Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

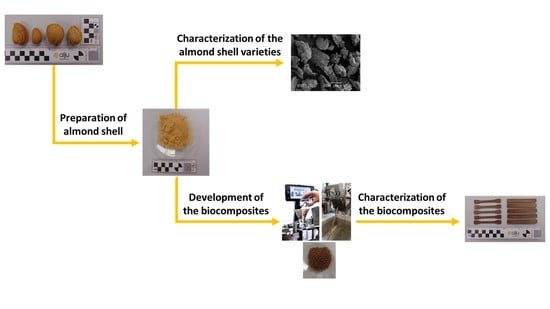

2.2. Experimental Procedure

2.2.1. Milling of Almond Shell

2.2.2. Infrared Spectroscopy (FTIR)

2.2.3. Thermogravimetric Analysis (TGA)

2.2.4. Differential Scanning Calorimetry

2.2.5. X-ray Diffraction

2.2.6. Scanning Electron Microscopy (SEM)

2.2.7. Preparation of Composites

2.2.8. Injection Moulding

2.2.9. Tensile Strength and Modulus

2.2.10. Impact Strength

2.2.11. Flexural

2.2.12. Shore D Hardness

3. Results and Discussion

3.1. Characterisation of Almond Shell Varieties

3.2. Development and Characterisation of the Biocomposites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Jawaid, M.; Paridah, M.T.; Saba, N. Introduction to Biomass and Its Composites; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A Review of the Recent Developments in Biocomposites Based on Natural Fibres and Their Application Perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Agroinformacion.com. La producción mundial de almendra alcanzará las 1.29 millones de toneladas, un 2.34 % más. Available online: https://agroinformacion.com/la-produccion-mundial-de-almendra-alcanzara-las-129-millones-de-toneladas-un-234-mas/ (accessed on 15 May 2020).

- Li, X.; Liu, Y.; Hao, J.; Wang, W. Study of Almond Shell Characteristics. Materials 2018, 11, 1782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Essabir, H.; Nekhlaoui, S.; Malha, M.; Bensalah, M.O.; Arrakhiz, F.Z.; Qaiss, A.; Bouhfid, R. Bio-Composites Based on Polypropylene Reinforced with Almond Shells Particles: Mechanical and Thermal Properties. Mater. Des. 2013, 51, 225–230. [Google Scholar] [CrossRef]

- Ledbetter, C.A. Shell Cracking Strength in Almond (Prunus Dulcis [Mill.] D.A. Webb.) and Its Implication in Uses as a Value-Added Product. Bioresour. Technol. 2008, 99, 5567–5573. [Google Scholar] [CrossRef]

- Jahanban, A.; Jamei, R.; Jahanban, R. The Importance of Almond (Prunus Amygdalus L.) and Its by-Products. Food Chem. 2010, 120, 349–360. [Google Scholar] [CrossRef]

- Ahmedna, M.; Marshall, W.E.; Husseiny, A.A.; Goktepe, I.; Rao, R.M. The Use of Nutshell Carbons in Drinking Water Filters for Removal of Chlorination By-Products. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2004, 1097, 1092–1097. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable Composites Based on Lignocellulosic Fibers-An Overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of Highly Sustainable Polylactide/Almond Shell Flour Composites by Reactive Extrusion with Maleinized Linseed Oil. Ind. Crops Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Quiles-Carrillo, L.; Montanes, N.; Balart, R.; Torres-Giner, S.; Garcia-Garcia, D. Effect of Different Compatibilizers on Injection-Molded Green Composite Pieces Based on Polylactide Filled with Almond Shell Flour. Compos. Part B Eng. 2018, 76–85. [Google Scholar] [CrossRef]

- Bouhfid, R.; Hilali, E.; Laaziz, S.A.; Rodrigue, D.; Raji, M.; el kacem Qaiss, A.; Essabir, H. Bio-Composites Based on Polylactic Acid and Argan Nut Shell: Production and Properties. Int. J. Biol. Macromol. 2017, 104, 30–42. [Google Scholar] [CrossRef]

- Chin, D.D.V.S.; Yahya, M.N.B.; Che Din, N.B.; Ong, P. Acoustic Properties of Biodegradable Composite Micro-Perforated Panel (BC-MPP) Made from Kenaf Fibre and Polylactic Acid (PLA). Appl. Acoust. 2018, 138, 179–187. [Google Scholar] [CrossRef]

- Pan, P.; Zhu, B.; Kai, W.; Serizawa, S.; Iji, M.; Inoue, Y. Crystallization Behavior and Mechanical Properties of Bio-Based Green Composites Based on Poly(L-Lactide) and Kenaf Fiber. J. Appl. Polym. Sci. 2007, 105, 1511–1520. [Google Scholar] [CrossRef]

- Ogbomo, S.M.; Chapman, K.; Webber, C.; Bledsoe, R.; D’Souza, N.A. Benefits of Low Kenaf Loading in Biobased Composites of Poly(l-Lactide) and Kenaf Fiber. J. Appl. Polym. Sci. 2009, 112, 1294–1301. [Google Scholar] [CrossRef]

- da Silva Moura, A.; Demori, R.; Leão, R.M.; Crescente Frankenberg, C.L.; Campomanes Santana, R.M. The Influence of the Coconut Fiber Treated as Reinforcement in PHB (Polyhydroxybutyrate) Composites. Mater. Today Commun. 2019, 18, 191–198. [Google Scholar] [CrossRef]

- Barkoula, N.M.; Garkhail, S.K.; Peijs, T. Biodegradable Composites Based on Flax/Polyhydroxybutyrate and Its Copolymer with Hydroxyvalerate. Ind. Crops Prod. 2010, 31, 34–42. [Google Scholar] [CrossRef]

- Chen, F.; Qian, J.; Huang, J.; Zhang, J.; Wolcott, M.P.; Zhu, Y.; Jiang, L. Study of Poly(3-Hydroxybutyrate-Co-3-Hydroxyvalerate) (PHBV)/Bamboo Pulp Fiber Composites: Effects of Nucleation Agent and Compatibilizer. J. Polym. Environ. 2008, 16, 83–93. [Google Scholar] [CrossRef]

- Buzarovska, A.; Bogoeva-Gaceva, G.; Grozdanov, A.; Avella, M.; Gentile, G.; Errico, M. Crystallization Behavior of Poly(Hydroxybytyrate-Co-Valerate) in Model and Bulk PHBV/Kenaf Fiber Composites. J. Mater. Sci. 2007, 42, 6501–6509. [Google Scholar] [CrossRef]

- Rosa, M.F.; Chiou, B.S.; Medeiros, E.S.; Wood, D.F.; Williams, T.G.; Mattoso, L.H.C.; Orts, W.J.; Imam, S.H. Effect of Fiber Treatments on Tensile and Thermal Properties of Starch/Ethylene Vinyl Alcohol Copolymers/Coir Biocomposites. Bioresour. Technol. 2009, 100, 5196–5202. [Google Scholar] [CrossRef] [Green Version]

- Grylewicz, A.; Spychaj, T.; Zdanowicz, M. Thermoplastic Starch/Wood Biocomposites Processed with Deep Eutectic Solvents. Compos. Part A Appl. Sci. Manuf. 2019, 121, 517–524. [Google Scholar] [CrossRef]

- Fazeli, M.; Keley, M.; Biazar, E. Preparation and Characterization of Starch-Based Composite Films Reinforced by Cellulose Nanofibers. Int. J. Biol. Macromol. 2018, 116, 272–280. [Google Scholar] [CrossRef]

- Liu, D.; Zhong, T.; Chang, P.R.; Li, K.; Wu, Q. Starch Composites Reinforced by Bamboo Cellulosic Crystals. Bioresour. Technol. 2010, 101, 2529–2536. [Google Scholar] [CrossRef] [PubMed]

- Moriana, R.; Vilaplana, F.; Karlsson, S.; Ribes-greus, A. Composites: Part A Improved Thermo-Mechanical Properties by the Addition of Natural Fibres in Starch-Based Sustainable Biocomposites. Compos. Part A 2011, 42, 30–40. [Google Scholar] [CrossRef] [Green Version]

- Liminana, P.; Balart, R.; Montanes, N. Development and Characterization of Environmentally Friendly Composites from Poly (Butylene Succinate) (PBS) and Almond Shell Fl Our with Di Ff Erent Compatibilizers. Compos. Part B 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Liu, L.; Yu, J.; Cheng, L.; Qu, W. Mechanical Properties of Poly(Butylene Succinate) (PBS) Biocomposites Reinforced with Surface Modified Jute Fibre. Compos. Part A Appl. Sci. Manuf. 2009, 40, 669–674. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Nakatani, H.; Kobayashi, S.; Song, J.I. Mechanical and Thermal Properties and Water Absorption of Jute Fiber Reinforced Poly(Butylene Succinate) Biodegradable Composites. Adv. Compos. Mater. 2012, 21, 241–258. [Google Scholar] [CrossRef]

- Bao, L.; Chen, Y.; Zhou, W.; Wu, Y.; Huang, Y. Bamboo Fibers @ Poly(Ethylene Glycol)-Reinforced Poly(Butylene Succinate) Biocomposites. J. Appl. Polym. Sci. 2011, 122, 2456–2466. [Google Scholar] [CrossRef]

- Dash, B.N.; Nakamura, M.; Sahoo, S.; Kotaki, M.; Nakai, A.; Hamada, H. Mechanical Properties of Hemp Reinforced Poly(Butylene Succinate) Biocomposites. J. Biobased Mater. Bioenergy 2008, 2, 273–281. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Ismail, S.O.; Zhang, Z.; Barber, A.; Welsh, E.; Maigret, J.E.; Beaugrand, J. Development of Sustainable Biodegradable Lignocellulosic Hemp Fiber/Polycaprolactone Biocomposites for Light Weight Applications. Compos. Part A Appl. Sci. Manuf. 2018, 113, 350–358. [Google Scholar] [CrossRef] [Green Version]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. Composites: Part A A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part A 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of Particle Size, Particle/Matrix Interface Adhesion and Particle Loading on Mechanical Properties of Particulate-Polymer Composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Mohamed, W.Z.W.; Baharum, A.; Ahmad, I.; Abdullah, I.; Zakaria, N.E. Effects of Fiber Size and Fiber Content on Mechanical and Physical Properties of Mengkuang Reinforced Thermoplastic Natural Rubber Composites. BioResources 2018, 13, 2945–2959. [Google Scholar] [CrossRef]

- Tawakkal, I.S.M.A.; Cran, M.J.; Bigger, S.W. Effect of Kenaf Fibre Loading and Thymol Concentration on the Mechanical and Thermal Properties of PLA/Kenaf/Thymol Composites. Ind. Crops Prod. 2014, 61, 74–83. [Google Scholar] [CrossRef]

- Moriana, R.; Vilaplana, F.; Karlsson, S.; Ribes, A. Correlation of Chemical, Structural and Thermal Properties of Natural Fibres for Their Sustainable Exploitation. Carbohydr. Polym. 2014, 112, 422–431. [Google Scholar] [CrossRef]

- Araújo, M.A.; Cunha, A.M.; Mota, M. Enzymatic Degradation of Starch-Based Thermoplastic Compounds Used in Protheses: Identification of the Degradation Products in Solution. Biomaterials 2004, 25, 2687–2693. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.F.; Sun, X. Mechanical Properties of Poly(Lactic Acid)/Starch Composites Compatibilized by Maleic Anhydride. Biomacromolecules 2004, 5, 1446–1451. [Google Scholar] [CrossRef]

- Aldas, M.; Rayón, E.; López-Martínez, J.; Arrieta, M.P. A Deeper Microscopic Study of the Interaction between Gum Rosin Derivatives and a Mater-Bi Type Bioplastic. Polymers 2020, 12, 226. [Google Scholar] [CrossRef] [Green Version]

- Lopez, J.P.; Vilaseca, F.; Barberà, L.; Bayer, R.J.; Pèlach, M.A.; Mutjé, P. Processing and Properties of Biodegradable Composites Based on Mater-Bi ® and Hemp Core Fibres. Resour. Conserv. Recycl. 2012, 59, 38–42. [Google Scholar] [CrossRef]

- Haque, M.; Alvarez, V.; Paci, M.; Pracella, M. Composites: Part A Processing, Compatibilization and Properties of Ternary Composites of Mater-Bi with Polyolefins and Hemp Fibres. Compos. Part A 2011, 42, 2060–2069. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Curvelo, A.A.S.; Teixeira, E.M.; Mendes, F.M.; Carvalho, A.J.F.; Felissia, F.E.; Area, M.C. Composite Materials of Thermoplastic Starch and Fibers from the Ethanol-Water Fractionation of Bagasse. Ind. Crops Prod. 2011, 33, 739–746. [Google Scholar] [CrossRef]

- Di Franco, C.R.; Cyras, V.P.; Busalmen, J.P.; Ruseckaite, R.A.; Vázquez, A. Degradation of Polycaprolactone/Starch Blends and Composites with Sisal Fibre. Polym. Degrad. Stab. 2004, 86, 95–103. [Google Scholar] [CrossRef]

- Campos, A.; Marconcini, J.M.; Martins-Franchetti, S.M.; Mattoso, L.H.C. The Influence of UV-C Irradiation on the Properties of Thermoplastic Starch and Polycaprolactone Biocomposite with Sisal Bleached Fibers. Polym. Degrad. Stab. 2012, 97, 1948–1955. [Google Scholar] [CrossRef]

- Alemdar, A.; Sain, M. Biocomposites from Wheat Straw Nanofibers: Morphology, Thermal and Mechanical Properties. Compos. Sci. Technol. 2008, 68, 557–565. [Google Scholar] [CrossRef]

- Elfehri, K.; Carrot, C.; Jaziri, M. Composites: Part A Biocomposites of Alfa Fibers Dispersed in the Mater-Bi Ò Type Bioplastic: Morphology, Mechanical and Thermal Properties. Compos. Part A 2015, 78, 371–379. [Google Scholar] [CrossRef]

- Blasco, C.; Varela, F.J.; Ibáñez, A. Consumer Attitudes and Bioplastic for Eco-Babies & Bio-Parenting. Bioplastic Mag. 2019, 22–24. [Google Scholar]

- Frutas y hortalizas. Available online: https://www.frutas-hortalizas.com/Fruits/Types-varieties-Almond.html (accessed on 1 September 2020).

- Bledzki, A.K.; Letman-Sakiewicz, M.; Murr, M. Influence of Static and Cyclic Climate Condition on Bending Properties of Wood Plastic Composites (WPC). Express Polym. Lett. 2010, 4, 364–372. [Google Scholar] [CrossRef]

- Marcovich, N.E.; Reboredo, M.M.; Aranguren, M.I. Dependence of the Mechanical Properties of Woodflour-Polymer Composites on the Moisture Content. J. Appl. Polym. Sci. 1998, 68, 2069–2076. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M.O.W. Effect of Water Absorption on the Mechanical Properties of Hemp Fibre Reinforced Unsaturated Polyester Composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Muñoz-Guillena, M.; Linares-Solano, A.; Salinas-Martinez de Lecea, C. Determination of Calorific Values of Coals by Differential Thermal Analysis. Fuel 1992, 71, 579–583. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Processing and Characterization of Natural Cellulose Fibers/Thermoset Polymer Composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, Z.; Dai, M.; Fang, S.; Liao, Y.; Yu, Z.; Ma, X. Co-Pyrolysis Kinetics of Sewage Sludge and Bagasse Using Multiple Normal Distributed Activation Energy Model (M-DAEM). Bioresour. Technol. 2018, 259, 173–180. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. A Comprehensive Review on the Pyrolysis of Lignocellulosic Biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Di Blasi, C. Modeling Chemical and Physical Processes of Wood and Biomass Pyrolysis. Prog. Energy Combust. Sci. 2008, 34, 47–90. [Google Scholar] [CrossRef]

- Antunes, F.J.A.; Figueiredo, J.L. 99/03241 Pyrolysis Kinetics of Lignocellosic Materials—Three Independent Reactions Model. Fuel Energy Abstr. 1999, 40, 340. [Google Scholar] [CrossRef]

- Pirayesh, H.; Khazaeian, A. Using Almond (Prunus Amygdalus L.) Shell as a Bio-Waste Resource in Wood Based Composite. Compos. Part B Eng. 2012, 43, 1475–1479. [Google Scholar] [CrossRef]

- Martínez-García, A.; Ibáñez-García, A.; León-Cabezas, M.A.; Sánchez-Reche, A. Study of the Influence of the Almond Variety in the Properties of Injected Parts with Biodegradable Almond Shell Based Masterbatches. Waste Biomass Valorization 2015, 6, 363–370. [Google Scholar] [CrossRef]

- Matrix, P.B.S.; Liminana, P.; Quiles-carrillo, L.; Boronat, T.; Balart, R. The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly (Butylene Succinate Linseed Oil (MLO). Materials 2018, 11, 2179. [Google Scholar] [CrossRef] [Green Version]

| Natural Fibre | Cellulose (%) | Hemicellulose (%) | Lignin (%) |

|---|---|---|---|

| Bagasse | 55.2 | 16.8 | 25.3 |

| Bamboo | 26–43 | 30 | 21–31 |

| Flax | 71 | 18.6–20.6 | 2.2 |

| Kenaf | 72 | 20.3 | 9 |

| Jute | 61–71 | 14–20 | 12–13 |

| Hemp | 68 | 15 | 10 |

| Ramie | 68.6–76.2 | 13–16 | 0.6–0.7 |

| Abaca | 56–63 | 20–25 | 7–9 |

| Sisal | 65 | 12 | 9.9 |

| Coir | 81 | -- | 12.7 |

| Pinapple | 81 | -- | 12.7 |

| Wheat straw | 38–45 | 15–31 | 12–20 |

| Rice husk | 35–45 | 19–25 | 20 |

| Rice straw | 41–57 | 33 | 8–10 |

| Characteristics | TEST | Values |

|---|---|---|

| Min. processing temperature (°C) | Novamont test | 170 |

| Max. processing temperature (°C) | Novamont test | 260 |

| Melting temperature (°C) | ASTM-D3418 | 160 |

| Melt viscosity (Pa·s) (T = 190 °C, γ = 1000 s−1) | ASTM-D3835 | 140 |

| Tensile strength at break (MPa) | ASTM-D638 | 20 |

| Max. tensile strength (MPa) | ASTM-D638 | 48 |

| Elongation at break (%) | ASTM-D638 | 22 |

| Elongation at max strength | ASTM-D638 | 2.5 |

| Young modulus (MPa) | ASTM-D638 | 2700 |

| Parameters | Injection Moulding Conditions |

|---|---|

| Injection temperature (°C) | 40–180–190–200–200 |

| Mould temperature (°C) | 30 |

| Injection speed (mm/s) | 70 |

| Injection pressure (max)(bar) | 165 |

| Back pressure (bar) | 83 |

| Cooling time (s) | 35 |

| Injection temperature (°C) | 40–180–190–200–200 |

| Mould temperature (°C) | 30 |

| Injection speed (mm/s) | 70 |

| Wavenumber (cm−1) | Functional Group | Vibration Type | Cause |

|---|---|---|---|

| 3300–3500 | ─OH | stretching vibration | cellulose, hemicellulose |

| 2900–2935 | ─CH | stretching vibration | - |

| 1640–1735 | C=O | stretching vibration | lignin, hemicellulose |

| 1580–1605 | benzene ring | stretching vibration | lignin |

| 1455–1465 | ─CH3O | stretching vibration | lignin |

| 1320–1430 | ─CH | bending vibration | - |

| 1221–1230 | C─C C─O | stretching vibration | lignin |

| 1025–1035 | C─O | stretching vibration | cellulose, hemicellulose and lignin |

| 885–895 | R2C=CH2 | bending vibration | - |

| 810–833 | benzene ring | disubstituted benzene | - |

| Almond Shell Variety | Moisture (%) | Volatile Matter (%) | Fixed Carbon (%) | Ash (%) |

|---|---|---|---|---|

| Desmayo Rojo | 6.2 | 73.9 | 18.9 | 1.0 |

| Largueta | 5.8 | 75.1 | 17.1 | 2.0 |

| Marcona | 5.2 | 73.1 | 17.7 | 4.0 |

| Mollar | 6.3 | 73.7 | 19.1 | 0.9 |

| Mixture | 7.4 | 64.5 | 19.4 | 8.7 |

| Almond Shell Variety | Component | Ea (kJ·mol−1) | K0 (s−1) | α (kJ∙mol−1) | α Ea−1 (%) | Tm (°C) | Weight Loss (%) | Amount (%) |

|---|---|---|---|---|---|---|---|---|

| Desmayo Rojo | Hemicellulose | 132 | 4.2·109 | 4.2 | 3.2 | 299 | 25.9 | 36 |

| Cellulose | 169 | 1.2·1012 | 0.0 | 0.0 | 351 | 33.8 | 40 | |

| Lignin LT | 170 | 1.4·1010 | 14.6 | 8.6 | 401 | 6.0 | 24 | |

| Lignin HT | 240 | 3.2·1011 | 60.0 | 25.0 | 445 | 5.8 | ||

| Largueta | Hemicellulose | 155 | 2.9·1011 | 6.6 | 4.2 | 308 | 33.0 | 44 |

| Cellulose | 202 | 3.6·1014 | 0.0 | 0.0 | 366 | 28.2 | 32 | |

| Lignin LT | 173 | 1.6·1010 | 17.9 | 10.3 | 398 | 6.7 | 24 | |

| Lignin HT | 242 | 8.8·1010 | 63.8 | 26.4 | 466 | 5.7 | ||

| Marcona | Hemicellulose | 140 | 1.9·1010 | 4.6 | 3.3 | 302 | 28.9 | 40 |

| Cellulose | 185 | 2.3·1013 | 0.0 | 0.0 | 356 | 30.7 | 36 | |

| Lignin LT | 170 | 1.5·1010 | 13.7 | 8.1 | 401 | 5.8 | 24 | |

| Lignin HT | 242 | 1.6·1011 | 64.8 | 26.8 | 450 | 6.3 | ||

| Mollar | Hemicellulose | 140 | 1.3·1010 | 7.3 | 5.2 | 302 | 28.6 | 40 |

| Cellulose | 185 | 2.2·1013 | 0.0 | 0.0 | 355 | 28.6 | 35 | |

| Lignin LT | 171 | 1.4·1010 | 14.6 | 8.6 | 402 | 6.2 | 25 | |

| Lignin HT | 240 | 3.2·1011 | 60.0 | 25.0 | 445 | 5.8 | ||

| Mixture | Hemicellulose | 127 | 1.2·109 | 9.1 | 7.1 | 287 | 22.6 | 37 |

| Cellulose | 173 | 4.9·1012 | 0.0 | 0.0 | 342 | 19.6 | 27 | |

| Lignin LT | 178 | 3.1·1010 | 22.0 | 22.0 | 389 | 8.7 | 36 | |

| Lignin HT | 240 | 3.2·1011 | 65.0 | 65.0 | 428 | 6.7 |

| Almond Shell Variety | CrI (%) |

|---|---|

| Desmayo Rojo | 31.3 |

| Largueta | 33.8 |

| Marcona | 29.7 |

| Mollar | 30.2 |

| Mixture | 25.1 |

| Materials | Melt Enthalphy (J·g−1) | Melt Peak Temperature (°C) |

|---|---|---|

| As-received Mater-Bi DI01A | 28.01 | 168.84 |

| Biocomposite Mater-Bi DI01A/Desmayo Rojo | 21.12 | 167.91 |

| Biocomposite Mater-Bi DI01A/Largueta | 21.31 | 168.02 |

| Biocomposite Mater-Bi DI01A/Marcona | 22.04 | 168.11 |

| Biocomposite Mater-Bi DI01A/Mollar | 21.41 | 167.95 |

| Biocomposite Mater-Bi DI01A/Mixture | 22.03 | 167.70 |

| Materials | TONSET (°C) | TMAX (°C) | Residual Weight (%) |

|---|---|---|---|

| As-received Mater-Bi DI01A | 325.98 | 353.58 | 2.33 |

| Almond shell | 254.67 | 351.06 | 22.81 |

| Biocomposite Mater-Bi DI01A/Desmayo Rojo | 256.76 | 304.46 | 0.63 |

| Biocomposite Mater-Bi DI01A/Largueta | 293.91 | 341.46 | 0.65 |

| Biocomposite Mater-Bi DI01A/Marcona | 281.00 | 325.27 | 0.74 |

| Biocomposite Mater-Bi DI01A/Mollar | 282.60 | 318.28 | 0.83 |

| Biocomposite Mater-Bi DI01A/Mixture | 286.19 | 319.09 | 0.92 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibáñez García, A.; Martínez García, A.; Ferrándiz Bou, S. Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites. Polymers 2020, 12, 2049. https://doi.org/10.3390/polym12092049

Ibáñez García A, Martínez García A, Ferrándiz Bou S. Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites. Polymers. 2020; 12(9):2049. https://doi.org/10.3390/polym12092049

Chicago/Turabian StyleIbáñez García, Ana, Asunción Martínez García, and Santiago Ferrándiz Bou. 2020. "Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites" Polymers 12, no. 9: 2049. https://doi.org/10.3390/polym12092049

APA StyleIbáñez García, A., Martínez García, A., & Ferrándiz Bou, S. (2020). Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites. Polymers, 12(9), 2049. https://doi.org/10.3390/polym12092049