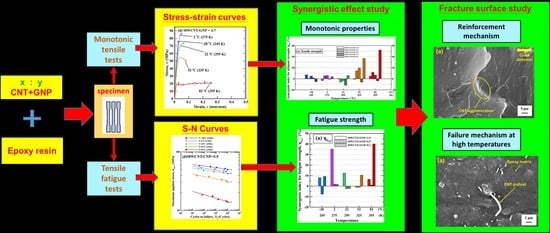

Temperature-Dependent Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets on the Tensile Quasi-Static and Fatigue Properties of Epoxy Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Specimen Preparation

2.2. Experimental Methods

3. Results and Discussion

Temperature-Dependent Monotonic Property

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rana, S.; Alagirusamy, R.; Joshi, M. A review on carbon epoxy nanocomposites. J. Reinf. Plast. Compos. 2009, 28, 461–487. [Google Scholar] [CrossRef]

- Saravanan, N.; Rajasekar, R.; Mahalakshmi, S.; Sathishkumar, T.P.; Sasikumar, K.S.; Sahoo, S. Graphene and modified graphene-based polymer nanocomposites—A review. J. Reinf. Plast. Compos. 2014, 33, 1158–1170. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 25, 11–25. [Google Scholar] [CrossRef]

- Singh, N.P.; Gupta, V.K.; Singh, A.P. Graphene and carbon nanotube reinforced epoxy nanocomposites: A review. Polymer 2019, 180, 121724. [Google Scholar] [CrossRef]

- Atif, R.; Inam, F. Reasons and remedies for the agglomeration of multilayered graphene and carbon nanotubes in polymers. Beilstein J. Nanotechnol. 2016, 7, 1174–1196. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y.; Hui, D. Influences of nanoparticles aggregation/agglomeration on the interfacial/interphase and tensile properties of nanocomposites. Compos. Part B-Eng. 2017, 122, 41–46. [Google Scholar] [CrossRef]

- Maghsoudlou, M.A.; Isfahani, R.B.; Saber-Samandari, S.; Sadighi, M. Effect of interphase, curvature and agglomeration of SWCNTs on mechanical properties of polymer-based nanocomposites: Experimental and numerical investigations. Compos. Part B-Eng. 2019, 175, 107119. [Google Scholar] [CrossRef]

- Marouf, B.T.; Mai, Y.W.; Bagheri, R.; Pearson, R.A. Toughening of epoxy nanocomposites: Nano and hybrid effects. Polym. Rev. 2016, 56, 70–112. [Google Scholar] [CrossRef]

- Chao, H.; Riggleman, R.A. Effect of particle size and grafting density on the mechanical properties of polymer nanocomposites. Polymer 2013, 54, 5222–5229. [Google Scholar] [CrossRef]

- Roy, S.; Sohail, T.; Bodiuzzaman, J. Effect of nanoparticle size on fracture behavior in polymer nanocomposites. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 2257. [Google Scholar]

- Shukla, M.K.; Sharma, K. Effect of carbon nanofillers on the mechanical and interfacial properties of epoxy based nanocomposites: A review. Polym. Sci. Ser. A 2019, 61, 439–460. [Google Scholar] [CrossRef]

- Steurer, P.; Wissert, R.; Thomann, R.; Mülhaupt, R. Functionalized graphenes and thermoplastic nanocomposites based upon expanded graphite oxide. Macromol. Rapid Commun. 2009, 30, 316–327. [Google Scholar] [CrossRef] [PubMed]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.Z.; Koratkar, N. Enhanced mechanical properties of nanocomposites at low graphene content. ACS Nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Rafiee, M.A.; Rafiee, J.; Srivastava, I.; Wang, Z.; Song, H.; Yu, Z.Z.; Koratkar, N. Fracture and fatigue in graphene nanocomposites. Small 2010, 6, 179–183. [Google Scholar] [CrossRef] [PubMed]

- Nadiv, R.; Shachar, G.; Peretz-Damari, S.; Varenik, M.; Levy, I.; Buzaglo, M.; Ruse, E.; Regev, O. Performance of nano-carbon loaded polymer composites: Dimensionality matters. Carbon 2018, 126, 410–418. [Google Scholar] [CrossRef]

- Nguyen, D.D.; Tai, N.H.; Chen, S.Y.; Chueh, Y.L. Controlled growth of carbon nanotube-graphene hybrid materials for flexible and transparent conductors and electron field emitters. Nanoscale 2012, 4, 632–638. [Google Scholar] [CrossRef]

- Yu, D.; Dai, L. Self-Assembled graphene/carbon nanotube hybrid films for supercapacitors. J. Phys. Chem. Lett. 2010, 1, 467–470. [Google Scholar] [CrossRef]

- Rong, M.Z.; Zhang, M.Q.; Ruan, W.H. Surface modification of nanoscale fillers for improving properties of polymer nanocomposites: A review. Mater. Sci. Technol. 2006, 22, 787–796. [Google Scholar] [CrossRef]

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A-Appl. S. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Loos, M.; Yang, J.; Feke, D.; Manas-Zloczower, I. Effect of block-copolymer dispersants on properties of carbon nanotube/epoxy systems. Compos. Sci. Technol. 2012, 72, 482–488. [Google Scholar] [CrossRef]

- Gkikas, G.; Barkoula, N.M.; Paipetis, A.S. Effect of dispersion conditions on the thermo-mechanical and toughness properties of multi walled carbon nanotubes-reinforced epoxy. Compos. Part B-Eng. 2012, 43, 2697–2705. [Google Scholar] [CrossRef]

- Ji, X.; Xu, Y.; Zhang, W.; Cui, L.; Liu, J. Review of functionalization, structure and properties of graphene/polymer composite fibers. Compos. Part A-Appl. S. Manuf. 2016, 87, 29–45. [Google Scholar] [CrossRef]

- Prasad, K.E.; Das, B.; Maitra, U.; Ramamurty, U.; Rao, C.N.R. Extraordinary synergy in the mechanical properties of polymer matrix composites reinforced with 2 nanocarbons. Proc. Natl. Acad. Sci. USA 2009, 106, 13186–13189. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, S.Y.; Lin, W.N.; Huang, Y.L.; Tien, H.W.; Wang, J.Y.; Ma, C.C.; Li, S.M.; Wang, Y.S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Al-Saleh, M.H. Electrical and mechanical properties of graphene/carbon nanotube hybrid nanocomposites. Synth. Met. 2015, 209, 41–46. [Google Scholar] [CrossRef]

- Ghaleb, Z.; Mariatti, M.; Ariff, Z. Synergy effects of graphene and multiwalled carbon nanotubes hybrid system on properties of epoxy nanocomposites. J. Reinf. Plast. Compos. 2017, 36, 685–695. [Google Scholar] [CrossRef]

- Szeluga, U.; Kumanek, B.; Trzebicka, B. Synergy in hybrid polymer/nanocarbon composites. A review. Compos. Part A-Appl. S. Manuf. 2015, 73, 204–231. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review of the mechanical and thermal properties of graphene and its hybrid polymer nanocomposites for structural applications. J. Mater. Sci. 2019, 54, 5992–6026. [Google Scholar] [CrossRef]

- Njuguna, J.; Pielichowski, K.; Alcock, J.R. Epoxy-based fibre reinforced nanocomposites. Adv. Eng. Mater. 2007, 9, 835–847. [Google Scholar]

- Prolongo, S.; Gude, M.; Ureña, A. Nanoreinforced Adhesives; IntechOpen: London, UK, 2010; Available online: http://www.intechopen.com/books/nanofibers/nanoreinforced-adhesives (accessed on 5 November 2020).

- Ren, P.G.; Di, Y.Y.; Zhang, Q.; Li, L.; Pang, H.; Li, Z.M. Composites of ultrahigh-molecular-weight polyethylene with graphene sheets and/or MWCNTs with segregated network structure: Preparation and properties. Macromol. Mater. Eng. 2012, 297, 437–443. [Google Scholar] [CrossRef]

- Li, W.; Dichiara, A.; Bai, J. Carbon nanotube–graphene nanoplatelet hybrids as high-performance multifunctional reinforcements in epoxy composites. Compos. Sci. Technol. 2013, 74, 221–227. [Google Scholar] [CrossRef]

- Zhang, S.; Yin, S.; Rong, C.; Huo, P.; Jiang, Z.; Wang, G. Synergistic effects of functionalized graphene and functionalized multi-walled carbon nanotubes on the electrical and mechanical properties of poly (ether sulfone) composites. Eur. Polym. J. 2013, 49, 3125–3134. [Google Scholar] [CrossRef]

- Pradhan, B.; Srivastava, S.K. Synergistic effect of three-dimensional multi-walled carbon nanotube–graphene nanofiller in enhancing the mechanical and thermal properties of high-performance silicone rubber. Polym. Int. 2014, 63, 1219–1228. [Google Scholar] [CrossRef]

- Montes, S.; Carrasco, P.M.; Ruiz, V.; Cabañero, G.; Grande, H.J.; Labidi, J.; Odriozola, I. Synergistic reinforcement of poly(vinyl alcohol) nanocomposites with cellulose nanocrystal-stabilized graphene. Compos. Sci. Technol. 2015, 117, 26–31. [Google Scholar] [CrossRef]

- Li, C.; Li, Y.; She, X.; Vongsvivut, J.; Li, J.; She, F.; Gao, W.; Kong, L. Reinforcement and deformation behaviors of polyvinyl alcohol/graphene/montmorillonite clay composites. Compos. Sci. Technol. 2015, 118, 1–8. [Google Scholar] [CrossRef]

- Cui, X.; Ding, P.; Zhuang, N.; Shi, L.; Song, N.; Tang, S. Thermal conductive and mechanical properties of polymeric composites based on solution-exfoliated boron nitride and graphene nanosheets: A morphology-promoted synergistic effect. ACS Appl. Mater. Interfaces 2015, 7, 19068–19075. [Google Scholar] [CrossRef]

- Moosa, A.A.; Sa, A.R.; Ibrahim, M.N. Mechanical and electrical properties of graphene nanoplates and carbon nanotubes hybrid epoxy nanocomposites. Am. J. Mater. Sci. 2016, 6, 157–165. [Google Scholar]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Enhancement of fracture toughness, mechanical and thermal properties of rubber/epoxy composites by incorporation of graphene nanoplatelets. Compos. Part A-Appl. S. Manuf. 2016, 87, 10–22. [Google Scholar] [CrossRef]

- Wang, J.; Jin, X.; Wu, H.; Guo, S. Polyimide reinforced with hybrid graphene oxide@ carbon nanotube: Toward high strength, toughness, electrical conductivity. Carbon 2017, 123, 502–513. [Google Scholar] [CrossRef]

- Sahu, S.K.; Badgayan, N.D.; Samanta, S.; Sreekanth, P.R. Quasistatic and dynamic nanomechanical properties of HDPE reinforced with 0/1/2 dimensional carbon nanofillers based hybrid nanocomposite using nanoindentation. Mater. Chem. Phys. 2018, 203, 173–184. [Google Scholar] [CrossRef]

- Ribeiro, H.; Trigueiro, J.P.; Owuor, P.S.; Machado, L.D.; Woellner, C.F.; Pedrotti, J.J.; Jaques, Y.M.; Kosolwattana, S.; Chipara, A.; Silva, W.M.; et al. Hybrid 2D nanostructures for mechanical reinforcement and thermal conductivity enhancement in polymer composites. Compos. Sci. Technol. 2018, 159, 103–110. [Google Scholar] [CrossRef]

- Min, C.; Liu, D.; Shen, C.; Zhang, Q.; Song, H.; Li, S.; Shen, X.; Zhu, M.; Zhang, K. Unique synergistic effects of graphene oxide and carbon nanotube hybrids on the tribological properties of polyimide nanocomposites. Tribol. Int. 2018, 117, 217–224. [Google Scholar] [CrossRef]

- Shukla, M.K.; Sharma, K. Effect of functionalized graphene/CNT ratio on the synergetic enhancement of mechanical and thermal properties of epoxy hybrid composite. Mater. Res. Express 2019, 6, 085318. [Google Scholar] [CrossRef]

- Wang, E.; Dong, Y.; Islam, M.Z.; Yu, L.; Liu, F.; Chen, S.; Qi, X.; Zhu, Y.; Fu, Y.; Xu, Z.; et al. Effect of graphene oxide-carbon nanotube hybrid filler on the mechanical property and thermal response speed of shape memory epoxy composites. Compos. Sci. Technol. 2019, 169, 209–216. [Google Scholar] [CrossRef]

- Li, J.; Wong, P.S.; Kim, J.K. Hybrid nanocomposites containing carbon nanotubes and graphite nanoplatelets. Mater. Sci. Eng. A 2008, 483, 660–663. [Google Scholar] [CrossRef] [Green Version]

- Chatterjee, S.; Nafezarefi, F.; Tai, N.; Schlagenhauf, L.; Nüesch, F.; Chu, B. Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon 2012, 50, 5380–5386. [Google Scholar] [CrossRef]

- Kumar, S.; Sun, L.L.; Caceres, S.; Li, B.; Wood, W.; Perugini, A.; Maguire, R.G.; Zhong, W.H. Dynamic synergy of graphitic nanoplatelets and multi-walled carbon nanotubes in polyetherimide nanocomposites. Nanotechnology 2010, 21, 105702. [Google Scholar] [CrossRef]

- Das, A.; Kasaliwal, G.R.; Jurk, R.; Boldt, R.; Fischer, D.; Stöckelhuber, K.W.; Heinrich, G. Rubber composites based on graphene nanoplatelets, expanded graphite, carbon nanotubes and their combination: A comparative study. Compos. Sci. Technol. 2012, 72, 1961–1967. [Google Scholar] [CrossRef]

- Jen, Y.M.; Huang, J.C.; Zheng, K.Y. Synergistic effect of multi-walled carbon nanotubes and graphene nanoplatelets on the monotonic and fatigue properties of uncracked and cracked epoxy Composites. Polymers 2020, 12, 1895. [Google Scholar] [CrossRef]

- Yuan, Q.; Misra, R.D.K. Impact fracture behavior of clay–reinforced polypropylene nanocomposites. Polymer 2006, 47, 4421–4433. [Google Scholar] [CrossRef]

- Wang, J.; Severtson, S.J.; Geil, P.H. Brittle–ductile transitions and the toughening mechanism in paraffin/organo-clay nanocomposites. Mater. Sci. Eng. A 2007, 467, 172–180. [Google Scholar] [CrossRef]

- Ha, S.R.; Rhee, K.Y.; Park, S.J.; Lee, J.H. Temperature effects on the fracture behavior and tensile properties of silane-treated clay/epoxy nanocomposites. Compos. Part B-Eng. 2010, 41, 602–607. [Google Scholar] [CrossRef]

- Bao, S.P.; Tjong, S.C. Mechanical behaviors of polypropylene/carbon nanotube nanocomposites: The effects of loading rate and temperature. Mater. Sci. Eng. A 2008, 485, 508–516. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Campo, M.; Gude, M.R.; Chaos-Morán, R.; Ureña, A. Thermo-physical characterisation of epoxy resin reinforced by amino-functionalized carbon nanofibers. Compos. Sci. Technol. 2009, 69, 349–357. [Google Scholar] [CrossRef]

- Chen, Z.K.; Yang, J.P.; Ni, Q.Q.; Fu, S.Y.; Huang, Y.G. Reinforcement of epoxy resins with multi-walled carbon nanotubes for enhancing cryogenic mechanical properties. Polymer 2009, 50, 4753–4759. [Google Scholar] [CrossRef]

- Gkikas, G.; Douka, D.D.; Barkoula, N.M.; Paipetis, A.S. Nano-enhanced composite materials under thermal shock and environmental degradation: A durability study. Compos. Part B-Eng. 2015, 70, 206–214. [Google Scholar] [CrossRef]

- Rathore, D.K.; Singh, B.P.; Mohanty, S.C.; Prusty, R.K.; Ray, B.C. Temperature dependent reinforcement efficiency of carbon nanotube in polymer composite. Compos. Commun. 2016, 1, 29–32. [Google Scholar] [CrossRef]

- Rathore, D.K.; Prusty, R.K.; Ray, B.C. Mechanical, thermomechanical, and creep performance of CNT embedded epoxy at elevated temperatures: An emphasis on the role of carboxyl functionalization. J. Appl. Polym. Sci. 2017, 134, 44851. [Google Scholar] [CrossRef]

- Prusty, R.K.; Rathore, D.K.; Sahoo, S.; Parida, V.; Ray, B.C. Mechanical behaviour of graphene oxide embedded epoxy nanocomposite at sub-and above-zero temperature environments. Compos. Commun. 2017, 3, 47–50. [Google Scholar] [CrossRef]

- Jen, Y.M.; Huang, C.Y. Effect of temperature on fatigue strength of carbon nanotube/epoxy composites. J. Compos. Mater. 2014, 48, 3469–3483. [Google Scholar] [CrossRef]

- ASTM International. Standard Test. Method for Tensile Properties of Plastics; D638-14; ASTM International: West Conshohocken, PA, USA, 2014; Available online: https://www.astm.org/Standards/D638.htm (accessed on 5 December 2020).

- ASTM International. Standard Test Method for Uniaxial Fatigue Properties of Plastics; D7791-17; ASTM International: West Conshohocken, PA, USA, 2017; Available online: https://www.astm.org/Standards/D7791.htm (accessed on 5 December 2020).

- Zhou, Y.; Jeelani, M.I.; Jeelani, S. Development of photo micro-graph method to characterize dispersion of CNT in epoxy. Mater. Sci. Eng. A 2009, 506, 39–44. [Google Scholar] [CrossRef]

- Samal, S.S. Role of temperature and carbon nanotube reinforcement on epoxy based nanocomposites. J. Miner. Mater. Charact. Eng. 2009, 8, 25–36. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Seidel, C.; Schulte, K. Preparation and characterization of graphite nano-platelet (GNP)/epoxy nano-composite: Mechanical, electrical and thermal properties. Eur. Polym. J. 2013, 49, 3878–3888. [Google Scholar] [CrossRef]

- Alexopoulos, N.D.; Paragkamian, Z.; Poulin, P.; Kourkoulis, S.K. Fracture related mechanical properties of low and high graphene reinforcement of epoxy nanocomposites. Compos. Sci. Technol. 2017, 150, 194–204. [Google Scholar] [CrossRef]

- Mefford, C.H.; Qiao, Y.; Salviato, M. Failure behavior and scaling of graphene nanocomposites. Compos. Struct. 2017, 176, 961–972. [Google Scholar] [CrossRef] [Green Version]

- Bortz, D.R.; Heras, E.G.; Martin-Gullon, I. Impressive Fatigue Life and Fracture Toughness Improvements in Graphene Oxide/Epoxy Composites. Macromolecules 2013, 45, 238–245. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Sato, N.; Tölle, F.; Mülhaupt, R.; Fiedler, B.; Schulte, K. Fracture toughness and failure mechanism of graphene based epoxy composites. Compos. Sci. Technol. 2014, 97, 90–99. [Google Scholar] [CrossRef]

- Park, Y.T.; Qian, Y.; Chan, C.; Suh, T.; Nejhad, M.G.; Macosko, C.W.; Stein, A. Epoxy toughening with low graphene loading. Adv. Funct. Mater. 2015, 25, 575–585. [Google Scholar] [CrossRef]

- Kostagiannakopoulou, C.; Tsilimigkra, X.; Sotiriadis, G.; Kostopoulos, V. Synergy effect of carbon nano-fillers on the fracture toughness of structural composites. Compos. Part. B-Eng. 2017, 129, 18–25. [Google Scholar] [CrossRef]

- Qi, Z.; Tan, Y.; Zhang, Z.; Gao, L.; Zhang, C.; Tian, J. Synergistic effect of functionalized graphene oxide and carbon nanotube hybrids on mechanical properties of epoxy composites. RSC Adv. 2018, 8, 38689–38700. [Google Scholar] [CrossRef] [Green Version]

- Cha, J.; Kim, J.; Ryu, S.; Hong, S.H. Comparison to mechanical properties of epoxy nanocomposites reinforced by functionalized carbon nanotubes and graphene nanoplatelets. Compos. Part. B-Eng. 2019, 162, 283–288. [Google Scholar] [CrossRef]

- Cha, J.; Jun, G.H.; Park, J.K.; Kim, J.C.; Ryu, H.J.; Hong, S.H. Improvement of modulus, strength and fracture toughness of CNT/Epoxy nanocomposites through the functionalization of carbon nanotubes. Compos. Part B-Eng. 2017, 129, 169–179. [Google Scholar] [CrossRef]

- Zhang, W.; Srivastava, I.; Zhu, Y.F.; Picu, C.R.; Koratkar, N.A. Heterogeneity in epoxy nanocomposites initiates crazing: Significant improvements in fatigue resistance and toughening. Small 2009, 5, 1403–1407. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Li, S.; Roy, S.; King, J.A.; Odegard, G.M. Fracture properties of nanographene reinforced EPON 862 thermoset polymer system. Compos. Sci. Technol. 2015, 114, 87–93. [Google Scholar] [CrossRef]

- Ladani, R.B.; Bhasin, M.; Wu, S.; Ravindran, A.R.; Ghorbani, K.; Zhang, J.; Kinloch, A.J.; Mouritz, A.P.; Wang, C.H. Fracture and fatigue behaviour of epoxy nanocomposites containing 1-D and 2-D nanoscale carbon fillers. Eng. Fract. Mech. 2018, 203, 102–114. [Google Scholar] [CrossRef]

| Filler Ratio | Monotonic Tensile Properties | |||

|---|---|---|---|---|

| MWCNT: GNP | Tensile Modulus, | Yield Strength, | Tensile Strength, | Elongation, |

| E (MPa) | σy (MPa) | σult (MPa) | εf (mm/mm) | |

| Temp. = −28 °C | ||||

| Neat epoxy | 3.38 ± 0.22 | - | 72.97 ± 1.51 | 0.029 ± 0.003 |

| 0:10 | 3.05 ± 0.69 (−9.8) | - | 72.02 ± 2.63 (−1.3) | 0.028 ± 0.002 (−3.4) |

| 1:9 | 3.46 ± 0.05 (+2.4) | - | 78.67 ± 0.42 (+7.8) | 0.030 ± 0.001 (+3.4) |

| 3:7 | 3.40 ± 0.06 (+0.6) | - | 76.71 ± 1.72 (+5.1) | 0.030 ± 0.001 (+3.4) |

| 5:5 | 3.40 ± 0.42 (+0.6) | - | 82.90 ± 1.07 (+13.6) | 0.033 ± 0.005 (+13.8) |

| 7:3 | 3.68 ± 0.58 (+8.9) | - | 83.05 ± 2.97 (+13.8) | 0.031 ± 0.003 (+6.9) |

| 9:1 | 3.54 ± 0.02 (+4.7) | - | 80.26 ± 1.72 (+10.0) | 0.029 ± 0.001 (+0.0) |

| 10:0 | 3.21 ± 0.14 (-5.0) | - | 86.03 ± 1.31 (+17.9) | 0.042 ± 0.008 (+44.8) |

| Temp. = 2 °C | ||||

| Neat epoxy | 3.03 ± 0.10 | 53.83 ± 4.19 | 79.89 ± 1.97 | 0.072 ± 0.009 |

| 0:10 | 3.24 ± 0.09 (+6.9) | 57.61 ± 3.86 (+7.0) | 77.72 ± 2.78 (−2.7) | 0.034 ± 0.006 (−52.8) |

| 1:9 | 3.10 ± 0.20 (+2.3) | 52.00 ± 2.89 (−3.4) | 75.58 ± 2.14 (−5.4) | 0.044 ± 0.015 (−38.9) |

| 3:7 | 3.16 ± 0.11 (+4.3) | 44.83 ± 2.36 (−16.7) | 83.22 ± 2.27 (+4.2) | 0.055 ± 0.014 (−23.6) |

| 5:5 | 3.18 ± 0.17 (+5.0) | 42.63 ± 0.25 (−20.8) | 84.31 ± 0.92 (+5.5) | 0.063 ± 0.002 (−12.5) |

| 7:3 | 3.31 ± 0.23 (+9.2) | 48.65 ± 3.79 (−9.6) | 79.88 ± 0.12 (−0.1) | 0.055 ± 0.032 (−23.6) |

| 9:1 | 3.66 ± 0.10 (+20.8) | 48.41 ± 3.25 (−10.1) | 84.25 ± 2.93 (+5.5) | 0.034 ± 0.003 (−52.8) |

| 10:0 | 3.26 ± 0.16 (+7.6) | 47.20 ± 4.39 (−12.3) | 81.58 ± 2.36 (+2.1) | 0.036 ± 0.006 (−50) |

| Temp. = 22 °C | ||||

| Neat epoxy | 3.27 ± 0.13 | 39.54 ± 1.04 | 70.98 ± 0.55 | 0.063 ± 0.007 |

| 0:10 | 3.32 ± 0.22 (+1.5) | 44.09 ± 4.43 (+11.5) | 78.35 ± 0.39 (+10.4) | 0.055 ± 0.001 (−12.7) |

| 1:9 | 3.14 ± 0.34 (−4.0) | 37.96 ± 10.1 (−4.0) | 78.40 ± 1.30 (+10.5) | 0.072 ± 0.003 (+14.3) |

| 3:7 | 3.03 ± 0.17 (−7.3) | 40.01 ± 3.06 (+1.2) | 73.00 ± 0.31 (+2.8) | 0.081 ± 0.018 (+28.6) |

| 5:5 | 2.95 ± 0.33 (−9.8) | 42.01 ± 4.52 (+6.2) | 74.29 ± 0.39 (+4.7) | 0.062 ± 0.002 (−1.6) |

| 7:3 | 3.02 ± 0.11 (−7.6) | 41.16 ± 3.39 (+4.1) | 67.47 ± 0.52 (−5.0) | 0.065 ± 0.010 (+3.2) |

| 9:1 | 3.58 ± 0.35 (+9.5) | 39.16 ± 4.66 (−1.0) | 80.14 ± 0.77 (+12.9) | 0.048 ± 0.007 (−23.8) |

| 10:0 | 3.39 ± 0.31 (+3.7) | 38.74 ± 7.43 (−2.0) | 75.37 ± 0.73 (+6.2) | 0.065 ± 0.012 (+3.2) |

| Temp. = 52 °C | ||||

| Neat epoxy | 2.80± 0.46 | 33.14 ± 5.33 | 51.10 ± 1.39 | 0.081 ± 0.015 |

| 0:10 | 3.04 ± 0.28 (+8.6) | 32.78 ± 2.57 (−1.1) | 52.00 ± 1.05 (+1.8) | 0.036 ± 0.008 (−55.6) |

| 1:9 | 2.69 ± 0.06 (−3.9) | 36.74 ± 4.43 (+10.9) | 50.93 ± 0.51 (−0.3) | 0.099 ± 0.012 (+22.2) |

| 3:7 | 2.75 ± 0.26 (−1.8) | 35.00 ± 3.36 (+5.6) | 57.17 ± 2.24 (+11.9) | 0.085 ± 0.024 (+4.9) |

| 5:5 | 2.78 ± 0.10 (−0.7) | 36.25 ± 0.98 (+9.4) | 58.23 ± 0.56 (+14.0) | 0.045± 0.003 (−44.4) |

| 7:3 | 2.49 ± 0.05 (−11.1) | 33.03 ± 1.17 (−0.3) | 44.64 ± 0.79 (−12.6) | 0.128 ± 0.043 (+58.0) |

| 9:1 | 2.79 ± 0.24 (−0.4) | 41.19 ± 1.65 (+24.3) | 63.04 ± 0.28 (+23.4) | 0.052 ± 0.016 (−35.8) |

| 10:0 | 2.58 ± 0.06 (−7.9) | 32.97 ± 2.25 (−0.5) | 45.47 ± 1.43 (−11.0) | 0.080 ± 0.060 (−1.2) |

| Temp. = 82 °C | ||||

| Neat epoxy | 1.62 ± 0.09 | 11.83 ± 0.67 | 17.00 ± 1.19 | 0.300 ± 0.028 |

| 0:10 | 2.12 ± 0.36 (+30.9) | 15.51 ± 1.73 (+31.1) | 21.38 ± 1.54 (+25.8) | 0.321 ± 0.141 (+7.0) |

| 1:9 | 2.08 ± 0.33 (+28.4) | 14.62 ± 2.40 (+23.6) | 21.96 ± 0.58 (+29.2) | 0.219 ± 0.065 (−27.0) |

| 3:7 | 2.01 ± 0.34 (+24.1) | 16.02 ± 0.55 (+35.4) | 22.55 ± 0.86 (+32.7) | 0.313 ± 0.068 (+4.3) |

| 5:5 | 1.84 ± 0.06 (+13.6) | 13.39 ± 0.76 (+13.2) | 20.64 ± 0.49 (+21.4) | 0.338 ± 0.086 (+12.7) |

| 7:3 | 1.49 ± 0.17 (−8.0) | 11.15 ± 1.28 (−5.7) | 17.93 ± 0.65 (+5.5) | 0.324 ± 0.122 (+8.0) |

| 9:1 | 2.57 ± 0.24 (+58.6) | 19.74 ± 0.95 (+66.9) | 27.02 ± 0.84 (+58.9) | 0.212 ± 0.053 (−29.3) |

| 10:0 | 1.43 ± 0.40 (−11.7) | 10.90 ± 2.90 (−7.9) | 17.39 ± 1.39 (+2.3) | 0.309 ± 0.078 (+3.0) |

| Filler Ratio | Synergistic Index (%) | |||

|---|---|---|---|---|

| MWCNT: GNP | Tensile Modulus | Yield Strength | Tensile Strength | Elongation |

| ηE | ησy | ησult | ηεf | |

| Temp. = −28 °C | ||||

| 1:9 | 12.851 | - | 7.149 | 2.041 |

| 3:7 | 9.748 | - | 0.639 | 2.041 |

| 5:5 | 8.626 | - | 4.904 | 12.245 |

| 7:3 | 16.382 | - | 1.495 | 5.442 |

| 9:1 | 10.833 | - | −5.163 | −1.361 |

| Temp. = 2 °C | ||||

| 1:9 | −4.380 | −8.077 | −3.234 | 28.655 |

| 3:7 | −2.649 | −17.724 | 5.505 | 58.96 |

| 5:5 | −2.154 | −18.653 | 5.851 | 80 |

| 7:3 | 1.721 | −3.325 | −0.674 | 55.367 |

| 9:1 | 12.339 | 0.35 | 3.764 | −5.028 |

| Temp. = 22 °C | ||||

| 1:9 | −5.621 | −12.846 | 0.446 | 28.571 |

| 3:7 | −9.309 | −5.826 | −5.753 | 39.655 |

| 5:5 | −12.072 | 1.437 | −3.344 | 3.333 |

| 7:3 | −10.359 | 2.02 | −11.531 | 4.839 |

| 9:1 | 5.823 | −0.293 | 5.91 | −25.000 |

| Temp. = 52 °C | ||||

| 1:9 | −10.154 | 12.016 | −0.812 | 145.05 |

| 3:7 | −5.238 | 6.587 | 14.246 | 72.764 |

| 5:5 | −1.068 | 10.266 | 19.483 | −22.414 |

| 7:3 | −8.389 | 0.355 | −5.880 | 91.617 |

| 9:1 | 6.245 | 25.004 | 36.678 | −31.217 |

| Temp. = 82 °C | ||||

| 1:9 | 1.414 | −2.851 | 4.666 | −31.520 |

| 3:7 | 5.071 | 13.4 | 11.728 | −1.386 |

| 5:5 | 3.662 | 1.401 | 6.474 | 7.302 |

| 7:3 | −8.980 | −9.224 | −3.535 | 3.647 |

| 9:1 | 71.448 | 73.752 | 51.892 | −31.657 |

| Temp. = −28 °C | Temp. = 2 °C | Temp. = 22 °C | Temp. = 52 °C | Temp. = 82 °C | |||||

|---|---|---|---|---|---|---|---|---|---|

| Max Stress | Fatigue Life | Max Stress | Fatigue Life | Max Stress | Fatigue Life | Max Stress | Fatigue Life | Max Stress | Fatigue Life |

| σmax (MPa) | Nf (cycles) | σmax (MPa) | Nf (cycles) | σmax (MPa) | Nf (cycles) | σmax (MPa) | Nf (cycles) | σmax (MPa) | Nf (cycles) |

| Neat epoxy | |||||||||

| 54.73 (75) | 4,879 | 43.94 (55) | 11,353 | 49.69 (70) | 1,074 | 35.77 (70) | 3,024 | 15.29 (90) | 13,436 |

| 52.90 (72.5) | 24,366 | 41.94 (52.5) | 120,927 | 47.91 (67.5) | 11,890 | 33.22 (65) | 22,814 | 14.44 (85) | 93,035 |

| 51.08 (70) | 109,629 | 39.94 (50) | 227,103 | 46.14 (65) | 50,065 | 30.66 (60) | 73,950 | 13.59 (80) | 144,046 |

| 49.25 (67.5) | 384,766 | 37.95 (47.5) | 664,987 | 42.59 (60) | 715,088 | 25.55 (50) | 275,503 | 11.67 (70) | 378,385 |

| 47.43 (65) | 687,215 | 35.95 (45) | >1,000,000 | 39.04 (55) | >1,000,000 | 20.44 (40) | >1,000,000 | 10.19 (60) | 741746 |

| MWCNT: GNP = 0:10 | |||||||||

| 64.82 (90) | 3,691 | 50.52 (65) | 5,710 | 50.93 (65) | 2,449 | 36.40 (70) | 9,837 | 19.07 (90) | 10,222 |

| 57.62 (80) | 47,485 | 48.57 (62.5) | 8,688 | 48.97 (62.5) | 12,930 | 33.80 (65) | 37,871 | 17.96 (85) | 49,923 |

| 54.02 (75) | 100,396 | 46.63 (60) | 165,947 | 47.01 (60) | 141,794 | 31.20 (60) | 124,484 | 16.90 (80) | 161,109 |

| 52.22 (72.5) | 666,366 | 44.69 (57.5) | 314,330 | 45.05 (57.5) | 436,494 | 29.90 (57.5) | 701,563 | 15.85 (75) | 341,171 |

| 50.42 (70) | >1,000,000 | 40.80 (52.5) | >1,000,000 | 43.09 (55) | >1,000,000 | 27.30 (52.5) | >1,000,000 | 14.79 (70) | 673,865 |

| MWCNT: GNP = 1:9 | |||||||||

| 59.00 (75) | 23,293 | 52.90 (70) | 44,227 | 50.96 (65) | 15,890 | 35.65 (70) | 13,339 | 18.66 (85) | 13,521 |

| 55.07 (70) | 32,127 | 51.02 (67.5) | 151,277 | 47.04 (60) | 50,147 | 33.10 (65) | 100,218 | 17.57 (80) | 40,325 |

| 51.14 (65) | 262,364 | 49.13 (65) | 243,229 | 43.12 (55) | 182,751 | 30.56 (60) | 124,922 | 16.47 (75) | 103,670 |

| 47.20 (60) | 444,633 | 45.35 (60) | 576,066 | 41.16 (52.5) | 853,780 | 29.28 (57.5) | 796,776 | 14.27 (65) | 480,323 |

| 43.27 (55) | >1,000,000 | 41.57 (55) | >1,000,000 | 39.20 (50) | >1,000,000 | 28.00 (55) | 955,567 | 13.72 (62.5) | 571,526 |

| MWCNT: GNP = 5:5 | |||||||||

| 58.03 (70) | 3,959 | 52.69 (62.5) | 5,598 | 52.00 (70) | 3,243 | 39.31 (67.5) | 2,334 | 18.57 (90) | 6,633 |

| 55.96 (67.5) | 34,130 | 50.58 (60) | 81,052 | 48.29 (65) | 8,706 | 37.85 (65) | 25,749 | 17.54 (85) | 52,415 |

| 53.89 (65) | 117,290 | 48.48 (57.5) | 480,799 | 46,43 (62.5) | 66,456 | 33.48 (57.5) | 315,186 | 15.48 (75) | 156,392 |

| 51.81 (62.5) | 599,923 | 46.37 (55) | 730,031 | 44.57 (60) | 445,486 | 32.03 (55) | 717,518 | 14.45 (70) | 760,488 |

| 49.74 (60) | >1,000,000 | 42.15 (50) | >1,000,000 | 42.72 (57.5) | >1,000,000 | 30.57 (52.5) | >1,000,000 | 13.93 (67.5) | >1,000,000 |

| MWCNT: GNP = 9:1 | |||||||||

| 58.19 (72.5) | 22,687 | 56.87 (67.5) | 2,795 | 54.10 (67.5) | 1,406 | 40.98 (65) | 8,405 | 21.62 (80) | 15,572 |

| 56.18 (70) | 77,595 | 54.76 (65) | 14,879 | 50.09 (62.5) | 8,419 | 37.83 (60) | 39,083 | 20.27 (75) | 58,065 |

| 54.18 (67.5) | 151,919 | 52.66 (62.5) | 108,667 | 48.08 (60) | 18,985 | 36.25 (57.5) | 167,016 | 18.92 (70) | 205,828 |

| 52.17 (65) | 238,821 | 50.55 (60) | 203,086 | 46.08 (57.5) | 90,882 | 34.67 (55) | 233,472 | 17.56 (65) | 394,266 |

| 48.16 (60) | >1,000,000 | 48.44 (57.5) | >1,000,000 | 44.08 (55) | 522,622 | 31.52 (50) | 530,495 | 15.54 (57.5) | 607,591 |

| MWCNT: GNP = 10:0 | |||||||||

| 60.22 (70) | 5,381 | 53.03 (65) | 10,804 | 50.87 (67.5) | 6,339 | 36.38 (80) | 10,240 | 15.65 (90) | 21,696 |

| 58.07 (67.5) | 8,524 | 50.99 (62.5) | 58,374 | 48.99 (65) | 17,633 | 34.10 (75) | 42,976 | 14.78 (85) | 136,663 |

| 55.92 (65) | 96,073 | 48.95 (60) | 166,549 | 47.11 (62.5) | 49,107 | 31.83 (70) | 195,187 | 13.91 (80) | 227,429 |

| 53.77 (62.5) | 125,387 | 46.91 (57.5) | 327,498 | 45.22 (60) | 107,018 | 29.56 (65) | 292,022 | 13.04 (75) | 636,555 |

| 51.62 (60) | 448,841 | 44.87 (55) | >1,000,000 | 41.45 (55) | 509,177 | 27.28 (60) | >1,000,000 | 12.17 (70) | >1,000,000 |

| Filer Ratio (MWCNT:GNP) | Temperature (°C) | Fatigue Strength Coefficient, A | Fatigue Strength Exponent, B | Coefficient of Determination R2 |

|---|---|---|---|---|

| 0:0 (Neat epoxy) | −28 | 69.584 | −0.027 | 0.968 |

| 2 | 66.636 | −0.042 | 0.894 | |

| 22 | 63.457 | −0.032 | 0.88 | |

| 52 | 82.523 | −0.095 | 0.9 | |

| 82 | 41.755 | −0.099 | 0.845 | |

| 0:10 | −28 | 91.476 | −0.043 | 0.966 |

| 2 | 67.491 | −0.034 | 0.874 | |

| 22 | 62.672 | −0.026 | 0.958 | |

| 52 | 60.419 | −0.055 | 0.944 | |

| 82 | 33.525 | −0.059 | 0.956 | |

| 1:9 | −28 | 119.689 | −0.072 | 0.935 |

| 2 | 122.992 | −0.076 | 0.905 | |

| 22 | 88.34 | −0.058 | 0.972 | |

| 52 | 59.098 | −0.053 | 0.921 | |

| 82 | 41.304 | −0.082 | 0.98 | |

| 5:5 | −28 | 73.043 | −0.027 | 0.956 |

| 2 | 72.06 | −0.034 | 0.716 | |

| 22 | 64.911 | −0.030 | 0.947 | |

| 52 | 55.214 | −0.041 | 0.937 | |

| 82 | 31.71 | −0.059 | 0.953 | |

| 9:1 | −28 | 98.834 | −0.051 | 0.971 |

| 2 | 71.017 | −0.027 | 0.974 | |

| 22 | 68.564 | −0.034 | 0.977 | |

| 52 | 69.561 | −0.057 | 0.922 | |

| 82 | 48.329 | −0.081 | 0.883 | |

| 10:0 | −28 | 78.239 | −0.031 | 0.937 |

| 2 | 76.129 | −0.038 | 0.97 | |

| 22 | 77.195 | −0.047 | 0.989 | |

| 52 | 65.945 | −0.063 | 0.961 | |

| 82 | 30.253 | −0.064 | 0.924 |

| Filler Ratio | Fatigue Strength (MPa) | |||

|---|---|---|---|---|

| MWCNT: GNP | S103 | S104 | S105 | S106 |

| Temp. = −28 °C | ||||

| Neat epoxy | 57.74 | 54.26 | 50.99 | 47.92 |

| 0:10 | 67.97 (+17.7) | 61.56 (+13.4) | 55.76 (+9.3) | 50.50 (+5.4) |

| 1:9 | 72.79 (+26.1) | 61.67 (+13.6) | 52.25 (+2.5) | 44.26 (−7.6) |

| 5:5 | 60.61 (+5.0) | 56.96 (+5.0) | 53.53 (+5.0) | 50.30 (+5.0) |

| 9:1 | 69.49 (+20.3) | 61.79 (+13.9) | 54.94 (+7.7) | 48.85 (+2.0) |

| 10:0 | 63.16 (+9.4) | 58.81 (+8.4) | 54.75 (+7.4) | 50.98 (+6.4) |

| Temp. = 2 °C | ||||

| Neat epoxy | 49.86 | 45.26 | 41.09 | 37.3 |

| 0:10 | 53.36 (+7.0) | 49.35 (+9.0) | 45.63 (+11.1) | 42.19 (+13.1) |

| 1:9 | 72.76 (+45.9) | 61.08 (+34.9) | 51.27 (+24.8) | 43.04 (+15.4) |

| 5:5 | 56.98 (+14.3) | 52.69 (+16.4) | 48.72 (+18.6) | 45.05 (+20.8) |

| 9:1 | 58.93 (+18.2) | 55.38 (+22.4) | 52.04 (+26.7) | 48.91 (+31.1) |

| 10:0 | 58.55 (+17.4) | 53.65 (+18.5) | 49.15 (+19.6) | 45.03 (+20.7) |

| Temp. = 22 °C | ||||

| Neat epoxy | 50.87 | 47.26 | 43.9 | 40.78 |

| 0:10 | 52.37 (+2.9) | 49.33 (+4.4) | 46.46 (+5.8) | 43.76 (+7.3) |

| 1:9 | 59.18 (+16.3) | 51.78 (+9.6) | 45.31 (+3.2) | 39.64 (−2.8) |

| 5:5 | 52.76 (+3.7) | 49.24 (+4.2) | 45.95 (+4.7) | 42.89 (+5.2) |

| 9:1 | 54.21 (+6.6) | 50.13 (+6.1) | 46.35 (+5.6) | 42.86 (+5.1) |

| 10:0 | 55.79 (+9.7) | 50.07 (+6.0) | 44.94 (+2.4) | 40.33 (−1.1) |

| Temp. = 52 °C | ||||

| Neat epoxy | 42.81 | 34.4 | 27.64 | 22.21 |

| 0:10 | 41.32 (−3.5) | 36.41 (+5.8) | 32.08 (+16.0) | 28.26 (+27.2) |

| 1:9 | 40.98 (−4.3) | 36.27 (+5.4) | 32.11 (+16.1) | 28.42 (+27.9) |

| 5:5 | 41.60 (−2.8) | 37.85 (+10.0) | 34.44 (+24.6) | 31.34 (+41.1) |

| 9:1 | 46.92 (+9.6) | 41.15 (+19.6) | 36.09 (+30.6) | 31.65 (+42.5) |

| 10:0 | 42.68 (−0.3) | 36.91 (+7.3) | 31.93 (+15.5) | 27.62 (+24.3) |

| Temp. = 82 °C | ||||

| Neat epoxy | 21.07 | 16.78 | 13.36 | 10.63 |

| 0:10 | 22.30 (+5.8) | 19.47 (+16.1) | 17.00 (+27.3) | 14.84 (+39.5) |

| 1:9 | 23.44 (+11.2) | 19.41 (+15.7) | 16.07 (+20.3) | 13.30 (+25.1) |

| 5:5 | 21.10 (+0.1) | 18.42 (+9.8) | 16.08 (+20.4) | 14.03 (+32.0) |

| 9:1 | 27.62 (+31.1) | 22.92 (+36.6) | 19.02 (+42.4) | 15.78 (+48.4) |

| 10:0 | 19.44 (−7.7) | 16.78 (+0.0) | 14.48 (+8.4) | 12.50 (+17.5) |

| Filler Ratio | Synergistic Index for Fatigue Strength (%) | |||

|---|---|---|---|---|

| MWCNT: GNP | ||||

| Temp. = −28 °C | ||||

| 1:9 | 7.853 | 0.622 | −6.130 | −12.434 |

| 5:5 | −7.547 | −5.355 | −3.129 | −0.869 |

| 9:1 | 9.191 | 4.581 | −0.159 | −4.084 |

| Temp. = 2 °C | ||||

| 1:9 | 35.029 | 22.705 | 11.504 | 1.325 |

| 5:5 | 1.819 | 2.31 | 2.801 | 3.292 |

| 9:1 | 1.55 | 4.066 | 6.644 | 9.285 |

| Temp. = 22 °C | ||||

| 1:9 | 12.267 | 4.816 | −2.161 | -8.693 |

| 5:5 | −2.441 | −0.923 | 0.56 | 2.006 |

| 9:1 | −2.235 | 0.266 | 2.81 | 5.396 |

| Temp. = 52 °C | ||||

| 1:9 | −1.150 | −0.507 | 0.138 | 0.783 |

| 5:5 | −0.959 | 3.243 | 7.614 | 12.161 |

| 9:1 | 10.297 | 11.63 | 12.976 | 14.334 |

| Temp. = 82 °C | ||||

| 1:9 | 6.47 | 1.081 | −4.037 | −8.897 |

| 5:5 | 1.066 | 1.608 | 2.149 | 2.69 |

| 9:1 | 39.99 | 34.44 | 29.109 | 23.987 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jen, Y.-M.; Chang, H.-H.; Lu, C.-M.; Liang, S.-Y. Temperature-Dependent Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets on the Tensile Quasi-Static and Fatigue Properties of Epoxy Nanocomposites. Polymers 2021, 13, 84. https://doi.org/10.3390/polym13010084

Jen Y-M, Chang H-H, Lu C-M, Liang S-Y. Temperature-Dependent Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets on the Tensile Quasi-Static and Fatigue Properties of Epoxy Nanocomposites. Polymers. 2021; 13(1):84. https://doi.org/10.3390/polym13010084

Chicago/Turabian StyleJen, Yi-Ming, Hao-Huai Chang, Chien-Min Lu, and Shin-Yu Liang. 2021. "Temperature-Dependent Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets on the Tensile Quasi-Static and Fatigue Properties of Epoxy Nanocomposites" Polymers 13, no. 1: 84. https://doi.org/10.3390/polym13010084

APA StyleJen, Y. -M., Chang, H. -H., Lu, C. -M., & Liang, S. -Y. (2021). Temperature-Dependent Synergistic Effect of Multi-Walled Carbon Nanotubes and Graphene Nanoplatelets on the Tensile Quasi-Static and Fatigue Properties of Epoxy Nanocomposites. Polymers, 13(1), 84. https://doi.org/10.3390/polym13010084