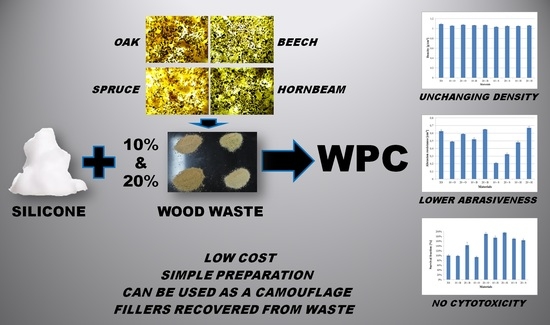

The Impact of Wood Waste on the Properties of Silicone-Based Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methodology

2.2.1. Composites

2.2.2. Density Testing by Hydrostatic Weighing

- dH20—density of water (g/cm3),

- m1—dry sample mass (g),

- m2—wet sample mass (g).

2.2.3. Rebound Resilience with Schober’s Test

2.2.4. Abrasion Resistance Tests

- m1—mass of sample before abrasion (g),

- m2—sample mass after abrasion (g),

- d—sample density (g/cm3).

2.2.5. Hardness Test

2.2.6. Tensile Test

2.2.7. Cytotoxicity Testing of Composite Samples

2.2.8. Ageing in Seawater Conditions

3. Results and Discussion

3.1. Characteristics of Fillers

3.2. Density Test Results

3.3. Rebound Resilience Results

3.4. Abrasion Resistance Results

3.5. Shore A Hardness Test

3.6. Tensile Test Results

3.7. Cytotoxicity Test Results

3.8. Possibly of Using WPC on the Seabed

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ashori, A. Wood–plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Klyosov, A.A. Wood—Plastic Composites, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007; pp. 15–37. [Google Scholar]

- Clemons, C. Wood-plastic composites in the United States: The interfacing of two industries. Forest Prod. J. 2002, 52, 10–18. [Google Scholar]

- Pritchard, G. Two technologies merge: Wood plastic composites. Plast. Addit. Compd. 2004, 6, 18–21. [Google Scholar] [CrossRef]

- Cui, Y.; Lee, S.; Noruziaan, B.; Cheung, M.; Tao, J. Fabrication and interfacial modification of wood/recycled plastic composite materials. Compos. Part A Appl. Sci. Manuf. 2008, 39, 655–661. [Google Scholar] [CrossRef]

- Najafi, S.K. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef]

- Rowell, R.M. Acetylation of wood: A journey from analytical technique to commercial reality. For. Prod. J. 2006, 56, 4–12. [Google Scholar]

- Rowell, R.M.; Ibach, R.E.; McSweeny, J.; Nilsson, T. Understanding decay resistance, dimensional stability and strength changes in heat-treated and acetylated wood. Wood Mater. Sci. Eng. 2009, 1–2, 14–22. [Google Scholar] [CrossRef]

- Lahtela, V.; Kärki, T. Effects of impregnation and heat treatment on the physical and mechanical properties of Scots pine (Pinus sylvestris) wood. Wood Mater. Sci. Eng. 2014, 11, 217–227. [Google Scholar] [CrossRef]

- Nuopponen, M.; Vuorien, T.; Jamsa, S.; Viitaniemi, P. The effects of a heat treatment on the behaviour of extractives in softwood studied by FTIR spectroscopic methods. Wood Sci. Technol. 2003, 37, 109–115. [Google Scholar] [CrossRef]

- Stark, N.M.; Rowlands, R.E. Effect of wood fiber characteristics on mechanical properties of wood/polypropylene composites. Wood Fiber Sci. 2003, 35, 167–174. [Google Scholar]

- Winandy, J.E.; Stark, N.M.; Clemons, C.M. Considerations in recycling of wood-plastic composites. In Proceedings of the 5th Global Wood and Natural Fibre Composites Symposium, Kassel, Germany, 27–28 April 2004. [Google Scholar]

- Beter, J.; Schrittesser, B.; Lechner, B.; Reza Mansouri, M.; Marano, C.; Fuchs, P.F.; Pinter, G.; Beter, J.; Schrittesser, B.; Lechner, B.; et al. Viscoelastic Behavior of Glass-Fiber-Reinforced Silicone Composites Exposed to Cyclic Loading. Polymers 2020, 12, 1862. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Wang, Z.; Zhang, X.; Deng, Z.; Fan, X.; Zhang, G. High Moisture Accelerated Mechanical Behavior Degradation of Phosphor/Silicone Composites Used in White Light-Emitting Diodes. Polymers 2019, 11, 1277. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, J.; Huang, Z.; Qin, Y.; Wang, H.; Shi, M. Effects of Zirconium Silicide on the Vulcanization, Mechanical and Ablation Resistance Properties of Ceramifiable Silicone Rubber Composites. Polymers 2020, 12, 496. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Imiela, M.; Anyszka, R.; Bieliński, D.M.; Pędzich, Z.; Zarzecka-Napierała, M.; Szumera, M. Effect of carbon fibers on thermal properties and mechanical strength of ceramizable composites based on silicone rubber. J. Therm. Anal. Calorim. 2016, 124, 197–203. [Google Scholar] [CrossRef] [Green Version]

- Song, P.; Peng, Z.-J.; Yue, Y.-L.; Zhang, H.; Zhang, Z.; Fan, Y.-C. Mechanical properties of silicone composites reinforced withmicron- and nano-sized magnetic particles. eXPRESS Polym. Lett. 2013, 7, 546–553. [Google Scholar] [CrossRef]

- Jin, H.; Bing, W.; Tian, L.; Wang, P.; Zhao, J. Combined Effects of Color and Elastic Modulus on Antifouling Performance: A Study of Graphene Oxide/Silicone Rubber Composite Membranes. Materials 2019, 12, 2608. [Google Scholar] [CrossRef] [Green Version]

- XIAMETER®RTV-4234-T4 Base and XIAMETER®T4/T4 OCuring Agent. Available online: https://www.notcutt.co.uk/wp-content/uploads/2014/06/rtv-4234-t4-base-t4-t4-0-cat-sales-lit.pdf (accessed on 10 December 2020).

- Bruechert, F.; Becker, G.; Speek, T. The mechanics of Norway spruce [Piceaabies]: Mechanical properties of standing trees from different thinning regimes. For. Ecol. Manag. 2000, 35, 45–62. [Google Scholar] [CrossRef]

- Kelley, S.S.; Rials, T.G.; Snell, R.; Groom, L.H.; Sluiter, A. Use of near infrared spectroscopy to measure the chemical and mechanical properties of solid wood. Wood Sci. Technol. 2004, 38, 257–276. [Google Scholar] [CrossRef]

- Plomion, C.; Leprovost, G.; Stokes, A. Wood Formation in Trees. Plant Physiol. 2001, 127, 1513–1527. [Google Scholar] [CrossRef]

- Wessels, C.B.; Malan, F.S.; Rypstra, T. A review of measurement methods used on standing trees for the prediction of some mechanical properties of timber. Eur. J. For. Res. 2011, 130, 881–893. [Google Scholar] [CrossRef]

- EN ISO. 1183-1: 2006 Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pyknometer Method and Titration Method; International Organization of Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. 4662:2017 Rubber, Vulcanized or Thermoplastic—Determination of Rebound Resilience; Springer: Cham, Switzerland, 2017. [Google Scholar]

- EN ISO. 4649:2007 Rubber, Vulcanized or Thermoplastic—Determination of Abrasion Resistance Using a Rotating Cylindrical Drum Device; International Organization of Standardization: Geneva, Switzerland, 2007. [Google Scholar]

- EN ISO. 7619-1:2010 Rubber, Vulcanized or Thermoplastic—Determination of Indentation Hardness—Part 1: Durometer Method (Shore Hardness); International Organization of Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- EN ISO. 527-1:2012 Plastics—Determination of Tensile Properties—Part 1: General Principles; International Organization of Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- Mrówka, M.; Jaszcz, K.; Skonieczna, M. Anticancer activity of functional polysuccinates with N-acetyl-cysteine in side chains. Eur. J. Pharmacol. 2020, 885, 173501. [Google Scholar] [CrossRef] [PubMed]

- Mrówka, M.; Szymiczek, M.; Machoczek, T.; Lenża, J.; Matusik, J.; Sakiewicz, P.; Skonieczna, M. The influence of halloysite on the physicochemical, mechanical and biological properties of polyurethane-based nanocomposites. Polimery 2020, 65, 784–791. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Practice for the Preparation of Substitute Ocean Water; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Skonieczna, M.; Hudy, D.; Hejmo, T.; Buldak, R.J.; Adamiec, M.; Kukla, M. The adipokine vaspin reduces apoptosis in human hepatocellular carcinoma (Hep-3B) cells, associated with lower levels of NO and superoxide anion. BMC Pharmacol. Toxicol. 2019, 20, 58. [Google Scholar] [CrossRef] [PubMed]

- Adamiec, M.; Skonieczna, M. UV radiation in HCT 116 cells influences intracellular H2O2 and glutathione levels, antioxidant expression, and protein glutathionylation. Acta Biochim. Pol. 2019, 66, 605–610. [Google Scholar] [CrossRef]

- Altmann, S.; Choroba, K.; Skonieczna, M.; Zygadło, D.; Raczyńska-Szajgin, M.; Maroń, A.; Małecki, J.G.; Szłapa-Kula, A.; Tomczyk, M.; Ratuszna, A.; et al. Platinum(II) coordination compounds with 4′-pyridyl functionalized 2,2′:6′,2″-terpyridines as an alternative to enhanced chemotherapy efficacy and reduced side-effects. J. Inorg. Biochem. 2019, 201, 110809. [Google Scholar] [CrossRef]

| Properties | Unit | Value |

|---|---|---|

| Ratio mixing A:B | 10:1 | |

| Density | (g/cm3) | 1.1 |

| Viscosity | (mPas) | 35,000 |

| Hardness | (ShA) | 40 |

| Linear shrinkage | (%) | <0.1 |

| Tensile strength | (MPa) | 6.7 |

| Tensile strain | (%) | 400 |

| Properties | Oak | Beech | Spruce | Hornbeam |

|---|---|---|---|---|

| After drying density (kg/m3) | 900–1150 | 820–1270 | 700–850 | 660–1200 |

| Flexural strength (MPa) | 74–105 | 74–210 | 49–136 | 58–200 |

| Flexural modulus (GPa) | 10–13.5 | 10–18 | 7.3–21.4 | 7–17.7 |

| Compressive strength (MPa) | 48 | 41–99 | 30–79 | 54–99 |

| Tensile strength (MPa) | 50–180 | 55–180 | 21–245 | 24 |

| Impact strength (J/cm2) | 1–16 | 3–19 | 1–11 | 8–12 |

| Brinell’s hardness (HBW) | 34 | 34 | 12 | 29–36 |

| Name | Base | Filler | Filler Content (%) |

|---|---|---|---|

| XS | XIAMETER 4234 - T4 | - | - |

| 10 - O | oak | 10 | |

| 20 - O | oak | 20 | |

| 10 - B | beech | 10 | |

| 20 - B | beech | 20 | |

| 10 - S | spruce | 10 | |

| 20 - S | spruce | 20 | |

| 10 - H | hornbeam | 10 | |

| 20 - H | hornbeam | 20 |

| Ingredients | Concentration (g/L) |

|---|---|

| Sodium chloride (NaCl) | 24.53 |

| Magnesium chloride (MgCl2) | 5.2 |

| Sodium sulfate (Na2SO4) | 4 |

| Calcium chloride (CaCl2) | 1.16 |

| Potassium chloride (KCl) | 0.695 |

| Sodium bicarbonate (NaHCO3) | 0.201 |

| Potassiumbromide (KBr) | 0.101 |

| Boric acid (H3BO3) | 0.027 |

| Strontium chloride (SrCl2) | 0.025 |

| Sodium fluoride (NaF) | 0.003 |

| Wood Filler | 10% | 20% |

|---|---|---|

| oak |  |  |

| beech |  |  |

| spruce |  |  |

| hornbeam |  |  |

| Własność | Wc | XS | 10-O | 20-O | 10-B | 20-B | 10-S | 20-S | 10-H | 20-H | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E | R | E | R | E | R | E | R | E | R | E | R | E | R | E | R | E | R | ||||

| Density | 1 | 5 | 5 | 3 | 3 | 4 | 4 | 5 | 5 | 4 | 4 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | ||

| 3 | 3 | ||||||||||||||||||||

| Resilience | 4 | 1 | 4 | 2 | 8 | 3 | 12 | 5 | 3 | 5 | 20 | 5 | 20 | 4 | 16 | 4 | 16 | 3 | 12 | ||

| Abrasion resistance results | 6 | 1 | 6 | 4 | 24 | 3 | 18 | 3 | 18 | 2 | 12 | 5 | 30 | 5 | 30 | 4 | 24 | 2 | 12 | ||

| Hardness | 3 | 1 | 3 | 2 | 6 | 2 | 6 | 4 | 12 | 3 | 9 | 5 | 15 | 5 | 15 | 3 | 9 | 4 | 12 | ||

| Strain at break | 2 | 5 | 10 | 3 | 6 | 3 | 6 | 4 | 8 | 2 | 4 | 2 | 4 | 2 | 4 | 1 | 2 | 4 | 8 | ||

| Stress at break | 5 | 5 | 25 | 3 | 15 | 4 | 20 | 4 | 20 | 3 | 15 | 1 | 5 | 1 | 5 | 2 | 10 | 2 | 10 | ||

| Suma | 53 | 62 | 66 | 66 | 64 | 76 | 73 | 65 | 59 | ||||||||||||

| 51 | |||||||||||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mrówka, M.; Szymiczek, M.; Skonieczna, M. The Impact of Wood Waste on the Properties of Silicone-Based Composites. Polymers 2021, 13, 7. https://doi.org/10.3390/polym13010007

Mrówka M, Szymiczek M, Skonieczna M. The Impact of Wood Waste on the Properties of Silicone-Based Composites. Polymers. 2021; 13(1):7. https://doi.org/10.3390/polym13010007

Chicago/Turabian StyleMrówka, Maciej, Małgorzata Szymiczek, and Magdalena Skonieczna. 2021. "The Impact of Wood Waste on the Properties of Silicone-Based Composites" Polymers 13, no. 1: 7. https://doi.org/10.3390/polym13010007

APA StyleMrówka, M., Szymiczek, M., & Skonieczna, M. (2021). The Impact of Wood Waste on the Properties of Silicone-Based Composites. Polymers, 13(1), 7. https://doi.org/10.3390/polym13010007