Influence of the Mold Material on the Injection Molding Cycle Time and Warpage Depending on the Polymer Processed

Abstract

:1. Introduction

2. Materials and Methods

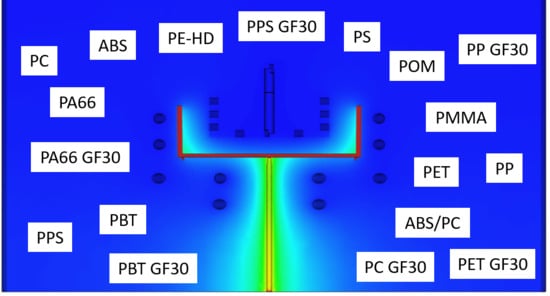

2.1. Simulation

2.2. Experimental Validation of Cycle Time Reduction

3. Results and Discussion

3.1. Cycle Time Reduction

3.2. Experimental Validation of Cycle Time Reduction

3.3. Warpage, Filling Pressure and Clamp Force

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Polymer | TC (-) | Cycle Time 1.2343 ESU (s) | Cycle Time Test Alloy (s) | Cycle Time Reduction (CTR) (%) |

|---|---|---|---|---|

| ABS | 4.3 | 12.3 | 10.8 | 11.9 |

| ABS/PC | 11.2 | 18.4 | 13.9 | 24.4 |

| PE-HD | 3.9 | 12.3 | 10.6 | 13.6 |

| PA 6.6 | 1.4 | 6.9 | 6.8 | 2.8 |

| PA 6.6 GF30 | 1.9 | 8.6 | 7.6 | 11.3 |

| PBT | 2.4 | 8.9 | 8.4 | 6.0 |

| PBT GF30 | 6.0 | 14.9 | 12.6 | 14.9 |

| PC | 4.7 | 11.8 | 10.0 | 14.6 |

| PC GF30 | 11.0 | 18.0 | 14.0 | 22.5 |

| PET | 3.4 | 10.4 | 9.4 | 9.7 |

| PET GF30 | 2.0 | 8.1 | 7.6 | 6.1 |

| PMMA | 6.9 | 17.8 | 14.7 | 17.6 |

| POM | 5.5 | 24.7 | 20.8 | 15.6 |

| PP | 2.8 | 10.6 | 9.5 | 10.3 |

| PP GF30 | 4.2 | 14.8 | 12.7 | 14.0 |

| PPS | 2.2 | 8.0 | 7.5 | 6.3 |

| PPS GF30 | 2.4 | 7.7 | 7.4 | 4.2 |

| PS | 6.0 | 13.0 | 11.3 | 13.4 |

| Polymer | TC (-) | Cycle Time 1.2343 ESU (s) | Cycle Time Test Alloy (s) | Cycle Time Reduction (CTR) (%) |

|---|---|---|---|---|

| ABS | 4.3 | 38.4 | 35.5 | 7.6 |

| ABS/PC | 11.2 | 48.8 | 42.1 | 13.8 |

| PE-HD | 3.9 | 35.8 | 32.6 | 9.0 |

| PA 6.6 | 1.4 | 21.4 | 20.2 | 5.6 |

| PA 6.6 GF30 | 1.9 | 25.8 | 24.1 | 6.7 |

| PBT | 2.4 | 29.2 | 27.2 | 6.7 |

| PBT GF30 | 6.0 | 42.9 | 37.7 | 12.2 |

| PC | 4.7 | 34.4 | 31.5 | 8.7 |

| PC GF30 | 11.0 | 48.5 | 41.7 | 13.9 |

| PET | 3.4 | 32.6 | 30.2 | 7.1 |

| PET GF30 | 2.0 | 21.6 | 20.1 | 6.8 |

| PMMA | 6.9 | 55.2 | 49.1 | 11.1 |

| POM | 5.5 | 96.1 | 88.6 | 7.8 |

| PP | 2.8 | 30.0 | 27.5 | 8.4 |

| PP GF30 | 4.2 | 46.4 | 41.8 | 9.9 |

| PPS | 2.2 | 19.1 | 17.6 | 8.0 |

| PPS GF30 | 2.4 | 20.8 | 19.2 | 7.8 |

| PS | 6.0 | 38.3 | 35.0 | 8.6 |

| Polymer | TC (-) | CTR Simulated 1 mm Part (%) | CTR Predicted 1 mm Part (%) | CTR Simulated 3 mm Part (%) | CTR Predicted 3 mm Part (%) |

|---|---|---|---|---|---|

| PVC | 5.5 | 11.9 | 14.0 | 8.6 | 9.6 |

| POM | 2.2 | 8.0 | 7.6 | 7.8 | 7.0 |

| PP | 3.1 | 12.6 | 9.4 | 7.9 | 7.7 |

| Polymer | Deformation 1 mm Part 1.2343 ESU (%) | Deformation 1 mm Part Test Alloy (%) | Deformation 3 mm Part 1.2343 ESU (%) | Deformation 3 mm Part Test Alloy (%) |

|---|---|---|---|---|

| ABS | 1.61 | 1.16 | 0.91 | 0.77 |

| ABS/PC | 0.96 | 0.72 | 0.88 | 0.80 |

| PE-HD | 3.77 | 2.65 | 2.60 | 2.06 |

| PA 6.6 | 2.61 | 1.89 | 1.57 | 1.34 |

| PA 6.6 GF30 | 2.18 | 1.83 | 1.20 | 1.11 |

| PBT | 2.21 | 1.66 | 2.50 | 2.17 |

| PBT GF30 | 2.23 | 1.95 | 1.96 | 1.82 |

| PC | 1.58 | 1.12 | 1.13 | 0.98 |

| PC GF30 | 1.08 | 0.90 | 0.86 | 0.82 |

| PET | 1.66 | 1.29 | 1.18 | 1.06 |

| PET GF30 | 1.10 | 0.91 | 0.84 | 0.79 |

| PMMA | 1.06 | 0.82 | 0.78 | 0.69 |

| POM | 1.44 | 1.05 | 2.33 | 2.18 |

| PP | 2.92 | 2.23 | 1.78 | 1.48 |

| PP GF30 | 1.27 | 1.04 | 0.81 | 0.72 |

| PPS | 0.73 | 0.62 | 0.47 | 0.44 |

| PPS GF30 | 0.68 | 0.55 | 0.99 | 0.98 |

| PS | 1.3 | 0.97 | 0.79 | 0.68 |

References

- Zorič, J.; Čatić, I. General Equation for Cooling Time Calculation of Plastomeric Parts. In Proceedings of the ANTEC, Boston, MA, USA, 4–7 May 1981; pp. 814–817. [Google Scholar]

- Čatić, I. Cavity Temperature—An Important Parameter in the Injection Molding Process. Polym. Eng. Sci. 1979, 19, 893–899. [Google Scholar] [CrossRef]

- Čatić, I.; Rujnić-Sokele, M.; Šercer, M. Influence of Cavity Materials on the Cooling Time of Molding. In Proceedings of the ANTEC, Boston, MA, USA, 1–5 May 2005; pp. 961–965. [Google Scholar]

- Kelly, A.L.; Mulvaney-Johnson, L.; Beechey, R.; Coates, P.D. The Effect of Copper Alloy Mold Tooling on the Performance of the Injection Molding Process. Polym. Eng. Sci. 2011, 51, 1837–1847. [Google Scholar] [CrossRef]

- Ozcelik, B.; Ozbay, A.; Demirbas, E. Influence of Injection Parameters and Mold Materials on Mechanical Properties of ABS in Plastic Injection Molding. Int. Commun. Heat Mass. Transf. 2010, 37, 1359–1365. [Google Scholar] [CrossRef]

- Reddy, K.P.; Panitapu, B. High Thermal Conductivity Mould Insert Materials for Cooling Time Reduction in Thermoplastic Injection Moulds. Mater. Today Proc. 2017, 4, 519–526. [Google Scholar] [CrossRef]

- Kovács, J.G.; Bercsey, T. Influence of Mold Properties on the Quality of Injection Molded Parts. Period. Polytech. Ser. Mech. Eng. 2005, 49, 115–122. [Google Scholar]

- Zink, B.; Szabó, F.; Hatos, I.; Suplicz, A.; Kovács, N.K.; Hargitai, H.; Tábi, T.; Kovács, J.G. Enhanced Injection Molding Simulation of Advanced Injection Molds. Polymers 2017, 9, 77. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Berger, G.R.; Zorn, D.; Friesenbichler, W.; Bevc, F.; Bodor, C.J. Efficient Cooling of Hot Spots in Injection Molding. A Biomimetic Cooling Channel versus a Heat-Conductive Mold Material and a Heat Conductive Plastics. Polym. Eng. Sci. 2019, 59, E180–E188. [Google Scholar] [CrossRef] [Green Version]

- Hassan, H.; Regnier, N.; Le Bot, C.; Defaye, G. 3D study of cooling system effect on the heat transfer during polymer injection molding. Int. J. Therm. Sci. 2010, 49, 161–169. [Google Scholar] [CrossRef]

- Kennedy, P.K.; Zheng, R. Flow Analysis of Molds, 2nd ed.; HANSER: Munich, Germany, 2013; pp. 64–80. [Google Scholar]

- Heinle, M.; Drummer, D. Heat Transfer Coefficient in Injection Molding of Polymers. Int. Polym. Process. 2015, 30, 434–441. [Google Scholar] [CrossRef]

- Urquhart, J.M.; Brown, C.S. The Effect of Uncertainty in Heat Transfer Data on The Simulation of Polymer Processing. In NPL Report DEPC-MPR 001; National Physical Laboratory: Teddington, UK, 2004. [Google Scholar]

- Nguyen-Chung, T.; Jüttner, G.; Löser, C.; Pham, T.; Gehde, M. Determination of the Heat Transfer Coefficient from Short-Shots Studies and Precise Simulation of Microinjection Molding. Polym. Eng. Sci. 2010, 50, 165–173. [Google Scholar] [CrossRef]

- Nylund, C.; Meinander, K. The influence of heat transfer coefficient on cooling time in injection molding. Heat Mass Transf. 2005, 41, 428–431. [Google Scholar] [CrossRef]

| Mold Property | 1.2343 ESU | Test Alloy |

|---|---|---|

| Thermal conductivity (W m−1 K−1) | 26 | 49 |

| Specific heat capacity (J kg−1 K−1) | 480 | 473 |

| Density (kg m−3) | 7780 | 7944 |

| Polymer | Filler | Grade Name | Manufacturer | Melt Temp. (°C) | Mold Temp. (°C) | Ejection Temp. (°C) |

|---|---|---|---|---|---|---|

| ABS | - | Lustran ABS LGA | INEOS ABS | 226 | 44 | 86 |

| ABS/PC | - | Cycoloy LG8002 | SABIC Innov. Pl. US, LLC | 277 | 87 | 104 |

| PE-HD | - | Marlex 9004 PE | Chevron Philips | 234 | 27 | 80 |

| PA 6.6 | - | Zytel ST801HS NC010 | DuPont Perf. Polymers | 280 | 70 | 220 |

| PA 6.6 | GF30 | Ultramid A3WG6 | BASF | 290 | 85 | 195 |

| PBT | - | Pocan B 1505 | Lanxess | 270 | 100 | 170 |

| PBT | GF30 | Ultradur B 4300 G6 HR | BASF | 260 | 80 | 110 |

| PC | - | Lexan ML7681 | SABIC Innov. Pl. US, LLC | 285 | 85 | 128 |

| PC | GF30 | Lexan 3413 | SABIC Innov. Pl. US, LLC | 329 | 99 | 120 |

| PET | - | J125 | Mitsui Chemicals Co Ltd. | 270 | 100 | 150 |

| PET | GF30 | Rynite FR530 NC010 | DuPont Perf. Polymers | 280 | 110 | 195 |

| PMMA | - | Plexiglas 8N | Evonik Roehm GmbH | 235 | 70 | 94 |

| POM | - | Ultraform N2320 003 | BASF | 200 | 90 | 110 |

| PP | - | RJ766MO | Borealis Europe | 240 | 40 | 111 |

| PP | GF30 | Hostacom G3 U01 | SF Hoechst | 230 | 50 | 93 |

| PPS | - | Fortron 6162A7 | Celanese | 325 | 147 | 228 |

| PPS | GF30 | Supec G301T | SABIC Innov. Pl. US, LLC | 320 | 150 | 220 |

| PS | - | Polystyrene 804 | TOTAL Petrochemicals | 230 | 50 | 80 |

| Mold Property | W300 | W600 | P20 | Copper Alloy |

|---|---|---|---|---|

| Thermal conductivity (W m−1 K−1) | 26 | 44.2 | 29 | 250 |

| Specific heat capacity (J kg−1 K−1) | 480 | 473 | 460 | 335 |

| Density (kg m−3) | 7780 | 7951 | 7800 | 8830 |

| Polymer | Filler | Grade Name | Manufacturer | Melt Temp. (°C) | Mold Temp. (°C) | Ejection Temp. (°C) |

|---|---|---|---|---|---|---|

| PVC | - | V-1 | Hepworth Building | 195 | 40 | 68 |

| POM | - | Kepital F10-02 | Korea Engineering Plastics Company Ltd. | 200 | 80 | 135 |

| PP | - | J3021 GR | Prime Polymer Co Ltd. | 225 | 40 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lucyshyn, T.; Des Enffans d’Avernas, L.-V.; Holzer, C. Influence of the Mold Material on the Injection Molding Cycle Time and Warpage Depending on the Polymer Processed. Polymers 2021, 13, 3196. https://doi.org/10.3390/polym13183196

Lucyshyn T, Des Enffans d’Avernas L-V, Holzer C. Influence of the Mold Material on the Injection Molding Cycle Time and Warpage Depending on the Polymer Processed. Polymers. 2021; 13(18):3196. https://doi.org/10.3390/polym13183196

Chicago/Turabian StyleLucyshyn, Thomas, Lara-Vanessa Des Enffans d’Avernas, and Clemens Holzer. 2021. "Influence of the Mold Material on the Injection Molding Cycle Time and Warpage Depending on the Polymer Processed" Polymers 13, no. 18: 3196. https://doi.org/10.3390/polym13183196

APA StyleLucyshyn, T., Des Enffans d’Avernas, L. -V., & Holzer, C. (2021). Influence of the Mold Material on the Injection Molding Cycle Time and Warpage Depending on the Polymer Processed. Polymers, 13(18), 3196. https://doi.org/10.3390/polym13183196