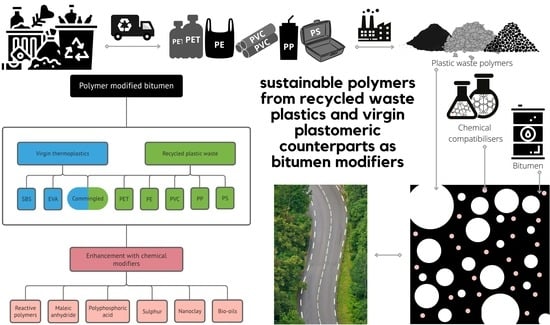

Sustainable Polymers from Recycled Waste Plastics and Their Virgin Counterparts as Bitumen Modifiers: A Comprehensive Review

Abstract

:1. Introduction

2. Bitumen

| Property | Value | References |

|---|---|---|

| Density (g/cm3) | 1.004–1.019 | [37,38,39,40] |

| Penetration (0.1 mm) | 59.10–98.0 | [37,41,42,43] |

| Penetration index (PI) | 0.152–0.601 | [44,45] |

| Softening point (°C) | 42–65 | [37,38,39,41,42,44,46,47] |

| Flash Point (°C) | 240–350 | [37,41,42] |

| Fire Point (°C) | 270–376 | [42] |

| Ductility (mm) | 76–720 | [37,41,42,46] |

| Viscosity @ 135 °C (cP) | 100–460.35 | [37,41] |

| Saturates (%) | 4.0–15.8 | [7,40] |

| Aromatics (%) | 39.6–69.0 | |

| Resins (%) | 15.0–34.8 | |

| Asphaltenes (%) | 9.0–14.0 | |

| Colloidal index | 0.190–0.333 | [7] |

3. Modification of Bitumen

4. Recycled Plastic Waste and Their Use in Roads

5. Virgin and Waste (Recycled) Plastomers to Improve Bitumen Performance

5.1. Polyethylene (PE) Modification of Bitumen

| Mixing Conditions | LDPE | HDPE | LLDPE | PP | EVA | EBA | References |

|---|---|---|---|---|---|---|---|

| Polymer/binder percentage (%) | 3–6 | 0.5–6 | 0.5–6 | 0.5–5 | 1–9 | 2–9 | [35,36,123,140,166,167,168] |

| Mixing temperature (°C) | 170 | 160–170 | 160–170 | 160–170 | 165–180 | 170–180 | [34,36,118,123,140,166,167,168,169] |

| Mixing time (h) | 1–2.5 | 1–2.5 | 1.2−2.5 | 1 | 2–7 | 2–6 | [34,36,118,123,140,166,167] |

| Mixing speed (rpm) | 4000 | 4000 | 4000 | 120 | 1000–3000 | 1000–1200 | [34,35,36,118,140,166,167,169] |

| Physical Properties | |||||||

| Softening point (°C) @ ASTM D-36 | 57–68.5 | 51–79 | 50–67 | 53–76 | 54–62 | 27–72 | [34,36,125,140,168,169] |

| Penetration (dmm) @ ASTM D-5 | 23.5–40.8 | 21–36 | 13–41 | 15–35 | 47–53 | 46–75 | [34,36,125,140,168,169,170] |

| Penetration index | 0.44–1.17 | −2–1.5 | −2–1.5 | 1.96–2.28 | 0.49–1.24 | 0.07–2.92 | [3,115,116,171] |

| Viscosity (cP) at 135–165 °C @ ASTM D4402 | 200–700 | 270–578 | 380 | 590–687.5 | 980 | 940 | [8,34,44,115,170,172] |

| Ductility (cm) at 25 °C @ ASTM D-113 | 91–148.5 | 79–133 | 40.25–73.5 | >100 | 5–22 | 10–40 | [7,36,45,125,168,169,173,174] |

| Specific gravity @ ASTM D-70–76 | 1.014–1.042 | 0.935–1.01 | - | 1.015 | 1.015–1.032 | - | [36,169,174,175] |

| Flash point (°C) @ ASTM D 92–02 | 200–240 | 215–257 | - | 199–292 | 260 | - | [36,175,176,177] |

| Storage stability(softening point top–bottom) | 0.8–2.5 | 0.96–1.1 | 3 | - | 1–1.9 | 0–3 | [34,170,171,172,178,179] |

| Stability Index | 48.1 | 5.42 | 8.43 | - | - | - | [167] |

| Rheological Properties | |||||||

| G*/Sinδ (kPa) | 0.756–5.911 | 9–12.3 | 1.12–15.20 | 3.7–32.2 | 0.8–1.7 | - | [163,170,171,180,181,182,183] |

| G’ (kPa) | - | - | 0.31–29.90 | 0.38–7.04 | - | 0.62–4.94 | [180,181,182,184] |

| G” (kPa) | - | - | 6.4–37.5 | 3.7–30.6 | - | 0.71–7.57 | |

| G* (kPa) at 10 rad/s | 3.97–10.75 | 7.15–23.08 | 6.5–38.9 | 3.72–31.36 | 0.3115–170.790 | 62.3–75.0 | |

| δ (°) | - | 42.9–83.9 | 71.5–88.1 | 77.01–84.05 | 80–87 | 6.25–64.2 | [180,181,182,183] |

| SARA Analysis (ASTM D-2006) | |||||||

| Asphaltene (%) | - | - | 17.6–18.8 | 11.1–13.6 | 11.7–14.7 | - | [180,181,185] |

| Aromatics (%) | - | - | 34.4–41.9 | 31.8–39.6 | 32.5–38.8 | - | |

| Resins (%) | - | - | 21.0–27.3 | 41.5–46.1 | 40.3–44.2 | - | |

| Saturates (%) | - | - | 17.3–19.7 | 6.8–8.1 | 8.6–9.2 | - | |

| Mixing Conditions | LDPE | HDPE | LLDPE | PP | EVA | EBA | References |

|---|---|---|---|---|---|---|---|

| Polymer/binder percentage (%) | 2–10 | 3–6 | 2–5 | 3–6 | 1–3 | N/A | [35,57,115,117,175,186,187,188] |

| Mixing temperature (°C) | 160–170 | 185 | 180 | 165–170 | 180 | N/A | [8,15,35,57,115,117,186,187,188] |

| Mixing time (h) | 1–2 | 1.5 | 1.5 | 2 | 6 | N/A | [8,35,57,117,175,186,187,189] |

| Mixing speed (rpm) | 3000–5000 | 4000 | 3750 | 500 | 1800–4000 | N/A | [8,35,57,115,175,186,187,189] |

| Physical Properties | |||||||

| Softening point (°C) @ ASTM D-36 | 44–68.5 | 43.7–60.5 | 58–70 | 52.05–64 | 26 | N/A | [8,9,115,175,176,186,189,190] |

| Penetration (dmm) @ ASTM D-5 | 41–74 | 46–68 | 47–56 | 27–68 | 37 | N/A | |

| Penetration index | 0.08–0.43 | −1.7–0.6 | −1.13–5.81 | −0.8–2.28 | 0.11–2.38 | N/A | [95,115,175,191,192,193] |

| Viscosity (cP) at 135–165 °C @ ASTM D4402 | 200–700 | 600 | 480 | 590–687.5 | 420 | N/A | [8,115,189,190,194] |

| Ductility (cm) at 25 °C @ ASTM D-113 | 58–69 | 48–68 | 22–61 | 52–66 | - | N/A | [176,189] |

| Flash point (°C) | 200–240 | 215–257 | - | 199–292 | - | N/A | [176] |

| Fire point (°C) | - | - | - | 345 | - | N/A | [175] |

| Storage stability @ ASTM D-7173(softening point top to bottom) | 2.8–4.7 | 41.8 | 3.1–4.9 | - | 0.2–5.2 | N/A | [8,189,191,195] |

| Rheological Properties | |||||||

| G*/Sinδ (kPa) | 0.09–12 | 2.26 | 1.12–15.20 | 2–47 | 4.08 | N/A | [8,180,190,196,197] |

| G* (kPa) at 1 rad/s | 1.23–11.7 | - | 6.5–38.9 | - | - | N/A | |

| δ (°) | 70.23–88.12 | 18 | 71.5–88.1 | - | 19 | N/A | [180,190] |

| SARA Analysis | |||||||

| Asphaltene (%) | 19.0 | 15.4 | - | - | 11.7 | N/A | [198,199] |

| Aromatics (%) | 24.0 | 24.6 | - | - | 38.8 | N/A | |

| Resins (%) | 37.8 | 34.9 | - | - | 40.3 | N/A | |

| Saturates (%) | 19.2 | 25.1 | - | - | 9.2 | N/A | |

5.2. Polyethylene Terephthalate (PET) Modification of Bitumen

5.3. Polyvinyl Chloride (PVC) Modification of Bitumen

5.4. Polypropylene (PP) Modification of Bitumen

5.5. Polystyrene (PS) Modification of Bitumen

5.6. Ethylene-Vinyl Acetate (EVA) Modification of Bitumen

6. Co-Mingled Plastomers for Bitumen Modification

7. Enhancements of Plastomer-Modified Bitumen Due to Chemical Modifiers

7.1. Chemically Functionalized Polymers

7.2. Maleated Bitumen

7.3. Polyphosphoric Acid

7.4. Sulphur

7.5. Nano-Clay and Nanomaterials

7.6. Bio-Oil

| Modifiers/Compatibilizers | Method/Weight% of Modifiers | Key Findings | References |

|---|---|---|---|

| Reactive polymer (TOR) |

|

| [41] |

| Reactive polymer, Amorphous poly alpha olefin (APAO) |

|

| [355] |

| EMA-GMA Terpolymer (ethylene/metilacrilate/glycidyl metacrylate) and HDPE |

|

| [9] |

| Malleated bitumen (Reaction of bitumen with maleic anhydride) |

|

| [57] |

| Maleic anhydride grafted polyethylene (PE-g-MA)Maleic anhydride-grafted ethylene-octene copolymer (POE-g-MA)Maleic anhydride-graftedlinear LDPEMaleic anhydride-grafted ethylenevinyl-acetate copolymerMaleic anhydride-graftedstyrene-ethylene-butylene-styrene |

|

| [356] |

| LLDPE-g-MA |

|

| [357] |

| Electron irradiated recycled low-density polyethylene (e-LDPER) |

|

| [207] |

| Electron irradiated recycled high-density polyethylene (e-HDPER) |

|

| [358] |

| Silane crosslinking agent (Si-XLPE) |

|

| [292] |

| Polyphosphoric acid |

|

| [9] |

| Sulphur |

|

| [359] |

| Sulphur |

|

| [360] |

| Flake graphiteGraphite nanoplatelets |

|

| [361] |

| Rapeseed bio-oilFish bio-oil |

|

| [354] |

| Bio-oil from waste wood |

|

| [362] |

| Bio-oil |

|

| [363] |

8. Critical Discussion

Drawbacks and Future Works

9. Conclusions and Recommendations

- The incorporation of recycled LDPE in bitumen saw a decrease in penetration value (approximately 16%) at 2% polymer content—a commonly adopted polymer loading; however, increments to the softening point (approximately 15%), flash point and fire point were also noticed. Moisture resistance and bitumen’s complex modulus were also increased by 13% and 11%, respectively;

- Recycled HDPE-modified bitumen results exhibited improvements up to 89% in MSCR tests, hence emphasizing the general rheological betterment at high temperature;

- The use of commingled PE (mainly from post-consumer waste plastics) provided general benefits to the bitumen performance although more variability compared to single-source recycled plastic was noticed;

- The suggested optimum polymer content for polyethylene-based modifiers is 4% by weight of bitumen although greater polymer contents were also evaluated; the greater the polymer content, the higher the chances of phase separation during storage at high temperature;

- PET-modified binders used to make plastic-asphalt exhibited improvements in the Marshall stability by 12%. Despite improvements with the use of PET, the high melting temperature of the plastic does not allow a homogenous blend during the mixing process, therefore, making it unfeasible to be considered as a candidate for bitumen modification;

- The addition of PVC into bitumen saw a reduction in penetration values by 57% and an increment in softening point by 26%. Viscosity was increased by 300% while ductility values dipped. PVC toxicity at high temperature remains a major issue, especially when treated with phthalates of various types;

- PP-modified binders showed a reduction in penetration values by 18% to 30% at 3% polymer content and 38% to 50% at 5% polymer content. However, the softening point was improved between 4% to 30% and 11% to 43.5% at 3% and 5% polymer contents, respectively. Ductility values were reduced by 20% at 5% polymer content;

- The use of PS increased softening points by 29% and 35% for 80/100-grade bitumen and 60/70 grade bitumen, respectively, however decreasing penetration values up to 20%;

- EVA-modified binders exhibited improvements of 22% to 53% in softening point, however decreasing penetration values by 33% to 51%. The ductility of bitumen was improved by 20% at 5% polymer content. Unlike other polymers such as PP, PVC, and PE, EVA-modified binders showed no major rheological drawbacks when polymer contents were increased;

- Commingled plastics modified binders comprising of HDPE/PP exhibited an improvement of up to 179% in Marshall tests on asphalt samples;

- Plastomeric modification of bitumen is mainly achieved by the use of EVA and PE; however, more polymers (especially in their recycled form) are being experimented with in a continuous effort to find a solution to the plastics waste problem;

- Some recycled plastomeric polymers have a melting temperature which is above the bitumen mixing temperature; this implies that their use is mainly as a filler or ‘synthetic’ aggregate, depending on their size. In these cases, the cost of the filler/aggregate vs. the cost of the polymer used as ‘synthetic’ aggregate should carefully be considered as the steps involved with recycling contribute to the higher final cost;

- Low melting temperature polymers (i.e., PE, both virgin and recycled) have demonstrated their suitable use as bitumen modifiers. Recycled plastomers are also considered to be cost effective due to their lower prices in comparison to a) chemically virgin plastomers and b) commonly used elastomers. Though, when used as bitumen modifier, their relative quantity in the mix is minimal (i.e., 0.25–0.5% by weight of the asphalt mix) hence reducing the environmental benefits commonly associated with recycling;

- Generally, plastomers provide excellent high-temperature properties and relatively good—depending on the specific polymer—low-temperature behaviour (i.e., EVA at high VA content). However, most of the research studies investigating plastomers are focused on the high-temperature behaviour;

- Plastomers are also acknowledged to be prone to phase separation due to the low compatibility (molecular weight, polarity, and crystallinity) between the polymer and bitumen. However, several commonly adopted elastomers (i.e., SBS) are also not immune from separation issues. New PE-based polymers are now being tested for bitumen applications that show self-crosslinking abilities and greater compatibility with bitumen;

- To improve plastomer-bitumen compatibility, several compounds have been used. These modifiers are reactive polymers, polyphosphoric acid, organometallic compounds, sulfonic acid, silanes, maleic anhydride, carboxylic anhydride, thiourea dioxide, sulphur, antioxidants, nanomaterials, clay minerals, and bio-oils. Despite the persistent use of sulphur and PPA, new additives are being investigated by many authors with promising results (i.e., maleic anhydride to improve polarity and decrease crystallinity, or nanoparticles). The use of nano materials as stabilisers, although appealing to many, have proved to be an expensive exercise, possibly too difficult for being applied on large scale.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| SARA | Saturate, Aromatic, Resin and Asphaltene |

| LCA | Life Cycle Assessment |

| CAGR | Compound Annual Growth Rate |

| PMB | Polymer Modified Bitumen |

| EPA | Environmental Protection Agency |

| PE | Polyethylene |

| m-PE | Metallocene-catalysed Polyethylene |

| LDPE | Low Density Polyethylene |

| VLDPE | Very Low-Density Polyethylene |

| LLDPE | Linear Low-Density Polyethylene |

| MDPE | Medium Density Polyethylene |

| HDPE | High Density Polyethylene |

| UHMWPE | Ultra-high Molecular Weight Polyethylene |

| PP | Polypropylene |

| aPP | Atactic Polypropylene |

| iPP | Isotactic Polypropylene |

| PS | Polystyrene |

| EPS | Expended Polystyrene |

| PVC | Polyvinyl Chloride |

| PET | Polyethylene Terephthalate |

| EBA | Ethylene Butyl Acrylate |

| EVA | Ethylene-Vinyl Acetate |

| SBS | Styrene-butadiene-styrene |

| MA-g-PE | Maleic Anhydride grafted Polyethylene |

| HCL | Hydrochloric Acid |

| PPA | Polyphosphoric Acid |

| XRF | X-ray fluorescence |

| TG/DTG | Thermogravimetric/Differential Thermogravimetric |

| FTIR | Fourier Transform Infra-red |

| GCMS | Gas Chromatography and Mass Spectroscopy |

| MFI | Melt Flow Index |

| MSCR | Multiple Stress Creep Recovery |

| UV | Ultraviolet |

References

- Tahmoorian, F.; Samali, B.; Yeaman, J. Modified asphalt. In Evaluation of Structural and Thermal Properties of Rubber and HDPE for Utilization as Binder Modifier; IntechOpen: London, UK, 2018; pp. 109–130. [Google Scholar] [CrossRef]

- Xu, L.; Li, X.; Zong, Q.; Xiao, F. Chemical, morphological and rheological investigations of SBR/SBS modified asphalt emulsions with waterborne acrylate and polyurethane. Constr. Build. Mater. 2021, 272, 121972. [Google Scholar] [CrossRef]

- Zhu, J.; Birgisson, B.; Kringos, N. Polymer modification of bitumen: Advances and challenges. Eur. Polym. J. 2014, 54, 18–38. [Google Scholar] [CrossRef] [Green Version]

- Rezakazemi, M.; Vatani, A.; Mohammadi, T. Synergistic interactions between POSS and fumed silica and their effect on the properties of crosslinked PDMS nanocomposite membranes. RSC Adv. 2015, 5, 82460–82470. [Google Scholar] [CrossRef]

- Farahani, H.Z.; Palassi, M.; Galooyak, S.S. Rheology investigation of waste LDPE and crumb rubber modified bitumen. Eng. Solid Mech. 2018, 6, 27–38. [Google Scholar] [CrossRef]

- Rahi, D.C.; Chandak, R.; Vishwakarma, A. Utilization of liquid plastic waste in bitumen for construction of roads. In Proceedings of the International Conference on Sustainable Materials And Structures For Civil Infrastructures (Smsci2019), Bhopal, India, 14–15 March 2019. [Google Scholar]

- Airey, G.D. Rheological evaluation of ethylene vinyl acetate polymer modified bitumens. Constr. Build. Mater. 2002, 16, 473–487. [Google Scholar] [CrossRef]

- Padhan, R.K.; Sreeram, A. Enhancement of storage stability and rheological properties of polyethylene (PE) modified asphalt using cross linking and reactive polymer based additives. Constr. Build. Mater. 2018, 188, 772–780. [Google Scholar] [CrossRef]

- Gama, D.A.; Yan, Y.; Rodrigues, J.K.G.; Roque, R. Optimizing the use of reactive terpolymer, polyphosphoric acid and high-density polyethylene to achieve asphalt binders with superior performance. Constr. Build. Mater. 2018, 169, 522–529. [Google Scholar] [CrossRef]

- Gautam, P.K.; Kalla, P.; Jethoo, A.S.; Agrawal, R.; Singh, H. Sustainable use of waste in flexible pavement: A review. Constr. Build. Mater. 2018, 180, 239–253. [Google Scholar] [CrossRef]

- Angelone, S.; Casaux, M.C.; Borghi, M.; Martinez, F.O. Green pavements: Reuse of plastic waste in asphalt mixtures. Mater. Struct. 2015, 49, 1655–1665. [Google Scholar] [CrossRef]

- Brasileiro, L.; Moreno-Navarro, F.; Tauste-Martínez, R.; Matos, J.; Rubio-Gámez, M.D.C. Reclaimed polymers as asphalt binder modifiers for more sustainable roads: A Review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef] [Green Version]

- Venturini, L.; Carrara, S.; Giustozzi, F. Pavement and Asset Management. In Proceedings of the World Conference on Pavement and Asset Management (WCPAM 2017), Baveno, Italy, 12–16 June 2017; pp. 433–442. [Google Scholar]

- Yadav, S.K.; Srivastava, V. Non-conventional materials in rigid pavement: Effect on mechanical properties. Int. J. Civ. Eng. Technol. 2017, 8, 10. [Google Scholar]

- Kishchynskyi, S.; Nagaychuk, V.; Bezuglyi, A. Improving quality and durability of bitumen and asphalt concrete by modifi-cation using recycled polyethylene based polymer composition. Proc. Eng. 2016, 143, 119–127. [Google Scholar] [CrossRef]

- Lambert, S.; Wagner, M. Environmental performance of bio-based and biodegradable plastics: The road ahead. Chem. Soc. Rev. 2017, 46, 6855–6871. [Google Scholar] [CrossRef]

- Bonicelli, A.; Calvi, P.; Martinez-Arguelles, G.; Fuentes, L.; Giustozzi, F. Experimental study on the use of rejuvenators and plastomeric polymers for improving durability of high RAP content asphalt mixtures. Constr. Build. Mater. 2017, 155, 37–44. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Effect of ageing on bitumen chemistry and rheology. Constr. Build. Mater. 2002, 16, 15–22. [Google Scholar] [CrossRef]

- García-Morales, M.; Partal, P.; Navarro, F.J.; Martínez-Boza, F.J.; Gallegos, C. Processing, rheology, and storage stability of recycled EVA/LDPE modified bitumen. Polym. Eng. Sci. 2007, 47, 181–191. [Google Scholar] [CrossRef]

- Fawcett, A.H.; McNally, T. Blends of bitumen with polymers having a styrene component. Polym. Eng. Sci. 2001, 41, 1251–1264. [Google Scholar] [CrossRef]

- Airey, G.D. Styrene butadiene styrene polymer modification of road bitumens. J. Mater. Sci. 2004, 39, 951–959. [Google Scholar] [CrossRef]

- García-Morales, M.; Partal, P.; Navarro, F.J.; Martínez-Boza, F.; Gallegos, C. Linear Viscoelasticity of Recycled EVA-Modified Bitumens. Energy Fuels 2004, 18, 357–364. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martınez-Boza, F.; Gallegos, C. Thermo-rheological behaviour and storage stability of ground tire rubber-modified bitumens. Fuel 2004, 83, 2041–2049. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martínez-Boza, F.J.; Gallegos, C. Influence of processing conditions on the rheological behavior of crumb tire rubber-modified bitumen. J. Appl. Polym. Sci. 2007, 104, 1683–1691. [Google Scholar] [CrossRef]

- Pérez-Lepe, A.; Martínez-Boza, F.J.; Attané, P.; Gallegos, C. Destabilization mechanism of polyethylene-modified bitumen. J. Appl. Polym. Sci. 2006, 100, 260–267. [Google Scholar] [CrossRef]

- Giustozzi, F.; Crispino, M.; Toraldo, E.; Mariani, E. Mix design of polymer-modified and fiber-reinforced warm-mix asphalts with high amount of reclaimed asphalt pavement: Achieving sustainable and high-performing pavements. Trans. Res. Rec. 2015, 2523, 3–10. [Google Scholar] [CrossRef]

- Raman, N.A.A.; Hainin, M.R.; Hassan, N.A.; Ani, F.N. A Review on the Application of Bio-oil as an Additive for Asphalt. J. Teknol. 2015, 72, 105–110. [Google Scholar] [CrossRef] [Green Version]

- Hossain, N.; Zaini, J.; Mahlia, T.M.I.; Azad, A.K. Elemental, morphological and thermal analysis of mixed microalgae species from drain water. Renew. Energy 2019, 131, 617–624. [Google Scholar] [CrossRef]

- García-Morales, M.; Partal, P.; Navarro, F.; Martı́nez-Boza, F.; Gallegos, C.; González, N.; Muñoz, M. Viscous properties and microstructure of recycled eva modified bitumen. Fuel 2004, 83, 31–38. [Google Scholar] [CrossRef]

- Fawcett, A.; McNally, T. Blends of bitumen with various polyolefins. Polymer 2000, 41, 5315–5326. [Google Scholar] [CrossRef]

- Eurobitume, A. The Bitumen Industry—A Global Perspective: Production, Chemistry, Use, Specification and Occupational Exposure; Asphalt Institute: Lexington, KY, USA, 2011. [Google Scholar]

- McNally, T. Polymer Modified Bitumen: Properties and Characterisation, 1st ed.; Woodhead Publishing: Philadelphia, PA, USA, 2011. [Google Scholar]

- Sengoz, B.; Topal, A.; Isikyakar, G. Morphology and image analysis of polymer modified bitumens. Constr. Build. Mater. 2009, 23, 1986–1992. [Google Scholar] [CrossRef]

- González, O.; Muñoz, M.; Santamarı́a, A.; Garcı́a-Morales, M.; Navarro, F.; Partal, P. Rheology and stability of bitumen/EVA blends. Eur. Polym. J. 2004, 40, 2365–2372. [Google Scholar] [CrossRef]

- Habib, N.Z.; Kamaruddin, I.; Napiah, M.; Isa, M.T. Rheological properties of polyethylene and polypropylene modified bitu-men. Int. J. Civ. Environ. Eng. 2011, 3, 96–100. [Google Scholar]

- Khan, I.M.; Kabir, S.; Alhussain, M.A.; Almansoor, F.F. Asphalt design using recycled plastic and crumb-rubber waste for sustainable pavement construction. Procedia Eng. 2016, 145, 1557–1564. [Google Scholar] [CrossRef] [Green Version]

- Onyango, F.; Wanjala, S.R.; Ndege, M.; Masu, L. Effect of rubber tyre and plastic wastes use in asphalt concrete pavement. Int. J. Civ. Environ. Eng. 2015, 2, 1403–1407. [Google Scholar]

- Belsare, C.P.; Kaley, A.A.J.D. Interpretation of bituminous mixes with modified binders. Int. J. Adv. Eng. Rese. Dev. 2015, 2, 1504–1512. [Google Scholar]

- Zhang, H.; Wu, X.; Cao, D.; Zhang, Y.; He, M. Effect of linear low density-polyethylene grafted with maleic anhydride (LLDPE-g-MAH) on properties of high density-polyethylene/styrene–butadiene–styrene (HDPE/SBS) modified asphalt. Constr. Build. Mater. 2013, 47, 192–198. [Google Scholar] [CrossRef]

- Gómez, N.H.C.; Oeser, M.; Fleischel, O. Chemical modification of bitumen with novel isocyanate-based additive to enhance asphalt performance. Cons. Build. Mater. 2021, 301, 124128. [Google Scholar] [CrossRef]

- Beena, K.; Bindu, C. Waste plastic as a stabilizing additive in Stone Mastic Asphalt. Int. J. Eng. Technol. 2010, 2, 379–387. [Google Scholar]

- Mohammadiroudbari, M.; Tavakoli, A.; Aghjeh, M.K.R.; Rahi, M. Effect of nanoclay on the morphology of polyethylene modified bitumen. Constr. Build. Mater. 2016, 116, 245–251. [Google Scholar] [CrossRef]

- Zachariah, J.P.; Sarkar, P.P.; Debnath, B.; Pal, M. Effect of polypropylene fibres on bituminous concrete with brick as aggregate. Constr. Build. Mater. 2018, 168, 867–876. [Google Scholar] [CrossRef]

- Gibreil, H.A.; Feng, C.P. Effects of high-density polyethylene and crumb rubber powder as modifiers on properties of hot mix asphalt. Constr. Build. Mater. 2017, 142, 101–108. [Google Scholar] [CrossRef]

- Malarvizhi, G.; Senthul, N.; Kamaraj, C. A study on Recycling of crumb rubber and low density polyethylene blend on stone matrix asphalt. Int. J. Sci. Res. 2012, 2, 1–16. [Google Scholar]

- Bala, N.; Napiah, M.; Kamaruddin, I. Effect of nanosilica particles on polypropylene polymer modified asphalt mixture performance. Case Stud. Constr. Mater. 2018, 8, 447–454. [Google Scholar] [CrossRef]

- Larsen, D.O.; Alessandrini, J.L.; Bosch, A.; Cortizo, M.S. Micro-structural and rheological characteristics of SBS-asphalt blends during their manufacturing. Constr. Build. Mater. 2009, 23, 2769–2774. [Google Scholar] [CrossRef]

- McNally, T. Introduction to polymer modified bitumen (PmB). Polym. Modif. Bitum. 2011, 1–21. [Google Scholar] [CrossRef]

- Pyshyev, S.; Gunka, V.; Grytsenko, Y.; Bratychak, M. Polymer modified bitumen. Chem. Chem. Technol. 2016, 10, 631–636. [Google Scholar] [CrossRef]

- Tayfur, S.; Ozen, H.; Aksoy, A. Investigation of rutting performance of asphalt mixtures containing polymer modifiers. Constr. Build. Mater. 2007, 21, 328–337. [Google Scholar] [CrossRef]

- Isacsson, U.; Zeng, H. Low-temperature cracking of polymer-modified asphalt. Mater. Struct. 1998, 31, 58–63. [Google Scholar] [CrossRef]

- Gorkem, C.; Sengoz, B. Predicting stripping and moisture induced damage of asphalt concrete prepared with polymer modi-fied bitumen and hydrated lime. Constr. Build. Mater. 2009, 23, 2227–2236. [Google Scholar] [CrossRef]

- Alataş, T.; Yilmaz, M. Effects of different polymers on mechanical properties of bituminous binders and hot mixtures. Constr. Build. Mater. 2013, 42, 161–167. [Google Scholar] [CrossRef]

- Von Quintus, H.L.; Mallela, J.; Buncher, M. Quantification of effect of polymer-modified asphalt on flexible pavement per-formance. Trans. Res. Rec. 2007, 2001, 141–154. [Google Scholar] [CrossRef]

- Chang, H.-L.; Wong, G.K.; Lin, J.-R.; Yen, T.F. Chapter 9 Electron Spin Resonance Study of Bituminous Substances and Asphaltenes. Dev. Pet. Sci. 2000, 40, 229–280. [Google Scholar] [CrossRef]

- Singh, B.P.; Kumar, L.; Gupta, M.M.; Chauhan, G. Polymer-modified bitumen of recycled LDPE and maleated bitumen. J. Appl. Polym. Sci. 2012, 127, 67–78. [Google Scholar] [CrossRef]

- Wang, T.; Yi, T.; Yuzhen, Z. The Compatibility of SBS-Modified Asphalt. Pet. Sci. Technol. 2010, 28, 764–772. [Google Scholar] [CrossRef]

- Khakimullin, Y.N.; Kimel’Blat, V.I.; Chebotareva, I.G.; Muruzina, E.V.; Murafa, A.V.; Khozin, V.G.; Vol’Fson, S.I. Properties of Bitumens Modified by Thermoplastic Elastomers. Mech. Compos. Mater. 2000, 36, 417–422. [Google Scholar] [CrossRef]

- Cook, C.R.; Halden, R.U. Ecological and health issues of plastic waste. In Plastic Waste and Recycling; Academic Press: Cambridge, MA, USA, 2020; pp. 513–527. [Google Scholar]

- Wang, J.; Yuan, J.; Xiao, F.; Li, Z.; Wang, J.; Xu, Z. Performance investigation and sustainability evaluation of multiple-polymer asphalt mixtures in airfield pavement. J. Clean. Prod. 2018, 189, 67–77. [Google Scholar] [CrossRef]

- Keijzer, E.E.; Leegwater, G.A.; de Vos-Effting, S.E.; de Wit, M.S. Carbon footprint comparison of innovative techniques in the construction and maintenance of road infra-structure in The Netherlands. Environ. Sci. Policy 2015, 54, 218–225. [Google Scholar] [CrossRef]

- Giustozzi, F.; Crispino, M.; Flintsch, G. Multi-attribute life cycle assessment of preventive maintenance treatments on road pavements for achieving environmental sustainability. Int. J. Life Cycle Assess. 2012, 17, 409–419. [Google Scholar] [CrossRef]

- Santos, J.; Pham, A.; Stasinopoulos, P.; Giustozzi, F. Recycling waste plastics in roads: A life-cycle assessment study using primary data. Sci. Total. Environ. 2021, 751, 141842. [Google Scholar] [CrossRef]

- Jasso, M.; Hampl, R.; Vacin, O.; Bakos, D.; Stastna, J.; Zanzotto, L. Rheology of conventional asphalt modified with SBS, Elvaloy and polyphosphoric acid. Fuel Process. Technol. 2015, 140, 172–179. [Google Scholar] [CrossRef]

- García-Travé, G.; Tauste, R.; Moreno-Navarro, F.; Sol-Sánchez, M.; Rubio-Gámez, M.C. Use of Reclaimed Geomembranes for Modification of Mechanical Performance of Bituminous Binders. J. Mater. Civ. Eng. 2016, 28, 04016021. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, D.; Antonelli, F.; Vlachovicova, Z.; Zanzotto, L. Rheology of asphalts modified with glycidylmethacrylate functionalized polymers. J. Colloid Interface Sci. 2004, 280, 366–373. [Google Scholar] [CrossRef]

- Li, B.; Li, X.; Kundwa, M.J.; Li, Z.; Wei, D. Evaluation of the adhesion characteristics of material composition for polyphosphoric acid and SBS modified bitumen based on surface free energy theory. Constr. Build. Mater. 2021, 266, 121022. [Google Scholar] [CrossRef]

- Navarro, F.; Partal, P.; García-Morales, M.; Martín-Alfonso, M.; Martínez-Boza, F.; Gallegos, C.; Bordado, J.; Diogo, A. Bitumen modification with reactive and non-reactive (virgin and recycled) polymers: A comparative analysis. J. Ind. Eng. Chem. 2009, 15, 458–464. [Google Scholar] [CrossRef]

- Anwar, M.K.; Shah, S.A.R.; Alhazmi, H. Recycling and Utilization of Polymers for Road Construction Projects: An Application of the Circular Economy Concept. Polymers 2021, 13, 1330. [Google Scholar] [CrossRef]

- Abuaddous, M.; Taamneh, M.M.; Rabab’Ah, S.R. The potential use of recycled polyethylene terephthalate (RPET) plastic waste in asphalt binder. Int. J. Pavement Res. Technol. 2021, 14, 579–587. [Google Scholar] [CrossRef]

- Moore, C.J. Synthetic polymers in the marine environment: A rapidly increasing, long-term threat. Environ. Res. 2008, 108, 131–139. [Google Scholar] [CrossRef]

- Parker, L. A Whopping 91% of Plastic Isn’t Recycled. National Geographic. 2017. Available online: https://www.nationalgeographic.com/science/article/plastic-produced-recycling-waste-ocean-trash-debris-environment (accessed on 12 September 2021).

- Rahman, T.; Mohajerani, A.; Giustozzi, F. Recycling of Waste Materials for Asphalt Concrete and Bitumen: A Review. Materials 2020, 13, 1495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arulrajah, A.; Naeini, M.; Mohammadinia, A.; Horpibulsuk, S.; Leong, M. Recovered plastic and demolition waste blends as railway capping materials. Transp. Geotech. 2020, 22, 100320. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef] [PubMed]

- Perugini, F.; Mastellone, M.L.; Arena, U. A life cycle assessment of mechanical and feedstock recycling options for manage-ment of plastic packaging wastes. Env. Prog. 2005, 24, 137–154. [Google Scholar] [CrossRef]

- Achilias, D.; Roupakias, C.; Megalokonomos, P.; Lappas, A.; Antonakou, Ε. Chemical recycling of plastic wastes made from polyethylene (LDPE and HDPE) and polypropylene (PP). J. Hazard. Mater. 2007, 149, 536–542. [Google Scholar] [CrossRef]

- Locock, K. The Recycled Plastics Market: Global Analysis and Trends; CSIRO: Canberra, Australia, 2017. [Google Scholar]

- d’Ambrières, W. Plastics recycling worldwide: Current overview and desirable changes. J. Field. Act. 2019, 19, 12–21. [Google Scholar]

- Goodship, V. Plastic recycling. Handb. Recycl. 2007, 90, 245–268. [Google Scholar] [CrossRef]

- Victoria, S. Resource Recovery Technology Guide; Sustainability Victoria: Victoria, Australia, 2018. [Google Scholar]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, C.-H.; Jeon, H.-S.; Yu, H.-S.; Han, O.-H.; Park, J.-K. Application of Electrostatic Separation to the Recycling of Plastic Wastes: Separation of PVC, PET, and ABS. Environ. Sci. Technol. 2008, 42, 249–255. [Google Scholar] [CrossRef] [PubMed]

- Silveira, A.; Cella, M.; Tanabe, E.; Bertuol, D. Application of tribo-electrostatic separation in the recycling of plastic wastes. Process. Saf. Environ. Prot. 2018, 114, 219–228. [Google Scholar] [CrossRef]

- Marand, H.; Xu, J.; Srinivas, S. Determination of the equilibrium melting temperature of polymer crystals: Linear and nonlin-ear Hoffman− Weeks extrapolations. Macromolecules 1998, 31, 8219–8229. [Google Scholar] [CrossRef]

- Stupp, S.; Supan, T.J.; Belton, D. Ice-water quenching technique for polypropylene. Ortho. Prosth. 1979, 33, 16–21. [Google Scholar]

- Lior, N. The cooling process in gas quenching. J. Mater. Process. Technol. 2004, 155, 1881–1888. [Google Scholar] [CrossRef]

- Cheng, S.Z.; Lotz, B. Enthalpic and entropic origins of nucleation barriers during polymer crystallization: The Hoffman–Lauritzen theory and beyond. Polymer 2005, 46, 8662–8681. [Google Scholar] [CrossRef]

- Urgen Voigt, J. Apparatus for Pelletizing Plastics. U.S. Patent 20100072252A1, 7 June 2011. [Google Scholar]

- Boothe, D.A.; Martin, W.J.; Wright, R.B. Apparatus and Method for Controlled Pelletization Processing. U.S. Patent CA2631160C, 15 September 2013. [Google Scholar]

- Mohammed, B.; Hassan, R.; Alaswadko, N. The effect of traffic data source on deterioration rates of heavy-duty flexible pavements. Int. J. Pavement Eng. 2016, 19, 1–15. [Google Scholar] [CrossRef]

- Plati, C. Sustainability factors in pavement materials, design, and preservation strategies: A literature review. Constr. Build. Mater. 2019, 211, 539–555. [Google Scholar] [CrossRef]

- Pouranian, M.R.; Shishehbor, M. Sustainability Assessment of Green Asphalt Mixtures: A Review. Environments 2019, 6, 73. [Google Scholar] [CrossRef] [Green Version]

- Shah, A.; Modha, H. Improving the Soil Subgrade with Plastic Waste Reinforcement—An Experimental Study. In Proceedings of the EECE 2020, St. Petersburg, Russia, 19–20 November 2020; pp. 153–161. [Google Scholar] [CrossRef]

- Khurshid, M.B.; Qureshi, N.A.; Hussain, A.; Iqbal, M.J. Enhancement of Hot Mix Asphalt (HMA) Properties Using Waste Polymers. Arab. J. Sci. Eng. 2019, 44, 8239–8248. [Google Scholar] [CrossRef]

- Nouali, M.; Derriche, Z.; Ghorbel, E.; Chuanqiang, L. Plastic bag waste modified bitumen a possible solution to the Algerian road pavements. Road Mater. Pavement Des. 2019, 21, 1713–1725. [Google Scholar] [CrossRef]

- Lastra-González, P.; Calzada-Pérez, M.A.; Castro-Fresno, D.; Vega-Zamanillo, Á.; Indacoechea-Vega, I. Comparative analysis of the performance of asphalt concretes modified by dry way with polymeric waste. Constr. Build. Mater. 2016, 112, 1133–1140. [Google Scholar] [CrossRef] [Green Version]

- Yusoff, N.I.M.; Mounier, D.; Marc-Stéphane, G.; Hainin, M.R.; Airey, G.; Di Benedetto, H. Modelling the rheological properties of bituminous binders using the 2S2P1D Model. Constr. Build. Mater. 2013, 38, 395–406. [Google Scholar] [CrossRef]

- Polacco, G.; Stastna, J.; Biondi, D.; Zanzotto, L. Relation between polymer architecture and nonlinear viscoelastic behavior of modified asphalts. Curr. Opin. Colloid Interface Sci. 2006, 11, 230–245. [Google Scholar] [CrossRef]

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Rossi, C.O. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef] [Green Version]

- Giavarini, C.; De Filippis, P.; Santarelli, M.L.; Scarsella, M. Production of stable polypropylene-modified bitumens. Fuel 1996, 75, 681–686. [Google Scholar] [CrossRef]

- Liu, P.; Lu, K.; Li, J.; Wu, X.; Qian, L.; Wang, M.; Gao, S. Effect of aging on adsorption behavior of polystyrene microplastics for pharmaceuticals: Adsorption mechanism and role of aging intermediates. J. Hazard. Mater. 2020, 384, 121193. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U.; Ekblad, J. Phase Separation of SBS Polymer Modified Bitumens. J. Mater. Civ. Eng. 1999, 11, 51–57. [Google Scholar] [CrossRef]

- Zani, L.; Giustozzi, F.; Harvey, J. Effect of storage stability on chemical and rheological properties of polymer-modified asphalt binders for road pavement construction. Constr. Build. Mater. 2017, 145, 326–335. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, S.; Zhou, H.; Hu, W.; Polaczyk, P.; Zhang, M.; Huang, B. Compatibility and rheological characterization of asphalt modified with recycled rubber-plastic blends. Constr. Build. Mater. 2021, 270, 121416. [Google Scholar] [CrossRef]

- Attaelmanan, M.; Feng, C.P.; Ai, A.-H. Laboratory evaluation of HMA with high density polyethylene as a modifier. Constr. Build. Mater. 2011, 25, 2764–2770. [Google Scholar] [CrossRef]

- Murphy, M.D.; O’Mahony, M.; Lycett, C.; Jamieson, I. Recycled Polymers for Use as Bitumen Modifiers. J. Mater. Civ. Eng. 2001, 13, 306–314. [Google Scholar] [CrossRef] [Green Version]

- Panda, M.; Mazumdar, M. Utilization of Reclaimed Polyethylene in Bituminous Paving Mixes. J. Mater. Civ. Eng. 2002, 14, 527–530. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Wang, H.; Jiang, H.; Zhang, J.; Yao, Z. Phase behavior and hot storage characteristics of asphalt modified with various polyethylene: Experimental and numerical characterizations. Constr. Build. Mater. 2019, 203, 608–620. [Google Scholar] [CrossRef]

- Cazan, C.; Cosnita, M.; Duta, A. Effect of PET functionalization in composites of rubber–PET–HDPE type. Arab. J. Chem. 2017, 10, 300–312. [Google Scholar] [CrossRef] [Green Version]

- Kuila, T.; Bose, S.; Mishra, A.K.; Khanra, P.; Kim, N.H.; Lee, J.H. Effect of functionalized graphene on the physical properties of linear low density polyethylene nanocompo-sites. Polym. Test. 2012, 31, 31–38. [Google Scholar] [CrossRef]

- Yousefi, A.A. Polyethylene dispersions in bitumen: The effects of the polymer structural parameters. J. Appl. Polym. Sci. 2003, 90, 3183–3190. [Google Scholar] [CrossRef]

- Al-Hadidy, A. Engineering behavior of aged polypropylene-modified asphalt pavements. Constr. Build. Mater. 2018, 191, 187–192. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Demirelli, K.; Günay, T.; Biryan, F.; Alqudah, O. Effects of Waste Polypropylene Additive on the Properties of Bituminous Binder. Procedia Manuf. 2015, 2, 165–170. [Google Scholar] [CrossRef] [Green Version]

- Luo, W.-Q.; Chen, J.-C. Preparation and properties of bitumen modified by EVA graft copolymer. Constr. Build. Mater. 2011, 25, 1830–1835. [Google Scholar] [CrossRef]

- Joohari, I.B.; Giustozzi, F. Waste tyres crumb rubber as a sustainability enhancer for polymer-modified and hybrid polymer-modified bitumen. Int. J. Pavem. Eng. 2021, 1–15. [Google Scholar]

- Liang, M.; Xin, X.; Fan, W.; Zhang, J.; Jiang, H.; Yao, Z. Comparison of rheological properties and compatibility of asphalt modified with various polyethylene. Int. J. Pavement Eng. 2021, 22, 11–20. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a promising plastic: A review. Amer. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Moyano, M.A.; París, R.; Martín-Martínez, J.M. Assessment of the compatibility in hot melts by using different thermoanalytical methods. Ethylene/n-butyl acrylate (EBA) hot melts containing tackifiers of different nature. J. Therm. Anal. Calorim. 2017, 129, 1495–1503. [Google Scholar] [CrossRef]

- Henderson, A. Ethylene-vinyl acetate (EVA) copolymers: A general review. IEEE Electr. Insul. Mag. 1993, 9, 30–38. [Google Scholar] [CrossRef]

- Reddy, N.M.; Venkatasubbaiah, M. Effects of high density polyethylene and crumb rubber powder on properties of asphalt mix. Int. Res. J. Eng. Technol. 2017, 4, 2572–2578. [Google Scholar]

- Lu, X.; Isacsson, U. Modification of road bitumens with thermoplastic polymers. Polym. Test. 2000, 20, 77–86. [Google Scholar] [CrossRef]

- Liang, S.; Yang, H.; Wang, K.; Zhang, Q.; Du, R.; Fu, Q. Unique crystal morphology and tensile properties of injection-molded bar of LLDPE by adding HDPE with different molecular weights. Acta Mater. 2008, 56, 50–59. [Google Scholar] [CrossRef]

- Al-Hadidy, A.; Yi-Qiu, T. Effect of polyethylene on life of flexible pavements. Constr. Build. Mater. 2009, 23, 1456–1464. [Google Scholar] [CrossRef]

- Costa, L.M.; Silva, H.M.; Peralta, J.; Oliveira, J.R. Using waste polymers as a reliable alternative for asphalt binder modification–Performance and morpho-logical assessment. Constr. Build. Mater. 2019, 198, 237–244. [Google Scholar] [CrossRef]

- Jun, L.; Yuxia, Z.; Yuzhen, Z. The research of GMA-g-LDPE modified Qinhuangdao bitumen. Constr. Build. Mater. 2008, 22, 1067–1073. [Google Scholar] [CrossRef]

- Ozdemir, D.K.; Topal, A.; McNally, T. Relationship between microstructure and phase morphology of SBS modified bitumen with processing parameters studied using atomic force microscopy. Constr. Build. Mater. 2021, 268, 121061. [Google Scholar] [CrossRef]

- Vargas, M.A.; Vargas, M.A.; Sánchez-Sólis, A.; Manero, O. Asphalt/polyethylene blends: Rheological properties, microstructure and viscosity modeling. Constr. Build. Mater. 2013, 45, 243–250. [Google Scholar] [CrossRef]

- Roman, C.; Cuadri, A.; Liashenko, I.; García-Morales, M.; Partal, P. Linear and non-linear viscoelastic behavior of SBS and LDPE modified bituminous mastics. Constr. Build. Mater. 2016, 123, 464–472. [Google Scholar] [CrossRef]

- Nawang, R.; Danjaji, I.; Ishiaku, U.; Ismail, H.; Ishak, Z.M. Mechanical properties of sago starch-filled linear low density polyethylene (LLDPE) composites. Polym. Test. 2001, 20, 167–172. [Google Scholar] [CrossRef]

- Luyt, A.; Molefi, J.; Krump, H. Thermal, mechanical and electrical properties of copper powder filled low-density and linear low-density polyethylene composites. Polym. Degrad. Stab. 2006, 91, 1629–1636. [Google Scholar] [CrossRef]

- El-Rahman, A.A.; El-Shafie, M.; Mohammedy, M.; Abo-Shanab, Z. Enhancing the performance of blown asphalt binder using waste EVA copolymer (WEVA). Egypt. J. Pet. 2018, 27, 513–521. [Google Scholar] [CrossRef]

- Haddadi, S.; Ghorbel, E.; Laradi, N. Effects of the manufacturing process on the performances of the bituminous binders modified with EVA. Constr. Build. Mater. 2008, 22, 1212–1219. [Google Scholar] [CrossRef]

- Moyano, M.A.; París, R.; Martín-Martínez, J.M. Changes in compatibility, tack and viscoelastic properties of ethylene n-butyl acrylate (EBA) copoly-mer–pentaerythritol rosin ester blend by adding microcrystalline wax, Fischer–Tropsch wax and mixture of waxes. Int. J. Adh. Adhes. 2016, 65, 47–53. [Google Scholar] [CrossRef] [Green Version]

- Bockhorn, H.; Hornung, A.; Schawaller, D. Kinetic study on the thermal degradation of polypropylene and polyethylene. J. Anal. Appl. Pyrolysis 1999, 48, 93–109. [Google Scholar] [CrossRef]

- Krupa, I.; Luyt, A. Thermal and mechanical properties of LLDPE cross-linked with gamma radiation. Polym. Degrad. Stab. 2001, 71, 361–366. [Google Scholar] [CrossRef]

- Duquesne, S.; Jama, C.; Le Bras, M.; Delobel, R.; Recourt, P.; Gloaguen, J. Elaboration of EVA–nanoclay systems—characterization, thermal behaviour and fire performance. Compos. Sci. Technol. 2003, 63, 1141–1148. [Google Scholar] [CrossRef]

- Sultan, B.-. Åke; Sörvik, E. Thermal degradation of EVA and EBA—A comparison. I. Volatile decomposition products. J. Appl. Polym. Sci. 1991, 43, 1737–1745. [Google Scholar] [CrossRef]

- Bala, N.; Kamaruddin, I.; Napiah, M.; Danlami, N. Rheological and rutting evaluation of composite nanosilica/polyethylene modified bitumen. IOP Conf. Series: Mater. Sci. Eng. 2017, 201, 12012. [Google Scholar] [CrossRef] [Green Version]

- Champion, L.; Gérard, J.-F.; Planche, J.-P.; Martin, D.; Anderson, D. Low temperature fracture properties of polymer-modified asphalts relationships with the morphology. J. Mater. Sci. 2001, 36, 451–460. [Google Scholar] [CrossRef]

- Naddeo, C.; Guadagno, L.; De Luca, S.; Vittoria, V.; Camino, G. Mechanical and transport properties of irradiated linear low density polyethylene (LLDPE). Polym. Degrad. Stab. 2001, 72, 239–247. [Google Scholar] [CrossRef]

- Isacsson, U.; Lu, X. Characterization of bitumens modified with SEBS, EVA and EBA polymers. J. Mater. Sci. 1999, 34, 3737–3745. [Google Scholar] [CrossRef]

- Eidesen, H.; Khawaja, H.; Jackson, S. Simulation of the HDPE Pyrolysis Process. Int. J. Multiphysics 2018, 12, 79–88. [Google Scholar] [CrossRef] [Green Version]

- Bureau, E.; Cabot, C.; Marais, S.; Saiter, J.M. Study of the α-relaxation of PVC, EVA and 50/50 EVA70/PVC blend. Europ. Polym. J. 2005, 41, 1152–1158. [Google Scholar] [CrossRef]

- Fang, C.; Wu, C.; Hu, J.; Yu, R.; Zhang, Z.; Nie, L.; Zhou, S.; Mi, X. Pavement properties of asphalt modified with packaging-waste polyethylene. J. Vinyl Addit. Technol. 2014, 20, 31–35. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Fainleib, A.; Günay, T.; Grygoryeva, O. Modification of bitumen by electron beam irradiated recycled low density polyethylene. Constr. Build. Mater. 2014, 69, 1–9. [Google Scholar] [CrossRef]

- Hu, J.; Fang, C.; Zhou, S.; Jiao, L.; Zhang, M.; Wu, D. Rheological properties of packaging-waste-polyethylene-modified asphalt. J. Vinyl Addit. Technol. 2015, 21, 215–219. [Google Scholar] [CrossRef]

- Jew, P.; Shimizu, J.A.; Svazic, M.; Woodhams, R.T. Polyethlene-modified bitumen for paving applications. J. Appl. Polym. Sci. 1986, 31, 2685–2704. [Google Scholar] [CrossRef]

- Qi, X.; Sebaaly, P.E.; Epps, J.A. Evaluation of Polymer-Modified Asphalt Concrete Mixtures. J. Mater. Civ. Eng. 1995, 7, 117–124. [Google Scholar] [CrossRef]

- Tian, Y.; Li, H.; Sun, L.; Zhang, H.; Harvey, J.; Yang, J.; Yang, B.; Zuo, X. Laboratory investigation on rheological, chemical and morphological evolution of high content polymer modi-fied bitumen under long-term thermal oxidative aging. Const. Build. Mater. 2021, 303, 124565. [Google Scholar] [CrossRef]

- Punith, V.S.; Veeraragavan, A. Behavior of Asphalt Concrete Mixtures with Reclaimed Polyethylene as Additive. J. Mater. Civ. Eng. 2007, 19, 500–507. [Google Scholar] [CrossRef]

- Aschuri, I.; Woodward, D. Modification of a 14mm asphalt concrete surfacing using RAP and waste HDPE plastic. Int. J. Pavem. 2010, 9, 70–78. [Google Scholar]

- Sui, Y.; Chen, Z. Application and Performance of Polyethylene Modifying Additive in Asphalt Mixture. ICTE 2011 2011, 1915–1919. [Google Scholar] [CrossRef]

- Punith, V.S.; Veeraragavan, A.; Amirkhanian, S.N. Evaluation of reclaimed polyethylene modified asphalt concrete mixtures. Int. J. Pavem. Res. Technol. 2011, 4, 1. [Google Scholar]

- Punith, V.S.; Suresha, S.N.; Raju, S.; Bose, S.; Veeraragavan, A. Laboratory Investigation of Open-Graded Friction-Course Mixtures Containing Polymers and Cellulose Fibers. J. Transp. Eng. 2012, 138, 67–74. [Google Scholar] [CrossRef]

- Ahmadinia, E.; Zargar, M.; Karim, M.R.; Abdelaziz, M.; Ahmadinia, E. Performance evaluation of utilization of waste Polyethylene Terephthalate (PET) in stone mastic asphalt. Constr. Build. Mater. 2012, 36, 984–989. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Karim, M.R.; Syammaun, T. Dynamic properties of stone mastic asphalt mixtures containing waste plastic bottles. Constr. Build. Mater. 2012, 34, 236–242. [Google Scholar] [CrossRef] [Green Version]

- Fawcett, A.H.; McNally, T.; McNally, G. An attempt at engineering the bulk properties of blends of a bitumen with polymers. Adv. Polym. Technol. 2002, 21, 275–286. [Google Scholar] [CrossRef]

- Polacco, G.; Berlincioni, S.; Biondi, D.; Stastna, J.; Zanzotto, L. Asphalt modification with different polyethylene-based polymers. Eur. Polym. J. 2005, 41, 2831–2844. [Google Scholar] [CrossRef]

- Fang, C.; Li, T.; Zhang, Z.; Wang, X. Combined modification of asphalt by waste PE and rubber. Polym. Compos. 2008, 29, 1183–1187. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Zhang, Y. Melt grafting of maleic anhydride onto low-density polyethylene/polypropylene blends. Polym. Test. 2003, 22, 191–195. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, H.; Liu, X.; Duan, H. A novel method for determining the time-temperature superposition relationship of SBS modified bitumen: Effects of bitumen source, modifier type and aging. Constr. Build. Mater. 2021, 280, 122549. [Google Scholar] [CrossRef]

- Morrison, G.R.; Lee, J.K.; Hesp, S.A.M. Chlorinated polyolefins for asphalt binder modification. J. Appl. Polym. Sci. 1994, 54, 231–240. [Google Scholar] [CrossRef]

- Daly, W.H.; Collier, J.R.; Negulescu, I.I.; Qiu, Z.; Runkle, J. Determination of Significant Factors Controlling Compatibility of Asphalts with Synthetic Polymers. 1995. Available online: https://rosap.ntl.bts.gov/view/dot/22244 (accessed on 12 September 2021).

- Bala, N.; Kamaruddin, I. Physical and storage stability properties of linear low density polyethylene at optimum content. In Engineering Challenges for Sustainable Future, Proceedings of the 3rd International Conference on Civil, Offshore and Environmental Engineering (ICCOEE), Kuala Lumpur, Malaysia, 15–17 August 2016; CRC Press: Boca Raton, FL, USA, 2016; p. 395. [Google Scholar]

- Muhammad, J.; Martinez-Arguelles, G.; Giustozzi, F. Effect of waste tyre rubber size on physical, rheological and UV resistance of high-content rubber-modified bitumen. Const. Build. Mater. 2021, 304, 124638. [Google Scholar]

- Maciejewski, K.; Ramiączek, P.; Chomicz-Kowalska, A. The impact of EBA and ECB polymer modification of 50/70 bitumen. Struct. Environ. 2013, 5, 15–20. [Google Scholar]

- Panda, M.; Mazumdar, M. Engineering Properties of EVA-Modified Bitumen Binder for Paving Mixes. J. Mater. Civ. Eng. 1999, 11, 131–137. [Google Scholar] [CrossRef]

- Kumar, P.; Chandra, S.; Bose, S. Strength characteristics of polymer modified mixes. Int. J. Pavement Eng. 2006, 7, 63–71. [Google Scholar] [CrossRef]

- Kök, B.V.; Aydoğmuş, E.; Yilmaz, M.; Akpolat, M. Investigation on the properties of new palm-oil-based polyurethane modified bitumen. Constr. Build. Mater. 2021, 289, 123152. [Google Scholar] [CrossRef]

- Moran, L.E. Polyethylene Modified Asphalts. CA1316279C, 13 April 1993. [Google Scholar]

- Kumar, U.A.; Satyanarayana, P. Studies on Polymer Modified Bitumen–A Laboratory Approach. Int. J. Civ. Eng. Res. 2013, 2, 123–134. [Google Scholar]

- Xia, T.; Chen, X.; Xu, J.; Li, Y.; Zhang, A. Influence of hydrophilic nanosilica premixing method on the property of isocyanate-based polymer modified bitumen. Constr. Build. Mater. 2021, 275, 122174. [Google Scholar] [CrossRef]

- Tapkın, S.; Cevik, A.; Uşar, Ü.; Kurtoğlu, A. Modelling Marshall Design Test Results of Polypropylene Modified Asphalt by Genetic Programming Techniques. Period. Polytech. Civ. Eng. 2015, 59, 249–265. [Google Scholar] [CrossRef] [Green Version]

- Nemade, S.N.; Thorat, P.V. Utilization of polymer waste for modification of bitumen in road construction. Sci. Rev. Chem. Commun. 2013, 2, 198–213. [Google Scholar]

- Yilmaz, M.; Kok, B.V.; Sengoz, B.; Sengur, A.; Avci, E. Investigation of complex modulus of base and EVA modified bitumen with Adaptive-Network-Based Fuzzy Inference System. Expert Syst. Appl. 2011, 38, 969–974. [Google Scholar] [CrossRef] [Green Version]

- Feng, Z.; Cai, F.; Yao, D.; Li, X. Aging properties of ultraviolet absorber/SBS modified bitumen based on FTIR analysis. Constr. Build. Mater. 2021, 273, 121713. [Google Scholar] [CrossRef]

- Saroufim, E.; Celauro, C.; Mistretta, M.C. A simple interpretation of the effect of the polymer type on the properties of PMBs for road paving applications. Constr. Build. Mater. 2018, 158, 114–123. [Google Scholar] [CrossRef]

- Kumar, P.; Garg, R. Rheology of waste plastic fibre-modified bitumen. Int. J. Pavement Eng. 2011, 12, 449–459. [Google Scholar] [CrossRef]

- Oluwasola, E.A.; Hainin, M.R.; Idham, M.K.; Abayomi, M. Workability and rheological properties of eva-modified bitumen compared with PG 76 binder. J. Teknol. 2018, 80, 117–124. [Google Scholar] [CrossRef] [Green Version]

- Lu, X.; Isacsson, U.; Ekblad, J. Rheological properties of SEBS, EVA and EBA polymer modified bitumens. Mater. Struct. 1999, 32, 131–139. [Google Scholar] [CrossRef]

- Nejad, F.M.; Gholami, M.; Naderi, K.; Rahi, M. Evaluation of rutting properties of high density polyethylene modified binders. Mater. Struct. 2015, 48, 3295–3305. [Google Scholar] [CrossRef]

- Pérez-Lepe, A.; Martınez-Boza, F.; Gallegos, C.; González, O.; Muñoz, M.; Santamarıa, A. Influence of the processing condi-tions on the rheological behaviour of polymer-modified bitumen. Fuel 2003, 82, 1339–1348. [Google Scholar] [CrossRef]

- Habib, N.Z.; Kamaruddin, I.; Tan, I.M.; Komiyama, M. Investigation on the Effect of Phase Segregation on the Mechanical Properties of Polymer Modified Bitumen Using Analytical and Morphological Tools. Available online: https://www.matec-conferences.org/articles/matecconf/abs/2017/34/matecconf_ascm2017_07002/matecconf_ascm2017_07002.html (accessed on 12 September 2021).

- Cuadri, A.; Roman, C.; García-Morales, M.; Guisado, F.; Moreno, E.; Partal, P. Formulation and processing of recycled-low-density-polyethylene-modified bitumen emulsions for reduced-temperature asphalt technologies. Chem. Eng. Sci. 2016, 156, 197–205. [Google Scholar] [CrossRef]

- Gökalp, I. The waste transparent nylon modified bitumen properties: Experimental assessment on physical, rheological properties and storage stability. Constr. Build. Mater. 2021, 303, 124353. [Google Scholar] [CrossRef]

- Audén, C.F.; Sandoval, J.A.; Jerez, A.; Navarro, F.J.; Martínez-Boza, F.J.; Partal, P.; Gallegos, C. Evaluation of thermal and mechanical properties of recycled polyethylene modified bitumen. Polym. Test. 2008, 27, 1005–1012. [Google Scholar] [CrossRef]

- Yu, R.; Fang, C.; Liu, P.; Liu, X.; Li, Y. Storage stability and rheological properties of asphalt modified with waste packaging polyethylene and organic montmorillonite. Appl. Clay Sci. 2015, 104, 1–7. [Google Scholar] [CrossRef]

- Costa, L.; Fernandes, S.R.; da Silva, H.M.R.D.; Oliveira, J.; Miranda, R.F.M. Mechanical analysis of asphalt mixtures produced with waste plastic modified binders. In Proceedings of the 6th International Conference on Mechanics and Materials in Design, Azores, Portugal, 26–30 July 2015; pp. 2053–2062. [Google Scholar]

- Saboo, N.; Kumar, P. Optimum Blending Requirements for EVA Modified Binder. Transp. Res. Procedia 2016, 17, 98–106. [Google Scholar] [CrossRef]

- Nizamuddin, S.; Jamal, M.; Gravina, R.; Giustozzi, F. Recycled plastic as bitumen modifier: The role of recycled linear low-density polyethylene in the modification of physical, chemical and rheological properties of bitumen. J. Clean. Prod. 2020, 266, 121988. [Google Scholar] [CrossRef]

- Nazmi, W.M.; Wahab, A.A. Influence of Recycled High Density Polyethylene on the Conventional and Morphology Properties of Bitumen. J. Eng. Technol. 2011, 2, 67–74. [Google Scholar]

- Casey, D.; McNally, C.; Gibney, A.; Gilchrist, M.D. Development of a recycled polymer modified binder for use in stone mastic asphalt. Resour. Conserv. Recycl. 2008, 52, 1167–1174. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, S.; Upadhyay, N. Composition Based Physicochemical Analysis of Modified Bitumen by High-density polyethylene (HDPE) and Low-density polyethylene (LDPE). Orient. J. Chem. 2019, 35, 1167. [Google Scholar] [CrossRef]

- Zhang, J.; Yao, Z.; Yu, T.; Liu, S.; Jiang, H. Experimental evaluation of crumb rubber and polyethylene integrated modified asphalt mixture upon related properties. Road Mater. Pavement Des. 2018, 20, 1413–1428. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Wahhab, H.I.A.-A. Performance of recycled plastic waste modified asphalt binder in Saudi Arabia. Int. J. Pavement Eng. 2017, 18, 349–357. [Google Scholar] [CrossRef]

- Okhotnikova, E.S.; Ganeeva, Y.M.; Frolov, I.N.; Yusupova, T.N.; Firsin, A.A. Plastic properties and structure of bitumen modified by recycled polyethylene. Pet. Sci. Technol. 2018, 36, 356–360. [Google Scholar] [CrossRef]

- Dehouche, N.; Kaci, M.; Mokhtar, K.A. Influence of thermo-oxidative aging on chemical composition and physical properties of polymer modified bitumens. Constr. Build. Mater. 2012, 26, 350–356. [Google Scholar] [CrossRef]

- Xia, T.; Chen, X.; Xu, J.; Chen, W.; Zhang, A. Effect of annealing method and chemical reaction on the structure and properties of polyeth-ylene/polyethylene glycol modified bitumen. Const. Build. Mater. 2021, 269, 121228. [Google Scholar] [CrossRef]

- Hussein, I.A.; Iqbal, M.H.; Al-Abdul-Wahhab, H.I. Influence of M w of LDPE and vinyl acetate content of EVA on the rheology of polymer modified asphalt. Rheol. Acta 2005, 45, 92–104. [Google Scholar] [CrossRef]

- Ho, S.; Church, R.; Klassen, K.; Law, B.; MacLeod, D.; Zanzotto, L. Study of recycled polyethylene materials as asphalt modifiers. Can. J. Civ. Eng. 2006, 33, 968–981. [Google Scholar] [CrossRef]

- Punith, V.S.; Veeraragavan, A. Behavior of Reclaimed Polyethylene Modified Asphalt Cement for Paving Purposes. J. Mater. Civ. Eng. 2011, 23, 833–845. [Google Scholar] [CrossRef]

- Fang, C.; Zhang, Y.; Yu, Q.; Zhou, X.; Guo, D.; Yu, R.; Zhang, M. Preparation, Characterization and Hot Storage Stability of Asphalt Modified by Waste Polyethylene Packaging. J. Mater. Sci. Technol. 2013, 29, 434–438. [Google Scholar] [CrossRef]

- Ma, D.; Zhao, D.; Zhao, J.; Du, S.; Pang, J.; Wang, W.; Fan, C. Functionalization of reclaimed polyethylene with maleic anhydride and its application in improving the high temperature stability of asphalt mixtures. Constr. Build. Mater. 2016, 113, 596–602. [Google Scholar] [CrossRef]

- Yan, K.; Xu, H.; You, L. Rheological properties of asphalts modified by waste tire rubber and reclaimed low density polyethylene. Constr. Build. Mater. 2015, 83, 143–149. [Google Scholar] [CrossRef]

- Memon, N.A.; Yusoff, N.I.M.; Jafri, S.F.; Sheeraz, K. Rheological Findings on Storage Stability for Chemically Dispersed Crumb Rubber Modified Bitumen. Const. Build. Mater. 2021, 305, 124768. [Google Scholar] [CrossRef]

- Gama, D.A.; Júnior, J.M.R.; Melo, T.; Rodrigues, J.K.G. Rheological studies of asphalt modified with elastomeric polymer. Constr. Build. Mater. 2016, 106, 290–295. [Google Scholar] [CrossRef]

- Yousefi, A.A. Rubber-polyethylene modified bitumen. Iran. Polym. J. 2004, 13, 101–112. [Google Scholar]

- González, O.; Muñoz, M.E.; Santamaría, A. Bitumen/polyethylene blends: Using m-LLDPEs to improve stability and viscoelastic properties. Rheol. Acta 2005, 45, 603–610. [Google Scholar] [CrossRef]

- Yeh, P.-H.; Nien, Y.-H.; Chen, W.-C.; Liu, W.-T. Evaluation of thermal and viscoelastic properties of asphalt binders by compounding with polymer modifiers. Polym. Compos. 2010, 31, 1738–1744. [Google Scholar] [CrossRef]

- Kim, K.W.; Kweon, S.J.; Doh, Y.S.; Park, T.-S. Fracture toughness of polymer-modified asphalt concrete at low temperatures. Can. J. Civ. Eng. 2003, 30, 406–413. [Google Scholar] [CrossRef]

- Liu, C.; Wang, J.; He, J. Rheological and thermal properties of m-LLDPE blends with m-HDPE and LDPE. Polymer 2002, 43, 3811–3818. [Google Scholar] [CrossRef]

- Spadaro, C.; Plummer, C.J.G.; Månson, J.-A.E. Thermal and dynamic mechanical properties of blends of bitumen with metallocene catalyzed polyolefins. J. Mater. Sci. 2011, 46, 7449–7458. [Google Scholar] [CrossRef] [Green Version]

- Ben Zair, M.; Jakarni, F.; Muniandy, R.; Hassim, S. A Brief Review: Application of Recycled Polyethylene Terephthalate in Asphalt Pavement Reinforcement. Sustainability 2021, 13, 1303. [Google Scholar] [CrossRef]

- El-Naga, I.A.; Ragab, M. Benefits of utilization the recycle polyethylene terephthalate waste plastic materials as a modifier to asphalt mixtures. Constr. Build. Mater. 2019, 219, 81–90. [Google Scholar] [CrossRef]

- Sojobi, A.; Nwobodo, S.E.; Aladegboye, O.J. Recycling of polyethylene terephthalate (PET) plastic bottle wastes in bituminous asphaltic concrete. Cogent Eng. 2016, 3, 1133480. [Google Scholar] [CrossRef] [Green Version]

- Ashoor, A.; Kareem, M.M.; Al-Baiati, M.N. Improved asphalt binder using recycle polyethylene terephthalate polymer. IOP Conf. Ser. Mater. Sci. Eng. 2019, 571, 12094. [Google Scholar] [CrossRef] [Green Version]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R. Evaluation of permanent deformation characteristics of unmodified and Polyethylene Terephthalate modified asphalt mixtures using dynamic creep test. Mater. Des. 2014, 53, 317–324. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, A.F.; Razali, A.R.; Razelan, I.S.M.; Jalil, S.A.; Noh, M.M.; Idris, A.A. Utilization of polyethylene terephthalate (PET) in bituminous mixture for improved performance of roads. IOP Conf. Ser. Mater. Sci. Eng. 2017, 203, 12005. [Google Scholar] [CrossRef]

- Bary, E.M.A.; Farag, R.K.; Ragab, A.A.; Abdel-Monem, R.M.; Abo-Shanab, Z.L.; Saleh, A.M.M. Green asphalt construction with improved stability and dynamic mechanical properties. Polym. Bull. 2020, 77, 1729–1747. [Google Scholar] [CrossRef]

- Abdelaziz, M.; Mohamed Rehan, K. Rheological evaluation of bituminous binder modified with waste plastic material. In Proceedings of the 5th International Symposium on Hydrocarbons and Chemistry, Sidi Fredj, Algiers, 23–25 May 2010; pp. 1–7. [Google Scholar]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Al-Jumaili, M.A.H. Sustainability of asphalt paving materials containing different waste materials. IOP Conf. Ser. Mater. Sci. Eng. 2018, 454, 12176. [Google Scholar] [CrossRef]

- Modarres, A.; Hamedi, H. Effect of waste plastic bottles on the stiffness and fatigue properties of modified asphalt mixes. Mater. Des. 2014, 61, 8–15. [Google Scholar] [CrossRef]

- Cong, L.; Peng, J.; Guo, Z.; Wang, Q. Evaluation of Fatigue Cracking in Asphalt Mixtures Based on Surface Energy. J. Mater. Civ. Eng. 2017, 29, 4015003. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R. Experimental characterization of rutting performance of Polyethylene Terephthalate modified asphalt mixtures under static and dynamic loads. Constr. Build. Mater. 2014, 65, 487–494. [Google Scholar] [CrossRef]

- Choudhary, R.; Kumar, A.; Murkute, K. Properties of Waste Polyethylene Terephthalate (PET) Modified Asphalt Mixes: Dependence on PET Size, PET Content, and Mixing Process. Period. Polytech. Civ. Eng. 2018, 62, 685–693. [Google Scholar] [CrossRef]

- PlasticsEurope Deutschland e.V. Plastics—The Facts 2016; PlasticsEurope Deutschland e.V.: Frankfurt, Germany, 2016. [Google Scholar]

- Behl, A.; Sharma, G.; Kumar, G. A sustainable approach: Utilization of waste PVC in asphalting of roads. Constr. Build. Mater. 2014, 54, 113–117. [Google Scholar] [CrossRef]

- Chan, H.S.O. Measurement of Hydrochloric Acid Emission from Burning PVC Compounds. J. Fire Sci. 1984, 2, 106–122. [Google Scholar] [CrossRef]

- Padhan, R.K.; Sreeram, A.; Mohanta, C.S. Chemically recycled polyvinyl chloride as a bitumen modifier: Synthesis, characterisation and performance evaluation. Road Mater. Pavement Des. 2021, 22, 639–652. [Google Scholar] [CrossRef]

- Wahhab, H.A.-A.; Dalhat, M.; Habib, M. Storage stability and high-temperature performance of asphalt binder modified with recycled plastic. Road Mater. Pavement Des. 2017, 18, 1117–1134. [Google Scholar] [CrossRef]

- Abdel-Goad, M.A.H. Waste polyvinyl chloride-modified bitumen. J. Appl. Polym. Sci. 2006, 101, 1501–1505. [Google Scholar] [CrossRef]

- Köfteci, S.; Ahmedzade, P.; Kultayev, B. Performance evaluation of bitumen modified by various types of waste plastics. Constr. Build. Mater. 2014, 73, 592–602. [Google Scholar] [CrossRef]

- Rahman, N.; Ahmeduzzaman, M.; Sobhan, M.A.; Ahmed, T.U. Performance Evaluation of Waste Polyethylene and PVC on Hot Asphalt Mixtures. Am. J. Civ. Eng. Arch. 2013, 1, 97–102. [Google Scholar] [CrossRef] [Green Version]

- Ghani, U.; Tanoli, W. Performance evaluation of waste PVC modified bitumen. Int. J. Adv. Struct. Geotechnol. 2015, 4, 207–210. [Google Scholar]

- Fang, C.; Liu, X.; Yu, R.; Liu, P.; Lei, W. Preparation and Properties of Asphalt Modified with a Composite Composed of Waste Package Poly(vinyl chloride) and Organic Montmorillonite. J. Mater. Sci. Technol. 2014, 30, 1304–1310. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [Green Version]

- Tapkın, S.; Uşar, Ü.; Tuncan, A.; Tuncan, M. Repeated Creep Behavior of Polypropylene Fiber-Reinforced Bituminous Mixtures. J. Transp. Eng. 2009, 135, 240–249. [Google Scholar] [CrossRef]

- Tapkın, S. The effect of polypropylene fibers on asphalt performance. Build. Environ. 2008, 43, 1065–1071. [Google Scholar] [CrossRef]

- Tapkın, S.; Çevik, A.; Uşar, Ü. Accumulated strain prediction of polypropylene modified marshall specimens in repeated creep test using artificial neural networks. Expert Syst. Appl. 2009, 36, 11186–11197. [Google Scholar] [CrossRef]

- Othman, A.M. Impact of Polypropylene Application Method on Long-Term Aging of Polypropylene-Modified HMA. J. Mater. Civ. Eng. 2010, 22, 1012–1018. [Google Scholar] [CrossRef]

- Al-Hadidy, A.; Yi-Qiu, T. Mechanistic approach for polypropylene-modified flexible pavements. Mater. Des. 2009, 30, 1133–1140. [Google Scholar] [CrossRef]

- Yeh, P.-H.; Nien, Y.-H.; Chen, J.-H.; Chen, W.-C.; Chen, J.-S. Thermal and rheological properties of maleated polypropylene modified asphalt. Polym. Eng. Sci. 2005, 45, 1152–1158. [Google Scholar] [CrossRef]

- Nien, Y.-H.; Yeh, P.-H.; Chen, W.-C.; Liu, W.-T.; Chen, J.-H. Investigation of flow properties of asphalt binders containing polymer modifiers. Polym. Compos. 2008, 29, 518–524. [Google Scholar] [CrossRef]

- Nekhoroshev, V.P.; Nekhoroshev, S.; Tarasova, O.I. Chemical modification of road asphalts by atactic polypropylene. Pet. Chem. 2017, 57, 643–648. [Google Scholar] [CrossRef]

- Al-Haidri, H.A.; Tofan, A.S. Evaluation of modified asphalt mixtures with APP and IPP polymers by fatigue distress criteria. Innov. Infrastruct. Solut. 2021, 6, 131. [Google Scholar] [CrossRef]

- Schaur, A.; Unterberger, S.H.; Lackner, R. Impact of molecular structure of PP on thermo-rheological properties of polymer-modified bitumen. Constr. Build. Mater. 2021, 287, 122981. [Google Scholar] [CrossRef]

- Awad, A.; Al-Adday, F. Utilization of waste plastics to enhance the performance of modified hot mix asphalt. Int. J. Geomate 2017, 13, 132–139. [Google Scholar] [CrossRef]

- Hansen, A.P.; da Silva, G.A.; Kulay, L. Evaluation of the environmental performance of alternatives for polystyrene production in Brazil. Sci. Total Environ. 2015, 532, 655–668. [Google Scholar] [CrossRef]

- Maharana, T.; Negi, Y.; Mohanty, B. Recycling of polystyrene. Polym.-Plast. Technol. Eng. 2007, 46, 729–736. [Google Scholar] [CrossRef]

- Baker, M.B.; Abendeh, R.; Abu-Salem, Z.; Khedaywi, T. Production of sustainable asphalt mixes using recycled polystyrene. Int. J. Appl. Environ. Sci. 2016, 11, 183–192. [Google Scholar]

- Fang, C.; Jiao, L.; Hu, J.; Yu, Q.; Guo, D.; Zhou, X.; Yu, R. Viscoelasticity of Asphalt Modified with Packaging Waste Expended Polystyrene. J. Mater. Sci. Technol. 2014, 30, 939–943. [Google Scholar] [CrossRef]

- Al-Haydari, I.S.; Jand Masued, G.G. Benefit of using Expanded Polystyrene Packaging Material to Improve Pavement Mixture Properties. Appl. Res. J. 2017, 3, 332–342. [Google Scholar]

- Abinaya, S.; Clement, M.; Shanmugam, S. An experimental study on the properties of extruded Polystyrene waste polymer modified bitumen for flexible pavements. Int. Res. J. Eng. Technol. 2016, 3, 304–308. [Google Scholar]

- Johnson, O.A.; Kamaruddin, I.; Akbar, I. Modification of Malaysia Bituminous Binder Using Waste Polystyrene. In AWAM International Conference on Civil Engineering; Springer: Cham, Switzerland, 2019; pp. 1091–1098. [Google Scholar]

- Padhan, R.K.; Sreeram, A.; Gupta, A. Evaluation of trans-polyoctenamer and cross-linking agents on the performance of waste polystyrene modified asphalt. Road Mater. Pavement Des. 2018, 21, 1170–1182. [Google Scholar] [CrossRef]

- Kim, T.H.; Lim, S.T.; Lee, C.H.; Choi, H.J.; Jhon, M.S. Preparation and rheological characterization of intercalated polystyrene/organophilic montmorillonite nanocomposite. J. Appl. Polym. Sci. 2003, 87, 2106–2112. [Google Scholar] [CrossRef]

- Stark, W.; Jaunich, M. Investigation of Ethylene/Vinyl Acetate Copolymer (EVA) by thermal analysis DSC and DMA. Polym. Test. 2011, 30, 236–242. [Google Scholar] [CrossRef]

- Liang, M.; Ren, S.; Fan, W.; Xin, X.; Shi, J.; Luo, H. Rheological property and stability of polymer modified asphalt: Effect of various vinyl-acetate structures in EVA copolymers. Constr. Build. Mater. 2017, 137, 367–380. [Google Scholar] [CrossRef]

- Valera-Zaragoza, M.; Ramírez-Vargas, E.; Medellín-Rodríguez, F.; Huerta-Martínez, B. Thermal stability and flammability properties of heterophasic PP–EP/EVA/organoclay nanocomposites. Polym. Degrad. Stab. 2006, 91, 1319–1325. [Google Scholar] [CrossRef]

- Hahladakis, J.N.; Purnell, P.; Iacovidou, E.; Velis, C.A.; Atseyinku, M. Post-consumer plastic packaging waste in England: Assessing the yield of multiple collection-recycling schemes. Waste Manag. 2018, 75, 149–159. [Google Scholar] [CrossRef] [PubMed]

- Ge, D.; Yan, K.; You, Z.; Xu, H. Modification mechanism of asphalt binder with waste tire rubber and recycled polyethylene. Constr. Build. Mater. 2016, 126, 66–76. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The research for crumb rubber/waste plastic compound modified asphalt. J. Therm. Anal. Calorim. 2015, 124, 729–741. [Google Scholar] [CrossRef]

- Brovelli, C.; Crispino, M.; Pais, J.; Pereira, P. Using polymers to improve the rutting resistance of asphalt concrete. Constr. Build. Mater. 2015, 77, 117–123. [Google Scholar] [CrossRef]

- García-Morales, M.; Partal, P.; Navarro, F.; Gallegos, C. Effect of waste polymer addition on the rheology of modified bitumen. Fuel 2006, 85, 936–943. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martínez-Boza, F.J.; Gallegos, C. Novel recycled polyethylene/ground tire rubber/bitumen blends for use in roofing applications: Thermo-mechanical properties. Polym. Test. 2010, 29, 588–595. [Google Scholar] [CrossRef]

- Joohari, I.B.; Giustozzi, F. Hybrid Polymerisation: An Exploratory Study of the Chemo-Mechanical and Rheological Properties of Hybrid-Modified Bitumen. Polymer 2020, 12, 945. [Google Scholar] [CrossRef]

- Yan, K.; Chen, J.; You, L.; Tian, S. Characteristics of compound asphalt modified by waste tire rubber (WTR) and ethylene vinyl acetate (EVA): Conventional, rheological, and microstructural properties. J. Clean. Prod. 2020, 258, 120732. [Google Scholar] [CrossRef]

- Abed, A.H. Effects of functionalized polyethylene and styrene butadiene styrene polymers on performance grade of local asphalt binder. J. Eng. 2012, 18, 735–742. [Google Scholar]

- Fang, C.; Zhang, M.; Yu, R.; Liu, X. Effect of Preparation Temperature on the Aging Properties of Waste Polyethylene Modified Asphalt. J. Mater. Sci. Technol. 2015, 31, 320–324. [Google Scholar] [CrossRef]

- Yuan, J.; Wang, J.; Xiao, F.; Amirkhanian, S.; Wang, J.; Xu, Z. Impacts of multiple-polymer components on high temperature performance characteristics of airfield modified binders. Constr. Build. Mater. 2017, 134, 694–702. [Google Scholar] [CrossRef]

- Syroezhko, A.M.; Begak, O.Y.; Fedorov, V.V.; Gusarova, E.N. Modification of Paving Asphalts with Sulfur. Russ. J. Appl. Chem. 2003, 76, 491–496. [Google Scholar] [CrossRef]

- Luo, W.; Zhang, Y.; Cong, P. Investigation on physical and high temperature rheology properties of asphalt binder adding waste oil and polymers. Constr. Build. Mater. 2017, 144, 13–24. [Google Scholar] [CrossRef]

- Appiah, J.K.; Berko-Boateng, V.N.; Tagbor, T.A. Use of waste plastic materials for road construction in Ghana. Case Stud. Constr. Mater. 2017, 6, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Hendrianie, N.; Juliastuti, S.R.; Darmawan, R.; Widjonarko; Aini, F.I.N.; Hakim, M.L. Utilization of plastic waste with mix plastic softening agregate method as performance of stability and quality asphalt concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 543, 12090. [Google Scholar] [CrossRef] [Green Version]

- Manju, R.; Sathya, S.; Sheema, K. Use of plastic waste in bituminous pavement. Int. J. ChemTech Res. 2017, 10, 804–811. [Google Scholar]

- Mahmuda; Sumiati; Flaviana, T.L. Asphalt Modified Plastic Waste to Defend Damage in Asphalt Concrete (Ac-Wc). J. Phys. Conf. Ser. 2019, 1167, 12011. [Google Scholar] [CrossRef]

- Nkanga, U.J.; Joseph, J.A.; Adams, F.V.; Uche, O.U. Characterization of Bitumen/Plastic Blends for Flexible Pavement Application. Procedia Manuf. 2017, 7, 490–496. [Google Scholar] [CrossRef]

- Chowdhury, P.S.; Kumar, S.; Sarkar, D. Performance Characteristic Evaluation of Asphalt Mixes with Plastic Coated Aggregates. In Transportation Research; Springer: Berlin/Heidelberg, Germany, 2019; pp. 793–803. [Google Scholar]

- Yao, Z.; Zhang, J.; Gao, F.; Liu, S.; Yu, T. Integrated utilization of recycled crumb rubber and polyethylene for enhancing the performance of modified bitumen. Constr. Build. Mater. 2018, 170, 217–224. [Google Scholar] [CrossRef]

- Ding, X.; Ma, T.; Zhang, W.; Zhang, D. Experimental study of stable crumb rubber asphalt and asphalt mixture. Constr. Build. Mater. 2017, 157, 975–981. [Google Scholar] [CrossRef]

- Nuñez, J.Y.M.; Domingos, M.I.; Faxina, A.L. Susceptibility of low-density polyethylene and polyphosphoric acid-modified asphalt binders to rutting and fatigue cracking. Constr. Build. Mater. 2014, 73, 509–514. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J.; Han, J. Effects of thermal oxidative ageing on dynamic viscosity, TG/DTG, DTA and FTIR of SBS- and SBS/sulfur-modified asphalts. Constr. Build. Mater. 2011, 25, 129–137. [Google Scholar] [CrossRef]

- Masson, J.; Gagné, M. Polyphosphoric acid (PPA)-modified bitumen: Disruption of the asphaltenes network based on the reaction of nonbasic nitrogen with PPA. Energy Fuels 2008, 22, 3402–3406. [Google Scholar] [CrossRef] [Green Version]

- Ortega, F.J.; Navarro, F.J.; García-Morales, M. Dodecylbenzenesulfonic Acid as a Bitumen Modifier: A Novel Approach to Enhance Rheological Properties of Bitumen. Energy Fuels 2017, 31, 5003–5010. [Google Scholar] [CrossRef]

- Peng, C.; Chen, P.; You, Z.; Lv, S.; Zhang, R.; Xu, F.; Zhang, H.; Chen, H. Effect of silane coupling agent on improving the adhesive properties between asphalt binder and aggregates. Constr. Build. Mater. 2018, 169, 591–600. [Google Scholar] [CrossRef]

- Cuadri, A.; Partal, P.; Navarro, F.; García-Morales, M.; Gallegos, C. Bitumen chemical modification by thiourea dioxide. Fuel 2011, 90, 2294–2300. [Google Scholar] [CrossRef] [Green Version]

- Romagosa, H.; Corun, R.; Berkley, R. SBS Polymer Supply Outlook; Association of Modified Asphalt Producers (AMAP): Glen Ellyn, IL, USA, 2008. [Google Scholar]

- Liu, L.; Xiao, F.; Zhang, H.; Amirkhanian, S. Rheological characteristics of alternative modified binders. Constr. Build. Mater. 2017, 144, 442–450. [Google Scholar] [CrossRef]

- Sarkari, N.M.; Ayar, P.; Oskouei, M.H.; Khosrowshahi, F.K.; Mohseni, M. Silane crosslinkable polyethylene waste as bitumen modifier: A new fortunate destiny by in time recycling of thermoplastic waste before conversion to thermoset end-of-life unrecyclable polymer. Constr. Build. Mater. 2021, 287, 122999. [Google Scholar] [CrossRef]

- Chiono, V.; Filippi, S.; Yordanov, H.; Minkova, L.; Magagnini, P. Reactive compatibilizer precursors for LDPE/PA6 blends. III: Ethylene–glycidylmethacrylate copolymer. Polymer 2003, 44, 2423–2432. [Google Scholar] [CrossRef]

- Ahmedzade, P. The investigation and comparison effects of SBS and SBS with new reactive terpolymer on the rheological properties of bitumen. Constr. Build. Mater. 2013, 38, 285–291. [Google Scholar] [CrossRef]

- EN 13399. Bitumen and Bituminous Binders—Determination of Storage Stability of Modified Bitumen; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Bulatović, V.O.; Rek, V.; Marković, J. Rheological properties of bitumen modified with ethylene butylacrylate glycidylmethacrylate. Polym. Eng. Sci. 2014, 54, 1056–1065. [Google Scholar] [CrossRef]

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci. 2015, 224, 72–112. [Google Scholar] [CrossRef]

- Zher’Akova, G.; Kochkan’An, R. Reactivity and structure investigation of coals in reaction with dienophiles. Fuel 1990, 69, 898–901. [Google Scholar] [CrossRef]

- Herrington, P.; Wu, Y.; Forbes, M.C. Rheological modification of bitumen with maleic anhydride and dicarboxylic acids. Fuel 1999, 78, 101–110. [Google Scholar] [CrossRef]

- Nadkarni, V.M.; Shenoy, A.V.; Mathew, J. Thermomechanical behavior of modified asphalts. Ind. Eng. Chem. Prod. Res. Dev. 1985, 24, 478–484. [Google Scholar] [CrossRef]

- Becker, M.Y.; Muller, A.J.; Rodriguez, Y. Use of rheological compatibility criteria to study SBS modified asphalts. J. Appl. Polym. Sci. 2003, 90, 1772–1782. [Google Scholar] [CrossRef]

- Zhang, F.; Hu, C. The research for SBS and SBR compound modified asphalts with polyphosphoric acid and sulfur. Constr. Build. Mater. 2013, 43, 461–468. [Google Scholar] [CrossRef]

- Miknis, F.P.; Thomas, K.P. NMR analysis of polyphosphoric acid-modified bitumens. Road Mater. Pavement Des. 2008, 9, 59–72. [Google Scholar] [CrossRef]

- Baumgardner, G.L.; Masson, J.; Hardee, J.R.; Menapace, A.M.; Williams, A.G. Polyphosphoric acid modified asphalt: Proposed mechanism. J. Assoc. Asph. Paving Technol. 2005, 74, 283–305. [Google Scholar]

- Rossi, C.O.; Spadafora, A.; Teltayev, B.; Izmailova, G.; Amerbayev, Y.; Bortolotti, V. Polymer modified bitumen: Rheological properties and structural characterization. Colloids Surf. A Physicochem. Eng. Asp. 2015, 480, 390–397. [Google Scholar] [CrossRef]

- Thomas, K.P.; Turner, T.F. Polyphosphoric-acid Modification of Asphalt Binders. Impact on Rheological and Thermal Properties. Road Mater. Pavement Des. 2008, 9, 181–205. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.; Wang, H.; Hao, P. Rheological property investigations for polymer and polyphosphoric acid modified asphalt binders at high temperatures. Constr. Build. Mater. 2014, 64, 316–323. [Google Scholar] [CrossRef]

- Wen, G.; Zhang, Y.; Zhang, Y.; Sun, K.; Fan, Y. Rheological characterization of storage-stable SBS-modified asphalts. Polym. Test. 2002, 21, 295–302. [Google Scholar] [CrossRef]