Material Extrusion Additive Manufacturing of Wood and Lignocellulosic Filled Composites

Abstract

:1. Background

2. Additive Manufacturing Overview

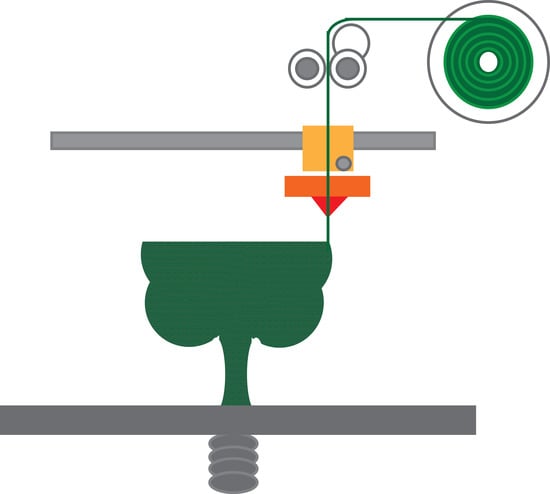

3D Printing Processes

3. Wood and Lignocellulosic Composites and their Properties

3.1. Wood Flour, Fiber, and Sawdust

3.2. Lignocellulosic-Components: Cellulose and Lignin

4. Challenges and Opportunities in 3D Printing of Wood Composites

4.1. Feedstock Processing

4.1.1. Material Compounding

4.1.2. Filament-Fed Systems

4.1.3. Pellet-Fed Systems

4.2. Polymer Crystallinity

4.3. Interlayer Adhesion

4.4. Printing Orientation

4.5. Filler Dimensions (Aspect Ratio)

4.6. Large-Scale Printing

5. Applications

5.1. Direct Uses

5.2. Indirect Uses

6. Future Trends and Outlook

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gephardt, A. Understanding Additive Manufacturing; Hanser Publications: Cincinnati, OH, USA, 2012. [Google Scholar]

- Duty Chad, E. Structure and mechanical behavior of Big Area Additive Manufacturing (BAAM) materials. Rapid Prototyping J. 2017, 23, 181–189. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Automat. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Ozcan, S. Green nanomaterials: On track for a sustainable future. Nano Today 2015, 10, 417–420. [Google Scholar] [CrossRef] [Green Version]

- Kyulavska, M.; Toncheva-Moncheva, N.; Rydz, J. Biobased Polyamide Ecomaterials and Their Susceptibility to Biodegradation. In Handbook of Ecomaterials; Martínez, L.M.T., Kharissova, O.V., Kharisov, B.I., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 2901–2934. [Google Scholar]

- Philp, J.C.; Ritchie, R.J.; Allan, J.E. Biobased chemicals: The convergence of green chemistry with industrial biotechnology. Trends Biotechnol. 2013, 31, 219–222. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dale, B.E. ‘Greening’ the chemical industry: Research and development priorities for biobased industrial products. J. Chem. Technol. Biotechnol. 2003, 78, 1093–1103. [Google Scholar] [CrossRef]

- Li, T.; Aspler, J.; Kingsland, A.; Cormier, L.M.; Zou, X. 3D printing–a review of technologies, markets, and opportunities for the forest industry. J. For. 2016, 5, 30. [Google Scholar]

- Wimmer, R.; Steyrer, B.; Woess, J.; Koddenberg, T.; Mundigler, N. 3D printing and wood. Pro Ligno 2015, 11, 144–149. [Google Scholar]

- Wang, Q.; Sun, J.; Yao, Q.; Ji, C.; Liu, J.; Zhu, Q. 3D printing with cellulose materials. Cellulose 2018, 25, 4275–4301. [Google Scholar] [CrossRef]

- Papadopoulos, A.N. Advances in Wood Composites. Polymers 2019, 12, 48. [Google Scholar] [CrossRef] [Green Version]

- Chaunier, L.; Guessasma, S.; Belhabib, S.; Della Valle, G.; Lourdin, D.; Leroy, E. Material extrusion of plant biopolymers: Opportunities & challenges for 3D printing. Addit. Manuf. 2018, 21, 220–233. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.; Sun, L.; Xu, W.; Wang, Q.; Yu, S.; Sun, J. Current advances and future perspectives of 3D printing natural-derived biopolymers. Carbohydr. Polym. 2019, 207, 297–316. [Google Scholar] [CrossRef] [PubMed]

- Gkartzou, E.; Koumoulos, E.P.; Charitidis, C.A. Production and 3D printing processing of bio-based thermoplastic filament. Manuf. Rev. 2017, 4, 1. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyping J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Tisserat, B.; Liu, Z.; Finkenstadt, V.; Lewandowski, B.; Ott, S.; Reifschneider, L. 3D Printing Biocomposites. Plast. Res. Online 2015, 2015. [Google Scholar] [CrossRef]

- Murphy, C.A.; Collins, M.N. Microcrystalline cellulose reinforced polylactic acid biocomposite filaments for 3D printing. Polym. Compos. 2018, 39, 1311–1320. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and Application of Wood Flour-Filled Polylactic Acid Composite Filament for 3D Printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Gardner, D.J.; Bousfield, D.W. Cellulose nanofibril-reinforced polypropylene composites for material extrusion: Rheological properties. Polym. Eng. Sci. 2018, 58, 793–801. [Google Scholar] [CrossRef]

- Nguyen, N.A.; Bowland, C.C.; Naskar, A.K. A general method to improve 3D-printability and inter-layer adhesion in lignin-based composites. Appl. Mater. Today 2018, 12, 138–152. [Google Scholar] [CrossRef]

- Nguyen, N.A.; Barnes, S.H.; Bowland, C.C.; Meek, K.M.; Littrell, K.C.; Keum, J.K.; Naskar, A.K. A path for lignin valorization via additive manufacturing of high-performance sustainable composites with enhanced 3D printability. Sci. Adv. 2018, 4, 4967. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chinga-Carrasco, G. Potential and Limitations of Nanocelluloses as Components in Biocomposite Inks for Three-Dimensional Bioprinting and for Biomedical Devices. Biomacromolecules 2018, 19, 701–711. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Wang, X.; Sandler, N.; Willför, S.; Xu, C. Three-Dimensional Printing of Wood-Derived Biopolymers: A Review Focused on Biomedical Applications. ACS Sustainable Chem. Eng. 2018, 6, 5663–5680. [Google Scholar] [CrossRef]

- Zeng, W.; Guo, Y.; Jiang, K.; Yu, Z.; Liu, Y.; Shen, Y.; Deng, J.; Wang, P. Laser intensity effect on mechanical properties of wood–plastic composite parts fabricated by selective laser sintering. J. Thermoplast. Compos. Mater. 2013, 26, 125–136. [Google Scholar] [CrossRef]

- Henke, K.; Treml, S. Wood based bulk material in 3D printing processes for applications in construction. Eur. J. Wood Wood Prod. 2013, 71, 139–141. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Kuzman, M.K. Use of wood powder and adhesive as a mixture for 3D printing. Eur. J. Wood Wood Prod. 2016, 74, 123–126. [Google Scholar] [CrossRef]

- Pitt, K.; Lopez-Botello, O.; Lafferty, A.D.; Todd, I.; Mumtaz, K. Investigation into the material properties of wooden composite structures with in-situ fibre reinforcement using additive manufacturing. Compos. Sci. Technol. 2017, 138, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Rosenthal, M.; Henneberger, C.; Gutkes, A.; Bues, C.T. Liquid Deposition Modeling: A promising approach for 3D printing of wood. Eur. J. Wood Wood Prod. 2018, 76, 797–799. [Google Scholar] [CrossRef]

- Gardan, J.; Nguyen, D.C.; Roucoules, L.; Montay, G. Characterization of Wood Filament in Additive Deposition to Study the Mechanical Behavior of Reconstituted Wood Products. J. Eng. Fiber. Fabr. 2016, 11, 56–63. [Google Scholar] [CrossRef]

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88. [Google Scholar] [CrossRef] [PubMed]

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Li, K.; Wang, Y.; Rowe, M.; Zhao, X.; Li, T.; Tekinalp, H.; Ozcan, S. Poly(lactic acid) Toughening through Chain End Engineering. ACS Appl. Polymer Mater. 2019, 2, 411–417. [Google Scholar] [CrossRef]

- Meng, X.; Nguyen, N.A.; Tekinalp, H.; Lara-Curzio, E.; Ozcan, S. Supertough PLA-Silane Nanohybrids by in Situ Condensation and Grafting. ACS Sustainable Chem. Eng. 2017, 6, 1289–1298. [Google Scholar] [CrossRef]

- Pringle, A.M.; Rudnicki, M.; Pearce, J.M. Wood Furniture Waste-Based Recycled 3-D Printing Filament. Forest Prod. J. 2018, 68, 86–95. [Google Scholar] [CrossRef] [Green Version]

- Kariz, M.; Sernek, M.; Obucina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Bi, H.H.; Ren, Z.C.; Guo, R.; Xu, M.; Song, Y.M. Fabrication of flexible wood flour/thermoplastic polyurethane elastomer composites using fused deposition molding. Ind. Crops Prod. 2018, 122, 76–84. [Google Scholar] [CrossRef]

- Daver, F.; Lee, K.P.M.; Brandt, M.; Shanks, R. Cork–PLA composite filaments for fused deposition modelling. Compos. Sci. Technol. 2018, 168, 230–237. [Google Scholar] [CrossRef]

- Kaynak, B.; Spoerk, M.; Shirole, A.; Ziegler, W.; Sapkota, J. Polypropylene/Cellulose Composites for Material Extrusion Additive Manufacturing. Macromol. Mater. Eng. 2018, 303, 1800037. [Google Scholar] [CrossRef] [Green Version]

- Koo, J.M.; Kang, J.; Shin, S.H.; Jegal, J.; Cha, H.G.; Choy, S.; Hakkarainen, M.; Park, J.; Oh, D.X.; Hwang, S.Y. Biobased thermoplastic elastomer with seamless 3D-Printability and superior mechanical properties empowered by in-situ polymerization in the presence of nanocellulose. Compos. Sci. Technol. 2020, 185, 107885. [Google Scholar] [CrossRef]

- Cataldi, A.; Rigotti, D.; Nguyen, V.D.H.; Pegoretti, A. Polyvinyl alcohol reinforced with crystalline nanocellulose for 3D printing application. Mater. Today Commun. 2018, 15, 236–244. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Meng, X.; Lu, Y.; Kunc, V.; Love, L.J.; Peter, W.H.; Ozcan, S. High modulus biocomposites via additive manufacturing: Cellulose nanofibril networks as “microsponges”. Compos. Part B Eng. 2019, 173. [Google Scholar] [CrossRef]

- Valentini, F.; Dorigato, A.; Rigotti, D.; Pegoretti, A. Polyhydroxyalkanoates/Fibrillated Nanocellulose Composites for Additive Manufacturing. J. Polym. Environ. 2019, 27, 1333–1341. [Google Scholar] [CrossRef]

- Dong, J.; Li, M.C.; Zhou, L.; Lee, S.; Mei, C.T.; Xu, X.W.; Wu, Q.L. The influence of grafted cellulose nanofibers and postextrusion annealing treatment on selected properties of poly(lactic acid) filaments for 3D printing. J. Polym. Sci. Part B Polym. Phy. 2017, 55, 847–855. [Google Scholar] [CrossRef]

- Tanase-Opedal, M.; Espinosa, E.; Rodríguez, A.; Chinga-Carrasco, G. Lignin: A Biopolymer from Forestry Biomass for Biocomposites and 3D Printing. Materials 2019, 12, 3006. [Google Scholar] [CrossRef] [Green Version]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Kim, J.; Zhai, L.; Mun, S.; Ko, H.-U.; Yun, Y.-M. Cellulose Nanocrystals, Nanofibers, and Their Composites as Renewable Smart Materials; SPIE: Bellingham, WA, USA, 2015; Volume 9434. [Google Scholar]

- Gardner, D.J.; Tajvidi, M. Hydrogen Bonding in Wood-Based Materials: An Update. Wood Fiber Sci. 2016, 48, 234–244. [Google Scholar]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A New Family of Nature-Based Materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef]

- Stokke, D.D.; Gardner, D.J. Fundamental aspects of wood as a component of thermoplastic composites. J. Vinyl Addit. Technol. 2003, 9, 96–104. [Google Scholar] [CrossRef]

- Isikgor, F.H.; Becer, C.R. Lignocellulosic biomass: A sustainable platform for the production of bio-based chemicals and polymers. Polym. Chem. 2015, 6, 4497–4559. [Google Scholar] [CrossRef] [Green Version]

- Fein, K.; Bousfield, D.W.; Gramlich, W.M. The influence of versatile thiol-norbornene modifications to cellulose nanofibers on rheology and film properties. Carbohydr. Polym. 2020, 230, 115672. [Google Scholar] [CrossRef] [PubMed]

- Kalia, S.; Boufi, S.; Celli, A.; Kango, S. Nanofibrillated cellulose: Surface modification and potential applications. Colloid. Polym. Sci. 2013, 292, 5–31. [Google Scholar] [CrossRef]

- Littunen, K.; Hippi, U.; Johansson, L.S.; Osterberg, M.; Tammelin, T.; Laine, J.; Seppala, J. Free radical graft copolymerization of nanofibrillated cellulose with acrylic monomers. Carbohydr. Polym. 2011, 84, 1039–1047. [Google Scholar] [CrossRef]

- Qu, P.; Zhou, Y.T.; Zhang, X.L.; Yao, S.Y.; Zhang, L.P. Surface modification of cellulose nanofibrils for poly(lactic acid) composite application. J. Appl. Polym. Sci. 2012, 125, 3084–3091. [Google Scholar] [CrossRef]

- Semba, T.; Ito, A.; Kitagawa, K.; Nakatani, T.; Yano, H.; Sato, A. Thermoplastic Composites of Polyamide-12 Reinforced by Cellulose Nanofibers with Cationic Surface Modification. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Spinella, S.; Lo Re, G.; Liu, B.; Dorgan, J.; Habibi, Y.; Leclere, P.; Raquez, J.M.; Dubois, P.; Gross, R.A. Polylactide/cellulose nanocrystal nanocomposites: Efficient routes for nanofiber modification and effects of nanofiber chemistry on PLA reinforcement. Polymer 2015, 65, 9–17. [Google Scholar] [CrossRef]

- Yang, X.P.; Ku, T.H.; Biswas, S.K.; Yano, H.; Abe, K.T.R.O. UV grafting: Surface modification of cellulose nanofibers without the use of organic solvents. Green Chem. 2019, 21, 4619–4624. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood–Plastic Composite Technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Gramlich, W.M.; Gardner, D.J.; Han, Y.; Tajvidi, M. Spray-Dried Cellulose Nanofibril-Reinforced Polypropylene Composites for Extrusion-Based Additive Manufacturing: Nonisothermal Crystallization Kinetics and Thermal Expansion. J. Compos. Sci. 2018, 2, 7. [Google Scholar] [CrossRef] [Green Version]

- Sanders, J.E.; Wang, L.; Gardner, D.J. Comparing mechanical properties of impact modified polypropylene-copolymer (IMPP) from injection molding (IM) and fused layer modeling (FLM) processes. Rapid Prototyping J. 2020, 26, 993–1003. [Google Scholar] [CrossRef]

- Wang, L.; Palmer, J.; Tajvidi, M.; Gardner, D.J.; Han, Y. Thermal properties of spray-dried cellulose nanofibril-reinforced polypropylene composites from extrusion-based additive manufacturing. J. Therm. Anal. Calorim. 2019, 136, 1069–1077. [Google Scholar] [CrossRef]

- Moreno Nieto, D.; Casal López, V.; Molina, S.I. Large-format polymeric pellet-based additive manufacturing for the naval industry. Addit. Manuf. 2018, 23, 79–85. [Google Scholar] [CrossRef]

- Zhou, Z.; Salaoru, I.; Morris, P.; Gibbons, G.J. Additive manufacturing of heat-sensitive polymer melt using a pellet-fed material extrusion. Addit. Manuf. 2018, 24, 552–559. [Google Scholar] [CrossRef] [Green Version]

- Li, T.Q.; Wolcott, M.P. Rheology of HDPE–wood composites. I. Steady state shear and extensional flow. Compos. Part A Appl. Sci. Manuf. 2004, 35, 303–311. [Google Scholar] [CrossRef]

- Thomasset, J.; Carreau, P.J.; Sanschagrin, B.; Ausias, G. Rheological properties of long glass fiber filled polypropylene. J. Non-Newton. Fluid. 2005, 125, 25–34. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Liu, R.W.; Sparks, T.; Liou, F. Large-Scale Deposition System by an Industrial Robot (I): Design of Fused Pellet Modeling System and Extrusion Process Analysis. 3D Print. Addit. Manuf. 2016, 3, 39–47. [Google Scholar] [CrossRef]

- Liu, X.J.; Chi, B.H.; Jiao, Z.W.; Tan, J.; Liu, F.F.; Yang, W.M. A large-scale double-stage-screw 3D printer for fused deposition of plastic pellets. J. Appl. Polym. Sci. 2017, 134, 45147. [Google Scholar] [CrossRef]

- Gardner, D.J.; Anderson, J.; Tekinalp, H.; Ozcan, S.; Sauerbier, P. Lignocellulosic-filled polymer feedstocks for large scale additive manufacturing of low cost composites. In Proceedings of the Internaional Forest Products Congress, Trabzon, Turkey, 26–29 September 2018; pp. 12–22. [Google Scholar]

- Spoerk, M.; Holzer, C.; Gonzalez-Gutierrez, J. Material extrusion-based additive manufacturing of polypropylene: A review on how to improve dimensional inaccuracy and warpage. J. Appl. Polym. Sci. 2020, 137, 48545. [Google Scholar] [CrossRef]

- Watanabe, N.; Shofner, M.L.; Rosen, D.W. Tensile Mechanical Properties of Polypropylene Composites Fabricated by Material Extrusion. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Spoerk, M.; Arbeiter, F.; Raguž, I.; Weingrill, G.; Fischinger, T.; Traxler, G.; Schuschnigg, S.; Cardon, L.; Holzer, C. Polypropylene Filled With Glass Spheres in Extrusion-Based Additive Manufacturing: Effect of Filler Size and Printing Chamber Temperature. Macromol. Mater. Eng. 2018, 303, 1800179. [Google Scholar] [CrossRef]

- Spoerk, M.; Gonzalez-Gutierrez, J.; Lichal, C.; Cajner, H.; Berger, G.R.; Schuschnigg, S.; Cardon, L.; Holzer, C. Optimisation of the Adhesion of Polypropylene-Based Materials during Extrusion-Based Additive Manufacturing. Polymers 2018, 10, 490. [Google Scholar] [CrossRef] [Green Version]

- Peng, F.; Jiang, H.; Woods, A.; Joo, P.; Amis, E.J.; Zacharia, N.S.; Vogt, B.D. 3D Printing with Core–Shell Filaments Containing High or Low Density Polyethylene Shells. ACS Appl. Polym. Mater. 2019, 1, 275–285. [Google Scholar] [CrossRef]

- Dong, J.; Mei, C.T.; Han, J.Q.; Lee, S.; Wu, Q.L. 3D printed poly(lactic acid) composites with grafted cellulose nanofibers: Effect of nanofiber and post-fabrication annealing treatment on composite flexural properties. Addit. Manuf. 2019, 28, 621–628. [Google Scholar] [CrossRef]

- Hart, K.R.; Dunn, R.M.; Sietins, J.M.; Mock, C.M.H.; Mackay, M.E.; Wetzel, E.D. Increased fracture toughness of additively manufactured amorphous thermoplastics via thermal annealing. Polymer 2018, 144, 192–204. [Google Scholar] [CrossRef]

- Landel, R.F.; Nielsen, L.E. Mechanial Properties of Polymers and Composites; CRC Press: Cleveland, OH, USA, 1993. [Google Scholar]

- Fornes, T.D.; Paul, D.R. Crystallization behavior of nylon 6 nanocomposites. Polymer 2003, 44, 3945–3961. [Google Scholar] [CrossRef]

- Northcutt, L.A.; Orski, S.V.; Migler, K.B.; Kotula, A.P. Effect of processing conditions on crystallization kinetics during materials extrusion additive manufacturing. Polymer 2018, 154, 182–187. [Google Scholar] [CrossRef] [PubMed]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of Porosity and Crystallinity on 3D Printed PLA Properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Gardner, D.J. Contribution of printing parameters to the interfacial strength of polylactic acid (PLA) in material extrusion additive manufacturing. Prog. Addit. Manuf. 2018, 3, 165–171. [Google Scholar] [CrossRef]

- Levenhagen, N.P.; Dadmun, M.D. Improving Interlayer Adhesion in 3D Printing with Surface Segregating Additives: Improving the Isotropy of Acrylonitrile-Butadiene-Styrene Parts. ACS Appl. Polym. Mater. 2019, 1, 876–884. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moon, K.-s.; Rumpf, R.C.; Kim, N.S. Thermo-mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 2015, 44, 771–777. [Google Scholar] [CrossRef]

- Wang, L.; Sanders, J.E.; Gardner, D.J.; Han, Y. Effect of fused deposition modeling process parameters on the mechanical properties of a filled polypropylene. Prog. Addit. Manuf. 2018, 3, 205–214. [Google Scholar] [CrossRef]

- Aliheidari, N.; Christ, J.; Tripuraneni, R.; Nadimpalli, S.; Ameli, A. Interlayer adhesion and fracture resistance of polymers printed through melt extrusion additive manufacturing process. Mater Design 2018, 156, 351–361. [Google Scholar] [CrossRef]

- Afrose, M.F.; Masood, S.H.; Nikzad, M.; Iovenitti, P. Effects of Build Orientations on Tensile Properties of PLA Material Processed by FDM. Adv. Mater. Res. 2014, 1044–1045, 31–34. [Google Scholar] [CrossRef]

- Kain, S.; Ecker, J.V.; Haider, A.; Musso, M.; Petutschnigg, A. Effects of the infill pattern on mechanical properties of fused layer modeling (FLM) 3D printed wood/polylactic acid (PLA) composites. European J. Wood Wood Prod. 2020, 78, 65–74. [Google Scholar] [CrossRef]

- Liu, Z.B.; Lei, Q.; Xing, S.Q. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Liu, H.; He, H.; Peng, X.D.; Huang, B.; Li, J.X. Three-dimensional printing of poly(lactic acid) bio-based composites with sugarcane bagasse fiber: Effect of printing orientation on tensile performance. Polym. Adv. Technol. 2019, 30, 910–922. [Google Scholar] [CrossRef]

- George, J.; Ishida, H. A review on the very high nanofiller-content nanocomposites: Their preparation methods and properties with high aspect ratio fillers. Prog. Polym. Sci. 2018, 86, 1–39. [Google Scholar] [CrossRef]

- Xu, X.; Liu, F.; Jiang, L.; Zhu, J.Y.; Haagenson, D.; Wiesenborn, D.P. Cellulose nanocrystals vs. cellulose nanofibrils: A comparative study on their microstructures and effects as polymer reinforcing agents. ACS Appl. Mater. Interfaces 2013, 5, 2999–3009. [Google Scholar] [CrossRef]

- Liu, D.G.; Chen, X.Y.; Yue, Y.Y.; Chen, M.D.; Wu, Q.L. Structure and rheology of nanocrystalline cellulose. Carbohydr. Polym. 2011, 84, 316–322. [Google Scholar] [CrossRef]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef]

- Zimmermann, T.; Pohler, E.; Geiger, T. Cellulose fibrils for polymer reinforcement. Adv. Eng. Mater. 2004, 6, 754–761. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Grigsby, W. From Nanocellulose to Wood Particles: A Review of Particle Size vs. the Properties of Plastic Composites Reinforced with Cellulose-based Entities. BioResources 2019, 15, 52. [Google Scholar] [CrossRef]

- Madyan, O.A.; Wang, Y.X.; Corker, J.; Zhou, Y.H.; Du, G.B.; Fan, M.Z. Classification of wood fibre geometry and its behaviour in wood poly(lactic acid) composites. Compos. Part A Appl. Sci. 2020, 133, 105871. [Google Scholar] [CrossRef]

- Bréchet, Y.; Cavaillé, J.Y.; Chabert, E.; Chazeau, L.; Dendievel, R.; Flandin, L.; Gauthier, C. Polymer Based Nanocomposites: Effect of Filler-Filler and Filler-Matrix Interactions. Adv. Eng. Mater. 2001, 3, 571–577. [Google Scholar] [CrossRef]

- Shah, J.; Snider, B.; Clarke, T.; Kozutsky, S.; Lacki, M.; Hosseini, A. Large-scale 3D printers for additive manufacturing: Design considerations and challenges. Int. J. Adv. Manuf. Technol. 2019, 104, 3679–3693. [Google Scholar] [CrossRef]

- Chesser, P.; Post, B.; Roschli, A.; Carnal, C.; Lind, R.; Borish, M.; Love, L. Extrusion control for high quality printing on Big Area Additive Manufacturing (BAAM) systems. Addit. Manuf. 2019, 28, 445–455. [Google Scholar] [CrossRef]

- Vijay, Y.; Sanandiya, N.D.; Dritsas, S.; Fernandez, J.G. Control of Process Settings for Large-Scale Additive Manufacturing With Sustainable Natural Composites. J. Mech. Des. 2019, 141. [Google Scholar] [CrossRef]

- Zhao, X.; Tekinalp, H.; Meng, X.; Ker, D.; Benson, B.; Pu, Y.; Ragauskas, A.J.; Wang, Y.; Li, K.; Webb, E.; et al. Poplar as Biofiber Reinforcement in Composites for Large-Scale 3D Printing. ACS Appl. Bio Mater. 2019, 2, 4557–4570. [Google Scholar] [CrossRef]

- Guo, R.; Ren, Z.; Bi, H.; Song, Y.; Xu, M. Effect of toughening agents on the properties of poplar wood flour/poly (lactic acid) composites fabricated with Fused Deposition Modeling. Eur. Polym. J. 2018, 107, 34–45. [Google Scholar] [CrossRef]

- Depuydt, D.; Balthazar, M.; Hendrickx, K.; Six, W.; Ferraris, E.; Desplentere, F.; Ivens, J.; Van Vuure, A.W. Production and characterization of bamboo and flax fiber reinforced polylactic acid filaments for fused deposition modeling (FDM). Polym. Compos. 2019, 40, 1951–1963. [Google Scholar] [CrossRef]

- Ajinjeru, C.; Kishore, V.; Chen, X.; Hershey, C.; Lindahl, J.; Kunc, V.; Hassen, A.A.; Duty, C. Rheological survey of carbon fiber-reinforced high-temperature thermoplastics for big area additive manufacturing tooling applications. J. Thermoplast. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Post, B.K.; Chesser, P.C.; Lind, R.F.; Roschli, A.; Love, L.J.; Gaul, K.T.; Sallas, M.; Blue, F.; Wu, S. Using Big Area Additive Manufacturing to directly manufacture a boat hull mould. Virtual Phy. Prototyp. 2019, 14, 123–129. [Google Scholar] [CrossRef]

| Additive Manufacturing Process | Primary Feedstock (Thermoplastic Matrix) | Wood/Lignocellulosic Component(s) | Other Additives |

|---|---|---|---|

| Extrusion-Based Fused Filament Fabrication Bioprinting | Thermoplastics (PLA, ABS, PP, nylon, polyurethane) Hydrogel material (collagen, carrageen) or nanocellulose in aqueous suspension | Wood flour, spray or freeze-dried cellulose nanofibers, microcrystalline cellulose, lignin | Pigments, coupling agents, lubricants, glass, carbon |

| Granular Material Binding Selective Laser Sintering Water Activation | Thermoplastics, Cementitious materials (Gypsum, Sodium silicate, Portland Cement) | Wood flour, Wood chips, lignin | Water |

| Liquid Deposition Modeling | Thermoplastic emulsion Resin | Sawdust, Wood Flour, methyl cellulose | Water |

| Filler Component | Particle Mesh Size | Particle Size (Microns) | Polymer | Loading Level (wt.%) | Additives/Filler Treatment | Printing Temperature (oC) | Nozzle Opening (mm) | Layer Thickness (mm) | Infill (Amount, Pattern) | Mechanical Testing f | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Osage Orange (Maclura pomifera) | 230 | ≤63 | PLA | 12.5 | Dried distillers’ grain a | 220 | 0.4 | 0.34 | 100% | T | [19] |

| Paulownia (Paulownia tomentosa) | |||||||||||

| Beech (Fagus sylvatica) | ~60 | ≤237 | PLA | 0–50 | Milled | 230 | 0.4 | 0.19 | 100% (Square) | R, FT | [38] |

| PVAc/UF (adhesives) | 7–87.5 | Milled | 3 | 2 | 85% | B | [29] | ||||

| European Softwood | ~200 | 75 (median) | UF | 13 | Hardener 2545 d | 21 | 1.6 | 2 | T, F | [30] | |

| Aspen (Populus sp) | 100 | 150 | TPU | 0–40 | PEG 6000, chitosan and MDIe | 185 | T, R | [39] | |||

| Cork (Quercus suber L.) | 27–733 | PLA | 0–50 | Tributyl citrate | 230 | 0.8 | 0.4 | 100% | T, I, DMA | [40] | |

| MDF Furniture Waste | ~200 | 80 | PLA | 10 to 40 (vol. frac.) | Milled | 185 | 0.5 | 0.15 | 25–100% | [37] | |

| Microcrystalline cellulose (MCC) | PP/PE | 0–10 | Silaneg | 190 | 1.75 | 0.2 | 100% | FT, DMA | [41]h | ||

| PLA | 1,3,5 | Titanate | 165–190 | 1.55i | 60% | FT, DMA | [20]h | ||||

| Cellulose Nanocrystals (CNC) | BTPEj | 0–60 | Polymer-grafted | 178 | 0.4 | 0.42 | 20%,100% | T, R | [42] | ||

| PVOH | 0–10 | MCC acid hydrolysis | 230 | 0.35 | 0.2 | 100% | T, DMA | [43] | |||

| Cellulose Nanofibrils (CNF) | PLA | 0–30 | 180–215 | 0.4 | 0.2 | 100% | T, DMA | [44] | |||

| PHB | 0–3 | 75 | 100% | T | [45] | ||||||

| PLA | 0–5 | Grafted with PLA | 165 | 1.75 | FT | [46]k | |||||

| Pine Kraft Lignin | PLA | 0–15 | 205 | 0.2–0.4 | 0.1 | 100% rectilinear | T, FT | [15] | |||

| Softwood Lignin | PLA | 0–40 | 205–230 | 0.4 | 100% | T | [47] | ||||

| Organosolv Lignin | Nylon 12 | 20–40 | Carbon fiber added | 210 | 0.5 | 2.5 | 100% | T, R, DMA | [24] | ||

| Organosolv Lignin Softwood Kraft | ABS, HIPS, Nylon 12 | 40–60 | Carbon fiber added | 210 | 0.5 | 2.5 | 100% | T, R, DMA | [23] |

| Polymer | Filler | Filler Amount (%) | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (GPa) | Ref. |

|---|---|---|---|---|---|---|

| PLA | Beech (Fagus sylvatica) | 0 10 20 30 40 50 | 55 ± 4.3 57 ± 1.1 49 ± 3.3 48 ± 5 42 ± 4.3 30 ± 4.4 | 3.27 ± 0.38 3.63 ± 0.5 3.94 ± 0.24 3.84 ± 0.55 3.86 ± 0.54 3.00 ± 0.56 | [38] | |

| Cork (Quercus suber L.) | 0 5 10 15 20 25 30 50 | 60.03 ± 2.34 38.3 ± 0.6 26.1 ± 0.5 21.9 ± 1.4 19.4 ± 2.7 17.2 ± 3.5 15.5 ± 2.5 10.4 ± 1.0 | 1.5 ± 0.01 0.8 ± 0.2 0.8 ± 0.2 0.6 ± 0.2 0.8 ± 0.2 0.6 ± 0.2 0.6 ± 0 0.2 ± 0 | 3.344 ± 0.0967 2.815 ± 0.127 2.111 ± 0.173 1.701 ± 0.167 1.455 ± 0.0731 1.375 ± 0.199 1.179 ± 0.234 0.985 ± 0.0743 | [40] | |

| Cellulose | 0 10 20 30 | 53.2 ± 0.3 64.8 ± 1.1 73.7 ±1.3 80.6 ± 0.9 | 2.97 ± 0.48 2.36 ± 0.31 1.94 ± 0.25 1.51 ± 0.16 | 3.19 ± 0.06 4.86 ± 0.23 6.01 ± 0.26 7.09 ± 0.41 | [44] | |

| nanofibrils (CNF) | 0 1 3 5 | 26.1 ± 7.8 28.3 ± 3.6 43.4 ± 1.8 34.4 ± 6.1 | 2.650 ± 0.0784 2.939 ± 0.168 3.407 ± 0.0995 3.076 ± 0.0958 | [46] | ||

| Pine Kraft lignin | 0 5 10 15 | 55.9 ± 0.6 50.3 ± 0.9 50.1 ± 0.5 41.3 ± 0.5 | 4.6 ± 0.22 2.8 ± 0.1 2.3 ± 0.17 1.9 ± 0.34 | 2.30 ± 0.04 2.33 ± 0.05 2.41 ± 0.06 2.39 ± 0.06 | [15] | |

| Softwood lignin | 0 20 40 | 58.45 ± 0.55 39.35 ± 1.05 45.65 ± 0.05 | 2.5 ± 0.1 1.8 ± 0.1 1.9 ± 0.08 | 2.89 ± 0.014 1.46 ± 0.156 2.695 ± 0.148 | [47] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lamm, M.E.; Wang, L.; Kishore, V.; Tekinalp, H.; Kunc, V.; Wang, J.; Gardner, D.J.; Ozcan, S. Material Extrusion Additive Manufacturing of Wood and Lignocellulosic Filled Composites. Polymers 2020, 12, 2115. https://doi.org/10.3390/polym12092115

Lamm ME, Wang L, Kishore V, Tekinalp H, Kunc V, Wang J, Gardner DJ, Ozcan S. Material Extrusion Additive Manufacturing of Wood and Lignocellulosic Filled Composites. Polymers. 2020; 12(9):2115. https://doi.org/10.3390/polym12092115

Chicago/Turabian StyleLamm, Meghan E., Lu Wang, Vidya Kishore, Halil Tekinalp, Vlastimil Kunc, Jinwu Wang, Douglas J. Gardner, and Soydan Ozcan. 2020. "Material Extrusion Additive Manufacturing of Wood and Lignocellulosic Filled Composites" Polymers 12, no. 9: 2115. https://doi.org/10.3390/polym12092115

APA StyleLamm, M. E., Wang, L., Kishore, V., Tekinalp, H., Kunc, V., Wang, J., Gardner, D. J., & Ozcan, S. (2020). Material Extrusion Additive Manufacturing of Wood and Lignocellulosic Filled Composites. Polymers, 12(9), 2115. https://doi.org/10.3390/polym12092115