Causes of the Gloss Transition Defect on High-Gloss Injection-Molded Surfaces

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Polymer Material

2.1.2. Injection Molds

2.2. Experiment Conditions

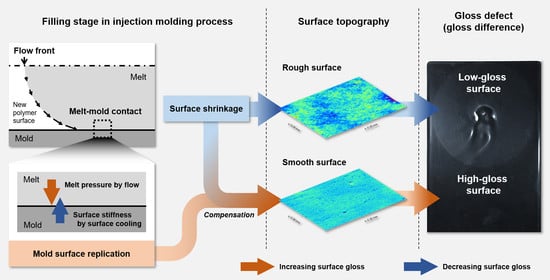

2.2.1. Surface Changes in the Filling Stage

2.2.2. Influence of Process Parameters on Surface Gloss

2.3. Measurement and Analysis

2.3.1. Surface Gloss

2.3.2. Gloss Distribution

2.3.3. Surface Topography

3. Results and Discussion

3.1. Gloss Difference Induced by Surface Topography

3.2. Surface Changes in the Filling Stage

3.3. Rough Surface Generation

3.4. Mold Surface Replication

3.5. Influence of Molding Conditions on Surface Gloss

3.5.1. Effect of Mold Temperature

3.5.2. Effect of the Flow Front Speed

3.5.3. Effect of Packing Pressure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Beaumont, J.P. Runner and Gating Design Handbook: Tools for Successful Injection Molding, 2nd ed.; Hanser Gardner Publications: Cincinnati, OH, USA, 2008. [Google Scholar]

- Rosato, D.V. Injection Molding Handbook: The Complete Molding Operation: Technology, Performance, Economics, 2nd ed.; Capman & Hall: New York, NY, USA, 1994. [Google Scholar]

- Wang, G.; Zhao, G.; Wang, W. Effect of cavity surface temperature on reinforced plastic part surface appearance in rapid heat cycle moulding. Mater. Des. 2013, 44, 509–520. [Google Scholar] [CrossRef]

- Berger, G.R.; Gruber, D.P.; Friesenbichler, W.; Teichert, C.; Burgsteiner, M. Replication of stochastic and geometric micro structures – aspects of visual appearance. Int. Polym. Process. 2011, 26, 131–322. [Google Scholar] [CrossRef]

- Dawkins, E.; Engelmann, P.; Horton, K. Color and gloss- the connection to process conditions. J. Injection Molding Technol. 1998, 2, 1–7. [Google Scholar]

- Dawkins, E.; Horton, K.; Engelmann, P.; Monfore, M. The effects of injection molding parameters on color and gloss. In Coloring Technology for Plastics; Harris, R.M., Ed.; William Andrew: Norwich, NY, USA, 1999; pp. 149–155. [Google Scholar]

- Koppi, K.; Ceraso, J.M.; Cleven, J.A.; Salamon, B.A. Gloss modeling of injection molded rubber-modified styrenic polymers. In Proceedings of the Society of Plastics Engineers’ Annual Technical Conference (SPE ANTEC), San Francisco, CA, USA, 5–9 May 2002. [Google Scholar]

- Oliveira, M.J.; Brito, A.M.; Costa, M.C.; Costa, M.F. Gloss and surface topography of ABS: A study on the influence of the injection molding parameters. Polym. Eng. Sci. 2006, 46, 1394–1401. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Research on a new variotherm injection molding technology and its application on the molding of a large LCD panel. Polym.-Plast. Technol. Eng. 2009, 48, 671–681. [Google Scholar] [CrossRef]

- Theilade, U.A.; Hansen, H.N. Surface microstructure replication in injection molding. Int. J. Adv. Manuf. Technol. 2007, 33, 157–166. [Google Scholar] [CrossRef]

- Pisciotti, F.; Boldizar, A.; Rigdahl, M.; Ariño, I. Effect of injection-molding conditions on the gloss and color of pigmented polypropylene. Polym. Eng. Sci. 2005, 45, 1557–1567. [Google Scholar] [CrossRef]

- Yuan, Z.; Astbury, D.; Costa, F.S.; Ward, D.; Prey, M. Simulation and validation of mold filling with velocity controlled valve gates. In Proceedings of the Society of Plastics Engineers’ Annual Technical Conference (SPE ANTEC), Orlando, FL, USA, 23–25 March 2015. [Google Scholar]

- Suhartono, E.; Chiu, H.-S.; Hsu, C.-C.; Wang, C.-C.; Wang, C.-W.; Pavan, N. Predict and solve stress mark on product’s cosmetic surface using controlled sequential valve gating simulation. In Proceedings of the Society of Plastics Engineers’ Annual Technical Conference (SPE ANTEC), Anaheim, CA, USA, 8–10 May 2017. [Google Scholar]

- Li, X.-P.; Zhao, G.-Q.; Guan, Y.-J.; Ma, M.-X. Optimal design of heating channels for rapid heating cycle injection mold based on response surface and genetic algorithm. Mater. Design. 2009, 30, 4317–4323. [Google Scholar] [CrossRef]

- Li, J.; Li, T.; Jia, Y.; Jiang, S.; Turng, L.-S. Modeling and characterization of crystallization during rapid heat cycle molding. Polym. Test. 2018, 71, 182–191. [Google Scholar] [CrossRef]

- Berger, G.R.; Friesenbichler, W.; Gruber, D.P.; Pacher, G.A.; Macher, J. Rapid heat cycle molding, surface topography and visual appearance of injection molded parts. Research work in Leoben in the last 10 years. In Proceedings of the Society of Plastics Engineers’ Annual Technical Conference (SPE ANTEC), Las Vegas, NV, USA, 28–30 April 2014. [Google Scholar]

- Chen, S.-C.; Chang, J.-A.; Cin, J.-C. Dynamic mold surface temperature control for molding high gloss, painting free part surface achieving cycle time and cost reduction. In Proceedings of the Society of Plastics Engineers’ Annual Technical Conference (SPE ANTEC), Chicago, IL, USA, 22–26 June 2009. [Google Scholar]

- Lee, J.; Turng, L.-S. Improving surface quality of microcellular injection molded parts through mold surface temperature manipulation with thin film insulation. Polym. Eng. Sci. 2010, 50, 1281–1289. [Google Scholar] [CrossRef]

- Lee, J.; Turng, L.-S.; Dougherty, E.; Gorton, P. A novel method for improving the surface quality of microcellular injection molded parts. Polymer 2011, 52, 1436–1446. [Google Scholar] [CrossRef]

- Yoshii, M.; Kuramoto, H.; Kawana, T.; Kato, K. The observation and origin of micro flow marks in the precision injection molding of polycarbonate. Polym. Eng. Sci. 1996, 36, 819–826. [Google Scholar] [CrossRef]

- Yoshii, M.; Kuramoto, H.; Kato, K. Experimental study of transcription of smooth surfaces in injection molding. Polym. Eng. Sci. 1993, 33, 1251–1260. [Google Scholar] [CrossRef]

- Tredoux, L.; Satoh, I.; Kurosaki, Y. Investigation of wave-like flow marks in injection molding: Flow visualization and micro-geometry. Polym. Eng. Sci. 1999, 39, 2233–2241. [Google Scholar] [CrossRef]

- Tredoux, L.; Satoh, I.; Kurosaki, Y. Investigation of wavelike flow marks in injection molding: A new hypothesis for the generation mechanism. Polym. Eng. Sci. 2000, 40, 2161–2174. [Google Scholar] [CrossRef]

- Yokoi, H.; Mashda, N.; Mitsuhata, H. Visualization analysis of flow front behavior during filling process of injection mold cavity by two-axis tracking system. J. Mater. Process. Technol. 2002, 130–131, 328–333. [Google Scholar] [CrossRef]

- Bogaerds, A.C.B.; Hulsen, M.A.; Peters, G.W.M.; Baaijens, F.P.T. Stability analysis of injection molding flows. J. Rheol. 2004, 48, 765–785. [Google Scholar] [CrossRef] [Green Version]

- Baltussen, M.G.H.M.; Hulsen, M.A.; Peters, G.W.M. Numerical simulation of the fountain flow instability in injection molding. J. Non Newton. Fluid Mech. 2010, 165, 631–640. [Google Scholar] [CrossRef]

- Isayev, A.I.; Kim, N.A. Co-injection molding of polymers. In Injection Molding Technology and Fundamentals; Kamal, M.R., Isayev, A.I., Liu, S.-J., White, J.L., Eds.; Hanser Publications: Cincinnati, OH, USA, 2009. [Google Scholar]

- Jeon, J.; Kim, H.; Rhee, B.; Chio, J.; Park, E.; Jung, K. A study on the halo surface defects of injection molded products. In Proceedings of the Society of Plastics Engineers’ Annual Technical Conference (SPE ANTEC), Anaheim, CA, USA, 8–10 May 2017. [Google Scholar]

- Bott, J. Do you still get stubborn surface defects, even with sequential valve gating? Plast. Technol. 2012, 58, 26–29. [Google Scholar]

- Yuan, Z.; Ward, D.; Prey, M. Application and simulation of velocity-controlled valve gates. In Proceedings of the Autodesk University, Las Vegas, NV, USA, 2–4 December 2014. [Google Scholar]

- Gim, J.; Kim, B.; Rhee, B.; Choi, J.; An, S.; Jung, K. Valve gate open lag time in conventional hot runner system. In Proceedings of the Society of Plastics Engineers’ Annual Technical Conference (SPE ANTEC), Orlando, FL, USA, 7–9 May 2018. [Google Scholar]

- ASTM D523-08. Standard Test Method for Specular Gloss; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM D2457-03. Standard Test Method for Specular Gloss of Plastic Films and Solid Plastics; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ISO 2013:2014(E). Paints and Varnishes—Determination of Gloss Value at 20 Degrees, 60 Degrees and 85 Degrees; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Gruber, D.P.; Buder-Stroisznigg, M.; Wallner, G.; Strauss, B.; Jandel, L.; Lang, R.W. A novel methodology for the evaluation of distinctness of image of glossy surfaces. Prog. Org. Coat. 2008, 63, 377–381. [Google Scholar] [CrossRef]

- Gruber, D.P.; Wallner, G.; Buder-Stroisznigg, M. Method for Analysing the Surface Properties of a Material. PCT-Patent WO2006135948, 28 December 2006. [Google Scholar]

- ASTM D4449-90. Standard Test Method for Visual Evaluation of Gloss Differences between Surfaces of Similar Appearance; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Stout, K.J.; Blunt, L. Three Dimensional Surface Topography, 2nd ed.; Penton Press: London, UK, 2000; pp. 19–94. [Google Scholar]

- Ariño, I.; Kleist, U.; Barros, G.G.; Johansson, P.-Å.; Rigdahl, M. Surface texture characterization of injection-molded pigmented plastics. Polym. Eng. Sci. 2004, 44, 1615–1626. [Google Scholar] [CrossRef]

- Nečas, D.; Klapetek, P. Gwyddion: An open-source software for SPM data analysis. Cent. Eur. J. Phys. 2012, 10, 181–188. [Google Scholar] [CrossRef]

- Ogilvy, J.A. Theory of Wave Scattering from Random Rough Surfaces; IOP Publishing: London, UK, 1991. [Google Scholar]

- Alexander-Katz, R.; Barrera, R.G. Surface correlation effects on gloss. J. Polym. Sci. 1998, 36, 1321–1334. [Google Scholar] [CrossRef]

- Ariño, I.; Kleist, U.; Mattsson, L.; Rigdahl, M. On the relation between surface texture and gloss of injection-molded pigmented plastics. Polym. Eng. Sci. 2005, 45, 1343–1356. [Google Scholar] [CrossRef]

- Lednický, F.; Pelzbauer, Z. Gloss as an inner morphology characteristic of ABS polymers. Angew. Makromol. Chem. 1986, 141, 151–160. [Google Scholar] [CrossRef]

- Fink, J.K. Handbook of Engineering and Specialty Thermoplastics; Scrivener Publishing: Salem, MA, USA, 2010; Volume 1, pp. 211–268. [Google Scholar]

- Wypych, G. Handbook of Polymers; ChemTec Publishing: Toronto, ON, Canada, 2012; pp. 3–10. [Google Scholar]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Oxford University Press: Oxford, UK, 1959; pp. 50–91. [Google Scholar]

- Shayfull, Z.; Sharif, S.; Zain, A.M.; Ghazili, M.F.; Saad, R.M. Potential of conformal cooling channels in rapid heat cycle molding: A review. Adv. Polym. Technol. 2013, 33, 21381. [Google Scholar] [CrossRef]

- Goodship, V. Troubleshooting Injection Moulding; Rapra Technology Ltd.: Shrewsbury, UK, 2004. [Google Scholar]

- Morrison, F.A. Understanding Rheology; Oxford University Press: Oxford, UK, 2001; pp. 59–98. [Google Scholar]

| Process Parameter | Values |

|---|---|

| Coolant temperature (°C) | 35 |

| Barrel temperature (°C) | 210 |

| Flow front speed, FFS (mm/s) | 17.8, 31.6, 56.2, 100, 178, 316, 562, 1000 |

| Process Parameter | Levels | Values |

|---|---|---|

| Flow front speed, FFS (mm/s) | 5 | 25, 50, 100, 250, 375 |

| Packing pressure (bar) | 3 | 400, 500, 600 |

| Coolant temperature (°C) | 3 | 40, 55, 70 |

| Design Parameters | Degree of Freedom | Sum of Squares | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| Coolant temperature | 2 | 3552.56 | 1776.28 | 45.77 | 0.000 |

| Flow front speed | 4 | 2007.25 | 501.81 | 12.93 | 0.000 |

| Packing pressure | 3 | 204.81 | 68.27 | 1.76 | 0.167 |

| Error | 50 | 1940.26 | 38.81 | ||

| Total | 59 | 7704.89 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gim, J.; Han, E.; Rhee, B.; Friesenbichler, W.; Gruber, D.P. Causes of the Gloss Transition Defect on High-Gloss Injection-Molded Surfaces. Polymers 2020, 12, 2100. https://doi.org/10.3390/polym12092100

Gim J, Han E, Rhee B, Friesenbichler W, Gruber DP. Causes of the Gloss Transition Defect on High-Gloss Injection-Molded Surfaces. Polymers. 2020; 12(9):2100. https://doi.org/10.3390/polym12092100

Chicago/Turabian StyleGim, Jinsu, Eunsu Han, Byungohk Rhee, Walter Friesenbichler, and Dieter P. Gruber. 2020. "Causes of the Gloss Transition Defect on High-Gloss Injection-Molded Surfaces" Polymers 12, no. 9: 2100. https://doi.org/10.3390/polym12092100

APA StyleGim, J., Han, E., Rhee, B., Friesenbichler, W., & Gruber, D. P. (2020). Causes of the Gloss Transition Defect on High-Gloss Injection-Molded Surfaces. Polymers, 12(9), 2100. https://doi.org/10.3390/polym12092100