Recording, Storage, and Reproduction of Information on Polyvinyl Chloride Films Using Shape Memory Effects

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dhanasekaran, R.; Sreenatha Reddy, S.; Girish Kumar, B.; Anirudh, A.S. Shape memory materials for biomedical and aerospace applications. Mater. Today Proc. 2018, 5, 21427–21435. [Google Scholar] [CrossRef]

- Sessini, V.; Arrieta, M.P.; Fernández-Torres, A.; Peponi, L. Humidity-activated shape memory effect on plasticized starch-based biomaterials. Carbohydr. Polym. 2018, 179, 93–99. [Google Scholar] [CrossRef]

- Korde, J.M.; Kandasubramanian, B. Naturally biomimicked smart shape memory hydrogels for biomedical functions. Chem. Eng. J. 2020, 379, 122430. [Google Scholar] [CrossRef]

- Bil, M.; Kijeńska-Gawrońska, E.; Głodkowska-Mrówka, E.; Manda-Handzlik, A.; Mrówka, P. Design and in vitro evaluation of electrospun shape memory polyurethanes for self-fitting tissue engineering grafts and drug delivery systems. Mater. Sci. Eng. C 2020, 110, 110675. [Google Scholar] [CrossRef]

- Liu, J.; Gao, Y.; Lee, Y.; Yang, S. Responsive and foldable soft materials trends in chemistry. Trends Chem. 2020, 2, 107–122. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, L.; Zhang, F.; Leng, J.; Liu, Y. Shape memory polymers and their composites in biomedical applications. Mater. Sci. Eng. C 2019, 97, 864–883. [Google Scholar] [CrossRef]

- Wang, J.; Luo, J.; Kunkel, R.; Saha, M.; Liu, Y. Development of shape memory polymer nanocomposite foam for treatment of intracranial aneurysms. Mater. Lett. 2019, 250, 38–41. [Google Scholar] [CrossRef]

- Lin, H.; Chang, Y.; Han, Y.; Yang, K.; Chen, M. Atomic layer deposited Al2O3 films on NiTi shape memory alloys for biomedical applications. Procedia Manuf. 2019, 37, 431–437. [Google Scholar] [CrossRef]

- Zheng, Y.F.; Zhang, B.B.; Wang, B.L.; Wang, Y.B.; Cui, L.S. Introduction of antibacterial function into biomedical TiNi shape memory alloy by the addition of element Ag. Acta Biomater. 2011, 7, 2758–2767. [Google Scholar] [CrossRef]

- Abdul Kadir, M.; Dewi, D.E.O.; Jamaludin, M.; Nafea, M.; Mohamed Ali, M.S. A multi-segmented shape memory alloy-based actuator system for endoscopic applications. Sens. Actuators A Phys. 2019, 296, 92–100. [Google Scholar] [CrossRef]

- Sharma, K.; Srinivas, G. Flying smart: Smart materials used in aviation industry. Mater. Today Proc. 2020, 27, 244–250. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Gisario, A.; Barletta, M.; Broggiato, G.B. Welding strength of dissimilar laser-welded NiTi and NiTiCu shape memory wires. Manuf. Lett. 2019, 22, 25–27. [Google Scholar] [CrossRef]

- Zare, M.; Prabhakaran, M.P.; Parvin, N.; Ramakrishna, S. Thermally-induced two-way shape memory polymers: Mechanisms, structures, and applications. Chem. Eng. J. 2019, 374, 706–720. [Google Scholar] [CrossRef]

- Gao, J.; Chen, W.; Yu, B.; Fan, P.; Peng, F. Effect of temperature on the mechanical behaviours of a single-ply weave-reinforced shape memory polymer composite. Compos. Part B Eng. 2019, 159, 336–345. [Google Scholar] [CrossRef]

- Wei, H.; Liu, L.; Zhang, Z.; Du, H.; Leng, J. Design and analysis of smart release devices based on shape memory polymer composites. Compos. Struct. 2015, 133, 642–651. [Google Scholar] [CrossRef]

- Chau, E.T.F.; Friend, C.M.; Allen, D.M.; Hora, J.; Webster, J.R. A technical and economic appraisal of shape memory alloys for aerospace applications. Mater. Sci. Eng. A 2006, 438–440, 589–592. [Google Scholar] [CrossRef]

- Garafolo, N.G.; McHugh, G.R. Mitigation of flutter vibration using embedded shape memory alloys. J. Fluids Struct. 2018, 76, 592–605. [Google Scholar] [CrossRef]

- Villoslada, Á.; Escudero, N.; Martín, F.; Flores, A.; Moreno, L. Position control of a shape memory alloy actuator using a four-term bilinear PID controller. Sens. Actuators A Phys. 2015, 236, 257–272. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Z.; Muliana, A.; Rajagopal, K.R. Modeling deformation induced anisotropy of light-activated shape memory polymers. Int. J. Non-Linear Mech. 2020, 120, 103376. [Google Scholar] [CrossRef]

- Saputo, S.; Sellitto, A.; Battaglia, M.; Sebastiano, V.; Riccio, A. Numerical simulation of the mechanical behaviour of shape memory alloys based actuators. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Leal, P.B.C.; Savi, M. A Shape memory alloy-based mechanism for aeronautical application: Theory, optimization and experiment. Aerosp. Sci. Technol. 2018, 76, 155–163. [Google Scholar] [CrossRef]

- Stoeckel, D. Shape memory actuators for automotive applications. Mater. Des. 1990, 11, 302–307. [Google Scholar] [CrossRef]

- Rogers, N.; Khan, F. Characterization of deformation induced changes to conductivity in an electrically triggered shape memory polymer. Polym. Test. 2013, 32, 71–77. [Google Scholar] [CrossRef]

- Williams, E.A.; Shaw, G.; Elahinia, M. Control of an automotive shape memory alloy mirror actuator. Mechatronics 2010, 20, 527–534. [Google Scholar] [CrossRef]

- Leary, M.; Huang, S.; Ataalla, T.; Baxter, A.; Subic, A. Design of shape memory alloy actuators for direct power by an automotive battery. Mater. Des. 2013, 43, 460–466. [Google Scholar] [CrossRef]

- Kumar, P.; Kishore, R.A.; Maurya, D.; Stewart, C.J.; Priya, S. Shape memory alloy engine for high efficiency low-temperature gradient thermal to electrical conversion. Appl. Energy 2019, 251, 113277. [Google Scholar] [CrossRef]

- Sobrinho, J.M.B.; Filho, F.M.F.; Emiliavaca, A.; Cunha, M.F.; Ries, A. Experimental and numerical analyses of a rotary motor using shape memory alloy mini springs. Sens. Actuators A Phys. 2020, 302, 111823. [Google Scholar] [CrossRef]

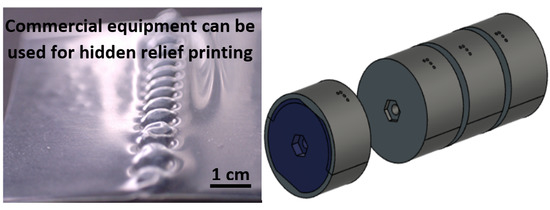

- Kondratov, A.P.; Volinsky, A.A.; Zhang, Y.; Nikulchev, E.V. Polyvinyl chloride film local isometric heat treatment for hidden 3D printing on polymer packaging. J. Appl. Polym. Sci. 2016, 133, 43046. [Google Scholar] [CrossRef]

- Mu, T.; Liu, L.; Lan, X.; Liu, Y.; Leng, J. Shape memory polymers for composites. Compos. Sci. Technol. 2018, 160, 169–198. [Google Scholar] [CrossRef]

- Kondratov, A.P.; Tishchenko, A.S. Interval shrincable materials with shape memory for the counterfeit protection of printed products and packaging. J. Int. Sci. Publ. Mater. Methods Technol. 2012, 6, 290–298. [Google Scholar]

- Kondratov, A.P. New materials for light strain-optical panels. Light Eng. Svetotekhnika 2014, 22, 74–77. [Google Scholar]

- Kondratov, A.P.; Konovalova, M.V.; Cherkasov, E.P.; Savenkova, I.A. Non-destructive assessment of relief marking parameters of heat shrinkable installation parts for aviation technology. MATEC Web Conf. 2017, 99, 01004. [Google Scholar] [CrossRef] [Green Version]

- Cherkasov, E.P.; Konovalova, M.V.; Kondratov, A.P. Comparison of apparatus and methods for tactile marking of polymeric films with Braille alphabet. Iop Conf. Ser. Mater. Sci. Eng. 2020, 862, 022064. [Google Scholar] [CrossRef]

- Kondratov, A.P.; Konovalova, M.V. Hidden Tactile Mark. RU Patent 150223, G09F 3/00, 10 February 2015. Bull. Number 4. [Google Scholar]

- Cherkasov, E.P.; Rasulov, T.E.; Sitkin, D.S.; Kondratov, A.P. Type-Setting Stamp. RU Patent # 184486, B41C 1/00, 29 September 2018. Bull. Number 31. [Google Scholar]

- Mehta, S.; Murugeson, S.; Prakash, B.; Deepak, A. A novel living ink based on saccharomyces cerevisae for screen printing process and its applicability in producing braille text dots. Mater. Today Commun. 2018, 15, 325–332. [Google Scholar] [CrossRef]

- Nater, P. Tactile graphics with the aid of a conventional braille printer. J. Microcomput. Appl. 1993, 16, 307–314. [Google Scholar] [CrossRef]

- Gual, J.; Puyuelo, M.; Lloveras, J. The effect of volumetric (3D) tactile symbols within inclusive tactile maps. Appl. Ergon. 2015, 48, 1–10. [Google Scholar] [CrossRef]

- Moon, S.; Cui, F.; Rao, I.J. A thermodynamic framework for the modeling of crystallizable triple shape memory polymers. Int. J. Eng. Sci. 2019, 134, 1–30. [Google Scholar] [CrossRef]

- Fana, P.; Chen, W.; Zhao, B.; Hu, J.; Gao, J.; Fang, G.; Peng, F. Formulation and numerical implementation of tensile shape memory process of shape memory polymers. Polymer 2018, 148, 370–381. [Google Scholar] [CrossRef]

- Kondratov, A.P.; Yakubov, V.; Volinsky, A.A. Melted photopolymer composite mass transfer effects during flexographic development. J. Print. Sci. Technol. 2017, 55, 190–195. [Google Scholar]

- Kondratov, A.P.; Cherkasov, E.P.; Nagornova, I.V. Identification and monitoring of the polymer thermo-shrinkable couplings and coatings by the relief marking. AIP Conf. Proc. 2019, 2141, 050006. [Google Scholar] [CrossRef]

- Kondratov, A.P.; Zachinyaev, G.M. Thermal Cyclic Tests of Shrink Polymeric Products with the Shape Memory Testing and Measurement: Techniques and Applications. In Proceedings of the 2015 International Conference on Testing and Measurement: Techniques and Applications (TMTA 2015), Phuket Island, Thailand, 16–17 January 2015; pp. 73–76. [Google Scholar] [CrossRef]

- Kondratov, A.P. Thermo shrinking films with interval macrostructure for protection of packaging from falsification. Mod. Appl. Sci. 2014, 8, 204–209. [Google Scholar] [CrossRef] [Green Version]

- Kondratov, A.P.; Cherkasov, E.P.; Paley, V.; Volinsky, A.A. Macrostructure of anisotropic shape memory polymer films studied by the molecular probe method. J. Appl. Polym. Sci. 2021, 138, 50176. [Google Scholar] [CrossRef]

- Cherkasov, E.P.; Kondratov, A.P. Method of Relief Marking of Shells. RU Patent 2740174, A22C 17/00, 12 January 2021. Bull. Number 2. [Google Scholar]

- Harper, M.; Jinlian, H. A Brief Review of Stimulus-active Polymers Responsive to Thermal, Light, Magnetic, Electric, and Water/Solvent Stimuli. J. Intell. Mater. Syst. Struct. 2010, 21, 859–885. [Google Scholar]

- Lu, H.; Liu, Y.; Leng, J.; Du, S. Qualitative Separation of the Physical Swelling Effect on the Recovery Behavior of Shape Memory Polymer. Eur. Polym. J. 2010, 46, 1908–1914. [Google Scholar] [CrossRef]

- Lu, H.; Du, S. A phenomenological thermodynamic model for the chemo-responsive shape memory effect in polymers based on Flory-Huggins solution theory. Polym. Chem. 2014, 5, 1155–1162. [Google Scholar] [CrossRef]

- Niu, H.; Liu, Y.; Song, H.; Meng, Q.; Du, Y.; Shirley, S.Z. Shen Facile preparation of flexible all organic PEDOT:PSS/methyl cellulose thermoelectric composite film by a screen printing process. Synth. Met. 2021, 276, 116752. [Google Scholar] [CrossRef]

- Rawson, F.J.; Purcell, W.M.; Xu, J.; Pemberton, R.M.; Fielden, P.R.; Biddle, N.; Hart, J.P. A microband lactate biosensor fabricated using a water-based screen-printed carbon ink. Talanta 2009, 77, 1149–1154. [Google Scholar] [CrossRef]

- Fasolt, B.; Hodgins, M.; Rizzello, G.; Seelecke, S. Effect of screen printing parameters on sensor and actuator performance of dielectric elastomer (DE) membranes. Sens. Actuators A Phys. 2017, 265, 10–19. [Google Scholar] [CrossRef]

- Xiao, B.; Huang, Q.; Chen, H.; Chen, X.; Long, G. A fractal model for capillary flow through a single tortuos capillary with roughened surfaces in fibrous porous media. Fractals 2021, 29, 2150017. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, Y.; Wang, Y.; Jiang, G.; Liang, M.; Chen, X.; Long, G. A fractal model for Kozeny–Carman constant and dimensionless permeability of fibrous porous media with roughened surfaces. Fractals. 2019, 27, 1950116. [Google Scholar] [CrossRef]

- Krebs, F.C. Pad printing as a film forming technique for polymer solar cells. Sol. Energy Mater. Sol. Cells 2009, 93, 484–490. [Google Scholar] [CrossRef]

- Zhuravleva, G.N.; Cherkasov, E.P.; Kondratov, A.P. Polymer forms (parts) of printing machines and heat shrinkage films for embossing of shells with solvents. Izv. Vys. Uchebn. Zaved. Problem Poligraphii I Izdat. Dela 2019, 4, 15–26. [Google Scholar]

- Cherkasov, E.P.; Kondratov, A.P.; Nazarov, V.G. The process of tactile (relief) marking of thermo shrinkable membranes and labels. J. Phys. Conf. Ser. 2019, 1399, 044036. [Google Scholar] [CrossRef] [Green Version]

- Kondratov, A.P.; Zachinyaev, G.M. Physical modeling of the process of fixing heat-shrink labels on cylindrical containers in automatic applicators. News of higher educational institutions. Problem. Print. Publ. 2013, 3, 31–39. [Google Scholar]

- Jucius, D.; Guobienė, A.; Grigaliūnas, V. Surface texturing of polytetrafluoroethylene by hot embossing. Appl. Surf. Sci. 2010, 256, 2164–2169. [Google Scholar] [CrossRef]

- Cheong, Y.K.; Lim, W.H.; Lee, S.H.; Pua, C.H.; Chong, W.Y.; Ahmada, H. 405 nm laser processing of thin SU-8 polymer film. Optik 2016, 127, 1651–1655. [Google Scholar] [CrossRef]

- Volynskii, A.L.; Bakeev, N.F. Structural aspects of deformation of amorphous polymers. Russ. Chem. Bull. 2005, 54, 1–15. [Google Scholar] [CrossRef]

- Oleinik, E.T.F.; Rudnev, S.N.; Salamatina, O.B.; Kotelyanskii, M.I. Mechanisms of anelastic deformation in solid polymers: Solidlike and liquidlike processes. Polym. Sci. Ser. A 2008, 50, 494–506. [Google Scholar] [CrossRef]

| Parameters | THF Aqueous Solution Concentration, wt.% | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 30% | 40% | 50% | |||||||

| Temperature, °C | 22 ± 1 | 36 ± 1 | 65 ± 1 | 22 ± 1 | 36 ± 1 | 65 ± 1 | 22 ± 1 | 36 ± 1 | 65 ± 1 |

| Max increase in film weight, % | 6 | 19.2 | 15.1 | 15.7 | 23.1 | 21.6 | 22.6 | 31.4 | 28.3 |

| Time to max weight gain, sec | 25 | 14 | 8 | 27 | 14 | 7 | 17 | 10 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kondratov, A.P.; Cherkasov, E.P.; Paley, V.; Volinsky, A.A. Recording, Storage, and Reproduction of Information on Polyvinyl Chloride Films Using Shape Memory Effects. Polymers 2021, 13, 1802. https://doi.org/10.3390/polym13111802

Kondratov AP, Cherkasov EP, Paley V, Volinsky AA. Recording, Storage, and Reproduction of Information on Polyvinyl Chloride Films Using Shape Memory Effects. Polymers. 2021; 13(11):1802. https://doi.org/10.3390/polym13111802

Chicago/Turabian StyleKondratov, Alexander P., Egor P. Cherkasov, Vladislav Paley, and Alex A. Volinsky. 2021. "Recording, Storage, and Reproduction of Information on Polyvinyl Chloride Films Using Shape Memory Effects" Polymers 13, no. 11: 1802. https://doi.org/10.3390/polym13111802

APA StyleKondratov, A. P., Cherkasov, E. P., Paley, V., & Volinsky, A. A. (2021). Recording, Storage, and Reproduction of Information on Polyvinyl Chloride Films Using Shape Memory Effects. Polymers, 13(11), 1802. https://doi.org/10.3390/polym13111802