeared at an angle of 45° that correspond to the maximum shear, are generated.

The microstructure of sutures changed during hydrolytic degradation as can be deduced from the SAXS pattern (

Figure 7b) of the sample exposed to the more aggressive conditions (i.e., pH3, 55 °C, and 27 days). Basically, differences concerning the meridional spots associated to the more imperfect crystals are placed in the core. Thus, the interlamellar spacing slightly increased (from 14.1 to 14.8 nm) as the reflections slightly moved to the center of the pattern. Furthermore, the intensity of these spots increased suggesting a higher electronic contrast between crystalline and amorphous layers. In this way, degradation mainly affected the more defective crystals, causing some molecular breakages on their folding surface. A slight reordering was produced leading to the observed increase of the crystalline lamellar thickness, while simultaneously the amorphous layer became less compact and more disordered.

Molecular chains in the crystalline lamellae remained aligned with the longitudinal direction of sutures, even those crystals with tilted surfaces. All observed reflections in WAXD patterns (

Figure 8) were in agreement with the published orthorhombic unit cell of P4HB [

16,

17]. Specifically, (110) and (020) reflections at 0.388 and 0.406 nm appeared as very small arcs in the equator.

The scheme of

Figure 9 illustrates the deduced microstructure of the annealed fiber and the consequences of the hydrolytic attack. The lamellar thickness remained unaltered for the more perfect tilted crystals and even a slight densification was detected for their stretched folds, since the intensity of the corresponding spots seemed to decrease. In fact, this deduction is in agreement with the previously indicated contradictory results determined from the analysis of the correlation function. The crystalline structure remained unchanged, as well as the degree of orientation of crystals since no change was detected in the WAXD patterns as displayed in

Figure 8c.

Intensification of the meridional spot and its shift to the center of the pattern shows a correlation with the degradation degree, as can be inferred from the gradual evolution (see blue spot) presented in

Figure 10 for representative conditions.

Despite the fact that enzymatic degradation was effective as deduced from a weight loss of 8–9% after 21 days of exposure to both assayed media (

Figure 2a), the impact on the microstructure of the remaining material should be minimum as reflected by the scarce change on the molecular weight (

Figure 2b) and the melting point (

Figure 4 and

Table 2). This is corroborated through analysis of SAXS patterns (

Figure 11), since no changes were detected between samples exposed to the less (i.e.,

Pseudomonas cepacia) and the more (i.e.,

Rhizopus oryzae) aggressive media for 14 days. Thus,

Lγ,

lc,

la, and

parameters remained practically constant and equal to 10.40–10.50, 8.33–8.56, 2.07–1.94, and 4.1 nm (

Table 3), respectively. Note again the high discrepancy between

Lγ and 2 ×

values as expected from the existence of two well differentiated types of lamellae.

Figure 11 also shows the clearly different susceptibility to the enzymatic attack of P4HB films constituted by spherulitic morphologies. In this case, a clear increase of lamellar spacing was detected (

Table 3), as well as on the electronic contrast. Logically, differences came from the different degradability of films and sutures, with the weight loss of the former being for example around (75–95%).

SAXS patterns of the less and more degraded sutures were again highly similar, considering both the position (angle and distance) of the observed spots and the relative intensity between meridional and off-meridional reflections (

Figure 12). In conclusion, there are no evidences of the observed morphological change that occurs at an advanced stage of hydrolytic degradation. These results are fully consistent with an enzymatic surface attack that led to an erosion of the suture (see

Figure 5) and did not change the internal microstructure of the remaining material.