Remediation of Punching Shear Failure Using Glass Fiber Reinforced Polymer (GFRP) Rods

Abstract

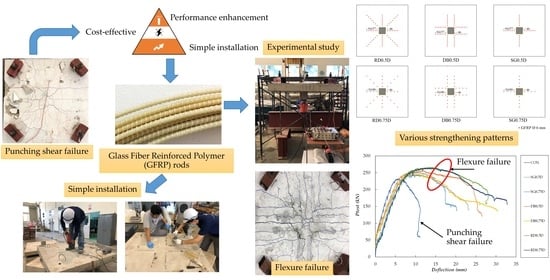

:1. Introduction

2. Experimental Program

2.1. Materials

2.2. Test Specimens

2.3. Strengthening Plan

2.4. Specimen Preparation

2.5. Loading and Instrumentation

3. Test Results

3.1. Load Capacity and Failure Modes

3.2. Ductility

| Specimen ID | Peak Load (kN) | Ductility (μ) | Failure Mode | Energy Dissipation (kN-mm) | ||

|---|---|---|---|---|---|---|

| CON | 230 | / | 5.8 | / | S | 1993.1 |

| SG0.5D | 251 | 4.59 | 10.1 | 2.20 | F | 4610.3 |

| DB0.5D | 256 | 4.07 | 11.8 | 2.89 | F | 5659.2 |

| RD0.5D | 266 | / | 13.7 | / | F | 6032.5 |

| SG0.75D | 243 | 6.21 | 9.6 | 1.55 | F | 3860.8 |

| DB0.75D | 247 | 7.54 | 9.3 | 1.24 | F | 5730.2 |

| RD0.75D | 264 | 9.26 | 12.78 | 1.41 | F | 6771.6 |

3.3. Initial Stiffness

3.4. Strain

3.5. Energy Dissipation Capacity

4. Analytical Validation

4.1. Punching Shear Failure Inside the Shear-Strengthened Zone

- = concrete cylinder compressive strength (MPa),

- = effective slab thickness for shear (mm),

- = perimeter of shear critical section at 0.5d from loading area periphery (mm),

- = Factor according to the type of connection; it is 40 for internal columns, 30 for external columns, and 20 for corner columns,

- = Ratio of the long side to the short side of the loading area periphery.

- = sum of the area of all shear reinforcement in one peripheral line,

- = Yield strength of shear reinforcement,

- = spacing between consecutive peripheral lines of shear reinforcement parallel to loading area periphery.

- = sum of the area of GFRP reinforcement in one peripheral line,

- = fracture strength of the GFRP,

4.2. Punching Shear Failure Outside Shear-Strengthened Zone

5. Conclusions

- The load–deflection curve of the control specimen exhibited a sudden drop after attaining peak load. Strengthened specimens successfully shifted this failure mode to a gradual and ductile one. Improvements in both peak load and corresponding deflections were observed. Reducing the spacing from 0.75D to 0.5D had a beneficial impact on peak load for each GFRP pattern.

- Strain measurement indicated no yielding of longitudinal bars in the control specimen. On the contrary, all strengthened specimens exhibited yielding. The highest strain values at peak loads were mobilized in double GFRP patterns followed by single and radial patterns, respectively. In terms of shear strain, the lowest shear strains were mobilized in SG patterns in both series. Specimen RD0.5D mobilized higher strain values than specimen DB0.5D. However, the opposite was true in series 0.75D. This implies that at reduced spacings, the radial pattern outperformed other patterns in terms of peak loads and ductility as the GFRP rods were able to withstand higher strain values.

- As expected, the control specimen did not show any ductility. Nevertheless, strengthening with GFRP rods developed ductility. Reducing the GFRP spacing resulted in an increase in ductility irrespective of the type of GFRP pattern.

- In each series, the SG pattern formed the lowest bound of dissipated energy. Results indicate that reducing the spacings had a beneficial effect on energy dissipation for the SG pattern. Maximum energy was dissipated by specimen RD0.75D and contrary to SG specimens, reducing the spacing to 0.5D resulted in a 12.25% reduction of energy dissipation capacity. Analogous to this, the DB pattern also exhibited a 1.26% reduction in energy dissipation capacity as GFRP spacings reduced from 0.75D to 0.5D.

- It can be concluded that the use of GFRP rods is beneficial in the remediation of punching shear failure and GFRP rods can be effectively used in existing structures to improve the structural response of flat slabs.

- ACI 318-14 equations for two-way shear strength were modified to incorporate shear strength contributions from the GFRP. A comparison of analytical results with experimental results suggests that the proposed approach is successful in predicting the shear strength capacity of flat slabs in the presence of GFRP rods.

6. Future Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Santos, G.S.; Nicaciol, W.G.; Limal, A.W.; Melol, G.S.S.A. Punching Strengthening in Flat Plates of Reinforced Concrete with Carbon Fiber Reinforced Polymer (CFRP); Departamento de Engenharia Civil e Ambiental, Universidade de Brasília: Brasília, Brasil, 2014. [Google Scholar]

- Park, R. Evaluation of Ductility of Structures and Structural Assemblages from Laboratory Testing. Bull. N. Z. Soc. Earthq. Eng. 1989, 22, 155–166. [Google Scholar] [CrossRef]

- Lapi, M.; Ramos, A.P.; Orlando, M. Flat slab strenghtening techniques against punchingshear. Eng. Struct. 2019, 180, 160–180. [Google Scholar] [CrossRef]

- Son, K.S.; Pilakoutas, K.; Neocleous, K. Behaviour of concrete columns with drilled holes. Mag. Concr. Res. 2006, 58, 411–419. [Google Scholar] [CrossRef] [Green Version]

- King, S.; Delatte, N.J. Collapse of 2000 Commonwealth Avenue: Punching shear case study. J. Perform. Constr. Facil. 2004, 18, 54–61. [Google Scholar] [CrossRef] [Green Version]

- Gardner, N.J.; Huh, J.; Chung, L. Lessons from the Sampoong department store collapse. Cem. Concr. Compos. 2002, 24, 523–529. [Google Scholar] [CrossRef]

- Wey, E.H.; Durrani, A.J. Seismic response of interior slab-column connections with shear capitals. Struct. J. 1992, 89, 682–691. [Google Scholar]

- Prawatwong, U.; Warnitchai, P.; Tandian, C.H. Seismic performance of bonded post-tensioned slab-column connections with and without drop panels. Adv. Struct. Eng. 2012, 15, 1653–1672. [Google Scholar] [CrossRef]

- Husain, M.; Eisa, A.S.; Roshdy, R. Alternatives to enhance flat slab ductility. Int. J. Concr. Struct. Mater. 2017, 11, 161–169. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, H.; Lúcio, V.; Ramos, A. Strengthening of concrete flat slabs with an overlaid reinforced concrete layer. In Proceedings of the 14th Fib Symposium, Performance-Based Approaches for Concrete Structures, Cape Town, South Africa, 21–23 November 2016. [Google Scholar]

- Ruiz, M.F.; Muttoni, A.; Kunz, J. Strengthening of Flat Slabs against Punching Shear Using Post-Installed Shear Reinforcement. ACI Struct. J. 2010, 107, 434–442. [Google Scholar]

- Garcez, M.; Meneghetti, L.; da Silva Filho, L.C. Structural performance of RC beams post strengthened with carbon, aramid, and glass FRP systems. J. Compos. Constr. 2008, 12, 522–530. [Google Scholar] [CrossRef]

- Mousa, S.; Mohame, H.M.; Benmokrane, B.; Nanni, A. Flexural behavior of long-span square reinforced concrete members with uniformly distributed fiber- reinforced polymer bars. ACI Struct. J. 2020, 117, 209–222. [Google Scholar]

- Saleh, H.; Kalfat, R.; Abdouka, K.; Al-Mahaidi, R. Punching shear strengthening of RC slabs using L-CFRP laminates. Eng. Struct. 2019, 194, 274–289. [Google Scholar] [CrossRef]

- Ferreira, D.R.S.M.; Moreno, C. Punching shear strengthening of flat slabs: CFRP and shear Reinforcement. In Proceedings of the Concrete—Innovation and Design, Fib Symposium, Copenhagen, Denmark, 18–20 May 2015. [Google Scholar]

- Junior, P.S.M.S.; Silva, A.G.M.; Oliveira, D.R.C. CFRP laminate as punching shear reinforcement. Eng. Struct. 2021, 237, 112072. [Google Scholar] [CrossRef]

- Huang, Z.; Zhao, Y.; Zhang, J.; Wu, Y. Punching shear behaviour of concrete slabs reinforced with CFRP grids. Structures 2020, 26, 617–625. [Google Scholar] [CrossRef]

- Akhundzada, H.; Donchev, T.; Petkova, D. Strengthening of slab-column connection against punching shear failure with CFRP laminates. Compos. Struct. 2019, 208, 656–664. [Google Scholar] [CrossRef] [Green Version]

- Nayak, C.B. Experimental and numerical investigation on compressive and flexural behavior of structural steel tubular beams strengthened with AFRP composites. J. King Saud Univ. Eng. Sci. 2021, 33, 88–94. [Google Scholar] [CrossRef]

- Breveglieri, M.; Aprile, A.; Barros, J.A.O. Embedded Through-Section shear strengthening technique using steel and CFRP bars in RC beams of different percentage of existing stirrups. Compos. Struct. 2015, 126, 101–113. [Google Scholar] [CrossRef] [Green Version]

- Baggio, D.; Soudki, K.; Noël, M. Strengthening of shear critical RC beams with various FRP systems. Constr. Build. Mater. 2014, 66, 634–644. [Google Scholar] [CrossRef]

- Chaallal, O.; Mofidi, A.; Benmokrane, B.; Neale, K. Embedded Through-Section FRP rod method for shear strengthening of RC beams: Performance and comparison with existing techniques. J. Compos. Constr. 2011, 15, 374–383. [Google Scholar] [CrossRef]

- Sundarraja, M.C.; Rajamohan, S. Strengthening of RC beams in shear using GFRP inclined strips—An experimental study. Constr. Build. Mater. 2009, 23, 856–864. [Google Scholar] [CrossRef]

- Chen, C.-C.; Chen, S.-L. Strengthening of reinforced concrete slab-column connections with carbon fiber reinforced polymer laminates. Appl. Sci. 2020, 10, 265. [Google Scholar] [CrossRef] [Green Version]

- Gherdaoui, M.; Guenfoud, M.; Madi, R. Punching behavior of strengthened and repaired RC slabs with CFRP. Constr. Build. Mater. 2018, 170, 272–278. [Google Scholar] [CrossRef]

- Amiri, S.; Talaeitaba, S.B. Punching shear strengthening of flat slabs with EBROG and EBRIG—FRP strips. Structures 2020, 26, 139–155. [Google Scholar] [CrossRef]

- Sissakis, K.; Sheikh, S.A. Strengthening Concrete Slabs for Punching Shear with Carbon Fiber-Reinforced Polymer. ACI Struct. J. 2007, 104, 49–59. [Google Scholar]

- Meisami, M.H.; Mostofinejad, D.; Nakamura, H. Strengthening of flat slabs with FRP fan for punching shear. Compos. Struct. 2015, 119, 305–314. [Google Scholar] [CrossRef]

- Llaurado, P.; Ibell, T.; Gomez, J.F. Pull-out and shear-strength models for FRP spike anchors. Compos. Part B 2017, 116, 239–252. [Google Scholar] [CrossRef]

- Sathishkumar, T.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Wahab, N.; Srinophakun, P.; Hussain, Q.; Chaimahawan, P. Performance of concrete confined with a jute–polyester hybrid Fiber reinforced polymer composite: A novel strengthening technique. Fibers 2019, 7, 72. [Google Scholar] [CrossRef] [Green Version]

- Rodsin, K.; Hussain, Q.; Suparp, S.; Nawaz, A. Compressive behavior of extremely low strength concrete confined with low-cost glass FRP composites. Case Stud. Constr. Mater. 2020, 13, e00452. [Google Scholar] [CrossRef]

- Hussain, Q. A study on sprayed fiber reinforced polymer composites for strengthening of reinforced concrete members. Ph.D. Thesis, Thammasat University, Bangkok, Thailand, 2015. [Google Scholar]

- Hassan, M.; Ahmad, E.A.; Benmokrane, B. Punching shear strength of glass fiber-reinforced polymer reinforced concrete flat slabs. Can. J. Civ. Eng. 2013, 33, 951–960. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, C.; Yu, G. Investigation of structural behaviors of laterally restrained GFRP reinforced concrete slabs. Compos. Part B 2012, 43, 1586–1597. [Google Scholar] [CrossRef]

- Carvelli, V.; Pisani, M.A.; Poggi, C. Fatigue behavior of concrete bridge deck slabs reinforced with GFRP bars. Compos. Part B 2010, 41, 560–567. [Google Scholar] [CrossRef]

- El-Gamal, S.E.; El-Salakawy, E.F.; Benmokrane, B. Durability and structural performance of carbon fibre reinforced polymer–reinforced concrete parking garage slabs. Can. J. Civ. Eng. 2009, 36, 617–627. [Google Scholar] [CrossRef]

- Said, M.; Adam, M.A.; Arafa, A.E.; Moatasem, A. Improvement of punching shear strength of reinforced lightweight concrete flat slab using different strengthening techniques. J. Build. Eng. 2020, 32, 101749. [Google Scholar] [CrossRef]

- Tang, Y.; Fang, S.; Chen, J.; Ma, L.; Li, L.; Wu, X. Axial compression behavior of recycled-aggregate-concrete-filled GFRP–steel compositetube columns. Eng. Struct. 2020, 216, 110676. [Google Scholar] [CrossRef]

- Hassan, M.; Ahmad, E.; Benmokrane, B. Punching-Shear Strength of Normal and High-Strength Two-Way Concrete Slabs Reinforced with GFRP Bars. J. Compos. Constr. 2013, 17, 04013003. [Google Scholar] [CrossRef]

- Ju, M.; Park, K.; Park, C. Punching Shear Behavior of Two-Way Concrete Slabs Reinforced with Glass-Fiber-Reinforced Polymer (GFRP) Bars. Polymers 2018, 10, 893. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jafarian, N.; Mostofinejad, D.; Naderi, A. Effects of FRP grids on punching shear behavior of reinforced concrete slabs. Structures 2020, 28, 2523–2536. [Google Scholar] [CrossRef]

- ACI 318: Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2014.

- ASTM D7205/D7205M-06(2011). Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

| Reinforcement | Diameter (mm) | Elastic Modulus (GPa) | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|

| Steel Bars | 16 | 210 | 488 | 652 |

| GFRP | 6 | 35.6 | / | 500 |

| Specimen ID | Slab Thickness (mm) | Effective Depth (mm) | Flexural Reinforcement | Shear Reinforcement | |||

|---|---|---|---|---|---|---|---|

| No. | Size (mm) | ||||||

| CON | 150 | 114 | 7DB-16@200 | / | / | / | / |

| SG0.5D | 150 | 114 | 7DB-16@200 | 0.4 | 0.5 | 7 | 6 |

| DB0.5D | 150 | 114 | 7DB-16@200 | 0.4 | 0.5 | 7 | 6 |

| RD0.5D | 150 | 114 | 7DB-16@200 | 0.4 | 0.5 | 7 | 6 |

| SG0.75D | 150 | 114 | 7DB-16@200 | 0.4 | 0.75 | 4 | 6 |

| DB0.75D | 150 | 114 | 7DB-16@200 | 0.4 | 0.75 | 4 | 6 |

| RD0.75D | 150 | 114 | 7DB-16@200 | 0.4 | 0.75 | 4 | 6 |

| Specimen ID | Percentage Strain at Percentage Peak Load | Failure | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 25 | 50 | 75 | 100 | ||||||

| L | S | L | S | L | S | L | S | ||

| CON | 0.01 | / | 0.09 | / | 0.16 | / | 0.22 | / | / |

| SG0.50D | 0.07 | 0.03 | 0.16 | 0.05 | 0.23 | 0.08 | 0.31 | 0.12 | 0.98 |

| DB0.50D | 0.01 | 0.01 | 0.11 | 0.03 | 0.24 | 0.07 | 0.46 | 0.17 | 0.91 |

| RD0.50D | / | 0.02 | / | 0.05 | / | 0.12 | / | 0.19 | / |

| SG0.75D | 0.02 | 0.01 | 0.14 | 0.02 | 0.26 | 0.04 | 0.37 | 0.08 | 1.29 |

| DB0.75D | 0.04 | 0.0 | 0.18 | 0.03 | 0.29 | 0.11 | 0.40 | 0.18 | 1.06 |

| RD0.75D | 0.11 | 0.02 | 0.17 | 0.04 | 0.23 | 0.07 | 0.34 | 0.12 | 1.35 |

| Specimen ID | ||||||

|---|---|---|---|---|---|---|

| CON | 1256 | / | 229.15 | / | 229.15 | 1.00 |

| SG0.50D | 1256 | 113.10 | 173.60 | 56.47 | 230.07 | 0.92 |

| DB0.50D | 1256 | 226.19 | 173.60 | 112.94 | 286.54 | 1.12 |

| RD0.50D | 1256 | 226.19 | 173.60 | 112.94 | 286.54 | 1.08 |

| SG0.75D | 1256 | 113.10 | 173.60 | 37.43 | 211.03 | 0.87 |

| DB0.75D | 1256 | 226.19 | 173.60 | 74.86 | 248.46 | 1.01 |

| RD0.75D | 1256 | 226.19 | 173.60 | 74.86 | 248.46 | 0.94 |

| Specimen ID | |||

|---|---|---|---|

| CON | / | / | / |

| SG0.50D | 2916 | 269.23 | 0.85 |

| DB0.50D | 2971 | 274.31 | 1.04 |

| RD0.50D | 3048 | 281.42 | 1.02 |

| SG0.75D | 2560 | 236.36 | 0.89 |

| DB0.75D | 2610 | 240.98 | 1.03 |

| RD0.75D | 2680 | 247.44 | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yooprasertchai, E.; Dithaem, R.; Arnamwong, T.; Sahamitmongkol, R.; Jadekittichoke, J.; Joyklad, P.; Hussain, Q. Remediation of Punching Shear Failure Using Glass Fiber Reinforced Polymer (GFRP) Rods. Polymers 2021, 13, 2369. https://doi.org/10.3390/polym13142369

Yooprasertchai E, Dithaem R, Arnamwong T, Sahamitmongkol R, Jadekittichoke J, Joyklad P, Hussain Q. Remediation of Punching Shear Failure Using Glass Fiber Reinforced Polymer (GFRP) Rods. Polymers. 2021; 13(14):2369. https://doi.org/10.3390/polym13142369

Chicago/Turabian StyleYooprasertchai, Ekkachai, Ratchanon Dithaem, Titi Arnamwong, Raktipong Sahamitmongkol, Jira Jadekittichoke, Panuwat Joyklad, and Qudeer Hussain. 2021. "Remediation of Punching Shear Failure Using Glass Fiber Reinforced Polymer (GFRP) Rods" Polymers 13, no. 14: 2369. https://doi.org/10.3390/polym13142369

APA StyleYooprasertchai, E., Dithaem, R., Arnamwong, T., Sahamitmongkol, R., Jadekittichoke, J., Joyklad, P., & Hussain, Q. (2021). Remediation of Punching Shear Failure Using Glass Fiber Reinforced Polymer (GFRP) Rods. Polymers, 13(14), 2369. https://doi.org/10.3390/polym13142369